Prince Fastener:How to distinguish stainless steel screws, galvanized and nickel -plated screws?

From the appearance, the method of distinguishing stainless steel screws, galvanizing and nickel -plated screws is to see the color of the screw. The color of the stainless steel screw is close to the original color of the iron. In addition, it can also be used to distinguish stainless steel screws, galvanized and nickel -plated screws with magnets, oxidants, and strong acidic alkali, spectral spectra.

Standard pieces screws include bolts, screws, screws, nuts, machine screws, self -attack screws, pads, sales, rivets, and ten categories. It is a basic part that is widely used in all aspects, and its function is to play a solid effect. The connection form can be divided into detachable connections (using screw fasteners such as bolts, nuts and other threads) and permanent connection (using rivet connection).

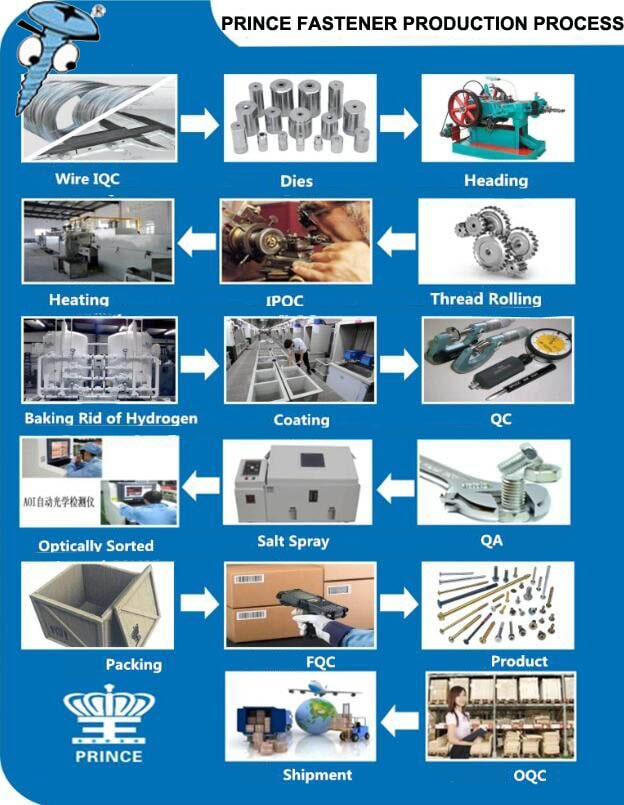

The production process of the screw is as follows:

How to distinguish stainless steel screws, galvanized and nickel -plated screws from appearance?

First distinguish by color:

Stainless steel is the original color of iron.

Galvanized screws are white, color, black.

Nickel -plated screws are silver.

1. Stainless steel screws are made of stainless steel. The color of stainless steel is mainly iron and carbon alloy, so the color is close to the color of the iron;

2. The surface of galvanized screws has white zinc, zinc, black zinc, etc., so the color of galvanized screws is generally white, color, and black;

3. The color of nickel -plated screws is related to nickel, and it generally presents very bright silver.

Divide stainless steel screws, galvanized and nickel -plated screws other methods

1. Magnetic distinction: 3 series of stainless steel are generally not magnetic, and stainless steel screws cannot be adsorbed by magnets (410, such as 410, galvanized and nickel -plated screws can be adsorbed by magnets.

2. Division of oxidant: Metal nickel has a strong passivation ability. When plating, it can quickly generate a layer of extremely thin passivation on the surface. Zinc, there is nothing to do on the surface of stainless steel, which can be distinguished in a strong oxidant.

3. Differentiated with strong acid and strong alkali: stainless steel contain chromium and nickel. It has a strong corrosion resistance. It is not corroded by strong acid and strong alkali. There is a layer of passivation film on the surface of the nickel -plated screws. The fastest corrosion.

