2.1.1. Nails

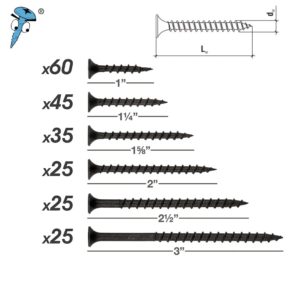

2.1.2. Screws

2.1.3. Bolts

2.1.4. Nuts

2.1.5. Washers

2.1.6. Anchors

2.1.7. Rivets

2.1.8. Studs

3. Fastener Materials and Grades

4.1.1. What are examples of fasteners?

4.2.2. How is a fastener used?

4.3.3. What is a fastener supplier?

4.4.4. Can fasteners resist extreme weather conditions?

4.5.5. Do fasteners have corrosion resistance?

4.6.6. How do you maintain fasteners in their applications?

4.7.7. What are common problems when using fasteners?

4.8.8. How to install fasteners properly?

4.9.9. What are the benefits of using fasteners?

4.10.10. What are the essential features and standards of quality on fasteners?

5. Production Process of Fasteners – Manufacturing Steps

6. Fastening Tips and Tricks: How to Select the Best Quality Fasteners

7. What are some tips to remember when using fasteners?

8.1. 1. Quality

8.2.2. Range of inventory

8.3.3. Pricing

8.4. 4. Customer service

8.5.5. Technical support

8.6. 6. Reputation

8.7.7. Time of delivery

In overview, fasteners as a general term for several components are designed to efficiently affix and join objects and surfaces together to create a connection. The assembly can be a permanent connection or non-permanent, which can be removed or dismantled without causing any damage to the surface of the materials. Fasteners are known to have different types and categories that are used for their purpose and function. The most commonly known types of fasteners include screws, bolts, nuts, rivets, anchors, studs, threaded rods, etc.

Read here: What are the different kinds of fasteners?

The use of mechanical devices called fasteners is not limited to any kind of application hence, it has multiple types and variations. To function effectively, each form and type of fastener have its purpose to offer depending on size, feature, quality, head style & drive, and others.

Traditionally, nails are the most common form of fastener which has been used in ages and different applications, especially in the building and construction industry. Nails are used for their great shear strength to hold materials together. Nails are easy to spot as they don’t have threads in the body or that they appear in a clean body shank with a diamond-point tip.

People usually think of screws when fasteners are mentioned insignificantly because of their general quality that describes other types of fasteners. Screws have a threaded shaft or body with a drill-point tip that allows them to easily pierce through the surface of their applications. The threads on a screw give the advantage to execute a greater holding power beneath the surface materials than a traditional nail.

Bolts are considered a variation of screws since they almost have the same function and features. The difference between a bolt and a screw is that bolts usually need a pre-matched device like nuts and washers to provide the ultimate holding power and strength, whereas screws may or may not need it.

Nuts are easily identified according to their look, they mostly appear circular with internal threading that matches the external threads of bolts or screws. The purpose of nuts is to tighten and secure the application of threaded fasteners. Basically, they cannot function without another component as they are designed specifically to fasten the other ends of the assembly.

A flat metal disc with an opening in the center part is called a washer. Washers are used to help distribute the load evenly into surfaces of materials, eliminating some possible damages due to several situations that may be encountered from fastening applications.

This type of fastener serves a similar purpose as a boat’s anchor, which embeds itself into the surface to hold the fastener in place making it have a more stable connection. Anchors are usually used in applications like drywall and masonry or concrete materials.

Rivets are a permanent type of fasteners. They are known for their remarkable durability in applications. Rivets have a cylindrical shaft with one head and tail on the other end that expands after its application, causing the permanent lock into objects.

Studs are a piece of an externally threaded bar that resembles bolts without a head. The common type of studs appears with a whole body thread or a clean shaft in the middle with the same threads on both ends. Studs are often used with nuts for a non-permanent joint but they are also welded into materials to provide a permanent connection.

Other helpful articles to read on getting to know fasteners:

What are the types of nuts, bolts, and screws?

Why should I select the right combination of nuts and bolts?

