Your

Self-drilling Screws

Supplier

Your Expert Self-drilling Screws Machine Manufacturer and Supplier-The Ultimate Solutions

Prince Fastener is a professional self-drilling screws supplier.Let Prince Fastener to be your trusted partner for all your needs.We will design and produce fasteners as your requirements

- Expert in the fastener manufacturing industry for more than 30 years

- Own full fastener production machines and testing machines

- You will Purchase the self drilling from fastener supplier directly with the wholesale price

- Excellent customer services

- Accept customized fastener requests

- Fast reply with professional staffs from screws company from China

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our self-tapping screws for wholesalers and importers.

Quick View

- → Why wholesale self-drilling screw from Prince Fastener?

- → Hot products for self-drilling screws

- → Estimated wholesale → Price for self-drilling Screws

- → Estimated self-drilling Screws Producing Period and Delivery Time

- → How areself-drilling screws made step by step?

- → Searching for self-drilling screws made in China?

- → Need Special screws for your clients or projects?

- → The Complete FAQ Guide about self-drilling screws

Why Buy Self-drilling Screws from Prince Fastener?

Prince Fastener is a trusted fastener supplier; founder Lacier Du is passionate about designing and producing high-quality fasteners.

At Prince Fastener, we are proud of the company’s growth over the years. Today, our factory in Nantong has more than 150 employees and covers an area of 25,300 square meters. We specialize in manufacturing fasteners. We also have all ODM/OEM for this project and have our R&D team.

Everything related to Prince Fastener is done in-house. We have our module design engineers, fabricators, painting, and assembly/testing rooms, all located in our Nantong factory. Our factory can produce more than 10,000 tons of fasteners annually, with an annual turnover of more than 7 million US dollars.

Affordable price without compromising quality

Our B2B business model keeps prices low and product quality high. Our ability to keep costs at such reasonable levels goes hand in hand with our mass production and supply chain’s advantages.

Prince Fastener make profits utilizing small profits but quick turnover. That’s why we usually do business with wholesalers, importing companies and brands that need fasteners.

Hot Products for Self-drilling Screws

Self drilling Screws

Self drill Screw

Self drilling Concrete Screws

Metal Self drilling Screws

Screw Self Drill

Self drilling screws for Thick Steel

Self drilling Metal Screws

1 4 Self drilling Screws

Self-drilling Wood Screws

Self drilling Screws Supplier in China:Estimated wholesale Price for Self drilling Screws

The estimated wholesale price for self drilling screw should include the below,

Fastener Manufacturing Costs

Just pay the costs of the self-drilling screws with the wholesale price from the fastener manufacturer directly, just waiting for the right quality self-drilling screws to be produced.

Self drilling Screws Packing Fee

You will pay a small amount for the Self-drilling Screws if you have special requirements for the package, you can apply to get rid of the fee if your order amount is big enough.

Shipping Costs

This payment is for transport the Self-drilling Screw orders from China fastener factory to you by sea or by air

Self-drilling Screws Sample Fee

Normally we will provide free Self-drilling screw samples for importers,clients need to afford the international shipping costs.

Customized Self-drilling Screw Fee

Prince Fastener accepts customized Self-drilling screws orders from clients, we could produce the products according to customer’s requests,of course,clients will need to pay customized screws costs

Custom Clearances Costs

The costs include the destination custom clearances costs, customs duties,and other miscellaneous fees

