Your One-stop Fastener Suppliers&Manufacturers

30 Years of Fastener Industrial Experiences

Main Products-Prince Fastener

Get what you need even the custom fastener requests

Why choose Prince Fastener

We will be your One-stop Fastener Suppliers & Manufacturers

Custom Orders

With professional making technology and the Machinery,Prince Fastener accept the custom screw orders

Factory Direct

You will get the screws from the Screw Suppliers factory directly with competitive costs

In Time Delivery

With skilled order management and enough production capability,Prince Fastener Promise In Time Delivery

Customer Services

Prince fastener will provide the comprehensive customer services with our professional team

Who is Prince Fastener

With 30 years of Fastener industrial manufacturing experiences, Prince Fastener Manufacturing Co., Ltd. Is a leading fastener manufacturer & Supplier who specializes in designing and producing various types of screws. , bolts and nuts,and other fasteners. We can be your one-stop Fastener Suppliers & Manufacturers with quick response and trust quality insurances,with Taiwan advanced production equipment ,Experienced professional technician support and Advanced customized solutions.

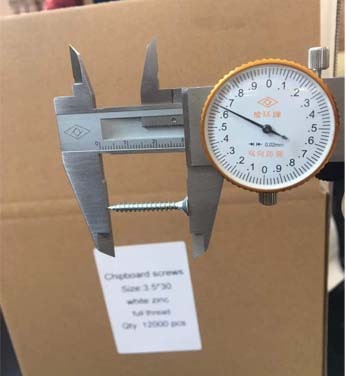

Our main products are: drywall screw,chipboard screw, machine screw,self tapping screw,self drilling screw,Non/standardscrews,Engineering fastener(High strength bolts;Nuts;Washers;Anchor),Stainless steel screws.

For more information,please visit About Prince Fastener

Material

Wire Drawing

Heading Making

Thread Rolling

Heat Treatment

Galvanization

Inspection

Packing

Shipment

Completed

Fastener Processes for manufacturing In the main manufacturing, the following methods are distinguished by one hand, there’s cutting-free forming as well as cutting.

When forming is not cutting, there is also a distinction between hot and cold making. This diagram is designed to help make the processes of production more clear: Figure. N.: A summary of various manufacturing processes

Cold form (cold extrusion) In the present day of fastening technology, many fasteners can be created by using the cold forming process. The fastener is made, typically using multi-stage processes. This can be done by pressing to form, forging cold,, reduction, or any combination of these methods. The term”solid or cold” forming was coined to describe this type of manufacturing. This process is generally used in large quantities since, from a cost perspective, it’s the most sensible approach. The selection of the right machine for forming is based on the dimensions of the fastener, and on the amount of being formed.

The more extensive the degree of forming, the greater number of necessary forming stages. Thin profiles or sharp edges are unsuitable for cold forming and cause wear on the tool. A significant role in your final quality product can be determined by the type of material used along with the high-quality of the material used for input (wire).

Screw producers typically receive wire wrapped on rolls that typically weigh more than 1000 kilograms. The wire is usually treated with phosphate to allow the wire to be used precisely and minimize wear on the tool. The person who designs the screw or fastener is trying to integrate the advantages and drawbacks of different materials in accordance with the specifications of the fastener. The differences in the materials are created, as are corrosion-resistant steels between non-alloyed and alloyed steels. For instance, if higher strength is needed, it is necessary to expose the components following pressing to a heat treatment process to alter the mechanical properties of the part specifically.

Schematic of the stages used for hexagon head din 7505 chipboard screw. They are generally made using the hot or cold forming process also. The selection of one or the other method is contingent on the dimension and the other on the quantities required. Section of wire Descaling Intermediate upsetting Finishing Calibrating Round die thread rolling The information provided is not a warranty or guarantee of its fullness. 1774 Diagram of phases of forming a hexagonal nuts Benefits of cold-forming the best utilization of material high output * Superior quality and dimensional accuracy

The strength properties are enhanced by strain hardening of the chamfers on the press part in accordance to the loads

The cold forming manufacturing method is commonly used for large diameters, starting at approx. M27 and larger pieces that start at around. 300 mm. Additionally, components are likely to be made with cold forming due to the tiny volumes or due to a high level of forming. This method involves heating the raw material (usually bar) is heated entirely or partly to the temperature of forging. This process allows even complicated geometries and extremely extreme degrees in forming realized. One of the most common characteristics for hot-formed components is the surface structure. Hardening of strains is not a part of hot form! The advantages of hot forming are: It allows the production of complex geometries with low production runs Long and large diameters

Machining Machining typically described as a process step that include turning, milling, or reaming.

The most commonly used method in regards to fasteners is turning however, this method has lost a lot of significance due to the advantages of cold pressing. When turning, the desired shape of the part is cut out of the material input using the tool for turning. The size of input materials will depend on the biggest diameter of the part. In general bars with a length of 6 meters or more are utilized. In contrast to cold and hot making, the chamfer path of the material used for input is removed. This procedure of production is utilized in cases where the production run is not large enough or the shape of the part is not able to be met when using hot or cold processes due to sharp edges, tiny radiuses, or even small sizes. Surface roughnesses as high as Ra 0.4 and Rz 1.7 are achievable by this process without difficulty. For massive production runs, the blanks are usually made using the cold extrusion technique and later manufactured.

Thread production In cases where screws are produced in mass quantities typically, the thread is created or made by rolling.

