Best

Self tapping Screw

Manufacturer

One-stop Fastener Manufacuturer and Supplier-The Ultimate Solutions

Are you sourcing for a self tapping screw manufacturer to expand your fastener business?

This exclusive guide will help you to find the right fastener supplier and products

- Purchasing the self tapping from fastener factory directly with wholesale price

- Get completely technical support and good after-sales services

- Accept customized fastener requests

- Fast reply with professional staffs from screws company from China

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our self-tapping screws for wholesalers and importers.

Quick View

- → Why wholesale self-tapping screw from Prince Fastener?

- → Hot products for self-tapping screws

- → Estimated wholesale → Price for self-tapping Screws

- → Estimated self-tapping Screws Producing Period and Delivery Time

- → How areself-tapping screws made step by step?

- → Searching for self-tapping screws made in China?

- → Need Special screws for your clients or projects?

- → The Complete FAQ Guide about self-tapping screws

Why purchase self tapping screws from Prince Fastener?

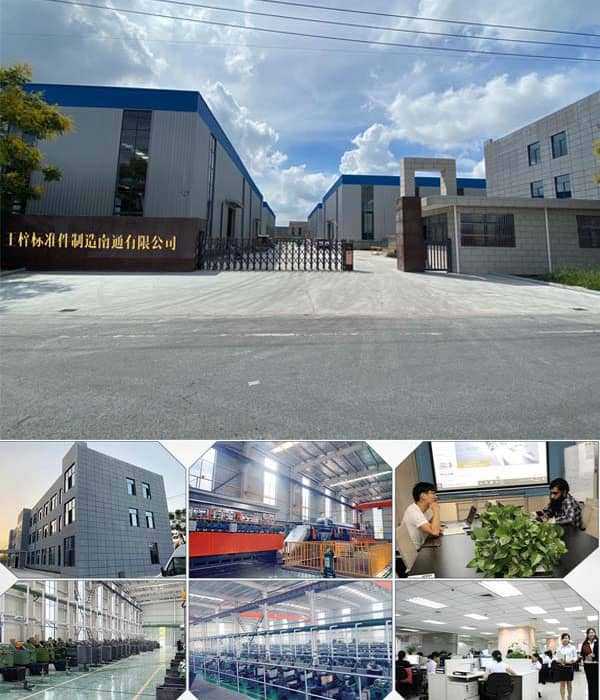

Prince Fastener is a custom fastener company integrating product development, sales, and service and can accept customers’ design and OEM & ODM design orders. Prince Fastener specialize in manufacturing long screws, non-standard screws, titanium screws, small screws, stainless steel screws, chipboard screws wholesale etc. Prince Fastener has provided over 440 billion screws for more than 1500 companies and have had more than 4600 kinds of customer experience for more than 30 years, and can propose reasonable design solutions for customers. Over 30 years of working experience in the fastener manufacturing team and 31 years experience in designing, developing, and manufacturing screws for chief engineers. Prince Fastener can provide different material screws for various industries, M1 to M16, lengths from 1 mm to 1990 mm. In addition, Prince Fastener can customize all kinds of screws, from artificial intelligence Prince Fastenerar-resistant M1.0 diameter precision screws to multi-stage linkage screws, complex mechanical and electrical equipment, and ship structure.

Prince Fastener has many years of history in fastener research and development, screw manufacturing, sales, and service development. Prince Fastener have accumulated rich experience in manufacturing national standard fasteners and non-standard fasteners, which has created several difficult and high-precision screws. Engineering and technical personnel and experienced front-line technicians design and manufacture shaped nails. With the deepening of the market economy and the continuous improvement of processing technology, our factory’s technological innovation and equipment transformation is changing daily, and the production scale is gradually expanding.

With advanced and perfect equipment and excellent product quality, our products are sold all over the country and have won the trust and praise of our customers. Choosing our products is the same as choosing a reliable guarantee for construction projects! Prince Fastener will provide you with sincere service throughout the whole process.

All products are made of high-quality, high-tech steel, with advanced production technology and perfect testing means, and the product qualification rate reaches 100%. In addition, Prince Fastener pursue the most excellent customer satisfaction. Over the years, our customers have won continuous attention and praise for our international quality, fine line, and platform production strategy.