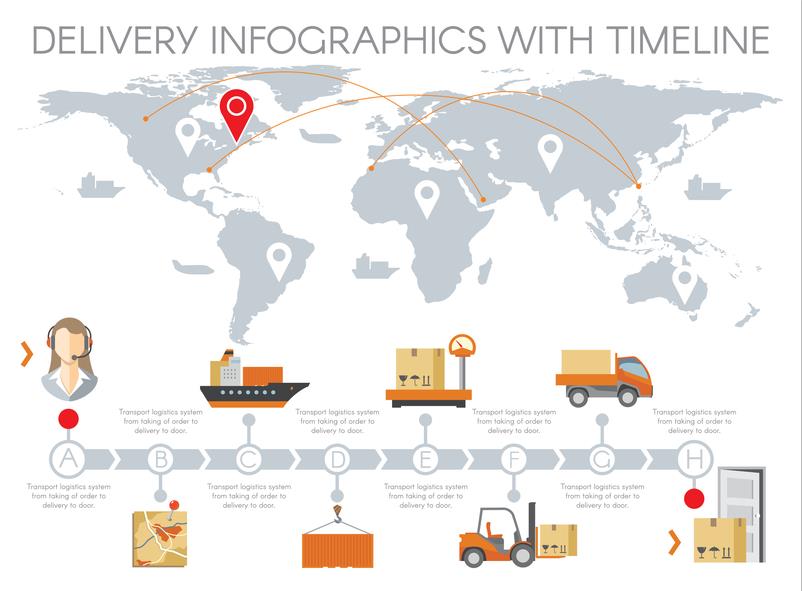

Self drilling Screws supplier in China:Estimated Self-drilling Screws Producing Period and Delivery Time

In order to meet the increasing customer demand for Self-drilling screws, Prince Fastener has no choice but to increase production capacity to achieve the desired goal. The process and time required to go through the following steps

Self-drilling Screw Design and Manufacturing

Prince Fastener designs and manufactures the Self-drilling screws in our own fastener factory

Products Packing Time

Put the Self-drilling screws into pp bag or small white boxes,then put them into a package,they will take a short time to do it.

International Shipping time and customs clearances time

Need time to ship the Self-drilling screws worldwide by sea or by air, and then make custom clearances also need time.

Local Logistics

You’ll finish the whole process and get what you want. You just wait for the local logistics to haul the Self-drilling screws from the port to your destination.

Prince fastener will introduce you all the process of the Self-drilling screw production.

Prince fastener production process

Basic concepts of Prince Fastener screw production

1、Prince Fastener Manufacturing screw can be divided into: cold heading, hot machining (turning, milling, etc.)

2、Cold heading is the use of plastic metal, by using cold mechanical pressure or drawing, reaches the metal solid deformation of.

3、Hot upsetting is the material after heating and pressure processing make the shape of the material to meet the

designrequirements.

4、Prince Fastener Machining is a small batch of special or special bolts of the six corners of the head is turned into after the milling.

5、 Screw bolt thread: mechanical and manual threading, similar to die.

6、 Milling tail: generally completed by the end of the Prince Fastener cutting machine.

7、 The difference between cold and hot upset: cold heading bolts` surface are more beautiful, dozen red bolt surface oxide skindoes not look good; cold heading high production is efficiency; general Prince Fastener M24 bolts will need to play red;

Analysis of the causes of the phenomenon and the causes of the forming process

1、Eccentric: two red and improper installation and adjustment machine.

2、Minow: a poor installation and improper Prince Fastener adjustment machine at.

3、Head is not round: the choice of a die or a punch forming is not enough.

4、Play the mode of crack: crack or die R angle, so that the model is hit by the two collision.

5、Head double: bad punch.

6、Flash: a bad, punching molding is mainly between punch and die hole clearance is too large or too short by red bars.

7、Crack angle: the punch needle burst or two punch and punch is not heavy.

8、Head cracking: material, or a die using error (such as pan head Hexagon washer head of a die), and lubricating oil.

Analysis of adverse phenomena and causes of common rolling

1、Processing crack: tooth plate and adjust the Prince Fastener old machine.

2、Blunt tail: the machine is not properly adjusted, the tooth plate is too old.

3、Crooked tail: the control screw on the seat board seat is too tight.

4、Tail: tooth wear plate and improper adjustment machine.

Self drilling Screws Supplier in China:Searching for Self-drilling screws made in China?

Prince Fastener will be your ideal self-drilling screw manufacturer with certified products and professional factory sites.

