Wholesale

Chipboard Screw

From One-stop Fastener Suppliers and Manufacuturer -The Ultimate Solutions

Want to wholesale chipboard screws with more margins? This exclusive guide will help you to find the right fastener suppliers and products

- Accept customized fastener requests

- Provide competitive imports costs for you

- Buy Chipboard Screws from China factory directly

- Fast reply with professional staffs from screws factory

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our chipboard screws for wholesalers and importers.

Quick View

- → Why wholesale chipboard screw from Prince Fastener?

- → Hot products for Chipboard screws

- → Estimated wholesale → Price for Chipboard Screws

- → Estimated Chipboard Screws Producing Period and Delivery Time

- → What is a Chipboard Screw?

- → What Is The Difference Between Wood Screw And Chipboard Screw?

- → How are chipboard screws made step by step?

- → Searching for chipboard screws made in China?

- → Need Special screws for your clients or projects?

- → The Complete FAQ Guide about chipboard screws

Why wholesale chipboard screw from Prince Fastener?

Prince Fastener is a professional fastener manufacturer with more than 30 years history in China, providing a wide range of fastener products for clients from all over the world.

We are ISO (International Quality System) approved and have exquisite technicians and managers from executive to sales, from technology to production, ensuring us fine qualities of our products and a good market reputation.

Our factory owns advanced manufacturing equipments introduced from Taiwan such as Head Making machines, Thread Rolling machines, Net Furnace and examining machines like Micro Hardness Tester and Microstructure Tester,etc.

Hot products for Chipboard screws

Chipboard Screws 50mm

Chipboard Screw Screwfix

Chipboard Flooring Screws

15mm Chipboard Screw

Best Screws for Chipboard Furniture

Chipboard Screw Yellow

Chipboard Screws 40mm

Chipboard Screws

Plasterboard Screws

Estimated wholesale Price for Chipboard Screws

The estimated wholesale price for chipboard screws includes the following factors below.

Fastener Manufacturing Costs

Generally, the production process is standard operation for creating and manufacturing the best quality chipboard screws. Since the facility is capable of sourcing materials for the process, the cost of wholesale chipboard screws is defined by the type of material and production method performed.

Chipboard Screws Packing Fee

After manufacturing the fastener products, the packaging is either done with a standard system or the customer’s special request.

Shipping Costs

The payment for transport and delivery of products to your doorstep comes with minimal cost and an estimated price by sea or air transportation.

Chibpoard Screws Free Sample

For convenience and quality assurance in our products, Prince Fastener provides free chipboard screw samples to customers worldwide with the only charge of shipping costs.

Customized Chipboard Screw Rate

Prince Fastener accepts custom orders from clients and distributors with intricate features and specific requirements for materials and features. The cost of customized chipboard screws varies on the type of method, materials, and quality checking of the fasteners.

Custom Clearances Costs

The custom clearance costs are the dues that are collected upon shipment of the commodities to their destination, including other miscellaneous fees.

