Custom Self-tapping Screws

Manufacturing the standard and non-standard fasteners for over 30 years.

Prince Fastener is one of the best custom screw developers catering to thousands of industries and sectors around the world. We deliver according to customer requirements and specifications in excellent quality. Here’s why we are a leading choice;

- Accurate fabrication of standard and non-standard screws

- Quality assurance with conformity to International grades

- Outstanding customer service is 24/7 availability and accessibility

- Flexible services (OEM, ODM, private-label, etc.)

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our chipboard screws for wholesalers and importers.

Quick View

- → Why Choose Prince Fastener as a Custom Self-tapping Screw Supplier?

- → Hot products for custom self-tapping screw

- → How to Evaluate Wholesale Prices for Custom Self-tapping Screws and Custom Fasteners

- → What Is a Custom Self-Tapping Screw and Where Is It Applied?

- → Estimated Production and Delivery of Custom Self-tapping Screws

- → How Are Custom Self-tapping Screws Made Step by Step?

- → Searching for Custom Self-tapping Screws Made in China?

- → Need Special screws for your clients or projects?

- → What Is There to Know More About Prince Fastener?

- → The Complete FAQ Guide About Custom Self-tapping Screws

Why Choose Prince Fastener as a Custom Self-tapping Screw Supplier?

Prince fastener has been manufacturing industrial products for over 30 years and has continually remained one of the leading manufacturers in China. The company specializes in custom orders and standard fasteners for different kinds of applications. It has served thousands of industries and sectors around the globe with 100% customer satisfaction as feedback. But what makes Prince Fastener different from the others is their capability to understand the needs of every client in fastening. With its extensive experience, they have gathered the knowledge that can sustain itself in the industry while expanding its services and capabilities. They have provided fastener solutions that were innovated in a state-of-the-art facility and advanced technology to consistently lead the market.

With the professional approach in business, the organization has never compromised its product qualities to prevent catastrophic events in the future. Its manufacturing facility is equipped with production and testing machines such as Head making machines, Thread rolling machines, Net furnaces, and examining types of equipment such as Micro hardness tester, Microstructure tester, etc. which ensures the best form and features of every product is up to standard qualifications.

In further description of its ability and competence, the company has produced numerous types of fasteners including plasterboard screws, chipboard screws, self-tapping screws, self-drilling screws, blind rivets, coil nails, common nails, concrete nails, plastic strip nails, ST nails, various shaped nails, bolts, nuts, washers, threaded rods, anchor rods, and many more. These products have been supplied to bigger brands and distributors around the world in triumph and cost value.

Hot products for custom self-tapping screws

Square Slotted Self-tapping Screw

Hexagon Head Cap Screw

Truss Head Self-tapping Screw

Self-tapping Screw

Round Head Self-tapping Screw

Phillip Flat Head Self-tapping screw

Stainless Self-tapping Screw

Self-tapping Screws for Plastic

Self-tapping Screws for Metal

How to Evaluate Wholesale Prices for Custom Self-tapping Screws and Custom Fasteners

Custom self-tapping screws are now altered according to specifications, the below are factors that will affect the overall costs and are only estimations according to broad details, to know better and find the best prices for you please contact us directly.

Manufacturing Costs/Raw Materials

Prince Fastener owns a manufacturing facility with advanced machinery for the development of custom self-tapping screws of their best quality. While raw materials are sourced from an associated enterprise the cost of production remains competitive to average pricing and is guaranteed to qualify in the high-class attributes.

Custom Self-tapping Screws Packing Fee

We provide secure packaging of products while special requests are also welcomed and accommodated to our best capacity. Private labeling and branding are offered to distributors and business associates that require customized packaging design.

Shipping Costs

The transportation of fastener commodities will have estimated shipping costs corresponding to the shipment method and is arranged by the company for the convenience of service to our clients.

Customized Custom Self-tapping Screw Supplier

Prince Fastener is delighted to provide the innovation that can change the world and the industry. That is why customer drawings or designs are accommodated to deliver our capabilities in creating a fastening solution with the utmost features.

Free Sample of Custom Self-tapping Screws

How confident we can be of our products? We can provide free samples of fastener products, especially self-tapping screws to ensure our commitment will never fail your expectations as well as the service we can further provide.

Custom Clearances Costs

The cost for shipment clearances in customs, miscellaneous fees, and other charges that may apply during the shipment of fastener products to their destination country are estimated upon the quotation of products.

What Is a Custom Self-Tapping Screw and Where Is It Applied?

Self-tapping screws comprise tapping threads that are a great fastening solution for DIY projects working in wood, metal, and concrete materials. Its pointed tip is the asset that brings convenience for its installation on different kinds of surfaces, however, self-tapping screws for metal assembly need a drilling tool and pilot hole to avoid the breakage of the shaft.