Hot products for Self tapping screws

Self tapping screws

Self tapping screw for plastic

dacromet self tapping screw

Self tapping screw for metal

Self-tapping screw for wood

Philips pan head self tapping screw

Metal self tapping screws

1 4 Self Tapping Screws

Square Slotted Self tapping screws

Self Tapping Screws Manufacturers in China:Estimated wholesale Price for Self tapping Screws

The estimated wholesale price for self tapping screw should include the below,

Fastener Manufacturing Costs

Just pay the costs of the self-tpping screws with the wholesale price from the fastener Factory directly, just waiting for the right quality self-tapping screws to be produced.

Self tapping Screws Packing Fee

You will pay a small amount for the Self-tapping Screws if you have special requirements for the package, you can apply to get rid of the fee if your order amount is big enough.

Shipping Costs

This payment is for transport the Self-tapping Screw orders from China fastener factory to you by sea or by air

Self-tapping Screws Sample Fee

Normally we will provide free Self-tapping screw samples for importers,clients need to afford the international shipping costs.

Customized Self-tapping Screw Fee

Prince Fastener accepts customized Self-tapping screws orders from clients, we could produce the products according to customer’s requests,of course,clients will need to pay customized screws costs

Custom Clearances Costs

The costs include the destination custom clearances costs, customs duties,and other miscellaneous fees

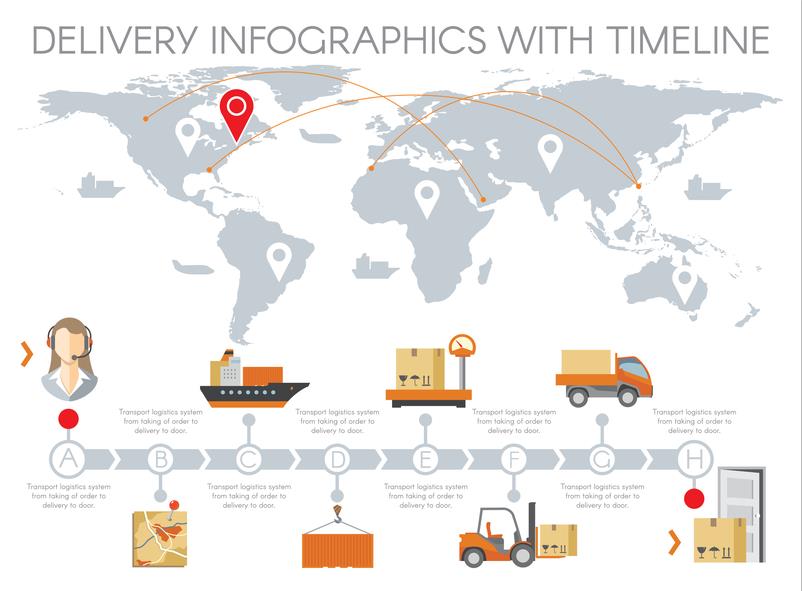

Self Tapping Screws Manufacturers in China:Estimated Self-tapping Screws Producing Period and Delivery Time

In order to meet the increasing customer demand for Self-tapping screws, Prince Fastener has no choice but to increase production capacity to achieve the desired goal. The process and time required to go through the following steps

Fastener Manufacturing Costs

Just pay the costs of the self-tpping screws with the wholesale price from the fastener Factory directly, just waiting for the right quality self-tapping screws to be produced.

Self tapping Screws Packing Fee

You will pay a small amount for the Self-tapping Screws if you have special requirements for the package, you can apply to get rid of the fee if your order amount is big enough.

Shipping Costs

This payment is for transport the Self-tapping Screw orders from China fastener factory to you by sea or by air

Self-tapping Screws Sample Fee

Normally we will provide free Self-tapping screw samples for importers,clients need to afford the international shipping costs.

Customized Self-tapping Screw Fee

Prince Fastener accepts customized Self-tapping screws orders from clients, we could produce the products according to customer’s requests,of course,clients will need to pay customized screws costs

Custom Clearances Costs

The costs include the destination custom clearances costs, customs duties,and other miscellaneous fees

Self-tapping Screw Design and Manufacturing

Prince Fastener designs and manufactures the Self-tapping screws in our own fastener factory

Products Packing Time

Put the Self-tapping screws into pp bag or small white boxes,then put them into a package,they will take a short time to do it.

International Shipping time and customs clearances time

Need time to ship the Self-tapping screws worldwide by sea or by air, and then make custom clearances also need time.