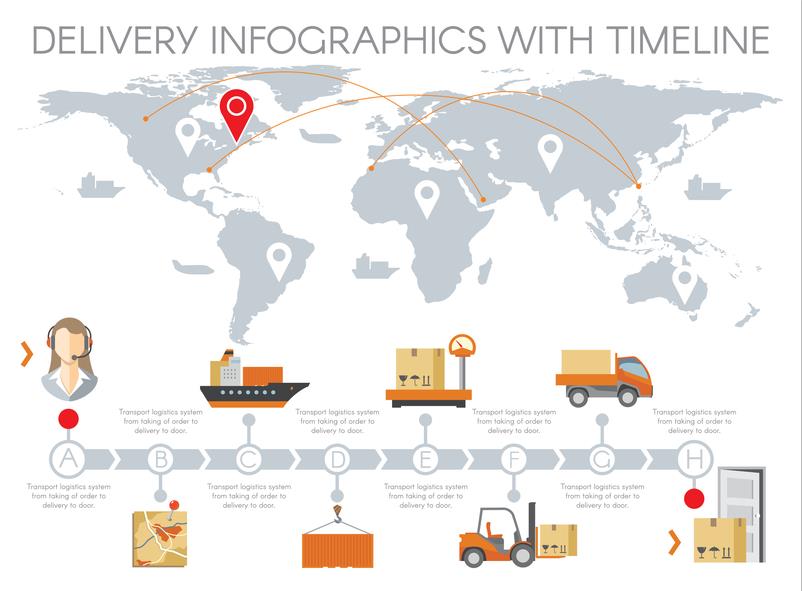

Production Period and Delivery Time of Chipboard Screws

To fulfil the wide demand of the industrial market for chipboard screws, Prince Fastener has equipped its facility with the best capabilities in advanced machinery and technology. The sustainable approach has allowed the company to provide innumerable solutions internationally. The following steps showcase the basic operational process of Prince Fastener.

Chipboard Screw Design and Manufacturing

The innovation and fabrication of fasteners are performed in the manufacturing facility owned by Prince Fastener.

Packaging of Products

The last process before handling the products in shipment and delivery, the chipboard screws are secured into pp bags or small white boxes and then packed into appropriate boxes.

International Shipping time and customs clearances time

Packed products are shipped in the proper mode of transportation and will take some time for customs clearance to export and import.

Local Logistics

The final process of delivering high-quality chipboard screws to your doorstep requires service from local logistics that are pre-arranged in the transaction.

What is a Chipboard Screw?