The types of self-tapping screws for metal and other applications available to Prince Fastener:

Flat head self-tapping screws, pan head self-tapping screws, round-head self-tapping screws, square-slotted self-tapping screws, truss head self-tapping screws, Phillips round head & Phillips truss head self-tapping screws, hex self-tapping screws, Phillips flat head self-tapping screws, self-tapping screw with washer, and custom self-tapping screws

Surface treatment of self-tapping screws: Galvanizing, Chromium Plating, Phosphating, Electrophoresis, Dacro, Hot Embroidery

Grades Available: Grade 2-8, 4.8, 6.8, 8.8, 10.9, 12.9, Gr1, Gr2, OEM according to your request, etc.

Materials used in manufacturing: Stainless Steel, Titanium and Titanium Alloy Brass, Carbon Steel, Aluminum, OEM according to your request

Applications of Self-tapping screws

Furniture Factory

Medical Equipment and objects

Mining Industry

Industrial Factory

Building and Construction Industry

Railway System

Food Processing Factory

Electrical Industry

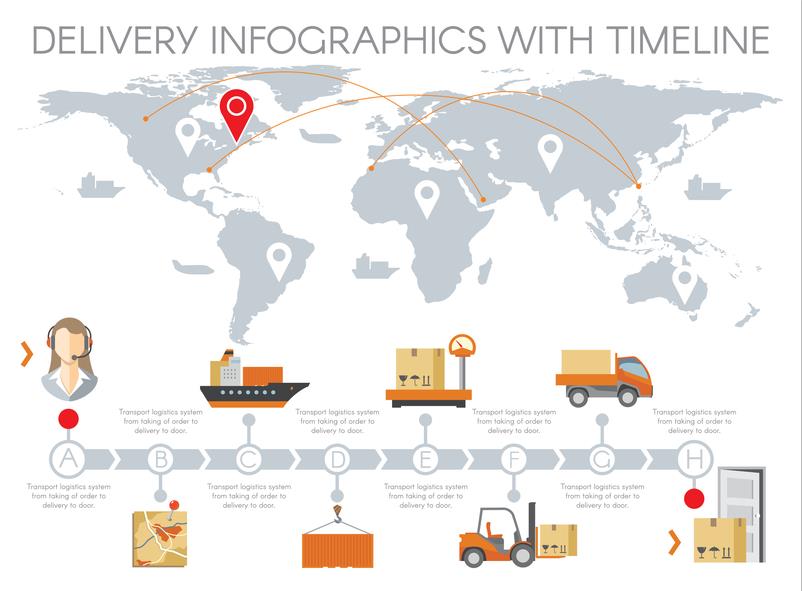

Estimated Production and Delivery of Custom Self-tapping Screws

Our production and management system are capable of limiting fabricating orders in mass quantity accompanied by the convenience of delivering them to your doorsteps. The manufacturing of custom self-tapping screws is an existing experience for our company and we can ensure their highest form before you test them out.

Custom Self-tapping Screw Design and Manufacturing

We gather the details and information on how the customer wants to modify the screw and execute them with professional research and calculations. The design is usually studied by our brilliant engineers and skilled metal workers to generate the ideal features of the final product.

Packing and Packaging Process of Screws

Packing of custom self-tapping screws will be regulated in general standard (pp bags or small white boxes) apart from the client’s further instructions. Checklists and double inspections are performed during the packaging process of the screws before we ship them out.

Exportation and Custom Clearance

Exportation from the country of China will be easily handled by our company and are almost always estimated in time and costs because we update our local port and establishment from time to time.

Local Logistics

The near-end process of the transaction yet the service of our company will never end to this point as we fully commit to knowing the further details such as the time of delivery of the package at your doorstep and feedback on our products.

How Are Custom Self-tapping Screws Made Step by Step?

Prince fastener will introduce you to all the processes of the self-tapping screw production.

Prince fastener production process

The basic concept of the screw production process by Prince fastener

- Prince fastener manufactures different kinds of screws with the process of cold heading and hot machining, such as turning, milling, etc.

- Cold heading refers to plastic metal that is pressured or drawn into low-temperature mechanical pressure until it reaches a solid metal form.

- The hot heading is another pressure machine that heats the material in the die until it reaches a certain form in head style.

- After the material has undergone heating and pressure, it will be shaped in the required design.

- Machining will then section batches of the screws or bolts to be milled and turned into special screws with six corners of head type.

- Screw bolt threading is usually done through mechanical and manual threading in a similar die.

- The use of a cutting machine generally completes the milling of the tail end.

- The difference between cold and hot heading: cold-headed materials are forged into a series of ‘die blows’ to achieve a smooth exterior while having strength and resistance; the hot heading is forming the Head of the bolts in lesser ‘die blows’ allowing it to be cost-efficient yet a slower process to take when purchasing several screws.

