What Are High-Tensile Fasteners?

When materials are being pulled away in pressure due to an external force, it is called tensile. Tensile is measured through tensile stress or tensile strength. They are typically specified to know the capacities of a material.

High-Tensile Fasteners

Fasteners should own qualities that are desirable to their applications. High tensile strength in fasteners is a crucial feature that provides them an overall ability in a successful performance outcome.

The tensile strength in components of materials can be highly altered in methods of special treatments. To increase its capacities and reach accuracy in detail, the fastener materials undergo a process of finishing and testing.

In commonly used fasteners, high-tensile properties are normally a need of qualities in nuts, bolts, and screws.

Read along >> What are the types of nuts, bolts, and screws?

>> How are bolts manufactured?

Thus, tensile strength can be applied to any solid material or as considered in the vast range of fasteners. The applicable measure of this quality on nuts, bolts, and screws is to test the materials in its production.

The Typical Tensile Strength of Fastener Materials

Fastener Material | Yield Strength (MPa) | Ultimate Tensile Strength (UTS) (MPa) |

Steel, structural ASTM A36 steel | 250 | 400–550 |

Steel, 1090 mild | 247 | 841 |

Steel, high strength alloy ASTM A514 | 690 | 760 |

Steel, stainless AISI 302 – cold-rolled | 520 | 860 |

aluminum | 15-20 | 40-50 |

titanium | 100–225 | 246–370 |

copper | 117 | 210 |

zinc alloy | 200–400 | 200–400 |

nickel | 140–350 | 140–195 |

Silicon | – | 5000-9000 |

Beryllium 99.9% Be | 345 | 448 |

Brass | 200+ | 500 |

MPa (MegaPascal) the pascal unit = SI units for pressure or tension

Source: wikipedia-UTS/ultimate tensile strength

Tensile testing in metals is usually used in the fabrication of fasteners and metalworking, it is an important process to help identify the limitation of their destructive composition. This also ensures the quality of the nuts, bolts, and screws to deliver their functionality at a predetermined breaking point.

Tensile Stress VS. Tensile Strength

The force per unit of stretching or tensile force refers to tensile stress. It is defined as an applied load associated with the axis of materials being drawn out. Whereas, tensile strength refers to the measurement of tensile stress in the compression of materials and its ability to resist a breaking point before cracking.

The formula for Tensile Stress: σ = F/A |

Formula for Tensile Strength: s = P/a |

Low ductility allows materials to withstand elongation while brittle materials fracture in stress before reaching the ultimate strength.

Tensile properties that affect the tensile force in materials:

- Modulus of Elasticity – also called the elastic modulus or coefficient of elasticity is the ratio of stress in the body of an object or substance in its deformity

- UTS or Ultimate Tensile Stress – often shortened to tensile strength, refers to the limitation of stress that a material can take while being stretched or pulled in force before its reaches the yielding point.

- Modulus of resilience – is the strain of maximum energy that is calculated per unit volume in resiliency or absorption of stress up to an elastic limit

- Fracture stress – is a material property indicating the resistance to cracking in the applied mode of loading, bending, compressing, and tensile.

The degree of tensile stress that materials can withstand explains the tensile strength. the applied force in components should not be able to perform a failure in form of breaking, fracturing, distortion, and permanent deformation.

The three types of measurement of tensile strength:

- Yield strength – is the size of stress at which a material begins to transform into a permanent deformation

- Ultimate strength – refers to the corresponding stress in maximum strength that any solid material can withstand before reaching a weak point of breaking

- Breaking strength – as generally, tensile strength defines the greatest capability of materials in resisting failure

Benefits of High-Tensile Qualities

- Provides tension resistance, and high yield strength in crucial levels

- Lowers the negative impact on the environment due to the production of lower carbon emissions

- Lighter materials or low tare weight that can carry heavy loads while withstanding an extreme amount of force (usually applies to transport industries)

- Ability to defy atmospheric corrosions from exposure to pollutants

The Application Industries of High-Tensile Fasteners

- Construction of trucks, trailers, and heavy-duty agricultural machinery

- Automotive parts like engines, shafts, rotors

- Spring applications such as bungee cords, entertainment rides, and others

- Infrastructures

- Buildings

- Bridges

- Roadways

- Railways

- Tunnels

- Waste Management

How Do You Pre-tension Bolts/Fasteners and Why Are They Required?