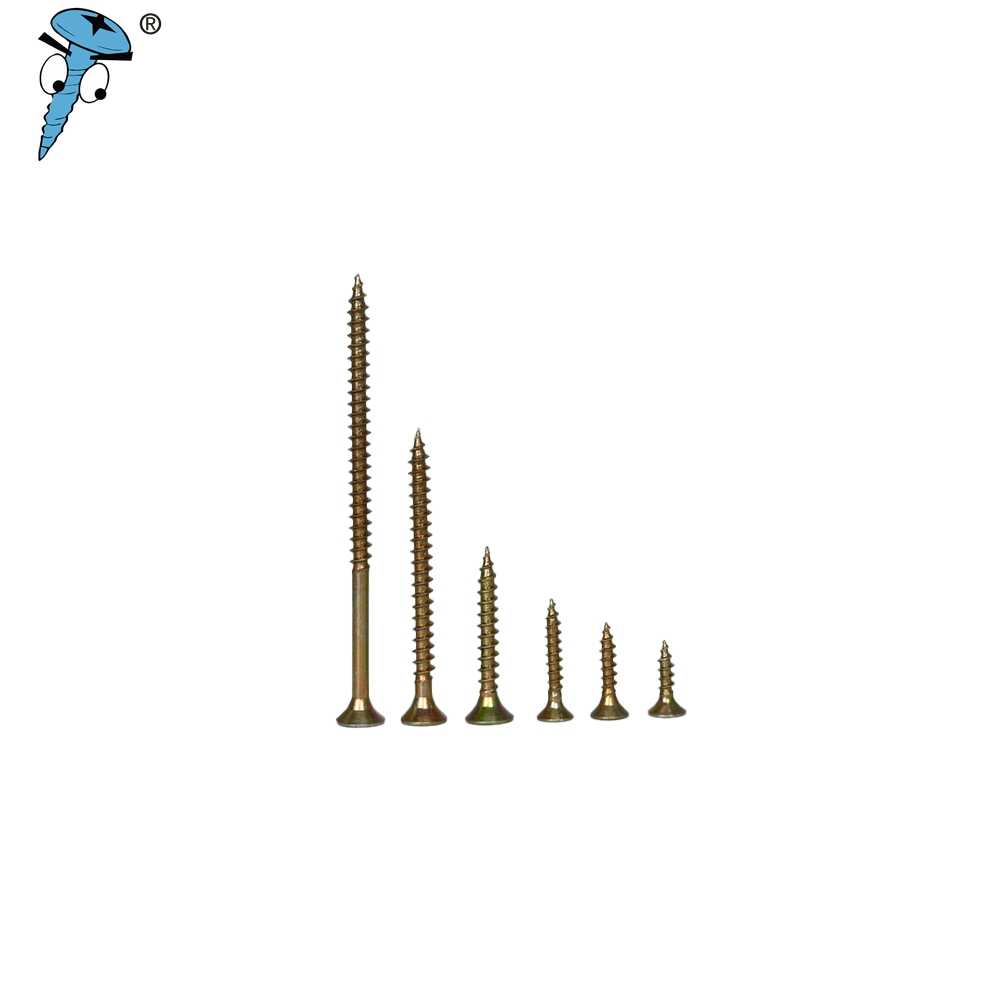

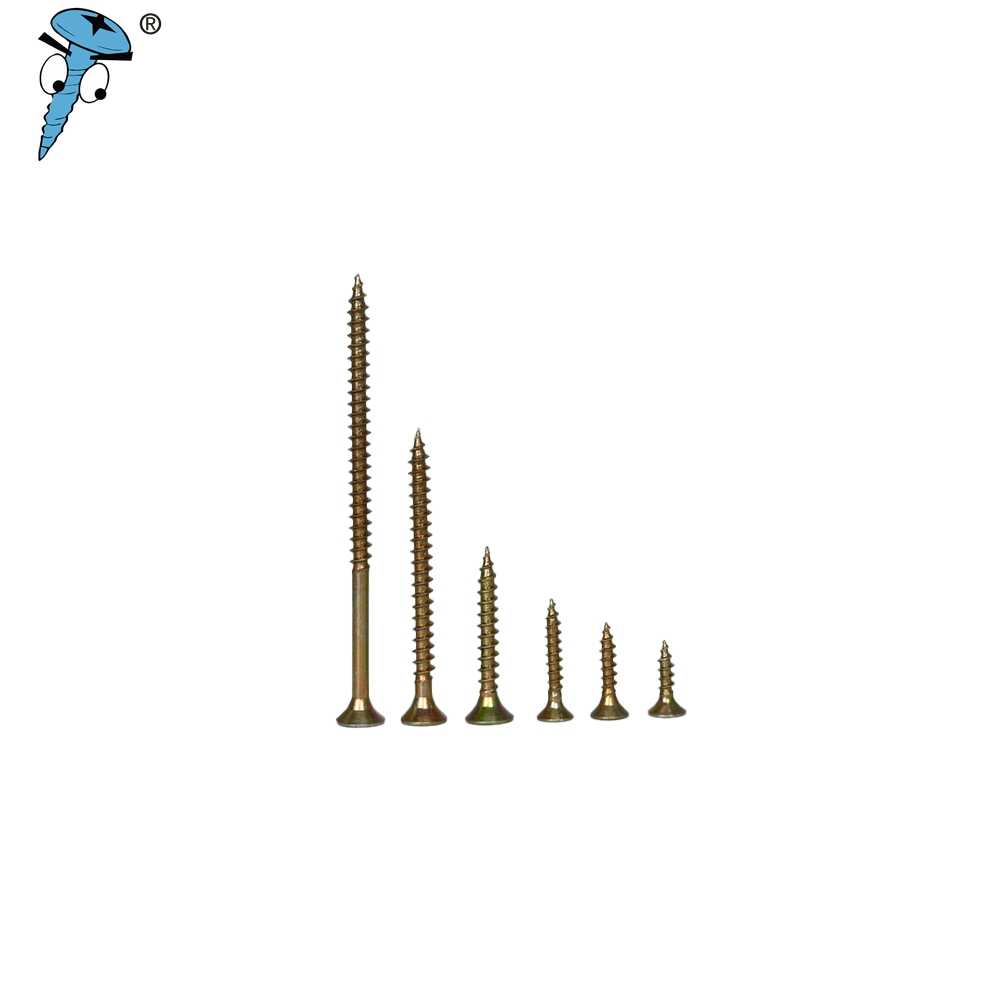

Chipboard screws are self-tapping components designed with a single type of thread that runs along its full length from tip to under the head section. The large distance between peaks of the thread on chipboard screws allows it to go through softer material such as plasterboard or chipboard hence its name. For this reason, the screw is commonly used as a fastening material to composite boards and other wood surfaces.

