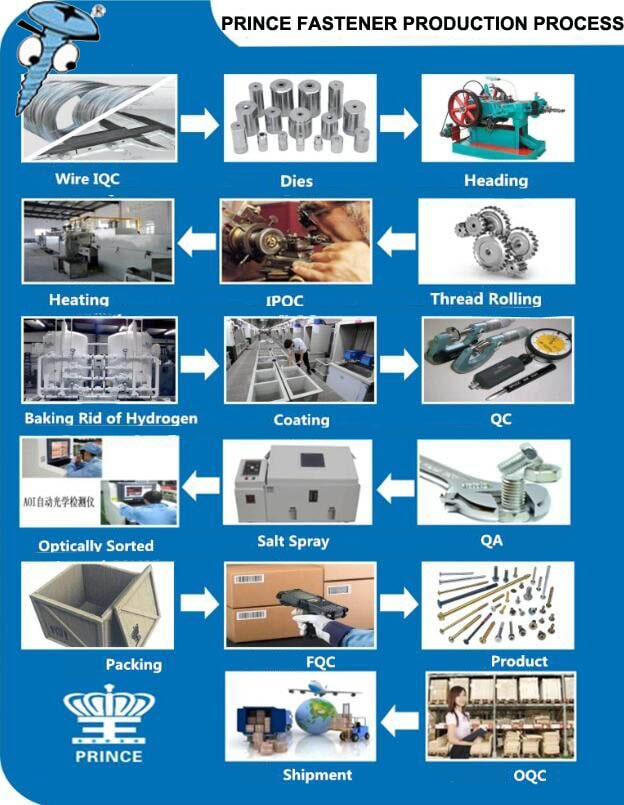

A:Prince fastener has advanced production and testing equipment .Every products will be 100%

inspected by our qc department before shipment

Q: Are you trading company or manufacturer of Drywall screw for metal?

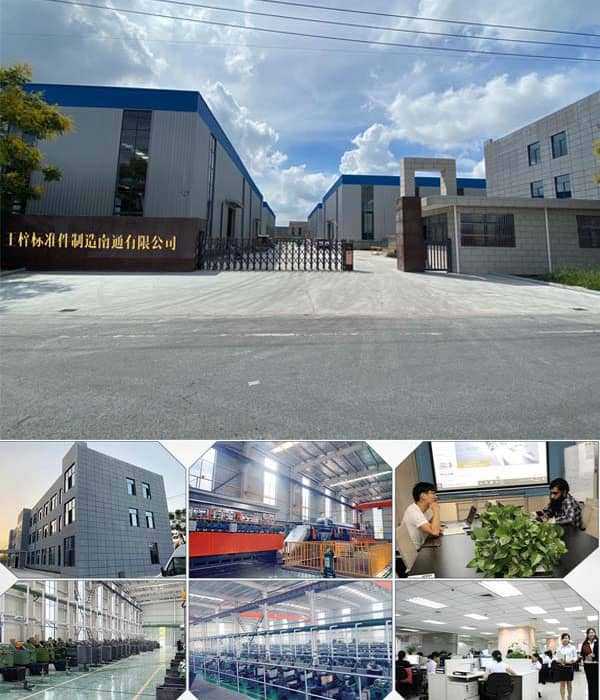

A:Prince fastener is a factory with 30 years of manufacturing experiences in Shanghai,China.

Q: What is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide Drywall screw for metal samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge and customers only afford the freight costs.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: Why choose us?

A: 1) Reply you in 24 working hours.

2)Experienced staffs would like to answer all your questions in time.

3) Customized design is available. ODM&OEM are welcomed.

4)Special discount and protection of sales are provided to our consumers.

5) Prince fastener can provide free sample, consumer should pay the freight first, and the expensive sample cost will be added in the next order.

6) As an honest exported seller, Prince fastener always use professional factory, quality quotation, good service, skilled

technicians to ensure our products to be finished in high quality and stable feature.

Q:How about your price?

A:Quality products with reasonable price. Please give me a inquire, we will quoted you a price for you refer at once.

