OEM & ODM Self-drilling Screws for Thick Steel

Want to manufacture the precise specifications of your self-drilling screws? Prince Fastener has the solution and accuracy to generate an ascending revenue for our clients. Few reasons to consider;

Have you been searching for a leading fastener manufacturer that ensures your standard demand will be met?

Prince Fastener has developed innovation in excellent productivity, analysis, and distribution of products. Here’s why we stand out;

- Accept OEM and ODM on self-drilling screws for thick steel

- Facilitate according to your design and requirement

- Factory direct from a leading manufacturer in China

- Unmatched reasonable costs of the overall customization process

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our OEM & ODM Self-drilling Screws for Thick Steel for wholesalers and importers.

Quick View

- → Why Purchase OEM/ODM Self-drilling Screws for Thick Steel from Prince fastener?

- → Hot products for Custom Self-drilling Screws

- → The Estimated Cost Value of OEM and ODM Self-drilling Screws for Thick Steel

- → Mass-production and Delivery Period of OEM and ODM Self-drilling Screws for Thick Steel

- → How are Custom Self-drilling screws made step by step?

- → Gradual Way of Factory OEM and ODM Self-drilling Screws for Thick Steel Supply

- → Fields in Massive Use of Self-drilling Screws for Thick Steel

- → Materials and Composition of Self-drilling Screws for Thick Steel

- → Dissimilar points of OEM (Original Equipment Manufacturer) vs ODM (Original Design Manufacturer)

- → Prince Fasteners’ Pivotal Role in Fabrication of Screws

- FAQs About Self-drilling Screws for Thick Steel

Why Purchase OEM/ODM Self-drilling Screws for Thick Steel from Prince fastener?

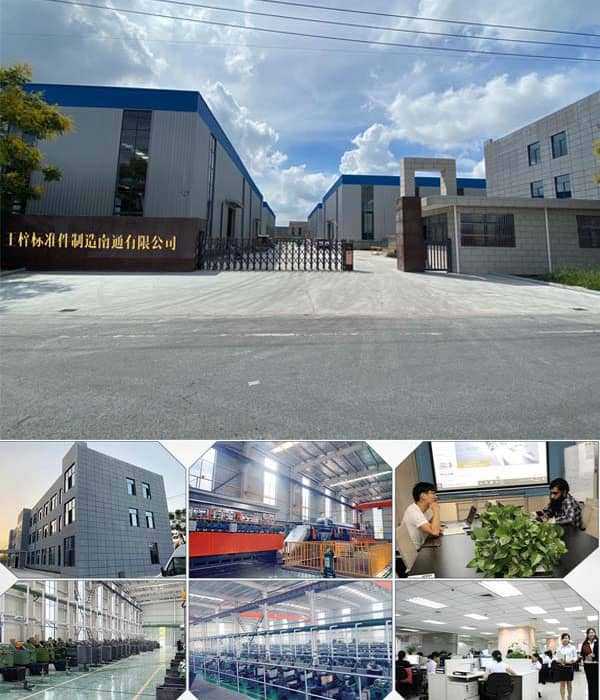

Prince Fastener has advanced specialization in producing the best quality fastener screws, especially the specific kind of self-drilling screws for thick steel. The innovation conducted in the process of manufacturing self-drilling screws for thick steel has passed high quality as well as the international standard. The use of utilizing a wide selection of machinery from Taiwan as follows are; Head making machines, Thread rolling machines, Net furnaces, and examining types of equipment such as Micro hardness tester, Microstructure tester, etc. To fully comply with the demand of the market industry, Prince fastener does not only stop at developing the best fastener products but ensures the best-valued service available to the clients and customers.

As a proof of quality check, Prince fastener products have been sold and supplied to big brands in over 100 different countries under multiple international standards such as GB, DIN, JIS, and ANSI.

Prince Fastener delivers what is expected from the product design and does its best to arrange the quantity of manufacturing in the shortest possible time. Self-drilling screws for thick steel can be customized depending on customer specifications for size, material, hardness, head or heat treatment surface treatment, and coating.