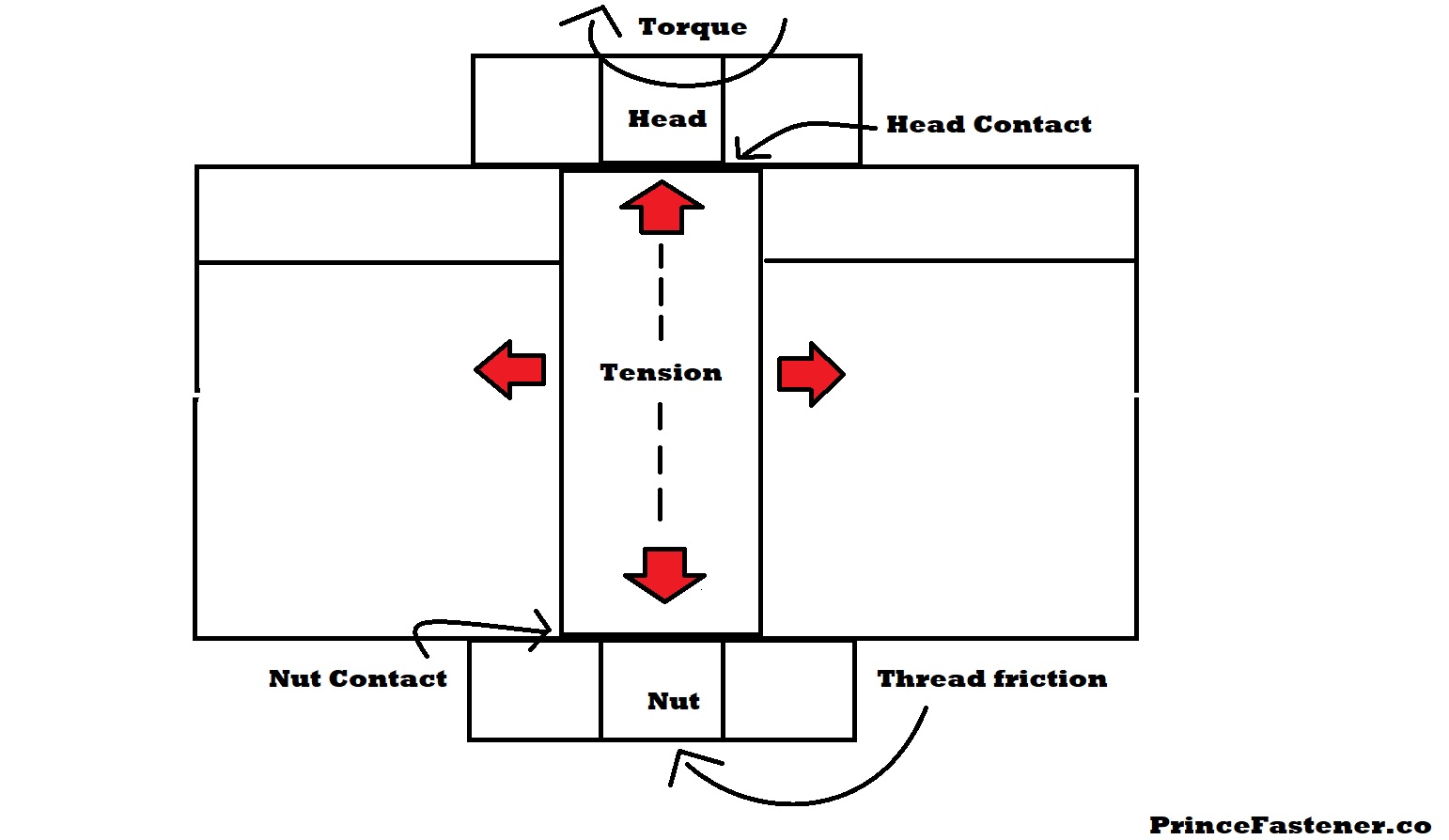

Bolts and fasteners are crucial devices manufactured in their highest form of quality, yet they’re not as strong as we think. When nuts are being tightened together in screws and bolts, during which the threads of the fasteners correspond to each other with an applied force to the surface material. This tension is called bolts/fasteners preload, the force created in compressing the nuts on bolts to tighten and vice versa.

