Private Label Self-drilling Concrete Screws

Committed to service in meeting your customization needs of industrial fastener screws.

Prince fastener exclusively outsources the perfect fastener products with the promise of delivering to your specifications under quality features.

Communicate with us today and find out why we are the top choice among other manufacturers of Self-drilling concrete screws.

- Reasonable costs of materials and service

- Transient reply to inquiries and quotation requests

- Offers private-label brand on self-drilling concrete screws

- Exceptional quality and quantity in productivity

Hi,i am Lacier,the manager of Prince Fastener,glad to have a chance to introduce our Private Label Self-drilling Concrete Screws for fastener wholesalers and importers.

Quick View

- → Why Choose Prince Fastener as Manufacturer for a Private Label Self-drilling Concrete Screws?

- → Hot products for Custom Self-drilling Screws

- → Estimated Wholesale Price for Self-drilling Concrete Screws

- → Estimated Self-drilling Concrete Screws Production and Delivery Time

- → How are Custom Self-drilling screws made step by step?

- → Searching for Self-drilling Concrete Screws made in China?

- → Knowing Private Label Brand for the Better

- → Need Special Screws for your Clients or Projects?

- The Complete FAQ Guide about custom self-drilling screws

Why Choose Prince Fastener as Manufacturer for a Private Label Self-drilling Concrete Screws?

The humble starting of our organization built the foundation of resilience in the enterprise industry. Prince Fastener has been operating for more than 30 years thus you can trust that we have a well-developed innovation in productivity, analysis, distribution, and service. To sustain the wide demand for fastener screws and other related products Prince fastener evidently attained international standards in ISO, DIN, ANSI/ASME, JIS, and GB certification.

With innumerable countries where we have distributed the fastener products we continue to provide precision and improve the process of specialization in custom manufacturing or private labeling to special brands in need of our service. We present transparency in our production process to let our clients know how we put the outermost importance of quality control in our final products. The process in surface treatment of self-drilling concrete screws is mainly galvanizing, chromium plating, phosphating, electrophoresis, dacro, hot embroidery, and 48-72 hours of salt spray test. We also provide blue zinc plating, yellow zinc plating, nickel plating, black zinc plating, gray phosphorus galvanizing, black phosphorus galvanizing, brass plating, steam plating, hot dip galvanizing, silver plating, gold plating, etc. to other fastener products we produced.

Prince fastener has definite solutions to ensure high-quality of production due to the reason that our advanced factory and facility owns special machinery from Taiwan and we practice effectiveness as motivation in meeting every client’s requirement. For those reasons, our customers and clients are always satisfied with all of the products, especially with our self-drilling concrete screws and the overall service we have provided.

Hot products for Custom Self-drilling Screws

Prince fasteners’ self-drilling concrete screws are commonly applied in numerous kinds of industry depending on the usage but some of them are as follows; building decoration, household appliances, auto parts, leisure goods, electronic equipment, hardware and electrical machinery, aviation and military industry, infrastructure, furniture industry, outdoor leisure goods and so on.

Prince fastener as a major fastener manufacturer and fastener supplier,we can produce kinds of self drilling screws for different applications,include:Phillips Modified Truss Head Full Thread Self Drill Screw,Phillips Flat Undercut Thread Cutting Screw,flat head self-drilling screws,Steel Self Drilling Screw,Hex Washer Head Type self drilling screws, Hex-Unslotted Drive Type self drilling screws,Phillips Flat Self Drilling Screw Full Thread Zinc Bake