Production Equipment

Prince Fastener own more than 100 production equipments with a month production capacity of 800 tons and annual production capacity of more than 10,000 tons.The equipments include advanced manufacturing equipments introduced from Taiwan such as head making machines, thread rolling machines, net Furnace and testing machines, such as salt spray machine, 3D projector, hardness tester and so on.

Testing Equipment

All products are made of high-tech high-quality steel, with a complete set of fastener processing technology, complete testing methods and advanced production technology, 24/7 service, Prince Fastener adapt the advanced production technology and perfect testing methods, and the qualified rate of products reaches 100 %. Pursue maximum customer satisfaction.

Self drilling Screws Supplier in China:Need Special screws for your clients or projects?

Try to get in touch with Prince Fastener,we could provide you a completely solutions

Prince Fastener is a Self drilling Screws supplier in China integrating product development, sales and service, and can accept customers’ own designs and OEM & ODM design orders. The company specializes in the production of self-drilling screws, long screws, non-standard screws, titanium screws, small screws, stainless steel screws, etc.

Prince Fastener use lathes to manufacture screws of various sizes and material types to deliver them to our customers in the shortest possible time.

Prince Fastener specializes in developing, manufacturing, and selling fasteners according to DIN, ANSI, ISO, GB standards and high strength grades 12.9/10.9 DIN 912 DIN 931 DIN 933 DIN 934 DIN 7991 ISO 7380 stainless steel, aluminum alloy, brass hexagonal bolts and nuts.

The screws we manufactured are widely used in machinery manufacturing, aerospace, medical, shipbuilding, ultrasonic, solar energy, electroplating, petroleum, chemical, and other high-tech fields. In addition, we have rich experience in producing all kinds of customization. So we also welcome OEM and ODM orders. Whether selecting current products from our catalog or seeking engineering help for your application, you can consult our customer service center for your purchasing needs. Our company adheres to the principle of ensuring stable and timely supply, reliable quality, and sincere service. Now we face the increasing business opportunities with firm confidence and look forward to the opportunity to serve you.

The Complete FAQ Guide about self drilling screws

Quick Index

1,What’s the difference between self tapping and self drilling screws?

2,How to use self drilling screws ?

3,What is a self drilling screw?

4,How are self drilling screws manufactured?

5,When to use self drilling screws ?

6,What is a self drilling screw used for ?

7,How to check the quality of self-drilling screw?

8,Will self drilling screws work in concrete ?

9,What types of business you are support to?

10,Will you provide free self tapping screw samples for clients?

11,What Tips for Installing Self drilling Screws ?

12,What processes do we need to be careful about when manufacturing and producing Self-drilling screw ?

13, Does Prince Fastener provide self drilling screw with wings and self drilling screw with washer ?

Many people may use various tools in their lives. For example, some reinforcing parts may need to be used. The most common are some screws and nuts. Nowadays, there are more and more types of screws. Two kinds of screws are more popular, namely stainless steel drill-tail screws and self-tapping screws, but many people don’t know what the difference between these two kinds of screws is?

1, The difference for application.

Stainless steel self drilling screws and self-tapping screws manufacturer have a lot of differences; the main difference is the use of distinctions; first of all, self-tapping screws supplier can only be used in some non-metallic or soft ground base; screws can be fixed on the material, but for the drill-tail screws, can be used in some high hardness material pudding, such as thin plate, colour steel tiles, so the drill-tail screws are more powerful!

2 The difference for applications for the screws

The differences in the use of these two screws are also very obvious. First of all, for the womb screw, the rotation must be squeezed downward; the user does not require drilling, so it is easy to complete, but drilling can not be drilled many times; otherwise, it is easy to slide when using stainless steel drill-tail screws, you can directly drill holes in the material, the whole process is also very simple, can effectively save installation time!

3,Tthe difference in appearance.