Hot products for Custom Self-drilling Screws

Self-driling Concrete Screw

Self-drilling Metal Screw

Self-drilling Screw for Plastic

Hexagon Head Self Drilling Screw

Self-drilling Screw Wood

Self-drilling Screw for Thick Steel

Self-drilling Screws

Self-drilling Screw for Steel

Custom Self-drilling Screws

The Estimated Cost Value of OEM and ODM Self-drilling Screws for Thick Steel

Production process and materials

Integrating the best resources in raw materials is one of the reasons why Prince fastener leads in manufacturing self-drilling screws for thick steel. Such components are classified accordingly in the use of the following: carbon steel, stainless steel, zinc, iron, aluminum, free-cutting iron, zinc aluminum alloy, copper, etc.

Free sample of OEM & ODM self-drilling screws for thick steel

Prince fastener gives importance to every inquiry that comes into our reach, which is why we cater to providing free samples of OEM or ODM self-drilling screws for thick steel. Clients will only take responsibility for the shipping costs of the complimentary products.

Shipping quotation

This quotation refers to the exportation fees encountered before arriving at its end destination via sea and air transport.

Packaging of Self-drilling screws for thick steel

Prince Fastener provide the complete experience of manufacturing products to the extent that we customize with special requests in packaging and branding the self-drilling screws for thick steel to your choice of packaging design.

Customized factory high-class OEM & ODM

Prince fastener defines the capability of increasing the desire into achieving the same goals our clients require. We analyzed and innovate the products, develop the design and customize them accordingly to the required classification in characteristics.

Freight Charges

This is the total cost of miscellaneous, customs, and clearance fees.

Want to cooperate with Fastener factory?or you want to get custom fastener?

Prince Fastener Is Here for Creating Quality Screws With Competitive Costs for You,and Offer the Technical Supports and Exclusive Services for Your Business.

Mass-production and Delivery Period of OEM and ODM Self-drilling Screws for Thick Steel

Prince Fastener can only increase manufacturing and development in order to meet the demand in the industry for custom self-drilling screws. Final results will always be guaranteed in excellent quality and value as the process we take in every step will always be to prioritize exceptional service as a mission. To estimate the time process of every production of custom self-drilling screws we take deep research and indulge in the attributes of the best brand we can supply. Hence, the precision of results is well-taken care to the potential of the capacity to develop future success. The evaluation of delivery and transportation of our custom self-drilling screws can only be estimated to the course of logistics in your area as well as domestic cases but it is for certain that these characteristics play a vital role in every transaction. In exaggeration, our high volume in production to meet your demand in the request for custom self-drilling screws is as competitive as we are in product quality and manufacturing experience in an extension of our incomparable service profile.

Design and Manufacturing process

The system used by Prince fastener in achieving maximum productivity showcases the top-tier factory equipment supplied from Taiwan.

Packaging of self-drilling screws for thick steel

We take checklists in packaging the self-drilling screws for thick steel into pp bags or small white boxes before putting them onto the box and packaging them well.

Exportation of OEM & ODM self-drilling screws for thick steel

Completing the initial steps when purchasing fastener screws some additional and vital element to manage will be the exportation process through sea or air transport.

Final and local logistics

This part is the near-end final process of receiving the products. Clients will have to wait for the hauling of self-drilling screws for thick steel at their local port before delivering the package to the destination to be completed.

Prince fastener will introduce you all the process of the Custom Self-drilling screws production.

Prince fastener production process

Basic concepts of Prince Fastener screw production

1、Prince Fastener Manufacturing screw can be divided into: cold heading, hot machining (turning, milling, etc.)

2、Cold heading is the use of plastic metal, by using cold mechanical pressure or drawing, reaches the metal solid deformation of.

3、Hot upsetting is the material after heating and pressure processing make the shape of the material to meet the

designrequirements.