There are two known types of chipboard screws; half-thread and fully threaded. Half-threaded chipboard screw is mainly used in joining two pieces of wood boards for its smooth section prevents the pull of the two materials together with no gap.

The fully threaded type is used to connect the metal sheets to composite boards because it secures the materials together in a tight grip.

This type of screw is technically used in wood-to-wood and wood-to-metal applications; however, the chances of cracking the surfaces when it is driven into soft materials are at great risk. Nowadays, fastener manufacturers such as Prince Fastener have come up with an innovation to modify the screw to a quality level to solve the problem of making it claw-cutting.

The body of a chipboard screw

Poze drive with countersunk or double countersunk Head – The flat Head enables the chipboard to screw in level to the surface material. The particular character of a double countersunk head is it is designed to increase the head strength.

Thin shaft – the thin shaft of the screw prevents the material from splitting during application and loosening.

The coarse thread – compared to the other types of screws, the coarse thread of chipboard screw is sharper and digs deeper and more tightly on soft materials such as particle board, MDF board, chipboard, and others. It allows the embedding of threads to the surface, creating an extremely firm grip.

A self-tapping point – The sharp point or self-tapping point of the screw drives it conveniently to materials without the need for a pilot drill hole.

Where to use chipboard screws?

There can be many uses for chipboard screws, particularly in wood projects such as furniture assembly, shelving, flooring, etc. There is a wide range of sizes of chipboard screws; the smaller screws are mainly used for fastening hinges on cabinets and other types of furniture, while larger screws are used to join bigger pieces of wood on cabinets, etc. The coating on chipboard screws can be classified into two kinds; white zinc-plated or yellow zinc plated; the zinc plating adds an extra layer of protection to resist corrosion and look aesthetically in projects.

What Is The Difference Between Wood Screw And Chipboard Screw?

The major difference between the two screws is their thread pattern; the thread is the helical structure that converts the rotation and linear movement or force exerted on the screw. The thread of a chipboard screw is usually seen to run from under the Head to the bottom point. This is why this type of screw is generally used in most projects that require additional holding or binding force, such as the case installation of garden decking and big cabinets. The main factor that creates the confusion and interchanging use of wood screws and chipboard screws is that they are both commonly known as particle board screws.

Aligning features that can be seen on chipboard screws and wood screws are;

- The two fasteners carry a coarse thread and a shaft, making them suitable for various woodwork and pieces.

- Both screws can be used in all types of timber, such as MDF, softwood, hardwood, eponymous chipboard, and others.

Prince fastener will introduce you all the process of the chipboard screw production.

Prince fastener production process

The basic concept of the screw production process by Prince fastener

- Prince fastener manufactures different kinds of screws with the process of cold heading and hot machining, such as turning, milling, etc.

- Cold heading refers to the use of plastic metal that is pressured or drawn into cold mechanical pressure until it reaches a solid metal form.

- The hot heading is another pressure machine that heats the material in the die until it reaches a certain form in head style.

- After the material has undergone heating and pressure, it will be shaped in the required design.

- Machining will then section batches of the screws or bolts to be milled and turned into special screws with six corners of head type.

- Screw bolt threading is usually done through mechanical and manual threading in a similar die.

- The use of a cutting machine generally completes the milling of the tail end.

- The difference between cold and hot heading: cold-headed materials are forged into a series of ‘die blows’ to achieve a smooth exterior while having strength and resistance; the hot heading is forming the Head of the bolts in lesser ‘die blows’ allowing it to be cost-efficient yet a slower process to take when purchasing several screws.

Analysis of forming process and the cause of the phenomenon

- Eccentric: placed improperly in the adjustment machine

- Minow: the poor installation

- The Head is non-circular: the choice of a die or punch form was insufficient

- The mode of cracks: properly choose a crack or die R angle to administer the model by two collision hit

- Head double: inadequate punch

- Flash: when poor moulding punch in the die hole clearance is too large or short by red bars

- Crack in angle: not enough punch or a burst in needle

- Head cracking: error in using of die, material, and lubricating oil

Analysis of common rolling and the cause of the adverse phenomenon

- Crack between the process: need an adjustment in Prince fastener old machine and tooth plate

- Blunt tail: when the device is improperly managed, or the tooth plate needs adjustment

- Crooked tail: occurs when the control screw on the board seat is too tight

- Tail: improper adjustment of machine and poor quality of tooth plate resulting in wearing

Searching for Chipboard Screws Made in China?