Local Logistics

You’ll finish the whole process and get what you want. You just wait for the local logistics to haul the Self-tapping screws from the port to your destination.

Prince fastener will introduce you all the process of the Self-tapping screw production.

Prince fastener production process

Basic concepts of Prince Fastener screw production

1、Prince Fastener Manufacturing screw can be divided into: cold heading, hot machining (turning, milling, etc.)

2、Cold heading is the use of plastic metal, by using cold mechanical pressure or drawing, reaches the metal solid deformation of.

3、Hot upsetting is the material after heating and pressure processing make the shape of the material to meet the

designrequirements.

4、Prince Fastener Machining is a small batch of special or special bolts of the six corners of the head is turned into after the milling.

5、 Screw bolt thread: mechanical and manual threading, similar to die.

6、 Milling tail: generally completed by the end of the Prince Fastener cutting machine.

7、 The difference between cold and hot upset: cold heading bolts` surface are more beautiful, dozen red bolt surface oxide skindoes not look good; cold heading high production is efficiency; general Prince Fastener M24 bolts will need to play red;

Analysis of the causes of the phenomenon and the causes of the forming process

1、Eccentric: two red and improper installation and adjustment machine.

2、Minow: a poor installation and improper Prince Fastener adjustment machine at.

3、Head is not round: the choice of a die or a punch forming is not enough.

4、Play the mode of crack: crack or die R angle, so that the model is hit by the two collision.

5、Head double: bad punch.

6、Flash: a bad, punching molding is mainly between punch and die hole clearance is too large or too short by red bars.

7、Crack angle: the punch needle burst or two punch and punch is not heavy.

8、Head cracking: material, or a die using error (such as pan head Hexagon washer head of a die), and lubricating oil.

Analysis of adverse phenomena and causes of common rolling

1、Processing crack: tooth plate and adjust the Prince Fastener old machine.

2、Blunt tail: the machine is not properly adjusted, the tooth plate is too old.

3、Crooked tail: the control screw on the seat board seat is too tight.

4、Tail: tooth wear plate and improper adjustment machine.

Self Tapping Screws Manufacturers in China:Searching for Self-tapping screws made in China?

Prince Fastener will be your ideal self-tapping screw manufacturer with certified products and professional factory sites.

Production Equipment

Prince Fastener own more than 100 production equipments with a month production capacity of 800 tons and annual production capacity of more than 10,000 tons.The equipments include advanced manufacturing equipments introduced from Taiwan such as head making machines, thread rolling machines, net Furnace and testing machines, such as salt spray machine, 3D projector, hardness tester and so on.

Testing Equipment

All products are made of high-tech high-quality steel, with a complete set of fastener processing technology, complete testing methods and advanced production technology, 24/7 service, Prince Fastener adapt the advanced production technology and perfect testing methods, and the qualified rate of products reaches 100 %. Pursue maximum customer satisfaction.

Self Tapping Screws Manufacturers in China:Need Special screws for your clients or projects?

Try to get in touch with Prince Fastener,we could provide you a completely solutions

Prince Fastener is a Self Tapping Screws Manufacturers in China integrating product development, sales and service, and can accept customers’ own designs and OEM & ODM design orders. The company specializes in the production of self-tapping screws, long screws, non-standard screws, titanium screws, small screws, stainless steel screws, etc.

Prince Fastener use lathes to manufacture screws of various sizes and material types to deliver them to our customers in the shortest possible time.

Prince Fastener specializes in developing, manufacturing, and selling fasteners according to DIN, ANSI, ISO, GB standards and high strength grades 12.9/10.9 DIN 912 DIN 931 DIN 933 DIN 934 DIN 7991 ISO 7380 stainless steel, aluminum alloy, brass hexagonal bolts and nuts.

The screws we manufactured are widely used in machinery manufacturing, aerospace, medical, shipbuilding, ultrasonic, solar energy, electroplating, petroleum, chemical, and other high-tech fields. In addition, we have rich experience in producing all kinds of customization. So we also welcome OEM and ODM orders. Whether selecting current products from our catalog or seeking engineering help for your application, you can consult our customer service center for your purchasing needs. Our company adheres to the principle of ensuring stable and timely supply, reliable quality, and sincere service. Now we face the increasing business opportunities with firm confidence and look forward to the opportunity to serve you.