This is also a very important difference between stainless steel drill-tail screws and self-tapping screws; first of all, for these self-tapping screws, the shape is generally pointed thick teeth with hard texture, with a corresponding taper in front, but for stainless steel drill-tail screws, the head is drilled, which is the main difference in appearance between the two, through the formation of the two screws can be respectively!

2,How to use self drilling screws ?

Custom Self-Drilling Screw are a kind of wood screws, mainly used for fixing coloured steel tiles in steel structures and thin plates in simple buildings. Self drilling screws have a drilled or pointed tail and can be drilled, tapped and locked directly on the set-up and base materials without additional processing, which saves a lot of construction time.

Unlike standard screws, Self drillinged screws supplier have higher tensile strength and maintenance force, and they do not loosen even after being combined for a long time. In the use of screws, if you can first understand the mechanical properties of screws, then you can better use the drill screws. Different types of screws have other mechanical properties; the mechanical properties of the different occasions that lead to screws will be different. That means that there are differences in the way they are installed.

1, stainless steel drill screws need a special electric drill (recommended power 600W).

2, the locator of the drill will be adjusted to the right position to ensure that the screws are drilled to the correct location. Check the speed of the training:

When using 3.5(6#); 3.9(7#); 4.2(8#); 4.8(10#) 410 screws supplier, make sure the drill speed is 1800-2500 rpm;

When using 5.5(12#); 6.3(14#) 410 screws; make sure the drill speed is 1000-1800 rpm. ;

Use 3.5(6#); 3.9(7#); 4.2(8#); 4.8(10#) 304 screws; make sure the drill speed is 1500-2000 rpm;

When using 5.5(12#); 6.3(14#) 410 screws, make sure the drill speed is 1000-1500 rpm.

3, Choose the right socket or cross bit to install on the electric drill and then connect the screws well.

4、. The screws and electric drill must be installed perpendicular to the surface of the pressed steel plate, click the power switch, and create a centre point with force.

5、Add about 13 kg of force to the drill by hand to ensure that the staff and the centre point are on the same vertical line.

6、Turn on the power switch, do not stop in the middle and stop the downward drilling quickly after the screw supplier is in place (to prevent the low drilling from not being in business and excessive low drilling from occurring)