Prince Fastener is your one-stop fastener vendor with an ideal service that has been proven to provide 100% customer satisfaction.

Production Equipment

Prince Fastener owns more than 100 pieces of production equipment with a monthly capacity of 600 tons and an annual capacity of more than 6000 tons. The types of equipment include advanced manufacturing machineries introduced from Taiwan, such as head-making machines, thread rolling machines, net furnaces, and testing machines (salt spray machines, 3D projectors, hardness testers, etc.)

Testing Equipment

Every product is made of high-quality steel in a high-technology production process and complete testing methods that ensure excellent qualifications for different fastener applications.

Need Special Screws for Your Clients or Projects?

Prince Fastener is more than capable of providing you with safety solutions and outstanding customer service.

As an industrial manufacturing company with more than 30 years of experience, Prince Fastener has achieved successful product development, excellent sales and service, and flexibility to cater to the complex needs of the industry. The company prioritizes quality and executes the standard processes in firm belief to deliver customer satisfaction and professional business relationship.

The main products of the company include chipboard screws, long screws, non-standard screws, titanium screws, small screws, stainless steel screws, bolts, nuts, self-tapping screws, self-drilling screws, etc. The production process and final output all conform to international standards such as ISO, DIN, EN, and more.

Prince Fastener has provided more than 500 billion screws for more than 1,000 companies and has customized 4,800 types of screws with further capabilities to fabricate according to customer requirements. We accommodate custom designs and drawings in reasonable plans and costs of the overall transaction.

The company comprises innovative engineers and a skilled team that caters to developing diverse types of fasteners. We have served multiple business sectors and industries in toy factories, handbag factories, furniture, building materials, sanitary ware, electronic, automobile, new energy, and aviation navigation fields, etc. to the countries of Hong Kong, Korea, Japan, Australia, the UK, Europe, and the Middle East.

The Complete FAQ Guide about chipboard screws

Quick Index

1. Where to get wholesale price for chipboard screws?

2. Are chipboard screws the same as wood screws?

3. Can you ship chipboard screws to other countries?

4. How to choose particle board screws?

5. Can you supply different chipboard screw sizes?

6. How to check the quality of chipboard screws?

7. Are you a fastener supplier for particle board fixings?

8. What are the terms of purchasing particle board fasteners?

9. Are you a standard screw supplier?

10. Do you have other fastening supplies like nuts and bolts?

11. Is there another type of wood screws for particle board?

1. Where to get wholesale price for chipboard screws?

The leading fastener manufacturers in China offer competitive pricing for different variations of fasteners, including chipboard screws. China has produced massive materials and components relating to screws and other fasteners, which makes them a great advantage regarding the costs of the final commodities. The country also has the most fastener manufacturers that can compete in quality with renowned brands from top-tier producers of fixings and fasteners.

With multiple facilities that perform the chipboard screw fabrication in a wholesale system, the country has exported millions of supplies to overseas countries for different distributors and organizations. It’s best to say that sourcing wholesale price for chipboard screws is more accessible and budget friendly if you can find a reliable fastener supplier in China.

You can check different virtual portals in this link to find a good supplier online >>

2. Are chipboard screws the same as wood screws?

The diverse range of types of screws has its functionality depending on their features and elements. Each different kind also proposes a particular type of application, yet the names are used interchangeably, creating confusion for some and in assembly. A perfect example of this situation is wood screws and chipboard screws; although both fasteners comprise largely similar forms and functions, they do have certain key differences.

The main difference that cannot be argued between woodscrews and chipboard screws can be seen through their threads, which on chipboard screw runs along the screw’s body or length to the underside of the Head. This feature particularly provides a useful advantage of extra strength in hold for crucial areas which require tight grip of materials such as decking, shelves, and others.

