Drywall Screws Manufacturer

Committed to service in meeting your customization needs of industrial fastener screws.

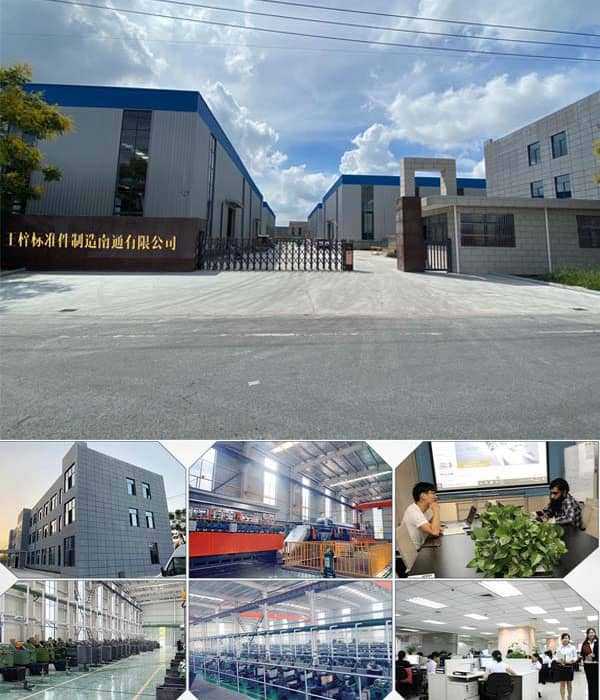

We are the one-stop fastener supplier for many industries and sectors who are looking to source their fastening needs. Prince Fastener manufactures customized screws and specific requirements on fasteners with the many capabilities we can provide in;

- Advanced technology and machinery for efficiency in the production process

- Convenient service that allows modification of elements and features on fasteners

- Reliable customer service and assistance

- High-quality materials and excellent product standards

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our chipboard screws for wholesalers and importers.

Quick View

- → Why wholesale drywall screw from Prince Fastener?

- → Hot products for Drywall screws

- → How to Evaluate Wholesale Prices for Drywall Screws and Custom Fasteners

- → Estimated Production and Delivery of Drywall Screws

- → How Are Drywall Screws Installed?

- → How are drywall screws made step by step?

- → Why Purchase your Drywall Screws with Prince Fastener?

- → Searching for drywall screws made in China?

- → Need Special screws for your clients or projects?

- → The Complete FAQ Guide about drywall screws

Why Choose Prince Fastener as a Furniture Screw Supplier?

Prince Fastener is one of a kind worldwide distributor of excellent fastener products. Our specialization in the fabrication of all kinds of screws has reached internationally in Hong Kong, Korea, Japan, Australia, the UK, Europe, and the Middle East. To emphasize services that we are known to meet requests in custom, OEM, ODM, and private label orders. We go over the top in providing the best results without compromising the features of our products. With a developed innovation in analysis and development, we have succeeded in qualifying in national and international standards and receiving certifications in ISO, DIN, ANSI/ASME, JIS, and GB types.

Customized fastener services are widely in demand in business nowadays but Prince Fastener put precision in the need to specialize in the market of drywall screws. We present transparency in our production process to let our clients know how we put the outermost importance of quality control in our final products We provide surface treatments like blue zinc plating, yellow zinc plating, nickel plating, black zinc plating, gray phosphorus galvanizing, black phosphorus galvanizing, brass plating, steam plating, hot dip galvanizing, silver plating, gold plating, etc. to other fastener products we produced.

Prince fastener has concrete solutions to ensure high-quality products because our advanced factory and facility are equipped with special machinery from Taiwan. We practice effectiveness as motivation in meeting every client’s requirement. Our customers and clients are constantly satisfied with our products, especially with our drywall screws and the overall service we have provided.

