Prince Fastener:What are bolts and the standards of bolts

We will see all kinds of bolts in our life, and there are some special places in the classification of bolts. Prince Fastener will simply introduce to you what kind of bolts and the relevant standards of bolts. Describe in detail.

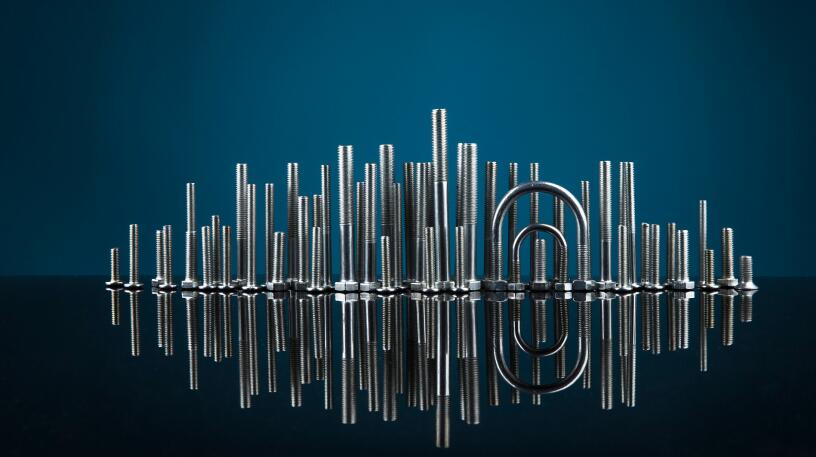

As mechanical parts, bolts are commonly used as fasteners in construction. Bolts are a particularly popular type of bolts in the fields of automobiles, construction, and decoration. They are cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external thread), which needs to be matched with a nut to fasten and connect two parts with through holes.

This form of connection is called a bolted connection. If the nut is unscrewed from the bolt, the two parts can be separated, so the bolt connection is a detachable connection.

The name of the bolt and its shape determine the life of the bolt. If the bolts with hexagons are hexagon bolts or hexagon screws. If the material is of good quality or not used in many places, then use high-strength bolts or high-strength screws. Similarly, hexagonal bolts may also be called high-strength hexagonal bolts. If it is used underground to stabilize the foundation, it will be called anchor bolts or anchor screws. Or for fixing various fasteners, if the shape is U-shaped, then it is U-bolt or U-screw. In fact, we can decide a bolt name according to the shape and material size of the production bolt.

The bolts are classified according to the force of the connection: ordinary and with hinged holes. According to the shape of the head: there are hexagonal head, round head, square head, countersunk head and so on.

Among them, the hexagonal head is the most commonly used. Generally, countersunk heads are used where connections are required.

The English name of the riding bolt is U-bolt. It is a non-standard part. The shape is U-shaped, so it is also called a U-bolt. There are threads at both ends that can be combined with nuts. It is mainly used to fix tubular objects such as water pipes or sheets such as automobile plates Springs are called riding bolts because of the way they fix things like a person rides a horse. According to the length of the thread, it is divided into two categories: full thread and non-full thread.

According to the thread type, it is divided into two types: coarse thread and fine thread. The coarse thread type is not displayed in the bolt mark. The bolts are divided into eight grades: 3.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, and 12.9 according to their performance grades. Among them, the bolts above grade 8.8 (including grade 8.8) are made of low-carbon alloy steel or medium-carbon steel and are heat-treated (quenched). + Tempering), commonly known as high-strength bolts, and below grade 8.8 (excluding 8.8) are commonly known as ordinary bolts.

Ordinary bolts can be divided into three grades: A, B, and C according to the production accuracy. Grades A and B are refined bolts, and grade C is rough bolts. For connecting bolts for steel structures, unless otherwise specified, they are generally ordinary rough grade C bolts.

There are differences in the processing methods of different grades. Usually the corresponding processing methods are as follows: ① The bolts of grade A and B bolts are processed by lathes, with smooth surfaces and accurate dimensions. High, rarely used; ②C-grade bolts are made of unmachined round steel, the size is not accurate enough, and its material property grade is 4.6 or 4.8.

The deformation is large during shear connection, but the installation is convenient and the production cost is low. It is mostly used for tensile connection or temporary fixation during installation.

The equivalent translation of bolts is generally divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc. Among them, the bolts of grade 8.8 and above are made of low-carbon alloy steel or medium-carbon steel and are heat-treated ( Quenching, tempering), commonly known as high-strength bolts, the rest are commonly known as ordinary bolts. The bolt performance grade label consists of two parts of numbers, which represent the nominal tensile strength value and yield ratio of the bolt material respectively.