However, both screws are also referred to as ‘particle board screws’ as their type are the most common mechanical woodworking fasteners used for joining wood to wood materials or primarily wood surfaces. Whatever the name they’re called, these are self-tapping components featuring a thin shaft and a coarse thread that makes them preferable to use for all types of timber, including hardwood, softwood, and manufactured wood.

Need help configuring the best type of screw for general or complicated applications? Don’t hesitate to contact us today and turn your questions into fair solutions. We can supply any kind of fasteners as well as answer your inquiries, click HERE to get all the information you need.

3. Can you ship chipboard screws to other countries?

As part of the reliable service that Prince Fastener has been providing over the past 30 years, the company supports international businesses such as exporting to different countries, which have the market demand for competitive and high-quality chipboard screws widely used in many forms of applications. Presently, Prince Fastener has extended its fastener products to the USA, UK, Australia, Canada, Russia, Brazil, Mexico, UAE, and other countries, which have all shown satisfaction and positive feedback to the company and its service.

4. How to choose particle board screws?

Particle board is furthermore known as chipboard which is a type of softwood made from wood chips, sawmill shavings, and wood dust, all combined with a powerful adhesive pressed and processed to form layers until it achieves the desired thickness.

The best type of screws suitable for joining particle boards together is chipboard screws and wood screws. The fastener should be inserted will a pre-drilled hole slowly so that the material will not be left damaged.

You can check our available products here>>

5. Can you supply different chipboard screw sizes?

Prince Fastener can supply a vast range of fasteners, especially chipboard screws, in different sizes; the available sizes that the company manufactures in diameter are M3mm-M8mm and lengths from 6.5mm-150mm. With its advanced machinery and use of technology, it can fabricate accordingly to customer drawings and specific sizes.

6. How to check the quality of chipboard screws?

Chipboard screws are commonly used in multiple fastening systems and applications; the product is expected to have the quality of the feature appropriate for the surface material it is going to be applied. To check the quality of the product, you can test it before assembly in different types of wood, know the process of production, check the coating if there is any, and check the standard grade with your supplier.

7. Are you a fastener supplier for particle board fixings?

Prince Fastener is a manufacturing company that can supply fasteners to different sectors and industries for commercial or assembly. The company is renowned for its calibre-rated capabilities in producing standard and non-standard fasteners for every application.

Always use your fasteners in the right way>>

8. What are the terms of purchasing particle board fasteners?

We offer 24/7 customer response, and we can get right to inquiries with a smooth transaction and good process. Prince Fastener provides professional service and aims for a successful relationship by associating the principles that have guided the company to prosper in the industry.

The company provides free samples for customers and a quick management system for processing orders to deliver the products on time. We customize designs and drawings to customer requirements with the offer of competitive pricing while the payment is 30% T/T in advance, and the balance should be paid before the shipment.

Find a reliable fastener supplier in this list>>

9. Are you a standard screw supplier?

Since having the many capabilities of a leading fastener manufacturer in China, Prince Fastener can provide solutions for many different features, including standard screws. Standard screws are common screws for general use and qualities, including the certification accomplished in the process of production. The organization is a successful entity with numerous conformity in international and local standards such as DIN, ISO, JIS, ASME, ASTM, ANSI, etc.

10. Do you have other fastening supplies like nuts and bolts?

Prince Fastener can supply other brands and businesses with the convenience of service through OEM, ODM, private labels, and so on. Nuts and bolts are a common type of fasteners which is also a big market for many fastener distributors. The company provides flexible service for the complexity of the affecting factors that should be considered in fastening.

Quickly know the fasteners through our written topics here>>

What are Nut and Bolt Fasteners?

Bolts and Nuts types and prices.

11. Is there another type of wood screws for particle board?

Screws have features for general use and standard quality that make them a preferable choice in fastening wood materials like particle board. Typical screws that are used for this type of surface include chipboard screws and self-tapping deck screws. Both fastener screws comprise an ability that can be similar to each other as well as other types of screws, yet the usual difference of the many screw types vary in shape, thread, sizes, form, etc.