Hot products for Chipboard screws

Bugle Head Drywall Screw

Collated Drywall Screws

Screw Drywall

Drywall Screw

Gysum Screw

Black Phosphated Drywall Screw

Round Head Drywall Screw

8.8 Drywall Screw

Drywall Screws in Shanghai

How to Evaluate Wholesale Prices for Drywall Screws and Custom Fasteners

The wholesale price of drywall screws from Prince Fastener is estimated accordingly to the factors that affect their value

Fastener Manufacturing Costs

The costs of raw materials and manufacturing processes are already included in the product price. Prince Fastener has efficiently provided reasonable pricing to its customers and clients over the years. The development of advanced technology and machinery has only impacted our product prices slightly.

Drywall Screw Packing Fee

We also specialize in demands of packaging types, Prince Fastener offers service of private label to distributors and further special requirements for a small amount of difference from the regular packaging fee.

Shipping Costs

The transport in a quantity of the fasteners from our facility to the area of delivery. Shipping to international countries is conducted via sea or air transport, preferably the fastest type of transportation.

Customized Drywall Screw Supplier

The differences in features between drywall screws and other types of fasteners are customizable depending on accuracy and design. Prince fastener specializes in custom orders for different kinds of drywall screws and has been providing them at cost-value quality.

Free Sample of Drywall Screws

Free samples of drywall screws are offered to our clients for them to inspect the quality beforehand. Drywall screws are reliable and have to provide security in assembly therefore Prince Fastener has manufactured the quality that assures reliability and tight hold of materials.

Custom Clearances Costs

The overall cost of custom clearances and other miscellaneous fees are estimated and included in the quotation of your order.

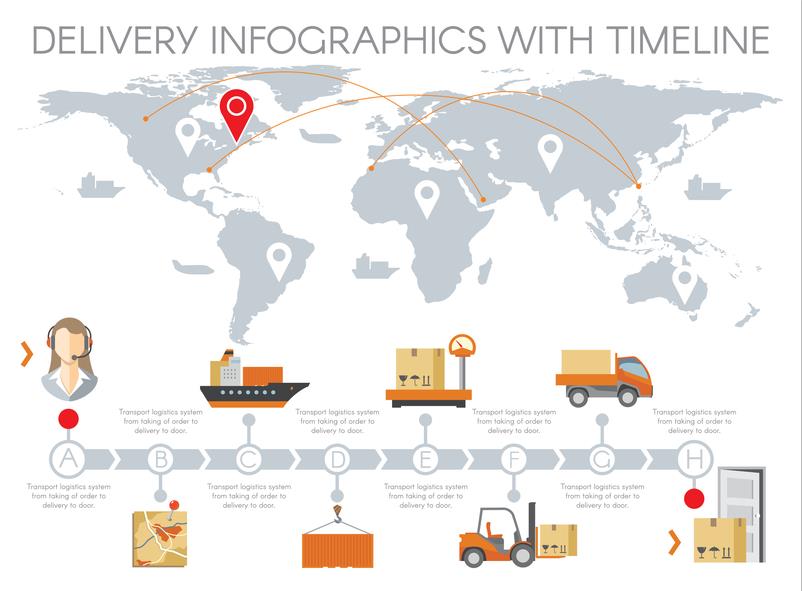

Estimated Production and Delivery of Drywall Screws

To cope with the rising demand for fasteners in a diverse range of industries and applications the capability of Prince Fastener was sorted and tested on many levels to meet the accuracy of efficient and sustainable supplying service. The company is well equipped in terms of advanced technology and machinery for different outputs, especially during intricate orders of custom screws. The production capacity is maintained and developed to cater fastening needs of the worldwide markets.

Furniture Screw Design and Manufacturing

Prince Fastener owns more than 100 pieces of production equipment with a monthly capacity of 600 tons and an annual capacity of more than 6000 tons. The types of equipment include advanced manufacturing machinery introduced from Taiwan, such as head-making machines, thread rolling machines, net furnaces, and testing machines (salt spray machines, 3D projectors, hardness testers, etc.)

