Vendors Self-drilling Wood Screws

A prime wholesale screw manufacturer from China devoted to serving the best fastener solutions in various industrial applications.

Expand your revenue when you choose the precise fastener screws that are in demand in the niche market today. Prince fastener specializes in the following:

- Convenience in fabricating every detail up to the client’s requirement

- Life-long service provider in fastener-related products

- A well-established company able to export and import worldwide

- High-quality materials and production process yet offers competitive prices

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce Vendors Self-drilling Wood Screws for fastener wholesalers and importers.

Quick View

- → Knowing the Assets of Service from Prince Fastener in Wholesale of Self-drilling Wood Screws

- → Hot products for Custom Self-drilling Screws

- → Estimating the Wholesale Price of Self-drilling Wood Screws

- → Approximate Production Period and Delivery Time of Self-drilling Wood Screws

- → How are self-drilling wood screws made step by step?

- → Searching for Self-drilling Wood Screws made in China?

- → Learning the Basic Structure of Wood Screws and their Functionality

- → Need Special Screws for your Clients or Projects?

- →The Complete FAQ Guide about Self-drilling Wood Screws

Knowing the Assets of Service from Prince Fastener in Wholesale of Self-drilling Wood Screws

Prince fastener is a well-established manufacturing screw company that can provide the overall service in customizing fastener products and customer support solutions. With an outstanding experience of more than 30 years in the industry, we have achieved multiple developments and continuous innovation of products.

Prince fastener specialization in the fabrication of all kinds of screws has reached internationally in Hong Kong, Korea, Japan, Australia, the UK, Europe, the Middle East, North America, South America, Europe, Southeast Asia, and Africa. We are continuing to grow in scale because the demand in the market for fasteners is interminable. Prince fastener is a one-stop-shop solution-oriented, that offers services in OEM, ODM, or private label brands to interested clients that are looking for high-quality customized screws.

Prince fastener is accredited and has passed international standards on our products in DIN, ISO, GB types, ASME/ANSI, BS, JIS, and AS to ensure the market reputation needed in manufacturing enterprises. The Prince fastener factory is well-equipped with efficient machines with the capacity to produce tons of screws and bolts and consists of skilled technicians, engineers, expert managers, factory production workers, competitive sales, and executives that do not disappoint in terms of service.

Hot products for Custom Self-drilling Screws

Self-driling Concrete Screw

Self Tapping Screws for Metal

Tek Screws for Structural Steel

Industrial Self Drilling Screws

Self Drilling Screws for Aluminum

Black Self Drilling Screws

Trailer Decking Screws Self Drilling

Custom Self-drilling Screws

Estimating the Wholesale Price of Self-drilling Wood Screws

The following list of details is to help clients determine the possible and estimated costs in the wholesale manufacture of self-drilling wood screws or any other fastener products from Prince fastener.

Fastener Manufacturing Costs in Raw Materials

When provided with accurate specifications from the client’s requirements, Prince fastener will shortly process the production of the self-drilling wood screws under the strict practice of producing high-quality screws. The material used in the production of self-drilling wood screws is mainly carbon steel which gives the effectivity and durability of the fastener when applied on any surface, other raw materials available for use are stainless steel and alloy steel which can be personalized according to the customer’s design.

Self-drilling Wood Screws Packing Fee in Customization

Prince fastener has the flexibility in masses of demand even within the packaging of the self-drilling wood screws. We further comply with special requests for brand packaging at reasonable costs for convenience in dealership provisions.

Shipping Costs

The main costs in shipping out the fastener self-drilling wood screws from China to the customer destination are either by land, sea, or air transport. The shipping cost is well calculated depending on freight charges by the cargo company.

Self-drilling Wood Screws Free Sample

When clients ask for a sample of fastener screw we generally provide them free of charge to show that we have confidence in the quality of our self-drilling wood screws. The receiving client will only have to pay the international shipping fee and costs.

Each fastener product can be categorized into lists of variations like the fastener finishings, screw head type, point/thread styles, raw material in use, surface treatment, and head set screws. In the specification of design, there can be endless options for every client’s demand, luckily Prince fastener provides the service in customization. We accept special designs and requirements in self-drilling wood screws and other fastener screws we produce.

Custom Clearance Costs

Custom costs, miscellaneous fees, and other charges in clearance for the shipment and transport of the products into the determined destination.

Want to cooperate with Fastener factory?or you want to get custom fastener?

