Types of Bolts and Their Functions: The Complete Guide to Understanding Bolts

Among the complex variety of fasteners that provide the essential holding of components, bolts are one of the main parts that can’t be missed in connections. Bolts are categorized as mechanical devices that join or hold two materials together for security and stability. They are often confused together with screws which are also mechanical devices due to the similarity of their threaded shanks, yet bolts have a distinct difference depending on their usage. As a crucial component of every structure and industry, let’s learn the types of bolts, their functions, general applications, material grades, advantages, and some of the top bolt manufacturers in this article.

What Is A Bolt?

Bolts are defined by classifying their body parts, material, grades, varying types, and their different applications. Generally, bolts have cylindrical bodies called shanks which are externally threaded partially or fully. They also consist of a head with various styles and types that create a functional purpose during use such as protection from leaks, eliminating loosening, and aesthetic appearance. There are numerous sizes of bolts in metric and standard, common examples include M4, M6, M8, 1/4 -20, 5/16-24, and 1/2 -13.

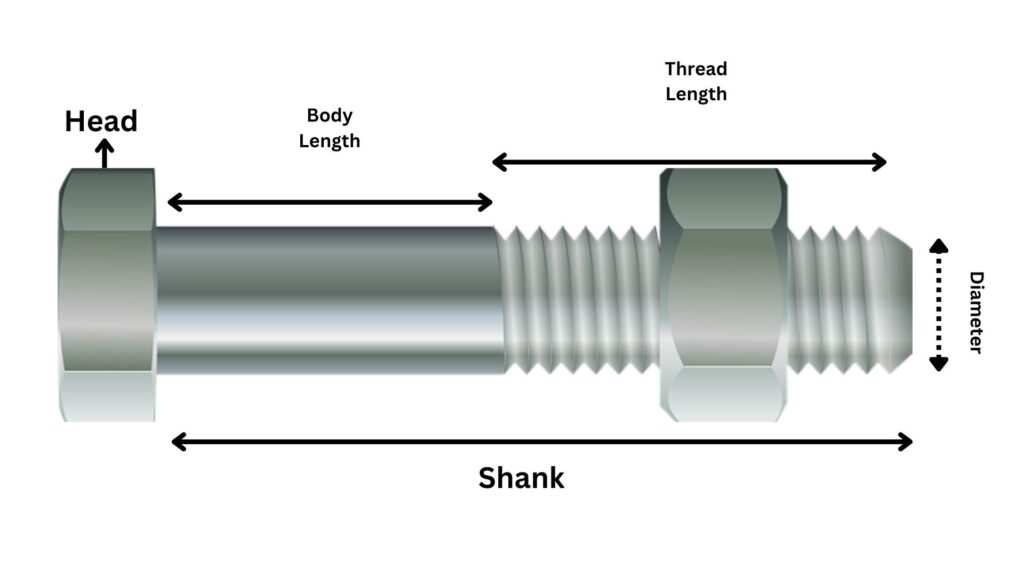

The Basic Components of Bolts

The Head of bolts is located at the other end of its body which is the portion wherein tools are inserted or driven into for tightening its body in materials.

Shank is the length of the body from under the head of bolts up to the other end.

Thread is the helical spline that spirals down in the shank of bolts creating the locking and tightening of components together.

How Are Bolts Made?

Like any other component, bolts are manufactured under high-quality equipment and machinery in three (3) common processes: cold forming, hot forging, and machining.

Cold Forming is a high-speed process of producing bolts at room temperature to form precise lengths and shapes. The process also gives increased strength low hardness and high ductility.

Hot Forging is the process of heating fastener materials at high temperatures to form the desired shape and dimension. It gives the bolts a consistent grain structure, improves tensile and yield strength, and becomes more malleable in the process.

Machining is an improved process of manufacturing fasteners in precision using machinery that cuts away materials in the desired shape and dimension.

Read More: The Life of Fasteners: Manufacturing Process of Bolts and Screws

General Applications of Bolts

Manufacturing, structural assemblies, engineering, and construction are some of the industries that widely use types of bolts in holding and securing assemblies together. Security and stability of various mechanical and industrial connections necessarily need bolts to ensure these items of machinery do not fail. Many operations in numerous sectors also depend on the capabilities of bolts to withstand heavy-duty applications in infrastructures like bridges, scaffoldings, skyscrapers, and more.

Material Specifications of Bolts

The characteristics of bolts are often a result of the type of material used in their manufacturing. Some of the most common bolt materials are stainless steel, carbon steel, alloy steel, titanium, brass, and more. Each material proposes significant qualities that become a disadvantage or advantage during and after using bolts.