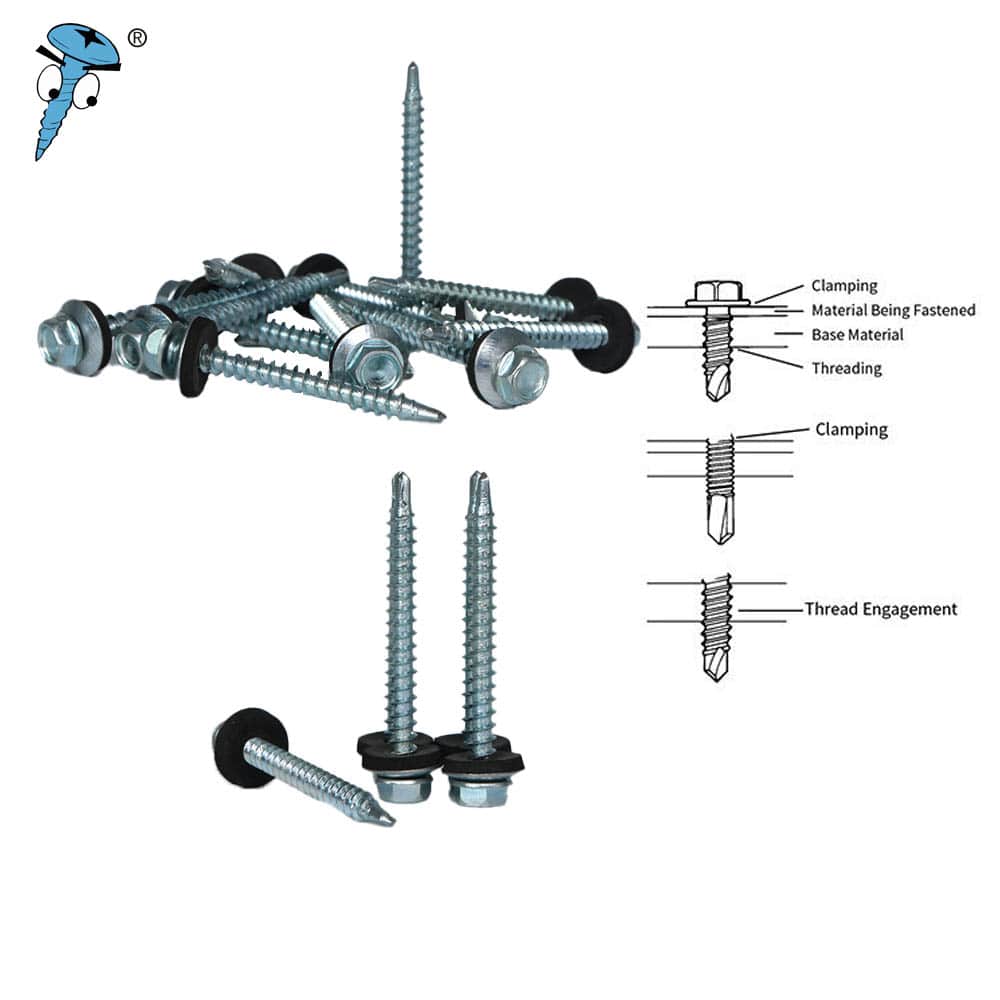

3,What is a self drilling screw?

Self drilling screws, self-drilling screws, also known as dovetail screws in northern China, are a type of wood screws. Drill tail screws are screws with a self- drilling head at the front of the screw, the tail of which is drilled or pointed tail, without additional processing, can be directly in the setting material, the base material _ on the drilling, tapping, locking substantial savings in the application of I time. The different drill ends can be divided into round head Miko / cross/plum, countersunk head (flat head) / Miko / cross/plum, hexagonal washer, round head washer (large flat head), horn head, etc.

4,How are self drilling screws manufactured?

The Self drilling screw is firstly made of a rod-shaped blank 10 with a head 11 at the upper end and the lower end in the middle of two modules I. The lower back of the rod-shaped blank ten is stamped out with a ^H-shaped tail 12 by stamping the moulding cavities I 1 of the two modules I in opposite directions, which has a taper 121 at the end of the Self drilling 12, and the Self drilling 12 is provided with slightly inclined When the locking action is carried out, the drilling edge 123 and the cutting edge 124 are used to drill the object and guide the external thread 13 of the Self drilling screw 1 to lock in gradually. At the same time, the chips generated during the drilling process are discharged by moving the chip removal groove 122 up the Self drilling section 12, thus achieving a stable locking and positioning effect.

However, the two chip slots 122 of the Self drilling screw supplier 1 made in the above method are set at a slight inclination, so the drilling speed is invasive when locking, the chip discharge is not smooth, and the deeper the locking and drilling, the deeper the internal chip cannot be smoothly discharged, which will easily lead to high temperature and blunting of the Self drilling 12, and even the situation of breaking when it cannot continue drilling.

The details of the steps are described in detail below.

(l). First, the upper end of a rod-shaped blank 20 is stamped with a rotating head 21, and the lower back is placed in the middle of two modules (as in Figure 1), and the lower end of the rod-shaped blank 20 is stamped with a tail 22 by stamping the cavities of the two modules in opposite directions. The Self drilling 22 is provided with two symmetrical chip slots 222, and the circumference of the Self drilling 22 is equipped with a cutter lip 223 at each side of the two chip slots 222.

(2). (2) Torsional forming: Two clamping fixtures, 100 and 200, are used to clamp the middle section of the bar stock 20 and the end section of the Self drilling 22, respectively, so that one of the clamping fixtures 100 (200) rotates about 180 degrees (or other angles) to form a symmetrical spiral shape for the chip groove 222 and cutting edge 225 of the tail 22.