This process involves the screw is formed by rolling it through two dies (flat dies) and one is fixed, and the other is running creating thread (see the diagram). This type of thread manufacturing, it is possible to make hundreds of screws every minute using thread. The thread is generally used prior to tempering and hardening. If there are special requirements that require the thread is rolled after heating treatment, it is called “finally rolling”. The information provided is not a warranty or guarantee of its completeness. 10 1775 Other ways of creating threads: plunge cutting Tool rolls driven by the same force, they rotate along the same angle. The workpiece moves without being axially displace. This technique can be utilized to create threads that have excellent pitch precision. Continuous method: The pitch of the thread is produced by inclining the axes of the roller through an angle of pitch. The workpiece receives an axial thrust. It then moves through one pitch of thread in an axial direction and then rotates completely.

Threads with overlength can be created using this method. Thread cutting in this method the thread is created using tapping or screw stock. When using screws, this method is mostly used for low production runs , or with manufactured parts too. But, the process is different when female threads are made. In this instance, the thread is typically cut using the use of a screw tap or taper tap. Thread cutting with an automatic lathe using taps for taper

Fibre pattern Both diagrams illustrate clearly the distinctions between a rolled or cut thread. When thread is formed, the material is hygienized further to the fibre pattern, so that it is not broken. In this instance the original size of the screws is equal to the flank diameter. When thread cutting is used, the initial dimension of the screw will be exactly the dimension of thread. The pattern of fibres is broken through the cutting.

Heating treatment

Tempering and hardening The combination of “hardening” and then “tempering” is known as tempering and hardening. It is a requirement of DIN EN ISO 898 Part 1 specifies tempering and hardening for screws of strength class 8.8 as well as DIN EN Part 2 recommends it for nuts that are in the strength class 8 and 05 (>M16) as well as for nuts in the strength class of 10.

In the process of hardening, the screw gets heated up to specified temperature, depending on the carbon content of the screw and then kept at that temperature for a lengthy period. The microstructure is altered. The increase in hardness is obtained through subsequent quenching (water or oil.). Die Fixed Running die Outside diameter of thread’s course of chamfer on thread cutting. Chamfer course on thread making All information is provided without any guarantee or claim to accuracy.

Annealing Glass-hard and hence brittle material can’t be used in under this situation. The material has to be heated again to the minimum temperature set in the standard so as to minimize the microstructure distortions. This method reduces the amount of hardness of the material that was previously achieved (but it’s much more than the hardness of the non-treated material) However, the ductility increases. This process can be a significant aid to manufacturers to create screws that meet the specifications required by customers.

Hardening of the case This method is utilized to tap screws thread grooving or self-drilling screws. In this instance, extremely tough surfaces are essential in order that screws are able to create their own threads automatically. The core of the screw, by contrast, is extremely soft. Steels that contain a carbon percentage of 0.05 percent to 0.2 percent are suitable for these kinds of screws. The steels are then heated and kept for a lengthy period in an environment which releases carbon (e.g. methane). The carbon disperses into zone of the surface, and this increases the carbon content of the surrounding area. This process is referred to as carburisation. Then, the material is quanned and thus hardened on the surface areas. This gives the advantage that the surface is extremely hard and yet there is enough ductility within the center of the screw.

The process of stress relief There’s several different methods of annealing that have distinct impacts on the microstructure as well as the conditions of stress within the material. One of the most important procedures when it comes to fasteners is the stress relief annealing (heating up to around. 600degC, and keeping the temperature for a lengthy time). The stress hardening that occurs during cold formation can be reversed through stress relief and annealing. This is especially important for screws that fall in the ranges of strength 4.6 and 5.6 since there must be an extensive elongation of the screw.

Tempering Tempering refers to the treatment that is applied to high-strength components (strengths of 1000 MPa or hardernesses greater than 320 HV) in the hope of reducing the chance from hydrogen embrittlement. Tempering should be completed within four hours following the completion process of galvanic treatment. The temperature that is the minimum will depend on the strength class or the materials which are being used.

Prince Fastener's certificate and attended the exhibitions

Packing and Shipping

What They Are Saying

Custom Screws Request?

Your customers or you need Special Fasteners?Non-standard fasteners?

As a trusted partner of fastener suppliers for various industries, including solar street light manufacturers, the Prince Fastener team is here to assist you.

Just feel free contact Prince Fastener team,we are here to accept the custom screws orders to meet your special screws orders.

Blog and News from Prince Fastener

Self-Tapping Screws versus Regular Screws Key Differences

You will notice a key difference when you use a tap screw: it cuts its own threads as you drive it in. Traditional screws require

Pros and Cons of Stainless Steel Self Tapping Metal Screws Compared to Other Fasteners

You will see that stainless steel self tapping metal screws do not rust easily. They are also easier to put in than many other fasteners.

M10 Screw Size Tips for Easy Online Buying

Ready to shop for M10 screws online? Start with these three smart moves: Always double-check the m10 screw size that fits your project. Grab a

Choosing Between Self Tapping Pan Head Screws and Other Fastening Solutions

You want the best fastening solution for your project. The right choice depends on the material and how you plan to use it. Self tapping

Guide to 8 32 Bolt Materials and Corrosion Resistance

You want your 8 32 bolt to be strong and last long. Stainless options protect best from rust, especially outside or near water. Choosing the

3 Metric Screw Size Chart Downloads You Need Now

Looking for the best metric screw size chart for your next project? Here are three top picks you can download and print right now: Accu