Fastener materials play a crucial role in the final form, performance, and quality of fasteners. To have a successful assembly it is important to determine the right kind of materials that goes well with its environment to prevent failure such as corrosion of elements.

For example, saltwater applications require critical material of fasteners which has high corrosion resistance to challenges of temperature and substances like stainless steel. Stainless steel fasteners are often used for their high corrosion resistance and strength. This material on fasteners is also the most commonly sought-after for many other great features, but some applications have rather different needs and stainless steel cannot perform well. Other than stainless steel, there are more materials available for fasteners such as carbon steel, alloy, brass, bronze, aluminum, titanium, nylon, and more.

The grades on fasteners are another essential consideration when choosing fasteners. Fastener grades refer to the specific strength of the component which are measured according to their manufacturing. The higher the grade the stronger and more durable the fasteners are. Usually, the grades are found within the head of screws or bolts for larger sizes and while the smaller ones will not have any indication written on them, fastener suppliers should be able to provide you with the proper information.

Having to determine the accurate material and grade on fasteners will inevitably affect the outcome of the fastening application. It is best to have a professional opinion if there is a critical need or specific requirement for the fasteners.

Fasteners have complex variations according to types, sizes, designs, forms, shapes, and standards but there are two categories that these variations fall into – permanent and non-permanent. As the names suggest, permanent fasteners are single-use fasteners meant to permanently join parts together like blind rivets, security screws, security nuts, anti-tampering screws, etc.

While non-permanent fasteners are designed to allow easy removal for maintenance or replacement, examples are wood screws, chipboard screws, hex head bolts, hex nuts, washers, etc.

As defined in the article above, fasteners provide a connection between two solid objects or surfaces for varying purposes. For threaded fasteners like screws and bolts, an efficient tool is used for their installation such as a screwdriver, wrench, Allen key, and power electric tools. While some fasteners require pre-drilling to easily cut their way through the material of application, and some are welded for permanent applications.

Fastener suppliers can refer to several organizations that deal with supplying fasteners to different channels of the market like commercialization, industry use, and consumer or retail. They can either be fastener manufacturers, vendors, suppliers, distributors, and retailers like hardware stores.

Every fastener material has its natural ability to withstand different issues in applications including weather and temperature. If not, they can have coating/plating that can specifically resist several conditions that can likely cause damage and failure to the assembly.

Stainless steel fasteners are one example of a material that has extreme resistance to certain temperatures and weather conditions. Aluminum fasteners are preferred for their ability to resist corrosion and provide a thin layer of oxidation when exposed to oxygen.

Fasteners having different available materials for fabrication have significant corrosion resistance depending on what kind they are. Stainless steel offers high corrosion resistance, non-magnetic abilities, strength, durability, and so on. Other types of steel like carbon steel and alloy can also provide similar corrosion resistance levels, the same goes for aluminum, brass, titanium, etc. for a varying result.

To maintain fasteners in their applications a regular lubrication and cleaning schedule of the components are highly suggested. It is also preferred to select fasteners with corrosion-resistant abilities to minimize the quick degrading of elements.

Damage and failure are two common problems that can be encountered in fastening. Multiple reasons can cause damage to either the fasteners or the surface of the application, one of which is improper use of the wrong kind of fastener. That is why it is best to determine the right fastener for your kind of application before purchasing them from the supplier.

Another problem that can happen in fastening is the loosening of parts. There are lesser chances of loosening in fasteners when due process is taken during and after the installation. Loosening usually occurs from constant vibrations and movements that are often present in automobiles and infrastructures like bridges, railways, etc. To prevent the failure of fasteners from loosening it is best to ensure the tightness of their application.

Standard fasteners like screws simply require a screwdriver hand tool that has a corresponding drive in the head of screws and bolts can be installed with wrench tools. While further applications may require power tools like hand drills or electric guns for pneumatic nails.

To properly install fastener screws you may refer to the following steps:

You can rely on the simple steps of installing fastener screws yet it is recommended to consult the fastener manufacturer’s instructions or an expert’s opinion to ensure a proper installation and likely successful assembly.