The Complete FAQ Guide about self tapping screws

Quick Index

1,Can you introudce the self-tapping screw?

2,What are self tapping screws made of?

3,What are the uses of Self Tapping Screws?

4,Can self tapping screw be used instead of machine screws?

5,What is Classification of self tapping screw?

6,6,Are your self-tapping screws reliable?

7,Is a self-tapping screw the same as a self-drilling screw?

8,Have you exported your self tapping screws before?

9,What types of business you are support to?

10,Will you provide free self tapping screw samples for clients?

Since it is self-forming or can be tapped to match its threads, it has a high loosening prevention ability in combination and can be loaded and unloaded. The small-shaped screws on its size, thread type, head type, tapping performance for engineering purposes, high tensile strength, single piece, and single-sided combination features are almost unlimited. Self-tapping nail material can be divided into two kinds: carbon steel and stainless steel, in which the carbon steel material to 1022 carbon steel is the main. Usually used in doors and windows, etc.

Its head is made at one end to increase the shape of the part formed by the bearing surface. For thread forming and thread cutting, self-tapping screws , flat-top countersunk head ( FlatCountersunk ), flat round countersunk head ( Oval Countersunk ), Pan head ( Pan ), Hex and Hex washer head ( Hex and Hex Washer Head ) is the most important, these five head types account for almost 90% of all self-tapping screws, The use of self-tapping screws should first consider this. Another five other types of flat-top concave bearing surface ( Flat Undercut ), whole flat-top edge ( Flat Trim ), flat round concave bearing surface ( Oval Undercut ), flat round top edge ( Oval Trim ), and cylindrical head ( Gang Hill head Fillister ) for the relatively minor head type, while the incense top buried head.

Threaded rolled into self-tapping screws head type selection and the same above, the use of the main consideration mushroom head ( Truss ), round head ( Round ) and 100 degrees flat top buried head for the new design is not taken, cover its function can be replaced by another head type, the disk head can replace the mushroom head, and round head, 82 degrees flat top buried head can replace the 100 degrees flat for the flat top, flat dome, disk head, hexagonal head and hexagonal washer head five kinds.

2,What are Self-tapping screws made of?

Self-tapping screws are mostly used for the connection between thin metal plates. When connecting, first make a threaded bottom hole for the connected piece, and then screw the self-tapping screw into the threaded bottom hole of the connected piece. Since the thread surface of the self-tapping screw has high hardness (≥45HRC), the internal thread can be tapped in the threaded bottom hole of the connected piece to form a connection. The aluminum profile itself is softer than steel, so generally self-tapping screws that meet the national standard can tap the aluminum profile. It is recommended to punch the bottom hole at the required position first.

So Normally the self-tapping screw made of stainless steel or carbon steel, titanium, aluminum, brass materials

3,What are the uses of Self Tapping Screws?

Self-tapping screws are mostly used for the connection between thin metal plates (steel plates, saw plates, etc.). When connecting, first make a threaded bottom hole for the connected piece, and then screw the self-tapping screw into the threaded bottom hole of the connected piece. Since the thread table of the self-tapping screw has high hardness (≥HR5), the internal thread can be tapped in the threaded bottom hole of the connected piece to form a connection.

Self-tapping screws are also mostly used for the connection between thin metal plates. The thread is an ordinary thread with an arc-shaped triangular section, and the thread surface also has high hardness, so when connecting, the self-tapping screw can also tap the inner thread in the threaded bottom hole of the connected piece to form a connection. This kind of screw is characterized by low screw-in torque and high locking performance, and has better working performance than ordinary self-tapping screws.

4,Can self tapping screw be used instead of machine screws?

When installing and disassembling self-tapping screws, slotted self-tapping screws need a flat-blade screwdriver, cross-recessed self-tapping screws need a cross-shaped screwdriver, hexagon socket self-tapping screws need a socket wrench, hexagon head self-tapping screws Tapping screws require a flat wrench, a Torx wrench, a socket wrench or an adjustable wrench.

Self-tapping screws are used for non-metallic or softer metals without drilling low holes and tapping;

Self-tapping screws are pointed, so that they can be self-tapping; ordinary screws are flat-headed and have the same thickness.

Self-tapping screw means: the drilled hole is a chip-free tapping hole. The screw used is different from the general one. The head is pointed and the tooth spacing is relatively large. Going in, metals and plastics usually use this method.

Self-tapping screws are screws without nuts.