Prince Fastener Is Here for Creating Quality Screws With Competitive Costs for You,and Offer the Technical Supports and Exclusive Services for Your Business.

Approximate Production Period and Delivery Time of Self-drilling Wood Screws

Prince fastener guarantees precision through the process of wholesale enterprise for self-drilling wood screws, we present transparency of our factory production and distribution process to show the dedication of the team that works diligently to accomplish 100% success and customer satisfaction.

Self-drilling Concrete Screws Design and Manufacturing

As an organization that has been around for more than 30 years in manufacturing fastener screws and related products, Prince fastener has acquired its factory and machines capable of producing in mass quantity and different material requirements. We design the self-drilling wood screws in our facility as well as manufacture custom orders of the like. Some of the different types of equipment we use in our factory are testing machines, hardness machines, cutting machines, grinding machines, box burying machines, and tensile machines.

Packaging of Products in Mass

Despite the technological innovation, we put significance in the packaging of self-drilling wood screws by having human resources as checkers and packers to double the efficient productivity in our factory process. The usual procedure of packaging screws starts from sliding screws into pp bags or small white packets before they get into boxes and are fragile-proofed for shipping.

International Shipping Period and Customs Clearances Time

The infographic timeline will show the overall shipment process of your self-drilling wood screws or fastener products. Despite the uncertain period of the transport of goods, Prince fastener will help and guide the clients in estimating the delivery, with the experience we have gathered in exporting through different countries for individual organizations we keep updated information on international shipments.

Coordination in Local Logistics

Finally, the fastener products will be delivered to your destination upon arriving at your local port or logistics and once it’s been cleared for release.

The basic concept of the screw production process by Prince fastener

Prince fastener production process

Basic concepts of Prince Fastener screw production

- Prince fastener manufactures different kinds of screws with the process of cold heading and hot machining such as turning, milling, etc.

- Cold heading refers to the use of plastic metal that is pressured or drawn into cold mechanical pressure until it reaches a metal solid form.

- The hot heading is another pressure machine that heats the material in the die until it reaches a certain form in head style.

- After the material has undergone heating and pressure it will be shaped in the required design.

- Machining will then section batches of the screws or bolts to be milled and turned into special screws with six corners of head type.

- Screw bolt threading is usually done through mechanical and manual threading in a similar die.

- Milling of the tail end is generally completed by the use of a cutting machine.

- The difference between cold and hot heading: cold-headed materials are forged into a series of ‘die blows’ to achieve a smooth exterior while having strength and resistance, hot heading is forming the head of the bolts in lesser ‘die blows’ allowing it to be cost-efficient yet a slower process to take when purchasing several screws.

Analysis of forming process and the cause of the phenomenon

- Eccentric: placed improperly in adjustment machine

- Minow: the poor installation

- The Head is non-circular: the choice of a die or punch form was insufficient

- The mode of cracks: properly choose a crack or die R angle to administer the model by two collision hit

- Head double: inadequate punch

- Flash: when poor molding punch in the die hole clearance is too large or short by red bars

- Crack in angle: not enough punch or a burst in needle

- Head cracking: error in using of die, material, and lubricating oil

Analysis of common rolling and the cause of the adverse phenomenon

- Crack between the process: need an adjustment in Prince fastener old machine and tooth plate

- Blunt tail: when the machine is improperly managed or the tooth plate needs adjustment

- Crooked tail: occurs when the control screw on the board seat is too tight

- Tail: improper adjustment of machine and poor quality of tooth plate resulting in wearing

Get further overview of references for self-drilling screws and self-tapping screws from Prince fastener.

Searching for Self-drilling Wood Screws made in China?

Prince Fastener is a well-established leading fastener supplier in China whose specialization is focused on the development, production, and sales of non-standard fasteners and standard fasteners be it in customized requirements to be as competitive with the big brands in the industry. We have been recognized as a leading manufacturer of self-tapping and other fastener screws among of the rest distributors in China.

Production Equipment

As an establishment with the capacity to produce high-standard fastener screws such as self-drilling wood screws, Prince fastener owns a fully equipped factory in terms of machinery and production team to ensure meeting the demand of the market industry. Our advanced production machinery includes; a multi-station nut forming machine, tail hole machine, screw machine, thread forming machine, tapping machine and more than two hundred machines, a centerless grinder, CNC machining, etc. In terms of specialization in the design of self-drilling wood screws, Prince fastener uses high-quality raw materials such as stainless steel, carbon steel, alloy steel, etc. With a total of over 100 production types of equipment, we accumulated more than 10000 tons of annual capacity in producing fastener-related products.