(3). Thread forming: Next, a section of external thread 23 is formed by thread rolling on the outer edge of the bar stock 20 with a tooth plate.

(4) . Heat treatment: The rod blank 20 is hardened by applying an appropriate high temperature.

(5) . Finished product: Finally, the finished product can be made with spiral chip groove 222 and cutting edge 225.

5,When to use self drilling screws?

Self-drilling screw can be directly drilled, tapped and locked on the setting material and base material at one time and can be quickly and automatically drilled and now Self-drilling screwed and fixed; the construction efficiency of Self-drilling screw is extremely high; it saves the maximum construction time, improves the engineering construction efficiency and enhances the economic efficiency. Self-drilling screw rivet the corresponding parts with strong bonding force, high preload, and high stability of the connected components.Self-drilling screws with a drill tip, the tip like a twist drill and named after theSelf-drilling screw, can drill their central hole in the assembly, and then with the help of the sparkling threaded part of the hole in the carrier self-drilling extrusion with the matching thread, so-called Self-drilling screw screws.

6,What is a self drilling screw used for?

Compared with ordinary screws, the hardness of Self-drilling screw is much stronger than standard screws, which not only have good maintenance ability but also have a very strong effect when connecting objects. Drill-tail screws do not require additional processing; they can be drilled directly on the thing to lock. The drill-tail screws produced by Prince Fastener are very easy to use and can greatly improve efficiency. Nowadays, drill-tail screws are the first choice of workers in various fields.

The application of the Self-drilling screw are: A: stainless steel, steel plate, galvanized steel plate, engineering installation. b: curtain wall, metal light compartment, plastic steel doors and windows and other indoor and outdoor installations. c: ordinary angle steel, channel steel, iron plate and other metal material combination installation (steel installation). d: car, container cabinet, shipbuilding, refrigeration equipment, environmental engineering and other assembly projects

7,How to check the quality of self-drilling screw?

As a professional self-drilling screw supplier, we guarantee that from the raw material to the finished products, we have to go through 8 inspection processes, and only after passing the inspection can we ship. To ensure the quality of self-drilling screws (Character) in customers’ is a qualified screw.

No matter what specifications of self-drilling screws fasteners, after the completion of production are required to do a series of tests, testing qualified (qualified) before shipment, then the regular size test, tolerance test, and appearance test, we also need to try what items? Self-drilling screws supplier mechanical (machinery) performance test (test) projects include (bāo kuò) surface hardness test, carburization (shèn tàn) layer depth test, core degree test, microstructure test, screwing performance test, and damage (vandalism) torque test.

1, Surface hardness test (test).

Surface hardness using GB/T5030 specification Vickers hardness (HV0.3) test (test), surface hardness test should be on the plane and priority in the head. Non-standard screws are tools that use the physics and mathematics of the object’s beveled circular rotation and friction to tighten the apparatus mechanism progressively.

2, Carburizing (C) layer depth (metallographic test)

The carburization (C) layer depth test (test) is carried out on the measuring surface of the self-drilling thread at a point half the distance between the top of the tooth and the bottom of the tooth, except for self-drilling screws with specifications <ST3.9, in which case the test should be carried out on the base of the tooth. The depth of the carburization layer shall be calculated from the point where it exceeds 30 HV.

3. Hardness of core test.

Vickers core hardness (Hardness) test according to GB/T4340 and should have sufficient distance (distance) with the end of the self-drilling screw (there should be a complete thread diameter) of the cross-section of 1/2 radius (radius). Non-standard screws are tools that use the physics and mathematical principles of beveled circular rotation and friction of objects to tighten objects and mechanisms progressively.

4, Screwing performance test (test)

Self-drilling screws (screw) nail test piece (with or without coating) screwed into the test (test) plate until there is a complete thread entirely through the test plate; the test plate should be made of low carbon steel (Steel) with a carbon content of <0.23%, the hardness of 130-170hv (measured by GB/T5030 and GB/T4340) test plate thickness (thickness) degree and test aperture. thickness) degree and test aperture by the hole or punching and then drilling or reaming system. Precision screws are widely used in electronics, electrical, appliances, furniture, machinery, etc.