Packing and Packaging Process of Screws

Every product is made of high-quality steel in a high-technology production process and complete testing methods that ensure excellent qualifications for different fastener applications.

Exportation and Custom Clearance

Prince Fastener has been distributing its manufactured products outside China for over 30 years and while catering to the worldwide demand the continuous development of the system is well implemented and improved.

Local Logistics

Local logistics are services from the destination area of products. This will be handled in your local port and is quoted properly before the shipment.

How Are Drywall Screws Installed?

For reference of the installation process of drywall screws

A pre-drilled hole/pilot hole is required on the drywall surface for the primary insertion of the drywall anchor. Once the anchor is fully tapped into the surface the drywall screw will be driven directly with the use of a screwdriver or drill. The application of drywall anchor allows the tight hold of revolvement of the screw and grip to the objects while distributing the loads evenly to prevent loose assembly.

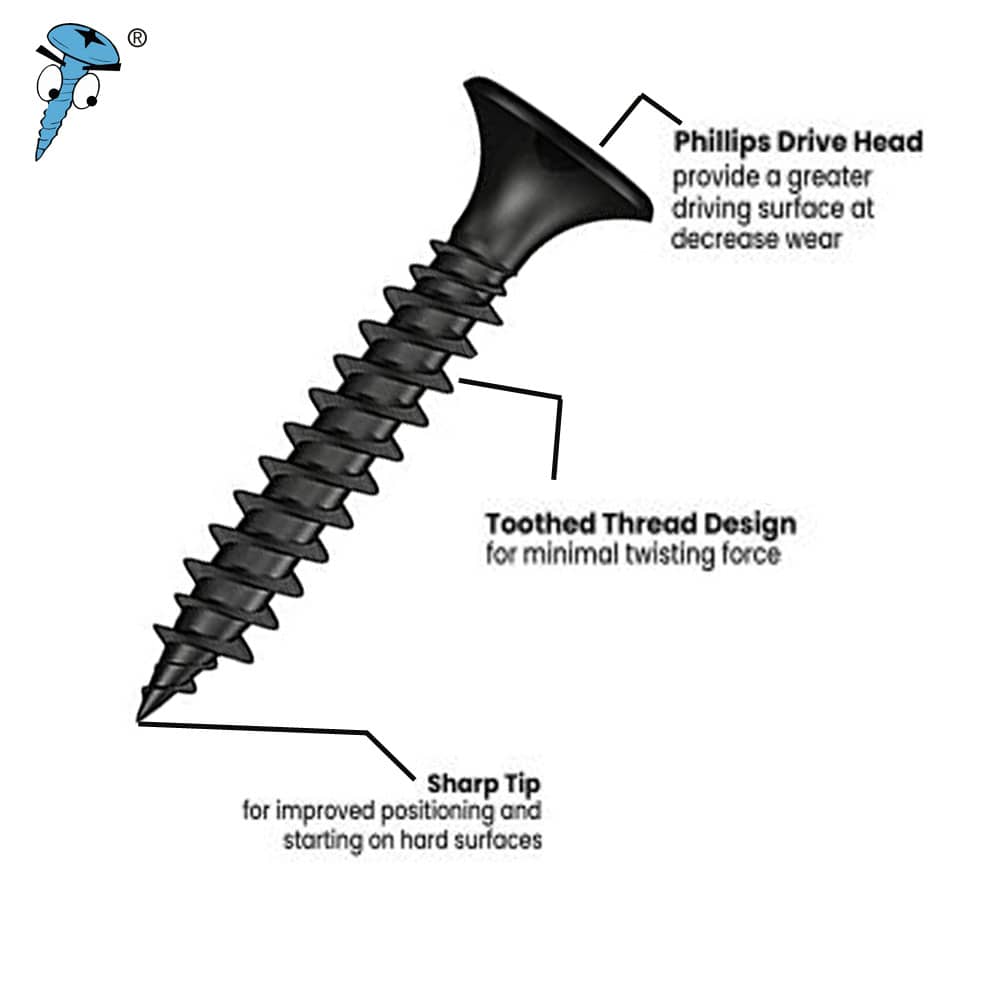

Drywall Screw Terminology and Features

Bugle head is the cone-like shape of the head which helps in driving the screw to stay in place to prevent tearing through its surface.