With the variety of choices in fasteners, they all propose a similar function to secure and hold two or more objects. From this function the following benefits of using fasteners are convenience, having durable & strong joints or connections, versatility from a wide range of applications, cost-value products, little to no maintenance, and an aesthetic look for decorative applications.

Some of the primary features that individuals or organizations should look for when choosing fasteners should be: materials used in the fasteners, grade, tensile strength, corrosion resistance, fastener coating & finishing, compliance to industry standards like ISO, ANSI, DIN, etc., salt spray test and other manufacturing details

The process of manufacturing fasteners varies on what type is being produced. Generally, the steps of producing fasteners are as follows: wire drawing, heading, thread rolling, heat treatment, surface treatment, sorting & inspection, and packaging. These processes follow standards and guidelines that constitute the production of high-quality solutions for a wide range of applications. Let’s get into the broad definition of the standard manufacturing steps of fasteners.

Although, nowadays many fastener manufacturers ought to use more advanced technology and machinery to fabricate innovations to meet the rising demands of some industries. Yet, of course, the standards in manufacturing are continually implemented to ensure the best quality of fasteners.

Every day we get to encounter multiple assemblies that efficiently operate or function through the use of fasteners. Whether it is small appliances, furniture, or cabinets, up to larger and more complicated applications in infrastructure, building, and machinery, fasteners are an essential part of their system and effectiveness. Thus, ensuring the safety and security of the applications is a standard procedure of responsible fastening.

How to select the best quality fasteners?

You may have read or heard about many ideologies on finding a reliable supplier of fasteners, but once you get to browse online the multitude of options and choices is overwhelming. To come up with an easier way to find the right supplier/s, we’ve identified some of the factors to consider that can be well applied for all ranges of industries.

How to choose the right fastener supplier?

Let’s say you have decided which type of fastener to purchase and you are already looking for the best supplier to accommodate your needs. What are the considerations should you take?

Quality is a very crucial factor for fasteners, every manufactured product should comply with industry standards and regulations. You can trust suppliers that offer fasteners under ISO standards.

Check for the availability of a variety of fasteners or custom manufacturing capabilities. Having a wide option of products can benefit and provide an advantage especially if there is a need for more than two types of fasteners. It can save you time and money when you purchase the components from one direct supplier.

When buying bulk or wholesale fasteners the price can be a little negotiable or discounted from some suppliers. It is best to research different companies ahead and compare the pricing to find the one that offers the most competitive price.

Suppliers with excellent customer service should be consistent from the start of the inquiry. You should consider a supplier that is responsive, accurate, and has the willingness to provide you with all the information and support you need.

Choose the supplier that can provide technical support through their best expertise. They should be able to deliver after-services, recommendations, and advice in fasteners and fastening applications to achieve a 100% success rate.

Choose the fastener company that has a proven reputation through services and products in the industry. Usually, reviews and customer testimonials from their past purchases will help in knowing how reliable the supplier is.

As a part of good customer service, the delivery time of your purchase will also matter. Find the supplier with a timely manner of deliverance from the quotation of products, production, shipment, and actual delivery.

Prince Fastener is one of the leading fastener manufacturers and suppliers of specialized fasteners in China. For more than 30 years we have provided solutions for a wide range of applications and industries. With a striving attitude to meet the accurate needs and demands of different industries, we continually serve only the best and high-quality standard products.

The manufacturing facility is located in Shanghai and Nan-tong province of China. A fully equipped factory with advanced technology and machinery to fabricate various types of fasteners. Moreover, the production team is comprised of professionals and skilled workers that have worked with us for a long time.

The company is dedicated to serving the world’s prime distributors, businesses, organizations, retailers, and others with full customization on the features of fasteners. We support any kind of business using only high-quality materials and equipment.

Prince Fastener has an abundance of capabilities from manufacturing superior fasteners to achieving a sustainable and reliable supply of products. We imply a continuous and effective system that can support multiple distributors around the world. Our shipment and delivery of fasteners have proven to provide satisfaction to our customers. We deeply understand the competitive industry of fasteners hence we are open to discussing reasonable prices for wholesale and bulk fasteners anytime. Contact us to improve your business right away!

We will contact you within 24 hours.

For your urgent inquiries,please contact us through whatsapp No. : +86-18930191254