8,Will self drilling screws work in concrete?

Self-drilling screws are screws that are capable of drilling the threads into the material. Self-drilling screws can be used in various materials, including wood, metal, and brick. These screws cannot be drilled through metal and require a pilot hole to be pre-drilled before installation. The pilot hole is created by using a drill bit slightly smaller than the screw, and the screw’s threads strike the metal or wood as the screw is installed. This drilling action holds the material together. In addition, self-drilling screws can have many different types of tips, which help tap the threads into various substrates.

Self-drilling screws are sometimes named under the Tek®Screws brand. These screws can be identified by the point of the screw’s drill shape and are designed for various applications, such as fastening metal to metal and wood. In addition, self-drilling screws do not require pilot holes, reducing installation time and costs and the need for additional drilling. This other functionality and cost-saving features make self-drilling screws the clear choice for metal construction. Drill points are numbered 1 through 5, and the amount of steel that can be drilled increases as the numbered points increase. Typically, self-drilling screws are used for light rail applications, but the #5 drill point can dig through and hold 1/2 of the steel.

So self-drilling screws are also self-drilling screws, but all self-drilling screws are not self-drilling hammers. Self-drilling screws do not require pilot holes, but they can be self-drilling. Self-drilling screws cannot drill through metal and require a pilot hole. These screws are not interchangeable, and mixing the two may cause a lot of trouble or cause failures in the field.

8,Self drilling Screws Supplier in China:Have you exported your self drilling screws before?

As you know,Prince Fastgener as a professional fastener manufacturer and supplier in China for more than 30 years, we cooperated with the international clients to help them import the self drilling from us made them more profits, because they buy the fasteners from screw factory directly.

We exported the self drilling screws to USA,UK,Australia,Canada,Russia,Brazil,Mexico,UAE and other countries,get lots of positive feedbacks from the clients.

9,Self drilling Screws Supplier in China:What types of business you are support to?

Prince Fastener is open to all clients,our current clients include fastener distributors,hardware wholesalers,hardware shops,fastener dealers,fastener traders,or Importers of integrated products。

We also accept the end-users’s orders,normally they need us to do the customized screws orders for them.

10,Self drilling Screws Supplier in China:Will you provide free self drilling screw samples for clients?

For the standard self drilling screws,Prince Fastener can provide free samples for you to check the quality and ensure that we are your right fastener supplier,you just afford the international express costs.

11,What Tips for Installing Self drilling Screws?

The self-drilling and self-tapping screw is a unique and versatile screw. Its design allows it to drill itself into the metal and form threads in the hole. It is commonly used to attach steel siding or roofing but can also be used in other applications where pre-made holes are not available or convenient. Given that this type of screw may be the right solution for your application, here are 4 factors to keep in mind.

1. Length of the drilling slot

The length of the drilling slot must be greater than the thickness of the material being drilled. If the material is too thick, chips cannot be discharged, leading to severe heat generation and damage to the screw or the matching fabric. The cutting edge length must be such that the drilling operation can be completed before the threads begin to form; otherwise, damage may occur.

2. Pitch

For thinner sheet metal, coarse threads (wider thread pitch) are recommended. Fine lines for thicker metals (3/8 to 1/2″ thick) provide less driving torque and better results.

3. Thread Length

The thread length of the screw should be long enough to fully engage the base metal, keeping in mind that the first few threads are not fully formed. Two to three lines should appear on the back side of the substrate.

4. Installation tools

Special tools for self-drilling and self-tapping screws supplier are available in both corded and cordless versions, with speeds up to 2500 rpm for fast screw installation. Standard drillers or screwdrivers can also be used, but impact screwdrivers are not recommended for structural hard joint applications. These tools often have a depth gauge on the head so that the screw head can be disengaged after the screw is properly installed. Some tools may also have an adjustable clutch for proper torque setting.