The sharp point/tip of a drywall screw makes the easy to stab into the drywall board for a quick process of installation.

The drill driver or drill head type is generally the drive access of the screw that allows the force to be orderly with the use of corresponding tool drives. Examples of head drives are Torx, square, Phillips, etc.

The coating of a drywall screw is usually black which refers to phosphate coating or thin vinyl coating that makes them more corrosion-resistant.

How Are Drywall Screws Made Step by Step?

Prince fastener will introduce you to all the processes of the drywall screw production.

Prince fastener production process

The basic concept of the screw production process by Prince fastener

- Prince fastener manufactures different kinds of screws with the process of cold heading and hot machining, such as turning, milling, etc.

- Cold heading refers to the use of plastic metal that is pressured or drawn into cold mechanical pressure until it reaches a solid metal form.

- The hot heading is another pressure machine that heats the material in the die until it reaches a certain form in head style.

- After the material has undergone heating and pressure, it will be shaped in the required design.

- Machining will then section batches of the screws or bolts to be milled and turned into special screws with six corners of head type.

- Screw bolt threading is usually done through mechanical and manual threading in a similar die.

- The use of a cutting machine generally completes the milling of the tail end.

- The difference between cold and hot heading: cold-headed materials are forged into a series of ‘die blows’ to achieve a smooth exterior while having strength and resistance; the hot heading is forming the Head of the bolts in lesser ‘die blows’ allowing it to be cost-efficient yet a slower process to take when purchasing several screws.

Analysis of forming process and the cause of the phenomenon

- Eccentric: placed improperly in the adjustment machine

- Minow: the poor installation

- The Head is non-circular: the choice of a die or punch form was insufficient

- The mode of cracks: properly choose a crack or die R angle to administer the model by two collision hit

- Head double: inadequate punch

- Flash: when poor molding punch in the die hole clearance is too large or short by red bars

- Crack in angle: not enough punch or a burst in needle

- Head cracking: error in using of die, material, and lubricating oil

Analysis of common rolling and the cause of the adverse phenomenon

- Crack between the process: need an adjustment in Prince fastener old machine and tooth plate

- Blunt tail: when the device is improperly managed, or the tooth plate needs adjustment

- Crooked tail: occurs when the control screw on the board seat is too tight

- Tail: improper adjustment of machine and poor quality of tooth plate resulting in wearing

Why Purchase your Drywall Screws with Prince Fastener?

In the wide manufacturing industry all over the world, Prince Fastener never fails to improve the progress of development in every aspect. Undoubtedly, our expertise is exceptional in showing value and a level of excellence.

Our organization is internationally accredited and acknowledged to be one of the rapid manufacturers in China of different screws having the use of top-tier equipment originating from Taiwan. Our method of exceptional craftsmanship is to ensure production of drywall screws is met perfectly by the prince fastener.

The high degree of competence we exhibit in the production of drywall screws is to strongly enterprise that our resources will never cease to please the trading in the market. With our competitive prices, prince fastener can achieve repeat orders from big brands and clients, supplying them with the highest quality of drywall screws. In the large-scale selection that these fastener screws can take we have produced numerous types in sizes, forms, applications, usage, and kinds that have matched up to the main requirements that customers look for especially in making drywall screws.

As the vast count of domestic fastener manufacturers keeps rising in the market, the percentage shares have a low concentration has resulted in the leading enterprises striving to obtain high-quality competence to monopolize the production of fastener products.

Searching for Drywall Screws Made in China?

Prince Fastener is your one-stop fastener vendor with an ideal service proven to provide 100% customer satisfaction. How is a screw made?