The Team Who Collaborates in Innovation

The self-drilling wood screws and all fastener products are made sure to comply with international standards and customer requirements. Prince fastener uses the control of testing types of equipment such as Rockwell hardness tester, Vickers hardness tester, three-dimensional projector, tensile machine, torque tester, salt spray tester, and center axis tester for the products to qualify in the disposal to clients and distributors.

Check out more information about the supply in wholesale of self-drilling screws in this link here.

The Factory, Machinery, and Proficiency

In the wide industry of manufacturing, Prince Fastener never fails to improve the progress of development in every aspect. Undoubtedly, our expertise is exceptional in showing value and a level of excellence.

Our organization is internationally accredited and acknowledged to be one of the rapid manufacturers in China for different screws having the use of top-tier equipment originating from Taiwan. This method of exceptional craftsmanship is to ensure production of custom self-drilling screws is met perfectly by the prince fastener.

The high degree of competence we exhibit in the production of custom self-drilling screws is to strongly enterprise that our resources will never cease to please the trading in the market. With our competitive prices, prince fastener can achieve repeat orders from big brands and clients, supplying them with the highest quality of custom self-drilling screws. In the large-scale selection that these fastener screws can take we have produced numerous types in sizes, forms, applications, usage, and kinds that have matched up to the main requirements that customers look for especially in making custom self-drilling screws.

Dynamically, as the vast count of domestic fastener manufacturers keeps rising, the market share in percentage has a low concentration, therefore, making the leading enterprises of custom self-drilling screws strive to obtain high-quality competence to monopolize the production of fastener products.

Understanding How to Establish the Custom Self-Drilling Screw Business

Like the demand for furniture making, the upsurge growth of mechanical fastener industries continues to improve as its significant use to derive final product results is essential.

To come about the choice of fastener products, the things to consider should start with examining supply chain solutions. This is where Prince Fastener emerges to be of service, the custom self-drilling screws have their advantages to propose. It is mainly applied to several different industries including furniture making, electronic types of equipment, construction, automotive, appliances, and even in the medical field. The usage of custom self-drilling screws covers standard components such as glass, wood, metal, metal sheets, concrete, brass, etc.

As aforementioned the importance of custom self-drilling screws, it is also a principal key point to evaluating the factors that can contribute to the business you will build. Deep research will be the cue to establish and execute the plan later on. To help in understanding the market value of custom self-drilling screws you have to innovate the following in order; market research, business plan, funding, location, business structure, and registration of the business as well as securing registration and tax requirements. We have collected reliable information from this website to showcase some important details when you are starting up your own business.

Once completed it will take motivation to keep sourcing the market niche and developments. Prince fastener comes vigorously to help with the tasks that come up against the supply of custom self-drilling screws. We will communicate and take you through the process of fulfilling the demand when either you are feasibly selecting the kind of fastener from our catalog, seeking engineering help, or consulting for the purchasing needs of custom self-drilling screws, Prince fastener will ensure firm service and maintain the best quality of serving you. With our commitment and sincerity to organizations and customers, we assure the utmost loyalty of service will be provided from day one. As a company that has excelled among other corporations in the production of custom self-drilling screws and stainless steel screws, it is gratifying to share the details of how we won the ranking and to have the product qualification rate of 100% among the other manufacturers in China. Stainless steel and custom self-drilling screws leading factory in China.