It can “tap-drill, squeeze, press” the corresponding thread on the consolidated material by its own thread to make them cooperate closely with each other.It can be used for below industries:

1.furniture industry 2.building industry3.toy industry 4.plastic case industry 5.auro industry 6.military industry 7.medical instruments industry 8.aerospace industry 9.shipbuilding industry 10.energy equipment industry 11.electronic industry 12.furniture industry 13.materials industry

5,What is Classification of self tapping screw?

I: The different heads can be divided into round head, flat head (i.e., hollow head), top pillar head, round top broadside head, large round head (i.e., large flat head), hexagonal cavity-bearing head, hexagonal cavity-bearing washi head, hexagonal head.

Round head self-tapping screw: It is the most common head type in the past.

Flat head self-tapping screw: A new design that can replace the round head and mushroom head, with a low head diameter and a high type of edge around the head’s periphery that indicates the drive’s characteristics for increased torque.

Head self-tapping screw: The standard flat round head has a smaller diameter than the round head but is taller due to the depth of the groove, and the smaller diameter increases the pressure on a small area, which can be tightly combined with the flange and the raised surface. They can be successfully used in internal drilling holes because they are punched in drilling molds to ensure concentration.

Domed broadside head self-tapping screws: Most commonly used in electrical appliances and recorders because of the undercutting of the head and the reduced wear on the wire components, providing a more attractive design type for the low and medium head types with their fuller bearing surface.

Large round head self-tapping screw: The oval top broadside head is a low profile, cleverly designed large-diameter head type. It can be used to cover sheet metal holes with large diameters when the combined tolerances of the additional roles allow. A flat head is also recommended as an alternative.

Hexagonal cavity head self-tapping screw: A joint with a wrench head height and a hexagonal head size. The hexagonal shape is entirely formed by cold forming in a counter-bored mold, and the top of the head has a distinctive depression.

Hexagonal cavity head self-tapping screw: Like the standard hexagonal cavity head, but with a cavity surface at the base of the skull to protect the assembly from wrench damage. Sometimes the function of the thing is more important than the appearance.

Hexagonal head self-tapping screw: This is a standard type of torque applied to the hexagonal head and has the feature of trimming sharp corners to close tolerances. It is recommended for general commercial use but can also be used for various standard patterns and thread diameters. However, it is more expensive than the available hexagon socket because of the second process required.

II: According to the groove type, there are four types of grooved head: one grooved head (also called slotted), cross grooved head, eleven composite grooved heads, and meter grooved head.

III: According to the standard can be divided into National Standard (GB), German Standard (DIN), American Standard (ANSI), British Standard (BS)

6,Self Tapping Screws Manufacturers in China:Are your self-tapping screws reliable?

As a professional self-tapping screw manufacturer, we guarantee that from the raw material to the finished products, we have to go through 8 inspection processes, and only after passing the inspection can we ship. To ensure the quality of self-tapping screws (Character) in customers’ is a qualified screw.

No matter what specifications of self-tapping screws fasteners, after the completion of production are required to do a series of tests, testing qualified (qualified) before shipment, then the regular size test, tolerance test, and appearance test, we also need to try what items? Self-tapping screws mechanical (machinery) performance test (test) projects include (bāo kuò) surface hardness test, carburization (shèn tàn) layer depth test, core degree test, microstructure test, screwing performance test, and damage (vandalism) torque test.

1, Surface hardness test (test).

Surface hardness using GB/T5030 specification Vickers hardness (HV0.3) test (test), surface hardness test should be on the plane and priority in the head. Non-standard screws are tools that use the physics and mathematics of the object’s beveled circular rotation and friction to tighten the apparatus mechanism progressively.

2, Carburizing (C) layer depth (metallographic test)

The carburization (C) layer depth test (test) is carried out on the measuring surface of the self-tapping thread at a point half the distance between the top of the tooth and the bottom of the tooth, except for self-tapping screws with specifications <ST3.9, in which case the test should be carried out on the base of the tooth. The depth of the carburization layer shall be calculated from the point where it exceeds 30 HV.

3. Hardness of core test.

Vickers core hardness (Hardness) test according to GB/T4340 and should have sufficient distance (distance) with the end of the self-tapping screw (there should be a complete thread diameter) of the cross-section of 1/2 radius (radius). Non-standard screws are tools that use the physics and mathematical principles of beveled circular rotation and friction of objects to tighten objects and mechanisms progressively.