Analysis of forming process and the cause of the phenomenon

- Eccentric: placed improperly in the adjustment machine

- Minow: the poor installation

- The Head is non-circular: the choice of a die or punch form was insufficient

- The mode of cracks: properly choose a crack or die R angle to administer the model by two collision hit

- Head double: inadequate punch

- Flash: when poor molding punch in the die hole clearance is too large or short by red bars

- Crack in angle: not enough punch or a burst in needle

- Head cracking: error in using of die, material, and lubricating oil

Analysis of common rolling and the cause of the adverse phenomenon

- Crack between the process: need an adjustment in Prince fastener old machine and tooth plate

- Blunt tail: when the device is improperly managed, or the tooth plate needs adjustment

- Crooked tail: occurs when the control screw on the board seat is too tight

- Tail: improper adjustment of machine and poor quality of tooth plate resulting in wearing

What Is There to Know More About Prince Fastener?

- International conformity to accreditations of ISO, DIN, ANSI/ASME, JIS, and GB types. We follow American and Japanese standards in manufacturing special screws

- Use of high-quality raw materials like stainless steel, carbon steel, and alloy steel, yet we also provide alterations in production via customer requests

- Tested product quality and service by our long-term customers abroad, especially in the countries of Hong Kong, Korea, Japan, Australia, the UK, Europe, the Middle East, and more

- Complex surface treatment availability for an overall corrosive resistance of our screws and fasteners that can be modified with a professional viewpoint

- Extensive knowledge and experience in industrial manufacturing

- Understanding of the diverse requirements and demands of different projects in sectors

- Continuous development of our capabilities in production and special services

- Ability to take responsibility for our manufactured commodities and recognize their importance in multiple kinds of application

Searching for Custom Self-tapping Screws Made in China?

Prince Fastener’s manufacturing facility is conveniently located in Shanghai, China which gives us the capacity to provide factory prices and adaptive service.

Production Equipment

The continuous improvement and development of our outcomes have been possible through our vision of meeting the demands of the industrial, mechanical, and engineering sectors.

Prince Fastener has more than 200 pieces of machinery namely; multi-station bolt forming machine, multi-station nut forming machine, tail hole machine, screw machine, thread forming machine, tapping machine, centerless grinder, CNC machining, etc., and types of quality control equipment; Rockwell hardness tester, Vickers hardness tester, three-dimensional (3D) projector, tensile machine, torque tester, salt spray tester, and center axis tester.

Testing Equipment

Prince Fastener ensures the quality of every product by optimizing the attributes and features in our advanced testing laboratory using equipment such as a projector, spectral filter, hardness tester, and salt spray tester. All while making sure the corrosive capabilities of the fasteners with the availability of different surface treatments in blue zinc plating, yellow zinc plating, nickel plating, black zinc plating, gray phosphorus galvanizing, black phosphorus galvanizing, brass plating, steam plating, hot dip galvanizing, silver plating, gold plating, etc..

Need Special Screws for Your Clients or Projects?

Prince Fastener is more than capable of providing you with safety solutions and outstanding customer service.

The primary reason for Prince Fastener’s exceptional service and ceaseless innovation is to make the world acquire structural developments with safety solutions at competitive costs of materials.

Customized fasteners especially self-tapping screws are a privilege that the company takes pride in. Many fastener suppliers and manufacturers are capable of the qualities we can offer but we guarantee our customers life-long components as well as service.

Services available to our company include standard fasteners, OEM, ODM, private-label, and different surface treatments in blue zinc plating, yellow zinc plating, nickel plating, black zinc plating, gray phosphorus galvanizing, black phosphorus galvanizing, brass plating, steam plating, hot dip galvanizing, silver plating, gold plating, etc. For decades of experience, we managed to deliver orders from abroad in countries of Hong Kong, Korea, Japan, Australia, the UK, Europe, the Middle East, and more.

The main products of Prince Fastener are the following; plasterboard screws, chipboard screws, drywall screws, furniture screws, self-tapping screws, self-tapping screws for metal, metal screws, steel screws, self-drilling screws, self-drilling wood screws, blind rivets, coil nails, common nails, concrete nails, various shaped nails, bolts, nuts, washers, threaded rods, anchors, and thousands of related products that have successfully delivered effectivity and satisfaction to our clients.