Steel Bolts

Steel is a popular metal that is easily available in the industry and from bolts manufacturers worldwide. It provides several features in bolts such as corrosion resistance, durability, strength, heat resistance, low maintenance, and aesthetic appeal. Steel bolts have varying tensile and yield strength depending on the amount of material used in their production which is identified through markings or grades in its body usually found in the head.

Example: Grade 2 Bolts have low or medium carbon steel and can have a minimum yield strength of 36,000 to 57,000 psi and a minimum tensile strength of 60,000 to 74,000 psi.

Stainless Steel Bolts

Popular for its high quality and good strength, stainless steel bolts are the most common materials used by many industries and sectors for securing and joining parts in conjunction with nuts and washers. They are also highly corrosion-resistant and are considered marine-grade material making them able to withstand saltwater and its environment.

Example: Bolts in 18-8 & 316 Stainless Steel have a minimum of 20,000 psi yield strength and 65,000 to 150,000 psi tensile strength.

Brass Bolts

Brass material in fasteners is known for its robust quality and aesthetic appearance. Brass bolts are suitable for tough and demanding applications due to their resistance to corrosion, rust, and wear which results in long-lasting performance. General applications like woodworking, furniture assembly, and some outdoor assemblies are examples of applications of brass bolts.

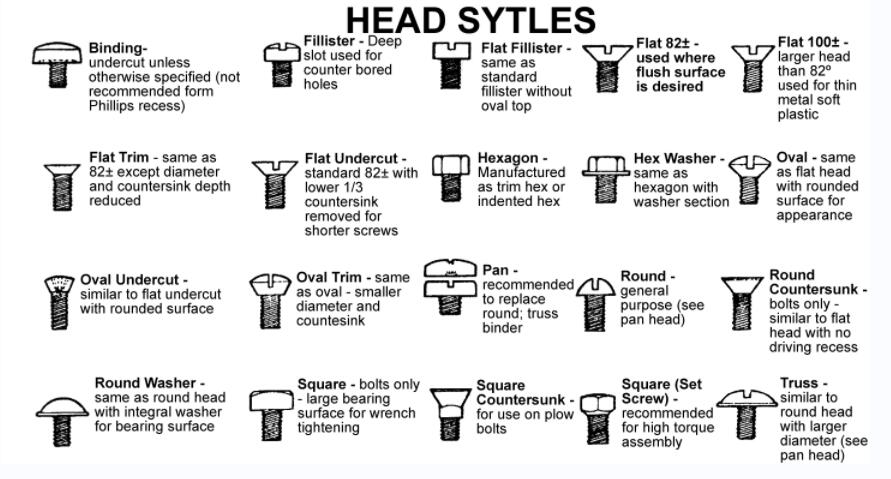

Bolt Head Types and Their Functions

Flat Bolt Head: This type of bolt head is a countersinking head that is designed to rest flush with the surface of the material. Flat bolt head provides a low profile in applications.

Oval Bolt Head: Another countersunk head type of bolts that is shaped like an oval.

Hex Bolt Head: Consists of six sides in the head or hexagon sides which is commonly used for general applications due to their ease of use with standard tools.

Socket Cap Bolt Head: A cylindrical-shaped head that requires a socket driver for installation and removal. Socket cap head bolts require a high level of torque for tightening and holding parts together.

Slotted Hex Washer Bolt Head: This unique type of bolt head provides a built-in washer feature and a slot for tightening and loosening. The washer feature helps distribute the load from its application into the surface of the material to eliminate fastener failures such as cracking or breakage.

Common Types of Bolts and Their Advantages

Numerous types of bolts have specific functions and features in the suitability of the kind of environment and challenges they are used for. Below is the list of the most common types of bolts in their significant characteristics and advantages.

Hex Bolts

Hexagon bolts have six-sided caps in the head which easily gives a proportion for tools in tightening or joining the parts together. This type of bolt is common for general applications meant to be used along with nuts and washers for a successful fastener assembly.

Carriage Bolts

This type of bolt was named after its traditional use in building carriages for the security of holding parts together and is known to be versatile. Carriage bolts are defined by their domed heads and various sizes and materials. Their common advantage includes less hassle during installation and removal with the help of standard tools.

Lag Bolts

There are various benefits of lag bolts in applications such as tough quality which offers durable properties and exceptional strength. They are usually employed in decks, pergolas, and other outdoor and indoor assemblies that require securing heavy items to wooden materials.

Eye Bolts

This bolt has a unique head that is shaped like an eye or a circle which is essential for the kind of applications they are used. Eye bolts are used for securing attachment points like rigging, anchoring, pulling, pushing, and hosting connections of components.

Want to have customized bolts for specific projects? Send us your inquiries and the demands of your application, visit our page and read more here: Custom Bolts Supplier and Manufacturer

How to Choose the Right Bolts?