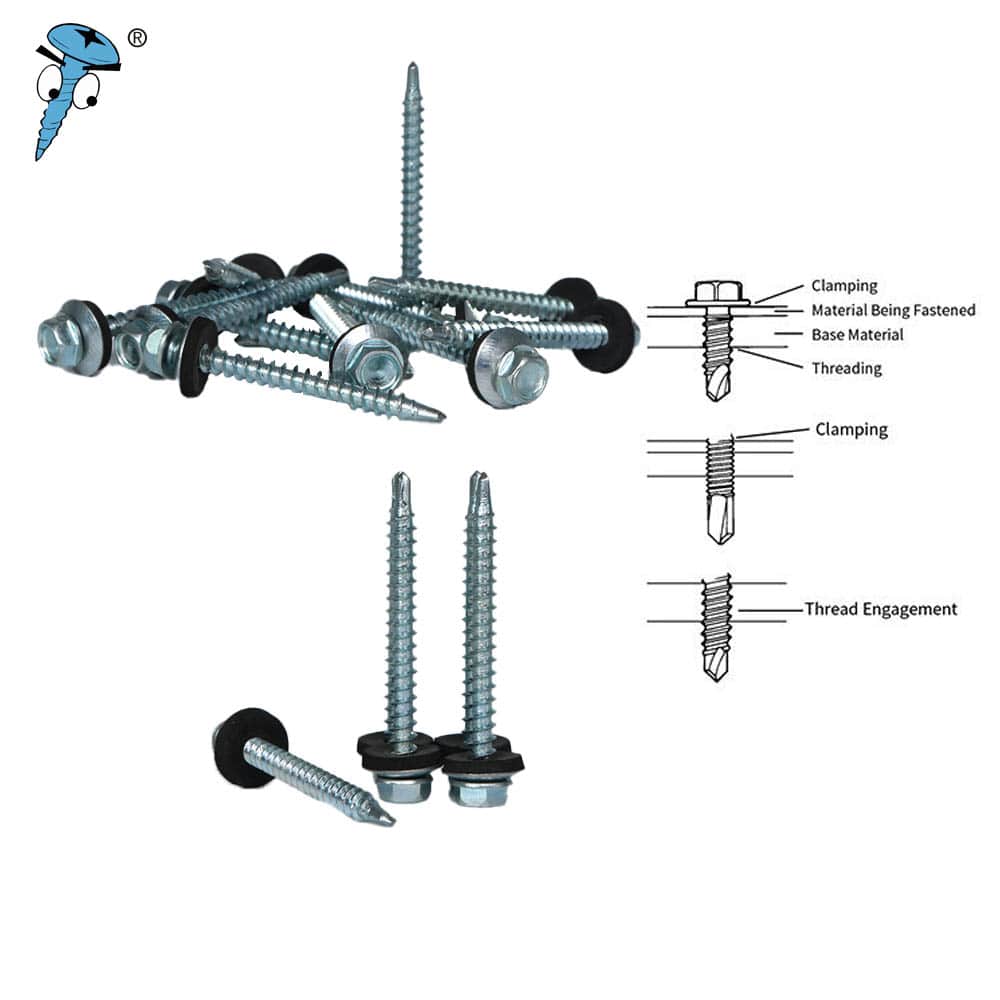

Learning the Basic Structure of Wood Screws and their Functionality

The Head of the screws

The head of a self-drilling wood screw can serve different purposes depending on its type as it is where the drill bit of the tool is inserted to twist on the base material for an installation. The main types are, pan head screws, flat head screws, and washer screws. You may also check the general types of self-drilling screws that can give contrast to the differences in features by clicking the full link here

Drive types

Drive shape or type of drill bit form in screws is the proportional hole found at the top of the screw for drilling and this carry out a different type of functionality such as Philips head, Star head or Torx, square head or Robertson, and slotted or flathead.

Shaft

The shaft refers to the center of the backbone of the screws where threads of the screw is attached. The shaft proposes factors in results that are useful for the overall function of a self-drilling wood screw. For instance, a thicker shaft can enable more resistance to damage. Proper length choice can result in a successful application on the thickness of the wood. And the non-threaded portion of a screw, can serve better hold of the materials fastened together because they are the primary foundation of the threads on self-drilling wood screws that joins the surrounding wood intact.

Threads

Threads are the spiral portions in screws, they differ in angles or sizes in inches serving the stronghold and effectivity of fastening. Hardwood and Softwood can have differences in the usage of thread types, screws used for hardwood need tight threads or consecutive spirals to avoid wood from splitting, while softwood screws possess fewer threads in appearance for the better hold of soft material and preventing it from tearing apart. Some threads of self-drilling wood screws are made in serrated proportions to prevent the wood from splitting during the installation.

Wood Screw Tip

The tip of the wood screw is usually the first liner that dives into the surface when drilling. Self-drilling wood screws are an easy option to avoid pre-drilling yet it cuts hastily on wood materials. Meanwhile, flat tip screws as the name suggests have a flat tip that punctures into wood well enough and is a more common use for woodworking.

Self-drilling Wood Screws in Application and Use

Need special screws for your clients or projects?

Prince fastener is a leading worldwide distributor of excellent fastener screws such as self-drilling wood screws and other related products manufactured in China.