4、Prince Fastener Machining is a small batch of special or special bolts of the six corners of the head is turned into after the milling.

5、 Screw bolt thread: mechanical and manual threading, similar to die.

6、 Milling tail: generally completed by the end of the Prince Fastener cutting machine.

7、 The difference between cold and hot upset: cold heading bolts` surface are more beautiful, dozen red bolt surface oxide skindoes not look good; cold heading high production is efficiency; general Prince Fastener M24 bolts will need to play red;

Analysis of the causes of the phenomenon and the causes of the forming process

1、Eccentric: two red and improper installation and adjustment machine.

2、Minow: a poor installation and improper Prince Fastener adjustment machine at.

3、Head is not round: the choice of a die or a punch forming is not enough.

4、Play the mode of crack: crack or die R angle, so that the model is hit by the two collision.

5、Head double: bad punch.

6、Flash: a bad, punching molding is mainly between punch and die hole clearance is too large or too short by red bars.

7、Crack angle: the punch needle burst or two punch and punch is not heavy.

8、Head cracking: material, or a die using error (such as pan head Hexagon washer head of a die), and lubricating oil.

Analysis of adverse phenomena and causes of common rolling

1、Processing crack: tooth plate and adjust the Prince Fastener old machine.

2、Blunt tail: the machine is not properly adjusted, the tooth plate is too old.

3、Crooked tail: the control screw on the seat board seat is too tight.

4、Tail: tooth wear plate and improper adjustment machine.

- Head making machine

- Thread production via thread rolling machine

- Forming machine

- Heat treatment

- Further quality testing

Head making machine

The material used in Prince fasteners’ self-drilling screws for thick steel starts from a blank piece of wire that will be measured differently depending on the gauge size and diameter of the screws.

Thread production via thread rolling machine

The next step includes transferring the measured length of wire to the thread-rolling machine where it will processed to be shaped before it goes into the hardening process.

Forming machine

The products then undergo into a forming machine that forms the thread to perfection in tensile.

Heat treatment

After the hardening process, screws will be heated and cooled in the treatment process to ensure durability, strength, and unequaled drilling performance.

Further quality testing

Providing the best fastener product Prince fastener will go beyond the scales and perform further testing in self-drilling screws for thick steel through microhardness and microstructure machine testers, etc., or as requested by the clients.

With a summation of more than 200 factory machines that can produce 600 tons of fastener screws together with self-drilling screws for thick steel, Prince fastener can manufacture 10,000 tons with more capacity in total annual production. How do we make it possible? With our world-class production and testing pieces of equipment, we don’t only aim for the standard quality of self-drilling screws for thick steel but also strive to be the best service provider and guarantee 100% customer satisfaction.

Fields in Massive Use of Self-drilling Screws for Thick Steel

In Prince fasteners’ accumulated development of production scale the use of fastening products is recognized in a wide range of industries.

The area of fields in an industry that self-drilling screws for thick steel are used in application is vast to the sense that there can be more unfamiliar usage of this fastener product. The following images are just to recognize the importance of value they can offer especially in production of another useful pieces of equipments.