Every fastening comes with various challenges and requirements that influence the selection of the type of bolts to use. In some specific and intricate applications, customization is an option to provide accurate features that are crucial to match its needs. Custom bolts can be supplied by direct manufacturers and suppliers that specialize in creating solutions for optimum security and stability. While general bolt applications can require simple steps that help to choose the right bolts such as the following:

1. Select the Right Material

The primary step in choosing bolts for projects is selecting the bolt material that can suit environmental conditions and challenges like withstanding heat and corrosion. The right material should be able to provide the required strength in bolts for durability. Some materials also improve the life span of bolts in assemblies which allows less maintenance and repair.

2. Know the Size

Bolt sizes are technical properties that are important in the success of their performance. Longer size of bolts can result in permanently damaging the materials during installation while shorter bolts can cause gradual loosening and fastener failure. To determine the right size of the bolts you can measure the diameter of holes or simply place the bolts inside to know the right fit in both length and diameter size.

3. Use the Suitable Thread Type

Bolts have external threads that can go partially or fully in their shank. The threads can be classified as coarse or fine threads which can be introduced in various types of metric or standard.

Standard thread in bolts are regulated by UTS or Unified Thread Standard and SAE or Society of Automotive Engineers which specifies the thread properties for general purposes.

Metric standards for bolt threads are defined by ISO or International Organization for Standardization and DIN or Deutsches Institut für Normung the German standards commonly followed in Europe.

Read More: Fastener Thread Terminology and Terms

Industry Applications of Bolts

Beyond the simple task of connecting and holding parts together, bolts provide the crucial role of securing the overall functionality of machinery, engines, structures, and other industrial applications. Here are the best examples of industries that use bolts in a wide range of fastening and joints:

Construction

From residential to commercial buildings, bolts and other types of fasteners are the backbone of connections and security in its structures. Bolts are applied in numerous construction applications like support in roofing, walls, ceilings, window framing, etc.

5 Types of Bolts Used in Construction

- Carriage Bolts

- Flange Bolts

- Hanger Bolts

- Hex Bolts

- Stud Bolts

Automotive

Automotive is a wide and complex industry that largely employs various types of fasteners from screws to rivets and different kinds of adhesives. Bolts are common parts of many automotive applications such as engines, vehicle bodies, electrical configurations, frames, and more.

5 Types of Bolts Used in Automotive

- Blind Bolt

- Hex Bolts

- Socket Head Bolts

- Structural Bolts

- Hanger Bolts

Marine Industry

Marine applications are considered one of the most demanding environments for bolt applications due to the exposure to harmful elements such as saltwater, fluctuating temperature, and load or pressure. Stainless steel bolts and brass bolts are suitable materials that can withstand corrosion caused by saltwater. The most particular grade for bolts in marine is 316 stainless steel with a mix of molybdenum – a metal that enables the material to withstand years of exposure to saltwater.

Know About Bolts Manufacturer and Supplier

Importance of Choosing a Reputable Bolt Manufacturer

Choosing bolts and a manufacturer that can deliver the demands of your industry or project requirements is an essential part of having a successful operation in fastening. Without a reputable supplier of bolts, complications may arise during the transaction and actual installation process, especially with the lack of proper technical support. A good manufacturer of bolts can benefit the customers in several ways cost savings, quality service, timely delivery, reliability, inventory management, and more. Thus finding a good bolt manufacturer is as necessary as selecting the right type of bolt before purchasing.

Benefits of Bolt Manufacturers for Industry Projects

- Bolt manufacturers provide timely delivery of products and quality customer service

- Bolt manufacturers ensure high-quality fasteners for distribution with the use of advanced technology

- Bolt manufacturers help make profits for distributors and wholesale retailers with the offer of factory-cheap prices

- Bolts manufacturers offer customization of features and design of bolts to suit the needs of their application

- Bolts manufacturers provide strict inventory management and a modernized approach to selling fasteners in different markets

- Bolts manufacturers have a wide variety of types, sizes, and designs to offer

Read More: Building Better Supply of Industrial Fasteners with Fastener Manufacturers

Top Bolt Manufacturers for Specific Industries

Prince Fastener Manufacturing Co., Ltd. is an expert manufacturer of industrial fasteners that specializes in custom manufacturing of bolts, screws, nuts, etc. for specific needs of businesses and industries. The company offers a wide variety of standard and non-standard bolts for general and intricate applications with customization needs in materials and design. We offer accurate solutions that provide reliable and secure connections of parts and components. We have over 30 years of experience in delivering high-quality bolts and exporting wholesale or bulk bolts and fasteners for a wide variety of industries.

Read Here: High-quality Galvanized Fastener Bolts and Screws