There are two types of bolt testing: manual and machine. Manual is the most primitive and the most commonly used consistent detection method. In order to minimize the outflow of defective products, general production enterprise personnel inspect the packaged or shipped products by visual means to exclude defective products (defective products include tooth damage, mixed materials, rust, etc.).

Another way is automatic machine detection, mainly magnetic particle inspection. Magnetic particle inspection is to use the interaction between the leakage magnetic field at the defect of the bolt and the magnetic powder, aiming at the difference between the magnetic permeability of the bolts (such as cracks, slag inclusions, mixed materials, etc.) and the magnetic permeability of steel, these materials are discontinuous after magnetization.

The magnetic field at the place will be turbulent, and a leakage magnetic field will be generated on the surface of the workpiece where part of the magnetic flux leaks, thereby attracting the magnetic powder to form the magnetic powder accumulation at the defect—magnetic traces. The accumulation of these magnetic powders is observed and explained, and the purpose of rejecting defective products has been achieved.

Market analysis of bolts: Advanced bolts are the foundation of high-end machinery manufacturing, and their role can be called “four ounces”. On the surface, the output value of bolts only accounts for a few percent of the machinery industry. In essence, the added value it brings to key components and equipment is much higher.

Over the years, after the continuous double-digit growth of Chinese bolts, the bolt industry experienced negative growth in 2012, down about 1.5% year-on-year, mainly due to insufficient market demand, especially after the bolts suffered from international anti-dumping, export sales declined. situation.

The competition in the bolt market is fierce, and it is moving towards brand management. In the past 10 years, the development speed of China Bolts has attracted the attention of the world, which surprised the developed countries, but also made them discover a new type of big market, and multinational companies filed in.

When domestic bolt companies suddenly feel that it is so difficult to survive in the market, powerful competitors have blossomed everywhere. In today’s Chinese bolt market, some small and medium-sized bolt enterprises manufacture a large number of common standard parts, which does not really bring core competitiveness to the enterprise, but is subject to changes in raw materials, labor costs and other conditions.

From 4.8 to 6.8 low-strength bolts, or 8.8 to 12.9 high-strength bolts, the production technology level of Chinese bolts will be basically close to the world’s advanced level, mainly ordinary standard parts and low- and medium-grade special and special-shaped bolts, with large quantities Inexpensive. It can be concluded that low-grade products flood the dominant market, and a small part of high-grade, high-precision, high-strength bolts still need to be imported, and the difference between the unit price of products imported and the bid price is about 6 times or more.

It can be seen that China’s bolt industry is still a developing industry by fastener suppliers, “big but not strong”, “fat but not strong”, and the gap with the United States, Japan, South Korea and Taiwan, my country, and lack of technical services to solve mechanical tightening. A solid solution to realize the digitalization of products, design, manufacturing and management, and the greening of products and manufacturing processes. It is understood that the development of Chinese bolts is under increasing pressure from resources and the environment.

An important way to alleviate resource constraints is to develop green manufacturing. The development of bolts will continue to be actively promoted in the direction of brand management for a period of time in the future, and promote the development of bolt projects in all directions.

In terms of products, mid-to-high-end products will accelerate the localization of quality research and development. The whole process from design, manufacturing, packaging, transportation, use to end-of-life disposal must consider the least waste, the lowest emissions, high resource utilization and environmental impact. Minimal, so as to optimize the coordination and optimization of enterprise benefits and social benefits.

In terms of circulation, explore various value-added service models to bring value and benefits to customers. From providing a single set of bolts to providing mechanical fastening solutions, customized services, remote monitoring, etc., the proportion of services in the sales revenue of bolt manufacturers will gradually increase.

Corporate restructuring is a trend, and strategic alliances seek development. At present, the low industrial concentration of China’s bolt enterprises has seriously restricted the improvement of China’s bolt competitiveness. The market opening over the years has not brought the core technology. In view of the above situation, the reorganization and strategic alliance between enterprises is a major trend. China’s bolt industry must conform to this trend and trend, strengthen strategic cooperation between enterprises, and improve the overall competitiveness of China’s bolts.

China’s growth in the field of bolt core technology lacks breakthroughs. At the same time, the living space of low-end products is getting smaller and smaller, and foreign capital through localized enterprises also has considerable cost advantages, coupled with the advantages of technology brands, and began to enter the market space of the original independent brands.