Placing weight on bolts alone leads to a limited amount of load they can take before failing. Bolts have a pre-determined elastic characteristic for elongation and stretching. But when bolts and nuts are applied to tighten materials together, they can distribute the load through the surface making them less vulnerable to pressure and force. The act of attaching the bolts to their final state with a tightened force is simply called pre-tensioning. This indicates the importance of applying the correct tension to the fasteners for them to hold the security of the application. Most fasteners are made with relative effectiveness to tightening torque values so they won’t loosen from vibration and possible permanent deformation.

Distinguishing the Main Terms to Remember

- Load – refers to the amount of weight or source of pressure borne in the assembly of the fastener

- Preload – is the state of compression required to distribute the force of load on the assembly

- Working Load – usually refers to the maximum force a device can take in mass without failure of breaking

- Bolt Preload – basically comprises the performance of terms. When bolts are applied in joining materials together, the preloaded force executed should perform the distribution of weight through the surface. As the tension creates the working load of assembly, the bolts should withstand the force while holding the complete setup of fastening.

Why Pre-tensioning Bolts/Fasteners Are Required? And What Importance Does It Portrays?

Bolts can be dependent on the surface application too as they’re mainly created for fastening and joining materials, the need for a supporting substance is required to exert its function. Hence, pre-tensioning commonly referred to as preloading is inevitable for preventing the bolts to loosen and permanent deformity. Preloading will help determine and understand the sustainability of fasteners in the application when an applied force is executed in the bolted joint.

- It prevents the assembly to have possible failure in the future; breakage, loosening, cracking, fracturing, corrosion, etc.

- Helps to determine the capacity of fasteners in bearing weight load and pressure forces

- When preloading is correctly performed, the outcome of maintenance could be lesser work

- Holding a load of distribution enables the bolts and fasteners to perform a high-quality attribute during the critical situation

- No slip in service (rigidity) or loosening of threads on nuts and bolts during vibrations

- Tolerance of some factors compromising the application

- The dominant advantage of applying preload to bolts is to avoid fatigue on the fasteners

The Minimal Disadvantages

- Difficulty in determining the certain tension force of fasteners may vary from time to time

- Pre-loading all bolts in some applications can have different outcomes and performance due to the variation of attributes

- An adequate pre-loading should be executed correctly or failure of breakage will follow in the assembly

- Loosened threads in nuts will result in poor-quality pre-loading

- Preloading has costs

Simpler Ways to Determine the Preloaded Bolts Fasteners

- Torque wrench tool – This method is considered an optional measure of bolt preload because during the tightening of material the torque will be directly affected within the substance it is spun against. The rougher the material the more friction it produces which makes the torque value higher while reducing the preload tension, or the opposite applies. An optimal torque will be achieved yet optimal preload will diminish. In summary, the results will depend on the material and the use of this process is unpredictable and may result in faulty or average guesses.

- Preload indicating washers – This type of washer is designed to spin into bolts until a specified amount of load is met. The idea is to commit the preload indicator washer to spin until it is no longer free-spinning or in other words until it meets the preload requirement. It is considered an easy way of determining accurate compression.

- Direct tension indicating washers – this washer indicates preload tension with its little bumps feature which turns into a flattened state when the required preload is met. When flattened, a feeler gauge is inserted in the bolt shaft to ensure the accessibility is not more than 50% or ideally less under the washer.

- Silicon direct tension indicating washers – This is another type of washer which performs similarly to the direct tension washer, with the only difference of having a silicon paste filled in small recesses. During the tightening of a nut against them, a silicon paste gradually comes out of the sides of the washer. To identify the optimal preload with the use of this washer, the number of recesses from the washer will be deducted by one from exposing the sides.