4. Use a spectrometer to analyze the elements of the metal.

Summarize:

From the appearance, the method of distinguishing stainless steel screws, galvanizing and nickel -plated screws is to see the color of the screw. The color of the stainless steel screw is close to the original color of the iron. In addition, it can also be distinguished from stainless steel screws, galvanized and nickel -plated screws with magnets, oxidatives, and strong acidic alkali.

In addition, hot -dip galvanized screws have the following advantages:

1. Low treatment costs: The cost of hot -dip galvanizing and rust -proof is lower than the cost of other paint coating;

2. Good reliability: The galvanized layer and steel are a combination of metallurgy, which becomes part of the steel surface, so the durability of the coating is more reliable;

3. Strong toughness of the coating layer: Galvanized layer forms a special metallurgical structure. This structure can withstand mechanical damage during transportation and use;

4. Comprehensive protection: Each part of the plating can be plated with zinc, and it can be fully protected even in the depression, the sharp corner and the hidden place;

5, Time -saving and effort: Galvanizing process is faster than other coating construction methods, and it can avoid the time required to paint on the construction site after installation.

In addition, the mechanical performance level of galvanized screws can reach 8.8 levels, while stainless steel screws can only be -70 at most, such as A2-70 and A4-70, which is equivalent to level 7, which is lower than galvanized screws.

Therefore, the use of galvanized screws is wide than stainless steel screws, and the amount is more than stainless steel screws.

However, it should be noted that the galvanized screws cannot be completely replaced by stainless steel screws. It is not better than stainless steel screws in corrosion resistance. Therefore, the appropriate material should be selected according to the occasion of use.

Will stainless steel screws rust?

Many people think that the non -standard screws of stainless steel will not rust. In fact, this is a wrong understanding. Although stainless steel non -standard screws are not easy to rust compared to iron screws, they do not mean that they will not rust at all. That is to say, they have a good rust -proof ability, and it is easy to rust in a certain ring. A rusty environment!

Generally speaking, the non -standard screws of stainless steel have good characteristics, resistance to corrosion, high temperature resistance, and strong rust resistance, but if it is stored and used in a humid environment for a long time, the screw surface rust is inevitable.

In addition, if the non -standard screws of stainless steel are stacked with some acid -base chemicals, a chemical reaction may occur, causing the screw to rust

There are also some occasions that are not suitable for using stainless steel non -standard screws. For example, in the sea, because the sea water itself contains salt, these screws are soaked in seawater for a long time.

It can be seen from the above that in some environments, the non -standard screws of stainless steel will rust, so when using this screw, pay attention to the environment and use it reasonably.

How to check the quality of stainless steel screws?

With the great improvement of international economic living, the scope of application of stainless steel screws is becoming wider and wider. It is mainly used for: environmental protection equipment, medical equipment, communications equipment, power facilities, electronics, instruments, petrochemicals, ships, pipelines, curtain walls, open -air occasions, sports facilities, outdoor decoration, etc. Because of the common application, some people are charged in the secondary and use other material screws to sell stainless steel. So how to judge whether the stainless steel screws are qualified?

1. One of the methods that everyone knows is to take magnets to suck the screw. If there is no response, this one is stainless steel screw, but this method is not accurate, because some stainless steel screws are also micro -magnetism, even if there is no, there is no no matter Magnetic stainless steel materials may also produce magnetic or weak magnetism during production and processing. Magnetic can only detect a part of stainless steel type.

2. In the inspection of the material, we usually use the stainless steel material detection agent of the page to drip it on the screw and wait for a while to see the result. If conditions permit, you can also find third -party testing agencies to help them help test the pages of this screw to get the page, accurate results.

3. Whether a stainless steel screw is qualified, we can distinguish from the appearance to see if the surface of this screw is smooth, flat, and whether there is a burr. If there is an electroplating The thickness of the plating layer is measured by a thousand feet or a barren caliper.

4. When detecting the adhesion intensity of the stainless steel screw coating layer, we can use friction and polishing, scratching method, and knife. After these plating conditions are paid in the industry, let’s see that this is not a qualified stainless steel screw.