Materials and Composition of Self-drilling Screws for Thick Steel

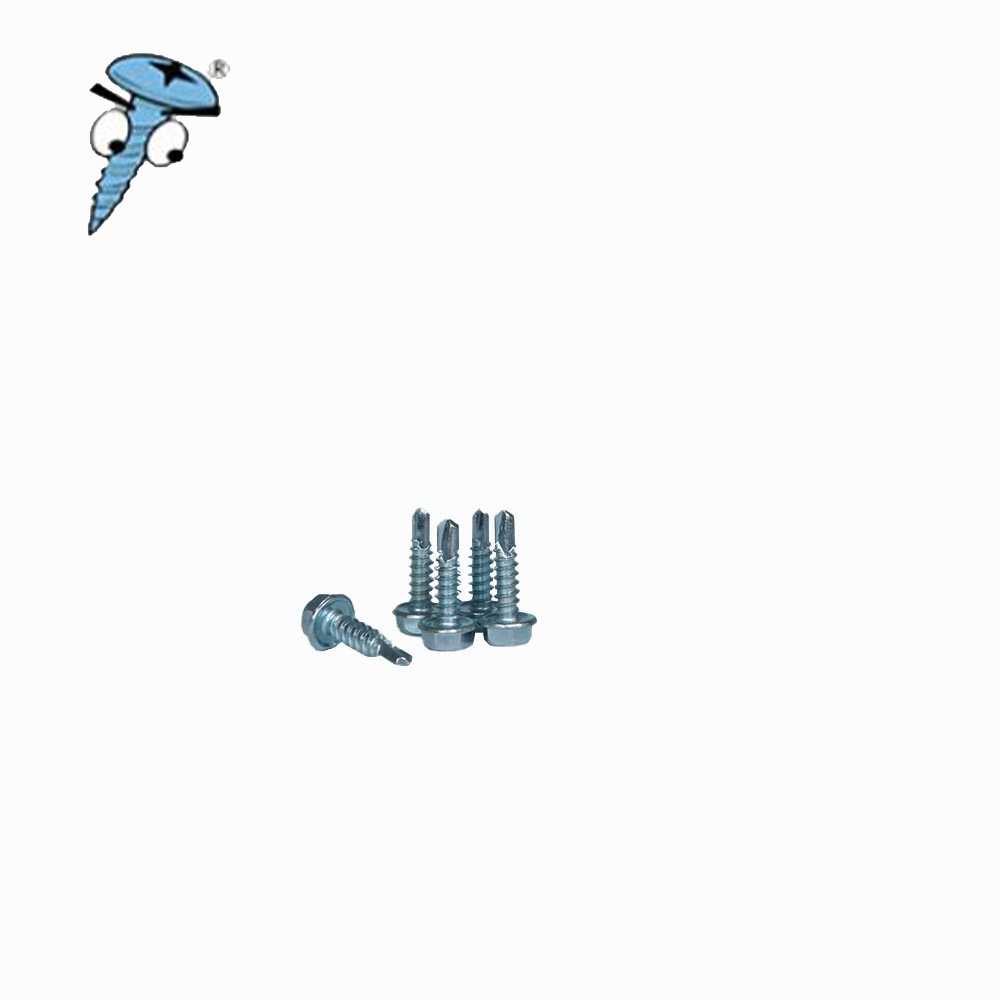

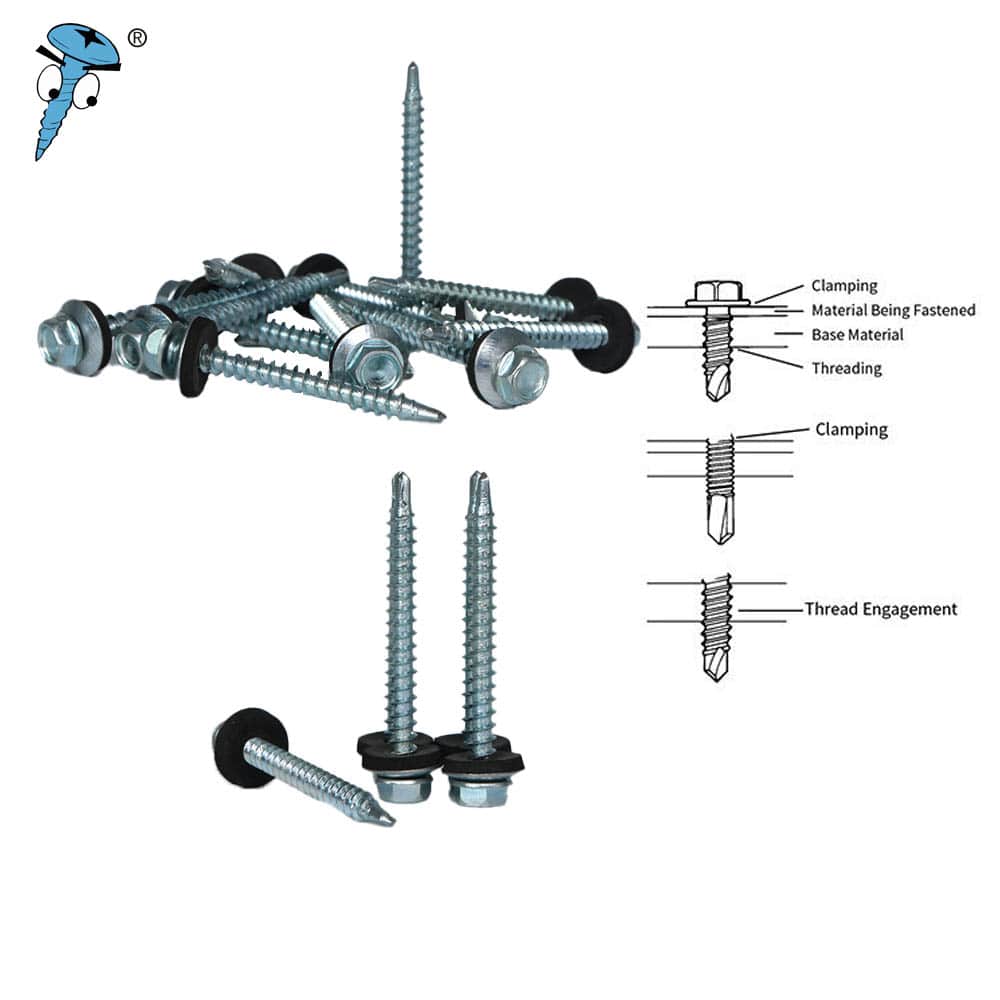

The type of self-drilling screw for thick steel has a range of factors that differentiates it from the other fastener screws starting with its size, feature, form, application or usage, and components of raw materials used to produce it.

The main material used in a self-drilling screws for thick steel is carbon steel which enhances the strength, ductility, and resistance to embrittlement and corrosion as well as having the drill bit which eliminates the pre-drilling process of fastening.

The availability of sizes for self-drilling screws for thick steel in outer diameter are 2.9mm-6.3mm;length 6.5mm-120mm. While the head types differ from hexagon head, pan head, countersunk head, round head, truss head, half countersunk head, or as custom order requires. To achieve maximum quality and fulfill incomparable reliability of self-drilling screws for thick steel the following production process is a standard for Prince fastener in manufacturing, we follow surface treatment such as galvanizing, chromium plating, phosphating, electrophoresis, dacro, hot embroidery, and 48-72 hours of salt spray test.

The known effectivity in performance is applied to building decoration, household appliances, auto parts, electronic equipment, hardware and electrical machinery, aviation and military industry, infrastructure, furniture industry, outdoor leisure goods, etc. As for package structures of the self-drilling screws for thick steel, they are packed accordingly with a box, carton, and pallet to ensure the safety of the fastener supplier goods in transport. Moreover, prince fastener also specializes in and produces long screws, non-standard screws, titanium screws, small screws, stainless steel, hardware screws, brass screws, iron screws, stainless steel screws, alloy steel screws, bolts, screws, nuts, washers, other related parts, and orders for special specifications.

Dissimilar points of OEM (Original Equipment Manufacturer) vs ODM (Original Design Manufacturer)

Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) are two acronyms that anyone had bumped into the e-commerce world. Many explanations and distinct information are being pointed out online to educate like-minded people and help them to carry on the important step of research.

OEM and ODM cover a global scale in different kinds of industry and not only on mechanical screws such as self-drilling screws for thick steel. In the business sector, a manufacturer plays a pivotal part in landing a predominant success. Many businesses and big brands today are known to have an involvement with a manufacturing companies mostly found in parts of China. The Chinese factories are notable for producing countless common goods available all around the world, which is why you would likely find innumerable manufacturers from the country that offers such services as self-drilling screws for thick steel. But what makes Prince fastener stand out among the rest is the proof that it is continually operating in quality for more than 30 years without an offset record.