Production Equipment

Prince Fastener owns more than 100 pieces of production equipment with a monthly capacity of 600 tons and an annual capacity of more than 6000 tons. The types of equipment include advanced manufacturing machinery introduced from Taiwan, such as head-making machines, thread rolling machines, net furnaces, and testing machines (salt spray machines, 3D projectors, hardness testers, etc.)

Testing Equipment

Every product is made of high-quality steel in a high-technology production process and complete testing methods that ensure excellent qualifications for different fastener applications.

Need Special Screws for Your Clients or Projects?

Prince Fastener is more than capable of providing you with safety solutions and outstanding customer service.

Prince Fastener is more than capable of providing you with safety solutions and outstanding customer service.

As an industrial manufacturing company with more than 30 years of experience, Prince Fastener has achieved successful product development, excellent sales and service, and flexibility to cater to the complex needs of the industry. The company prioritizes quality and executes the standard processes in firm belief to deliver customer satisfaction and professional business relationship.

The main products include chipboard screws, long screws, non-standard screws, titanium screws, small screws, stainless steel screws, bolts, nuts, self-tapping screws, self-drilling screws, etc. The production process and final output all conform to international standards such as ISO, DIN, EN, and more.

Prince Fastener has provided more than 500 billion screws for more than 1,000 companies and has customized 4,800 types of screws with further capabilities to fabricate according to customer requirements. We accommodate custom designs and drawings in reasonable plans and costs of the overall transaction.

The company comprises innovative engineers and a skilled team that caters to developing diverse types of fasteners. We have served multiple business sectors and industries in toy factories, handbag factories, furniture, building materials, sanitary ware, electronic, automobile, new energy, and aviation navigation fields, etc. to the countries of Hong Kong, Korea, Japan, Australia, the UK, Europe, and the Middle East.

The Complete FAQ Guide About Drywall Screws

Quick Index

1. What screws are used in drywall?

2. What are the shipping options for Drywall screws?

3. How to install a drywall anchor?

4. What is special about anchors for drywall?

5. How to purchase drywall screws in China?

6. Does screw drywall have quality types?

7. What is the difference between drywall anchors and screws for drywall?

8. Can manufacturers customize drywall screws?

9. How long is the shipment of drywall screws from fastener suppliers?

10. How long is the shipment of drywall screws from fastener suppliers?

11. What other fastener products does your company manufacture and supply?

1. What screws are used in drywall?

Plasterboard, often called drywall, is a panel board widely used for construction made of mixtures that reduce flammability and water absorption. Drywall requires screws for easy installation and finish joints, sometimes fasteners are also covered by drywall compound. Drywall screws are designed for workpieces of drywall panels, they are comprised of deeper threads than regular screws and are usually made of steel. Plastic anchors are more often used along with drywall screws to help distribute the weight of the objects evenly to their surface.

2. What are the shipping options for Drywall screws?

Usually, in overseas orders, the shipment of products is conducted via sea or air transportation, while during the delivery and local logistics wheeled vehicles are expected to deliver them to your doorstep.

If you are sourcing drywall screws from China multiple fastener suppliers can cater to mass orders and even special or customized fastener products. One of the leading fastener manufacturers that have extensive knowledge and experience in the production of industrial solutions is Prince Fastener. The company has been delivering thousands of screws, especially drywall screws to international countries for the past 30 years with excellent quality and service.

3. How to install a drywall anchor?

Generally, anchors are additional devices used to distribute the weight of materials or items that you wish to hang. Drywall anchors are typically made of plastic and while there are many types available, some of them are more known than others.

To install drywall anchors you need to mark the surface with a pencil and drill or make a pilot hole in it, the pilot hole should be set smaller than the anchor. After drilling, you will stick the anchor into the hole and tap into the place, when suitably positioned you will then screw the fastener into the anchor with a screwdriver or drill.