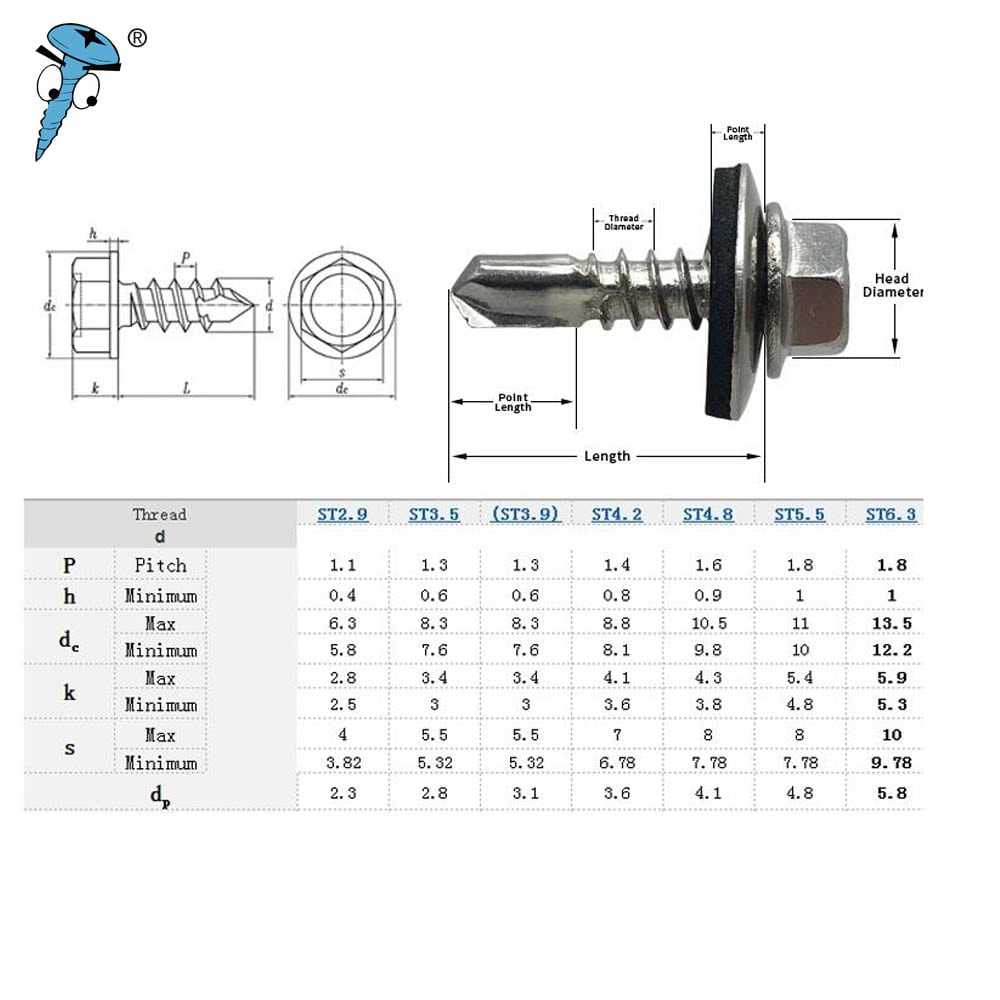

The main material used in self-drilling concrete screws is carbon steel to ensure durability and strength in fastening installation, however, it can be modified with the use of other raw materials such as stainless steel and alloy steel. The usual head type available for self-drilling concrete screws are hexagon head, pan head, countersunk head, round head, truss head, and half countersunk head with an outer diameter size of 2.9mm-6.3mm; length of 6.5mm-120mm but can also vary in numbers or inches from #6 to #14 and 1/4″ and length span of 3/8″ to 6″.