The things to remember about Original Design Manufacturer (ODM) to help us identify the set of variability it has to offer will be that, ODM is the product itself ready to be leased out to manufacturers with fewer modifications as it is already set to be in the market for specific use and available for rebranding and selling.

For a shorter classification of what ODM and ODM customers do, you can check this link.

Meanwhile, Original Equipment Manufacturer (OEM) is the service that a manufacturing company renders out to another organization that has made their own particular details in designs, classification, product development, concept, and requirements into producing or manufacturing products just like how Prince fastener supplies self-drilling screws for thick steel to well-established companies internationally.

Prince Fasteners’ Pivotal Role in Fabrication of Screws

Let’s start to acknowledge why Prince fastener plays a crucial importance concerning the development of success in OEM (Original Equipment Manufacturer) & ODM (Original Design Manufacturer) enterprises for self-drilling screws for thick steel. As a leading wholesale manufacturer in mainland China, Prince fastener has a rich experience of over 30 years.

Since it’s establishment the main focus of the company has always been to accumulate sustainability in development, production of high-quality fasteners manufacturer, innovation in technology, a platform with a qualification rate of 100% (hence the accreditation we have received from international standards), and sales strategy focusing on the guaranteed quality of service. Prince fastener is continually growing over the years yet we never fail to provide our expertise and knowledge in ensuring the best craftsmanship on self-drilling screws for thick steel and other related fastener products. The competence we cover in custom screw production also gives our company the praise that strongly advertises our exceptionality among the other screw factories in the world.

The 5W’s of OEM & ODM Self-drilling Screws for Thick Steel

The 5 W’s stand for What, How, Why, Who, and When. These are the basic questions to ask when gathering information on a certain subject, which is the discussion regarding OEM & ODM Self-drilling screws for thick steel to fully elaborate the ideal preferences any client can set when deciding to manufacture fastener products especially self-drilling screws for thick steel.

The ‘What’

As the worldwide economy is known to have industry fluctuations, an expanding number of manufacturers of fastener screws continues to pile up on the stock market. Many organizations are finding their way into the industry of supplying self-drilling screws for thick steel and other fastener products. Therefore the introduction of customizing and production of new designs is favorably increasing and gaining importance to the present day.

To highlight the roles of OEM and ODM in self-drilling screws for thick steel, we will define it accordingly with the detailed structure in the production process up to the service for the client’s end. The prominent abbreviation terms OEM or Original Equipment Manufacturer is a contract between businesses to develop and build products solely to market for retail use. Meanwhile, ODM stands for Original Design Manufacturer and refers to the products manufactured and ready to be leased by a well-developed company.

The ‘How’

Usually when companies have established their own product development, research and designs they opt on choosing a manufacturer that can facilitate the demand and finalization of products to lessen the production costs and for more other reasons. This is where Prince fasteners role becomes vital in the industry as a flexible one-stop fastener screws shop specifically in self-drilling screws for thick steel. Prince Fasteners’ availability in providing service on specializing screws opportunely renders Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) solutions to organizations. These two acronyms doesn’t only applies to technical materials as it is also known to a vast field of products such as clothing, furniture, automobiles, chemicals, computers, consumer electronics, electrical equipment, heavy machinery, refined petroleum products, ships, steel, tools, etc.

The ‘Why’

The benefits that various stakeholders will achieve in choosing Prince fastener as a supplier for factory manufacturing of fastener products will be a definite success. As we are already known to commit with foreign screw distributors and screw manufacturers as well as

users in niche industries on meeting the supply of the highest quality of self-drilling screws for thick steel.