Q:What kind of products do your factory manufacturing?

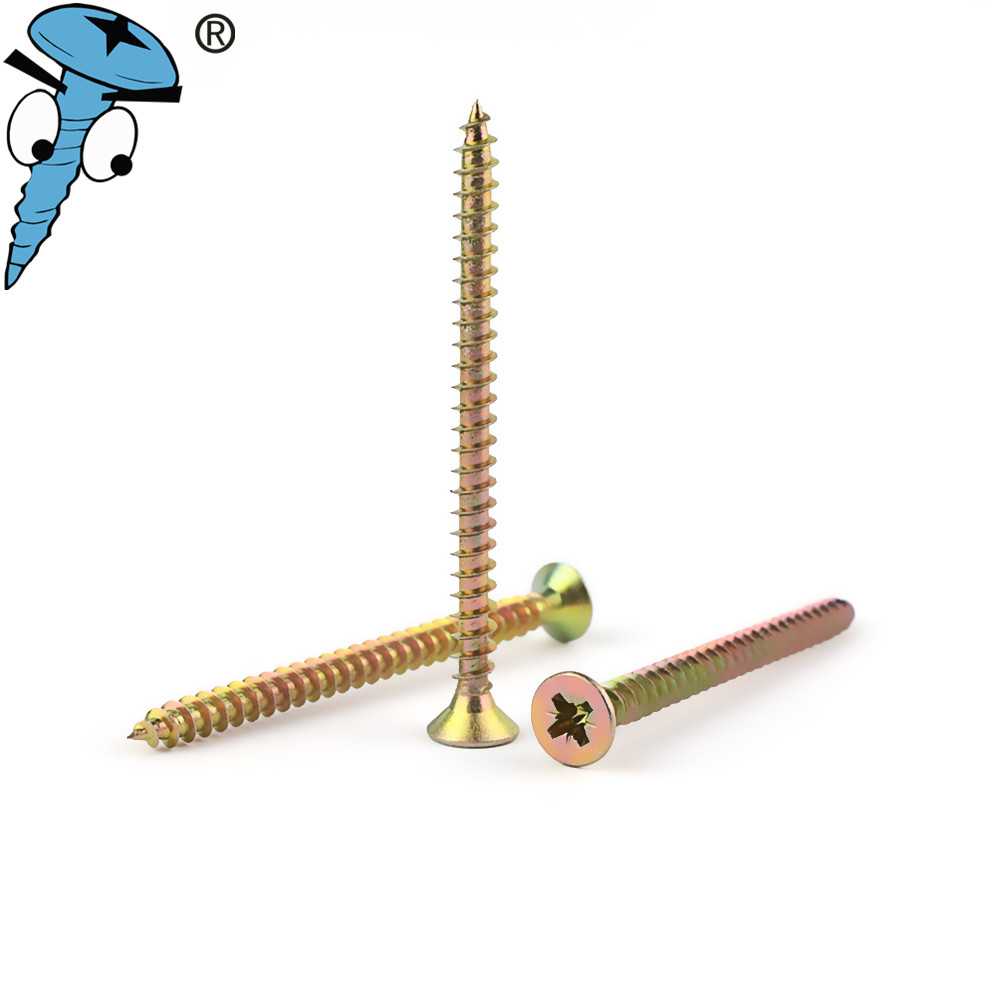

A:Our main products are: drywall screw,chipboard screw, machine screw,self tapping screw,self drilling screw,Non/standard

screws,Engineering fastener(High strength bolts;Nuts;Washers;Anchor),Stainless steel screws,Self Drilling Screw, Self Tapping Screw, Thread Rolling Screw, Thread Cutting Screw, Machine Screw, Concrete Screw, Roofing Screw,

Drywall Screw, Particle Board Screw, Chipboard Screw, Construction screws, Coach screws, Lag screw, Wood Screw, Euro

Screw,Collated Screw, Furniture Screw, Sems Screw, Thumb Screw, Wing Screw, Phillips Head Screw, Set screws, Metric set screws,Sheet metal screws, Eye screw, Security head screw