- Tighten until snug and “X” degrees – This method will give you a practically near-to-close approach to preload. This will likely indicate preloaded bolts by tightening the nut until snug and torque the nut “X” degrees.

- More indicators can also be shown through the bolts with different types of grades (400- 800 MPa)

Preloaded vs Non-preloaded Fasteners

Aside from the obvious difference in size (the diameter of the bolt’s head may be bigger and the same goes for nuts when they are preloaded), the primary difference will be the execution of the fasteners.

Non-preloaded bolts/fasteners are usually tightened to at least snug-tight (refers to the tightness of assembly attained by an impact wrench or ironworker with a little to no visible gap). The connected materials are joined together without any specific preload in achieving a firm condition that sufficiently prevents the removal or rattling when shaken.

Preloaded bolts/fasteners are tightened to at least a minimum specified force or preload. The joining of materials is carried out in conformity with installation methods. This type of fastener is commonly used in applications with critical requirements like slip-resistant, seismic connections, fatigue resistance, execution purposes, or sometimes as a quality measure.

The measures of variables affecting the torque and tension in fasteners

- Finishing and tolerance absorption of the threads on bolts and nuts

- Factors which regards the lubrication

- The environmental conditions that affect the probability of corrosion

- The existing friction within the degrees of nut’s bearing area to the head of the bolt and their supporting surface

- air supply parameters on impact wrenches

- The pressure force from the torque wrench which may change within shifting

- When an applied torque level responds to the repeatability of wrench

Analysis of the Modes of Failures in Bolting

- Overloading – occurs when the application produces and operates an exceeding load causing the joint to loosen or fail

- Over-torquing – refers to the failure of threads in a fastener due to the damage caused by forcing the torque or through a long time process of deformation. While the opposite allows the failure of loosening in the joint which may fail in fatigue because of under-torquing.

- Fatigue Failure – this is usually encountered from the build-up of movement and small cracks in the material. When preloaded bolts turn in axial and transverse loading causing them to slip from rigidity.

- Brinelling – generally occurs from choosing a poor quality washer, the leads to a clamp load loss and fatigue failure to the joining materials.

- Other reasons of failure – includes other predetermined and undetermined factors that may affect the overall reliability of bolts and nuts. (includes corrosion, embedment, exceeding portion of shear stress, etc.)

Locking Mechanisms in Bolted Joints

Jam Nuts

Is a common type of locking device or locknut wherein it is jammed up against a standard nut to secure the application. It is usually half the diameter of a standard nut for them to fit in perfectly into the thicker nut. The thicker nut relieves the force from the thinner nut and distributes it evenly into the surrounding surface. Resulting in the thinner nut applying tight compression in the joints and pressing the threads to lock against each other.

Prevailing Torque Nuts

A common example of this is a Nyloc nut, they are considered an insert for the internal threads binding them to the opposing fastener which creates a friction force and prevailing torque. This method will allow the resistance to loosening the joints and possibly back out from being fastened.

Chemical locking compounds

Examples of chemical locking compound contains anaerobic which was developed as the thread-locking adhesive during the absence of oxygen in joints. They create a higher friction during the rotation of the nut and a prevailing torque. They are a reliable compound in eliminating the loosening of fasteners from vibration.

Lockwire

This method is usually applied in critical joints to prevent a back-rotation. The process is done by drilling a hole through bolt heads and nuts and then a threading wire is inserted into the hole.

Spring washers and lock washers

These are types of washers that bend axially during the tightening of fasteners. Spring washers are designed to create an axial force that absorbs shock while providing spring force to counter vibrations. While lock washers exert spring tension on fasteners to the surfaces to provide more resistance from vibration and rotation.

What Professions and Industries Use Fasteners?

Some various industries and applications require fastening solutions. Nowadays, these devices are a crucial element in making final products. Most of the product devices and types of machinery found in our society are made with the use of fasteners. Let’s dig into detailed information on industries with the applications of fastening materials.

Aerospace

This industry requires critical fastening materials because of multiple factors affecting its performance and overall function. Aerospace comprises a large sector of manufacturing in aircraft or spacecraft products like passenger and military airplanes, helicopters, gliders, spacecraft, launch vehicles, satellites, and a wide range of space-related items.