The Complete FAQ Guide About Custom Self-tapping Screws

Quick Index

1. Can you manufacture other custom screws?

2. Are custom self-tapping screws modified to full customer requirements?

3. What are the capabilities of custom fastener manufacturers?

4. Are there differences between custom screws and bolts to custom self-tapping screws?

5. Are there self-tapping screws for metal?

6. Can you supply custom self-tapping screws in sizes?

7. What is the best quality of a self-tapping metal screw?

8. Where to purchase a factory price of self-tapping and self-drilling screws?

9. What is the shipment method for custom self-tapping screws?

10. What are your company’s main products and manufacturing abilities?

11. Can you provide service to distributors outside the country?

12. What can be the advantages of custom screws to standard fasteners?

1. Can you manufacture other custom screws?

Prince Fastener Manufacturing Co., Ltd has an adaptive system that maintains our company’s principles in catering to the complexity of fastener products. Custom screw-making is one of our company’s best capabilities yet it has never been our limit. We also welcome other custom designs and drawings per standards and professional help. Overall, we can provide further service at our best capacity by only requiring you to communicate with us from the basic to technicalities of modification.

2. Are custom self-tapping screws modified to full customer requirements?

Custom self-tapping screws are a made-to-order type of fastener that can be modified to our best manufacturing capability. On the occasion that the customer has made the design with professional guidance, we can arrange the order with our engineers and metallurgists. Other than that, the company will have to seek the advice of our skilled team.

3. What are the capabilities of custom fastener manufacturers?

Generally, fastener manufacturers set degrees of proficiency in their production capabilities. The many characteristics are based on some factors that impact the output of an organization. Some of the aspects will be the years of service they have, principles of the company, accumulated types of equipment, the competence of the team, vision of a better and well-developed future, reliability and sustainability to the evolving industries, and type of service that they propose.

Fortunately, Prince Fastener has all the elements that make a perfect suit for a reliable service of a custom fastener manufacturer.

4. Are there differences between custom screws and bolts to custom self-tapping screws?

Custom self-tapping screws are normally screws with the ability to tap into surfaces with or without a pilot hole because of the elements in the head drive, threads, and point. They are mechanical devices that handily tap on different surfaces like wood, metal, and concrete.

Custom bolts and screws are a distinct type of fasteners yet bolts are generally considered as a type of screw only with their enhanced characteristics to provide greater hold of materials.

Read the informative description of these fasteners in the article below

5. Are there self-tapping screws for metal?

Metal surfaces can be classified as metal sheets or thick metal depending on the variability of their material. Self-tapping screws are useful components that can tap into kinds of metal with a need for a pre-drilled pilot or hole for efficiency. The type of metal elements on self-tapping screws is regarded as relevant to sustaining the joints of the material and the fastener.

6. Can you supply custom self-tapping screws in sizes?

We keep our inventory stocked with standard sizes of self-tapping screws in sizes of outer diameter 9mm-6.3mm and lengths 6.5mm-120mm. For custom orders of self-tapping screws, the dimensions will depend on the customer’s requirement and we can also advise the best features.

7. What is the best quality of a self-tapping metal screw?

The best quality metal screws are deemed suitable for their application. Unless specified we can directly support the features preferable to the specific type of environment and functionality of the self-tapping screw on the metal material.

For reference, the best quality should be fabricated per standards of quality such as International certification in ISO and others. Raw materials of self-tapping screws should also be made from elements that prevent natural corrosion.

Want to find out more? Read below the highlighted article

8. Where to purchase a factory price of self-tapping and self-drilling screws?

For the commercialization of fasteners or any reason, it’s best to research the type of fastener/s that you need. Once a proper analysis has been established the next best step is to find a reliable fastener supplier and manufacturer that comprises the abilities suited to accessibility and convenience for you.

The most preferred option of many fastener distributors and end-users for the cheapest factory price of fasteners is typically found in China. The country has thousands of manufacturing companies that offer the most competitive prices in the worldwide market.

One of the renowned leading organizations that cater to the diverse services of manufacturing industrial devices is Prince Fastener Manufacturing Co., Ltd.

9. What is the shipment method for custom self-tapping screws?

We allow the exportation of our products to International destinations via air and sea shipment and local logistics will cater to them in wheeled delivery.

Why purchase custom self-tapping screws in Prince Fastener? Because we can offer you factory prices and outstanding service.

10. What are your company's main products and manufacturing abilities?

As forenamed in the details above, Prince fastener can manufacture in services of OEM, ODM, private-label, standard fasteners, and custom drawings. The major products of the company include all kinds of screws, bolts, nuts, washers, rods, nails, etc.

11. Can you provide service to distributors outside the country?

The company favors the prospect of more business associations in different countries and stockists/distributors. We admire the trading of markets in different industries for the development of structures in the world with the use of our safety solutions.

12. What can be the advantages of custom screws to standard fasteners?

Standard screws or fasteners are usually designed for general use and while this is a useful element for many, their capacities are limited to critical and intricate kinds of application. Custom screws are altered devices that are adept to meet the required elements and classification in the assembly. They are deliberately used in systems that are rigidly operated for the prevention of unlikely damage. The advantage of custom screws from standard fasteners is that they are fabricated to suit and become the accurate fastening material to its environment therefore the chances of failure are less to never gonna happen.