We have succeeded in the accreditation of ISO, DIN, ANSI/ASME, JIS, and GB types due to the proficiency we execute in the fabrication of standard and custom screws, the organization has reached an international scale in distributing to Hong Kong, Korea, Japan, Australia, the UK, Europe, the Middle East, and more countries and Customized fastener service wholesale is widely in demand in different industries nowadays, that is why Prince fastener makes sure to innovate the development of our self-drilling wood screws that undergoes complex treatment on blue zinc plating, yellow zinc plating, nickel plating, black zinc plating, gray phosphorus galvanizing, black phosphorus galvanizing, brass plating, steam plating, hot dip galvanizing, silver plating, gold plating, etc.

Prince fastener can provide the best solutions for every client’s demand in requirements because we are highly motivated to increase the productivity of self-drilling wood screws to continually expand and grow our reach in supplying the best screws domestically and abroad. Prince fasteners’ main products manufactured over the years are the following; plasterboard screws, chipboard screws, self-tapping screws, self-drilling screws, self-drilling wood screws, blind rivets, coil nails, common nails, concrete nails, plastic strip nails, ST nails, various shaped nails, bolts, nuts, washers, threaded rods, anchor rods, and thousands of related products. Lastly, we take additional processes on producing top-of-the-list fastener self-drilling wood screws in strength, durability, and exceptional resistance to embrittlement and corrosion.

The Complete FAQ Guide about Self-drilling Wood Screws

Quick Index

- What is the best screw for drilling into wood?

- What is tek screw?

- What’s the difference between self-tapping and a wood screw?

- Can you screw wood into metal surfaces?

- How do you install self-drilling wood screws?

- What are self-drilling wood screws used for?

- How to purchase wholesale self-drilling wood screws in Prince fastener?

- What are the different types of wood screws?

- Can you make customized self-drilling wood screws?

- Can you provide a quotation for your fastener products, especially on self-drilling wood screws?

- What is the best option in importing and manufacturing your fastener screws?

- Do you offer ODM and OEM self-drilling wood screws?

1. What is the best screw for drilling into wood?

Screws are common fasteners used in woodworking and they have complex types to enumerate depending on functionality and application process as they play a big role in assembling solid structures. The choice of defining the best screw for drilling in the wood will differ on many principles, however, a self-drilling wood screw is best suited in the application of furniture making such as wood to wood and wood to metal sheets as it can form a strong joint with the elimination of pilot hole or pre-drilled process.

How to distinguish the type of wood screw for better use? Click this link.

2. What is tek screw?

Tek screws are also self-drilling and self-tapping screws that are popularized by their brand name. Prince fastener self-drilling wood screws are as good as tek screws in quality and effectivity.

3. What’s the difference between self-tapping and a wood screw?

Self-tapping screws are screws that come in different variations and they are useful in different applications but they need pilot holes before they can tap on surfaces to work efficiently. There is also a kind of self-tapping wood screw that can be compared with a self-drilling wood screw, however, they differ in the application because self-drilling screws can be installed directly without the need for pre-drilling and are more effective in purpose.

4. Can you screw wood into metal surfaces?

Technically, the self-drilling wood screws are useful in fastening two materials together even with wood to metal category. They equally work as any self-drilling screws will on purpose. A common example of this instance is the usual furniture making nowadays that joins wood with metal sheets for the construction of a solid structure.

5. How do you install self-drilling wood screws?

The installation of self-drilling wood screws is an easy task for anyone as it would only take the right tool to use and the proper length size of the screw to complete the procedure. When working on wood-to-wood or wood-to-metal sheets applications you can also simply use the manual screwdriver for self-drilling wood screws as it is forged with precise functionality.

6. What are self-drilling wood screws used for?

Self-drilling wood screws, brass, bronze, aluminum, other steel screws, and aluminum steel screws are useful for woodworking and interior DIY projects.

7. How to purchase wholesale self-drilling wood screws in Prince fastener?

As emphasized enough that Prince fastener can cater to different kinds of dealerships and enterprises we are humbled to be chosen as a supplier in wholesale for our fastener products and on self-drilling wood screws, the process will only take a short span in time for our service can give transient replies in 24/7 availability. You can contact us directly at this link so that you will get a quotation for the products you wish to purchase.