4. What is special about anchors for drywall?

Drywall anchors are reliable and will benefit the assembly in many ways. They provide quick processes yet useful functions for hanging objects. Some better options are also available depending on the type of anchoring and fastening that you will perform which provides effective and successful work if you plan accordingly.

5. How to purchase drywall screws in China?

To purchase drywall screws from China, you have to make research the correct screw and its features to be able to find them easily from the Chinese fastener market.

Prince Fastener is a renowned drywall screw supplier that has been in service for over 30 years for different fastening needs. The company has shipped millions of drywall screws outside its region and is known to commit to delivering accurate and reliable products to its customers. Many have attested to its capabilities and services to be of world-class quality and that it has provided them nothing but outstanding satisfaction.

6. Does screw drywall have quality types?

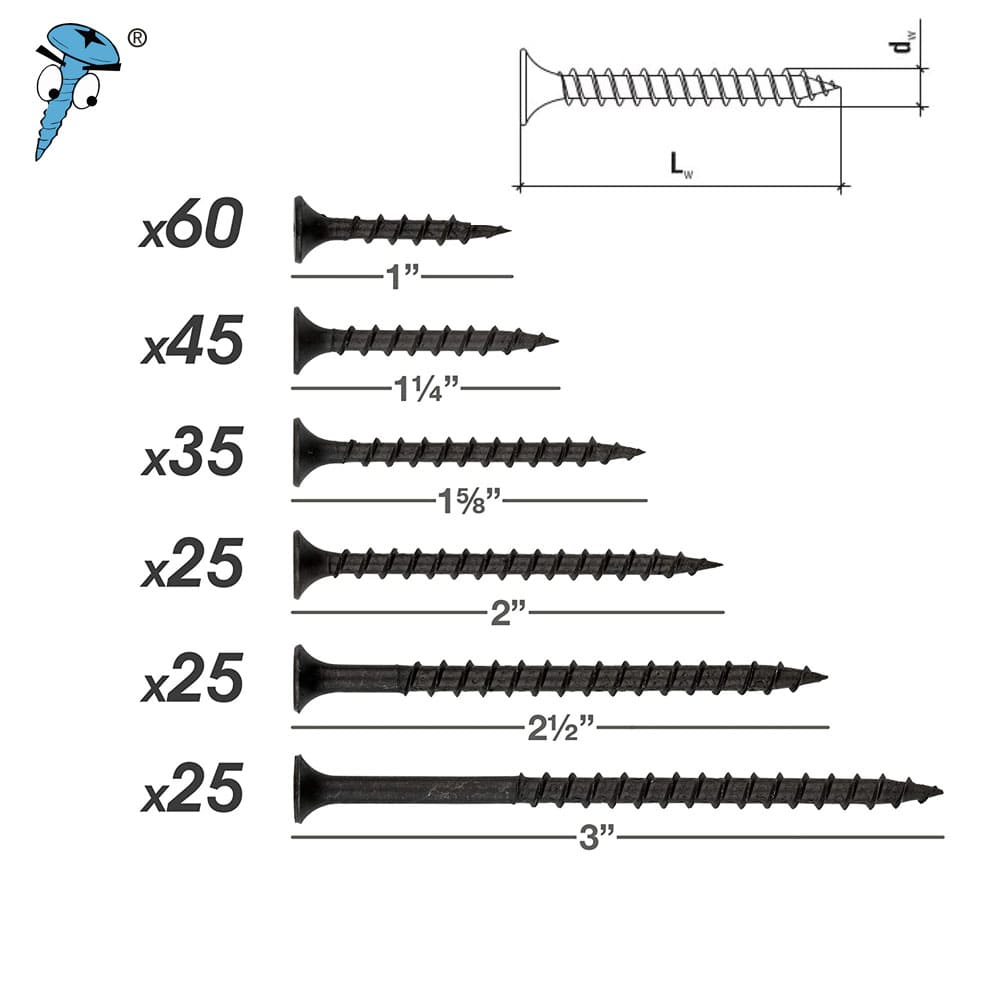

Drywall screws are determined through their length and pitch. There are two classifications of the common types of drywall screw lengths; S-type and W-type. S-type screws are designed with sharp points to penetrate drywall and metal materials easier. While W-type screws are significantly thinner and longer than the others.