Automotive

Is one of the largest sectors that converts the use of fasteners into useful products of today’s innovation. The automotive industry involves designing, manufacturing, and developing motor vehicles. They require specified fasteners particularly capable of providing security and safety for their product output.

Appliances

Are considered a subsector of the manufacturing industry, this comprises simple things that can be found in our house that require fastening for security or hold. Usually, appliances refer to the electrical equipment or household appliances used in the comfort of our homes such as microwave ovens, refrigerators, televisions, coffee makers, toasters, kettles, iron, and more.

Buildings and Construction Industry

This industry primarily engages in building and developing buildings (residential or non-residential) and other engineering projects (highways, utility systems). The establishments that comprise this industry play a bigger role in the structure renovations and extensions of many evolving countries.

7 types of building systems engineering:

- Civil – a system that works closely with landscape architecture to improve surrounding facilities, infrastructure, routing of site utilities (stormwater piping, sanitary, natural gas, etc.), and support to buildings.

- Electrical – the key element of electrical engineering is power distribution in buildings. It also applies to safety alarm systems and power support.

- Energy – as alternative energy sources are growing in importance over the increasing environmental concerns. The use of solar power, wind energy, fossil fuels, coal-generated energy, photovoltaics, and others are high aspects of energy efficiency in the world today.

- Mechanical – heating, ventilation, and air conditioning are big parts of building systems contributing to fastener usage.

- Plumbing – piping systems for roof drainage, restroom sinks and toilets, water heating systems, fire alarm systems, water sprinklers, and another plumbing-related engineering.

- Structural – this involves the installation of stability in buildings like columns, trusses, beams, and footers.

- Technology – this system can be considered as a sub-category for electrical, but it covers a broad range of products in building systems such as security cameras, card access, IT infrastructure, wireless internet access, telephone systems, AV (audio visual) equipment, and centralized clock systems.

Furniture

Involves companies and establishments that provide activities in the design, manufacture, and distribution of furniture such as decorative objects or household equipment. Modern manufacturing of furniture requires a fastening solution in joining materials and securing the form of the furniture. Materials commonly used in this industry that suits the application of fasteners are wood, chipboard, plywood, natural solid wood, plastic, and metal or metal sheets.

Electronics

This industry has variations of subtypes that are considered a wide factor in the use of fastener variations. Electronic devices and equipment are almost essential to the way of living in this generation. This industry is a sector that primarily operates with the use of electronic power for consumers and establishments. Some of the common devices that require fasteners are television, radio transmitters, computers, telephones, smartphones, calculators, digital cameras, automotive electronics, audio equipment, and more.

Industrial Machinery

This sector belongs to a broad industry that involves manufacturing, designing, distributing, and shipping products to other businesses which supply to retail and end-consumers. With the large scope of driving growth in production and reliability for purchasers, the industrial sector is the ultimate industry that uses fasteners for sustainability.

5 main economic sectors:

- Primary – a sector that works with raw materials. The industries common in this sector are agriculture, mining, forestry, quarrying, and fishing.

- Secondary – the industrial sector uses and creates products from the primary sector for businesses and distributors.

- Tertiary – is the service sector as they follow the primary and secondary sectors by selling the completed products directly to consumers. Industries include retail, banking, transportation, tourism, and health care.

- Quaternary – is a subset sector to the tertiary sector that focuses on intellectual development. Common industries; are libraries, research centers, academic institutions, scientific research organizations, and government.

- Quinary – is another subset sector of tertiary and is considered the final sector that includes industries that gather an impact on society.

Manufacturing Industry

This industry involves different types of manufacturing capabilities, and many of these organizations are primary users of machinery and pieces of equipment that require fasteners. There are more broad examples of fastening requirements in this industry but overall they are commonly found and known in every aspect of this industry.

Read more>>

What are types of nuts, bolts, and screws?

Where can I get a low-price nut and bolt from China?

What is a custom self-drilling screw?

What are self-drilling screws and self-tapping screws?