The ‘Who’

On the road to achieving the picture of success, we are most confident with the team of people that works behind the production, management, engineering, sales, marketing, and overall company workers who put all the efforts into meeting the innovation of high volume production and supply chain. Prince fastener is always developing the standard quality screws especially when it comes to self-drilling screws for thick steel for the purpose that these fastener products are widely used in different industries and can be basic sub-part to produce another product.

The ‘When’

The common goal that manufacturers share is to secure success in the future. Prince fastener emphasized excellence in production, development in research, the competitive market, the course of logistics, and the prioritization of exceptional service. Which are all believed as the key factors to recognize the best option in deciding which company can strategize and supply to meet your demands.

FAQs About Self-drilling Screws for Thick Steel

Quick Index

4,What are the cons of self-drilling screws for thick steel?

5,Why do self-drilling screws for thick steel break?

6,What’s the standard grade is self-drilling screws for thick steel made?

7,How do you install self-drilling screws in the thick steel and what tool do you use?

8,Are self-drilling screws the same as tek screws?

9,What’s the best self-drilling screw to use for fastening steel?

10,How strong can self-drilling screws for thick steel be?

1. What are the advantages of OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) businesses?

There a far more reasons for considering the choice of having OEM or ODM service. Fortunately enough with Prince fastener clients can examine their choices well as we give the outermost transparency in our company business operation, management, B2B dealership, and other professional services we offer.

2. What’s the total number of self-drilling screws for thick steel or fastener screws produced by Prince fastener?

We have accumulated an extraordinary number of 430 billion screws for more than 1400 companies with the exclusion of 5000 kinds of customization experiences.

3. How do I choose between OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) for self-drilling screws for thick steel?

Price fastener is mostly open to discussing the terms of dealership and business contract through both options of OEM and ODM on self-drilling screws for thick steel.

We have the best quality of service that any client will want as their supplier.

4. What are the cons of self-drilling screws for thick steel?

We know that thick steel is one of the toughest materials to work on fastening or drilling but as the development of the screw industry made it possible and easier on installing fastener screws, the best type to use for a tough surface like thick steel is the self-drilling metal screws.

5. Why do self-drilling screws for thick steel break?

When self-drilling screws for thick steel encounters a failure or even break on installation certain reasons can be the cause. It can be the improper use of the screw on the material you are working on or the drill pressure and positioning of a screw.

6. What's the standard grade is self-drilling screws for thick steel made?

Prince fastener screws are made of carbon steel which is proven to have more effectiveness in use and is considered safe material for self-drilling screws, The main grades of carbon steel are the following: 4.8, 4.8, 6.8, 8.8, 10.9, 12.9 grades and the main materials are stainless steel SS201, SS304, SS316 and various galvanized and brass materials.

7. How do you install self-drilling screws in the thick steel and what tool do you use?

There can be a list of tools you can use in drilling the screws to thick steel but the most common tool in use is a hand-held or electric screwdriver.

A video clip provided in this link will show you how efficiently self-drilling screws for thick steel can work.

8. Are self-drilling screws the same as tek screws?

Tek screws are basically just self-drilling screws which have the drill bit end that allows easy drilling on thick surfaces. Being said, tek screws are the brand name of self-drilling and self-tapping screws.

9. What’s the best self-drilling screw to use for fastening steel?

Some types of screws can be in use for fastening steel but nothing can be compared to using the proper kind of screw which is the self-drilling screw for thick steel. It can be applied perfectly with ease of pressure and less work from pre-drilling the surface with the help of a proper tool.

10. How strong can self-drilling screws for thick steel be?

With Prince fasteners’ specialization in quality kinds of screws especially self-drilling screws for thick steel, we are known to create the best hardware screws proven by the adequate presence of our company for more than 30 years and counting in service.

11. What are other custom screws your company has produced?

We have an experience with producing M1-M14 special screws, long screws, shoulder screws, small screws, titanium screws, stainless steel screws, etc. according to the sample requirements or drawings from the clients.

12. What payment methods does your company accept?

We accept payments by TT, L/C, and western union.