12,What processes do we need to be careful about when manufacturing and producing Self-drilling screw?

Self-drilling screw are the basic parts of machinery and necessary hardware screws in industry. The demand for Self-drilling screw is a best seller and the first choice of many people today. Therefore many manufacturers have chosen to manufacture carbon steel, low alloy steel and non-ferrous materials to ensure that Self-drilling screw can function in harsh environments or other dangerous projects. But when Self-drilling screw need to meet severe corrosion or high-strength conditions, many manufacturers use paired stainless steel and super-strength stainless steel to produce Self-drilling screw. Look seemingly simple, but in the manufacturing and maintenance of the self drilling screws supplier or there are a few points we need to pay attention to

Rinsing is very important for the first step of the drill tail screw because the process of rinsing the drill tail screw will inevitably leave residues on the surface. The rinsing step is after cleaning with silicate cleaner. In addition, Self-drilling screw should be stacked neatly during the tempering and heating process. Otherwise, it will lead to slight oxidation in the quenching oil. The phenomenon of slipping wire of drill tail screws is also something we need to pay attention to. Most of the reasons for slippery wire is the raw material depleted of carbon. Pickling is also a very important point of the drill tail screw to remove the surface of the wire surface of a layer of oxidation film, while the wire surface lubrication for wire drawing. Drill tail screw head forming is to complete the appearance of the product, the shape of the tooth shape. The last thing is definitely to pack the produced Self-drilling screw. The products should be boxed/boxed according to the standard or customer requirements.

Prince Fastener produces door and window screws, curtain wall screws, Self-drilling screw, composite screws, stainless steel Self-drilling screw, high-strength carbon steel screws, stainless steel fasteners, photovoltaic bracket bolts, screws for light steel houses, screws for solar panels, etc.

13,Does Prince Fastener provide self drilling screw with wings and self drilling screw with washer?

Yes,if you have any special requests to the self drilling screws,just let us know your ideas,then we will make it true for you,because Prince Fastener have experienced product development department and staffs,we could design and produce the products as client’s requests,so we prodive OEM/ODM fastener services,to provide customized fastener for you.

14,About the self drilling screw size chart

You can find many types of screws for different tasks. While many such as wood screws require pilot holes in thicker materials, other screws used for plates or thinner materials are very different. Self-tapping screws are a great addition because they do not rely as much on this degree of pilot hole.

Self-drilling screw:Self-drilling screws are available in csd (mechanical teeth),bsd (self-tapping ab teeth). Its tooth pitch or number of teeth can be referred to mechanical screws (csd teeth) and self-tapping screws (bsd teeth), respectively.

The angle of the tooth hill and the angle of the tail tip: the angle of the tooth hill is the angle between the side of the tooth and the side of the tooth, and the angle of the tail tip is the tip angle of the unending thread.

- Self-tapping screw teeth: tooth hill angle of 60 °, the tail tip angle of 45 ° ± 5 °.

- wall plate nail: tooth angle of 60 °, (also can be produced according to customer requirements, such as 45 ° ± 5 °) the tail tip angle of 25 ° ± 3 °.

- Plywood screw chipboard screws wholesale) angle of 40 ° ± 3 °, the tail tip angle of 25 ° ± 3 ° or 34 ° ± 3 ° (customer special requirements).

- Self tapping screws: the angle of 60 ° ± 5 °, the tail for different specifications of the product selection of different types of pinch tail, pinch tail of the main geometric parameters for the pinch tail diameter and the amount of extension.

Some self-tapping screws are also self-drilling, combining a drilling-like action with fastener installation. Although you are using the same principle as other screws, they create their own holes with coarse threads.

Prince Fastener produces all kinds of self-drilling screws, For more information about the self-drilling screw size chart, please contact Prince Fastener, we will provide you with details.