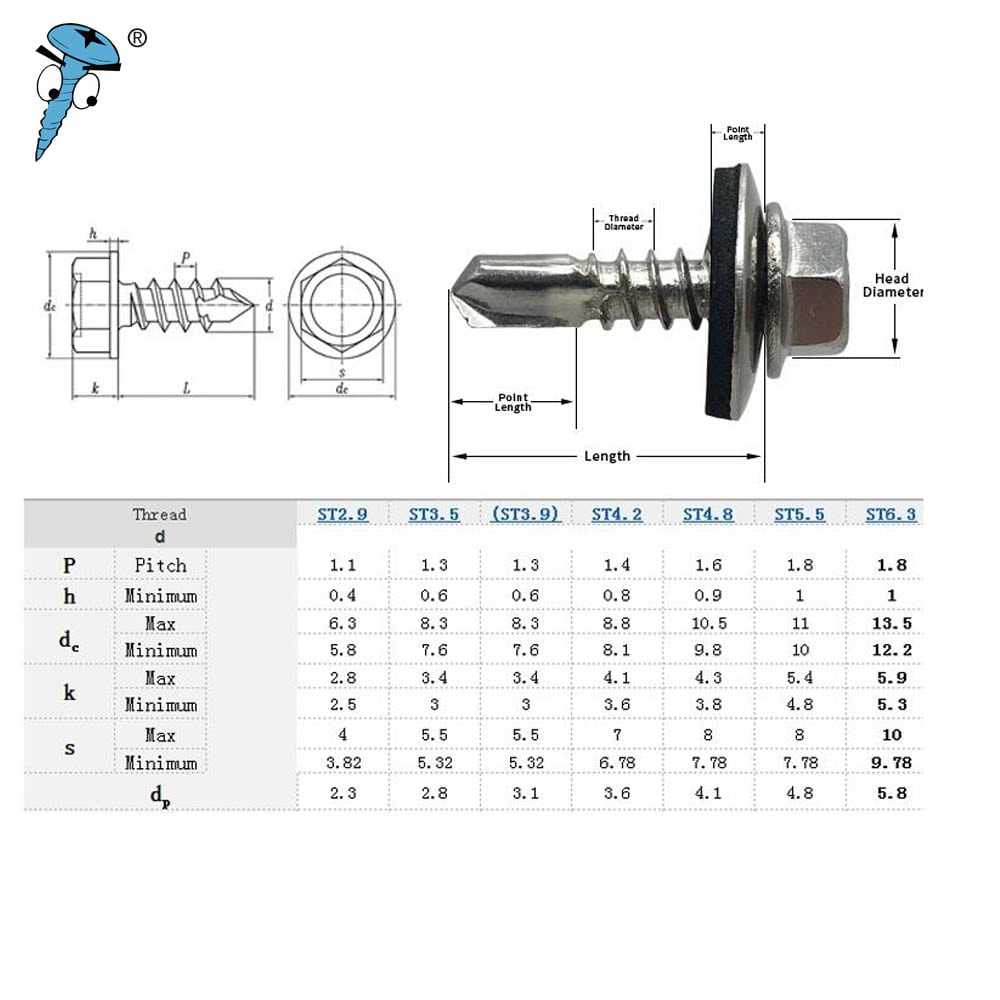

8. What are the different types of wood screws?

There is a number of characteristics to ponder before we can classify the different types of wood screws. However, the shorter explanation will be that in choosing self-drilling wood screws you have to realize the anatomy of the screw which is the head, shaft, threads, and tip. Once you classified them according to the design you want, you will have to define the type of metal it is made from because this will affect how you will use the self-drilling wood screws, may it be for indoor or outdoor use. A few terminologies will also help to determine the proper type of self-drilling wood screw such as the gauge of the screw (thickness of shank), length in inches or diameter, and pitch of the screw thread per inch.

9. Can you make customized self-drilling wood screws?

Prince fastener can customize accordingly to the client’s requirement. We only need the design plan in detail to accomplish your product specification which is why the endless capabilities in producing Private Label Self-drilling Concrete Screws or fastener screws are possible with us.

10. Can you provide a quotation for your fastener products, especially on self-drilling wood screws?

Our customer service line provides an immediate response to inquiries, from technical support, asking for catalogs, and quotations for some products.

11. What is the best option in importing and manufacturing your fastener screws?

We can cater to worldwide shipment as we have been a manufacturer and supplier of screws for over 30 years to different countries. The usual transport of fastener goods or self-drilling wood screws is via sea, air, or land for delivery to the destination. Prospective clients can discuss the options with our service line for a faster process in production and distribution.

12. Do you offer ODM and OEM self-drilling wood screws?

Prince fasteners offer ODM or private label and OEM services to businesses and brands around the globe. We propose the flexibility it takes to be the best in service of producing the fastener screws for a variety of uses.