4, Screwing performance test (test)

Self-tapping screws (screw) nail test piece (with or without coating) screwed into the test (test) plate until there is a complete thread entirely through the test plate; the test plate should be made of low carbon steel (Steel) with a carbon content of <0.23%, the hardness of 130-170hv (measured by GB/T5030 and GB/T4340) test plate thickness (thickness) degree and test aperture. thickness) degree and test aperture by the hole or punching and then drilling or reaming system. Precision screws are widely used in electronics, electrical, appliances, furniture, machinery, etc.

7,Is a self-tapping screw the same as a self-drilling screw?

Self-tapping screws are screws that are capable of tapping the threads into the material. Self-tapping screws can be used in various materials, including wood, metal, and brick. These screws cannot be drilled through metal and require a pilot hole to be pre-drilled before installation. The pilot hole is created by using a drill bit slightly smaller than the screw, and the screw’s threads strike the metal or wood as the screw is installed. This tapping action holds the material together. In addition, self-tapping screws can have many different types of tips, which help tap the threads into various substrates.

Self-drilling screws are sometimes named under the Tek®Screws brand. These screws can be identified by the point of the screw’s drill shape and are designed for various applications, such as fastening metal to metal and wood. In addition, self-drilling screws do not require pilot holes, reducing installation time and costs and the need for additional drilling. This other functionality and cost-saving features make self-drilling screws the clear choice for metal construction. Drill points are numbered 1 through 5, and the amount of steel that can be drilled increases as the numbered points increase. Typically, self-drilling screws are used for light rail applications, but the #5 drill point can dig through and hold 1/2 of the steel.

So self-drilling screws are also self-tapping screws, but all self-tapping screws are not self-drilling hammers. Custom Self-drilling screws do not require pilot holes, but they can be self-tapping. Self-tapping screws cannot drill through metal and require a pilot hole. These screws are not interchangeable, and mixing the two may cause a lot of trouble or cause failures in the field.

8,Self Tapping Screws Manufacturers in China:Have you exported your self tapping screws before?

As you know,Prince Fastgener as a professional fastener manufacturer and supplier in China for more than 30 years, we cooperated with the international clients to help them import the self tapping from us made them more profits, because they buy the fasteners from screw factory directly.

We exported the self tapping screws to USA,UK,Australia,Canada,Russia,Brazil,Mexico,UAE and other countries,get lots of positive feedbacks from the clients.

9,Self Tapping Screws Manufacturers in China:What types of business you are support to?

Prince Fastener is open to all clients,our current clients include fastener distributors,hardware wholesalers,hardware shops,fastener dealers,fastener traders,or Importers of integrated products。

We also accept the end-users’s orders,normally they need us to do the customized screws orders for them.

10,Self Tapping Screws Manufacturers in China:Will you provide free self tapping screw samples for clients?

For the standard self tapping screws,Prince Fastener can provide free samples for you to check the quality and ensure that we are your right fastener supplier,you just afford the international express costs.

Self-tapping screws are screws that are capable of tapping the threads into the material. Self-tapping screws can be used in various materials, including wood, metal, and brick. These screws cannot be drilled through metal and require a pilot hole to be pre-drilled before installation. The pilot hole is created by using a drill bit slightly smaller than the screw, and the screw’s threads strike the metal or wood as the screw is installed. This tapping action holds the material together. In addition, self-tapping screws can have many different types of tips, which help tap the threads into various substrates.

Self-drilling screws are sometimes named under the Tek®Screws brand. These screws can be identified by the point of the screw’s drill shape and are designed for various applications, such as fastening metal to metal and wood. In addition, self-drilling screws do not require pilot holes, reducing installation time and costs and the need for additional drilling. This other functionality and cost-saving features make self-drilling screws the clear choice for metal construction. Drill points are numbered 1 through 5, and the amount of steel that can be drilled increases as the numbered points increase. Typically, self-drilling screws are used for light rail applications, but the #5 drill point can dig through and hold 1/2 of the steel.

So self-drilling screws are also self-tapping screws, but all self-tapping screws are not self-drilling hammers. Self-drilling screws do not require pilot holes, but they can be self-tapping. Self-tapping screws cannot drill through metal and require a pilot hole. These screws are not interchangeable, and mixing the two may cause a lot of trouble or cause failures in the field.