What to know when deciding the quality and type of drywall screw to purchase are; drywall screw length, gauge, and thread.

7. What is the difference between drywall anchors and screws for drywall?

Chipboard screws are self-tapping components designed with a single type of thread that runs along its full length from tip to under the head section. The large distance between peaks of the thread on chipboard screws allows it to go through softer material such as plasterboard or chipboard hence its name. For this reason, the screw is commonly used as a fastening material to composite boards and other wood surfaces.

There are two known types of chipboard screws; half-thread and fully threaded. Half-threaded chipboard screw is mainly used in joining two pieces of wood boards for its smooth section prevents the pull of the two materials together with no gap.

The fully threaded type is used to connect the metal sheets to composite boards because it secures the materials together in a tight grip.

This type of screw is technically used in wood-to-wood and wood-to-metal applications; however, the chances of cracking the surfaces when it is driven into soft materials are at great risk. Nowadays, fastener manufacturers such as Prince Fastener have come up with an innovation to modify the screw to a quality level to solve the problem of making it claw-cutting.

8. Are drywall screws essential in industries and revenue-generating?

Chipboard screws are self-tapping components designed with a single type of thread that runs along its full length from tip to under the head section. The large distance between peaks of the thread on chipboard screws allows it to go through softer material such as plasterboard or chipboard hence its name. For this reason, the screw is commonly used as a fastening material to composite boards and other wood surfaces.

There are two known types of chipboard screws; half-thread and fully threaded. Half-threaded chipboard screw is mainly used in joining two pieces of wood boards for its smooth section prevents the pull of the two materials together with no gap.

The fully threaded type is used to connect the metal sheets to composite boards because it secures the materials together in a tight grip.

This type of screw is technically used in wood-to-wood and wood-to-metal applications; however, the chances of cracking the surfaces when it is driven into soft materials are at great risk. Nowadays, fastener manufacturers such as Prince Fastener have come up with an innovation to modify the screw to a quality level to solve the problem of making it claw-cutting.

9. Can manufacturers customize drywall screws?

Fastener manufacturers are direct factory owners with various equipment that can produce drywall screws in standard or non-standard forms. However, some of these organizations have limited services to deliver the standard fasteners to their customers, while many are also flexible in the system to fabricate customized screws and other fasteners.

One of the best fastener manufacturers that customize drywall screws through customer specifications and requirements is Prince Fastener. For decades the company has developed thousands of custom orders from around the world without compromising its quality and kind of service.

Prince Fastener promises satisfaction with high-quality products and services to its customers of different industries or sectors.

10.How long is the shipment of drywall screws from fastener suppliers?

The estimated shipment of drywall screws from fastener suppliers depends on their capability to manufacture the products in time. A reliable fastener company can estimate their production time and management of orders as a commitment to their dependable service.

With Prince Fastener we can always guarantee the type of service we provide to our customers through a proper establishment of transactions.

You can contact us directly and we always answer with efficiency and transparency to inquiries.

11. What other fastener products does your company manufacture and supply?

Prince Fastener has diverse qualities in the manufacturing industry making us capable to supply variations of fasteners for mechanical, industrial, and engineering needs. With the numerous kinds of industries and sectors that require these devices and components, the fastener products from our company have helped in developing and building structures, final products, furniture, machinery, and others, as well as commercialization in the market of distributors and stockists.

Prince Fastener has mainly produced and supplied different kinds of fasteners such as self-tapping screws, self-drilling screws, chipboard screws, drywall screws, machine screws, bolts and nuts, stainless steel screws, and custom-made fasteners.