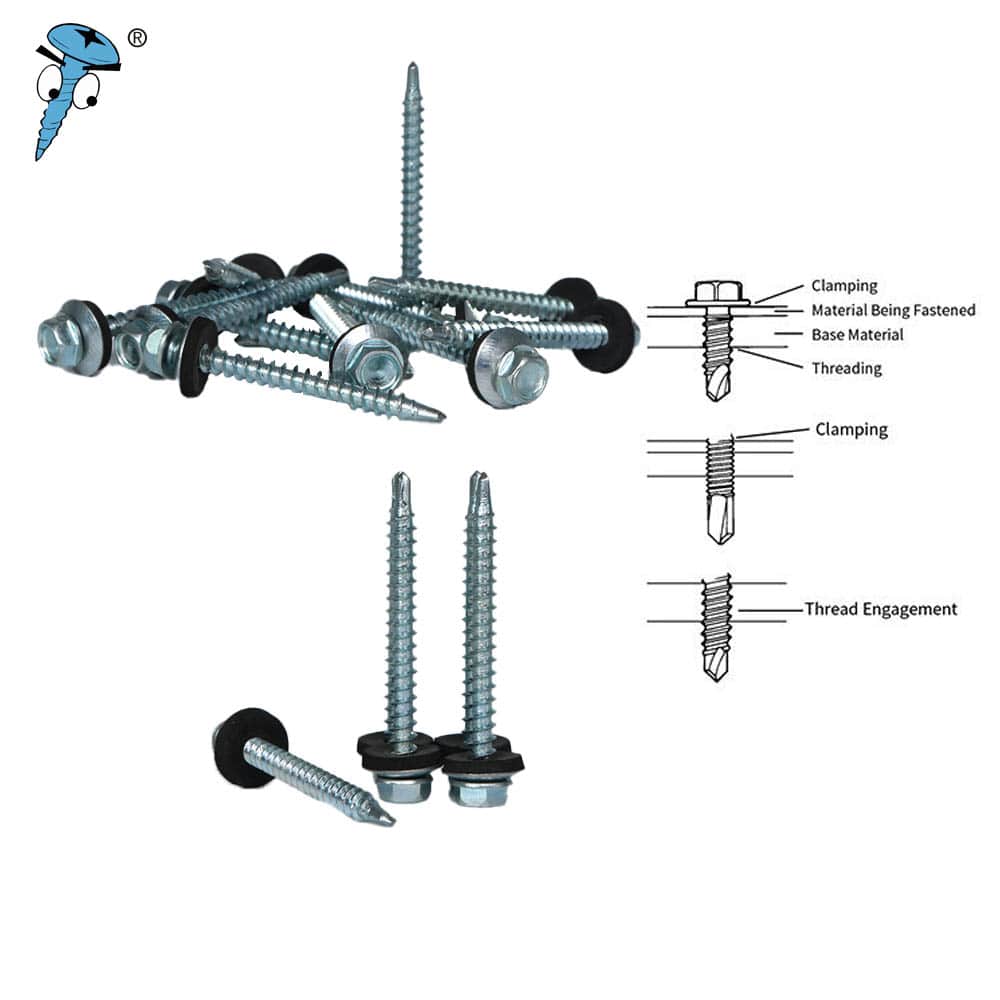

There are types of fastening materials that can be used in concrete and masonry, the common fastener types are poly-set anchors, hammer-set anchors, sleeve anchors, concrete screws or self-drilling concrete screws, and wedge anchors. Each kind differs in features and functionality but self-drilling concrete screws have a thread-cutting end that suits the strong hold into concrete.

Self-driling Concrete Screw

Self Tapping Screws for Metal

Tek Screws for Structural Steel

Industrial Self Drilling Screws

Self Drilling Screws for Aluminum

Black Self Drilling Screws

Trailer Decking Screws Self Drilling

Custom Self-drilling Screws

Estimated Wholesale Price for Self-drilling Concrete Screws

The estimated wholesale price for self-drilling concrete screws includes the below

Fastener Manufacturing Costs

Prince fastener will provide you with an exact quotation price of the materials, production, and quantity of products as we are a factory direct manufacturer and we can give reasonable costs to our self-drilling concrete screws with a guarantee that the quality will never be compromised.

Self-drilling Concrete Screws Packing Fee

We can also specialize to your demand of packaging type, Prince fastener offers further service to meet your special requirements with a minor amount of difference to the original packaging fee.

Shipping Costs

The transport of the ordered fastener screws or self-drilling concrete screws from our facility to the area of delivery via sea or air.

Customized Self-drilling Concrete Screws

The different features in material, size in diameter, head type, thread type, and other characteristics of a fastener screw can be customized accordingly by Prince fastener. Clients will have to specify their requirements and will then be given a quotation for the cost value in quality and quantity of fasteners such as self-drilling concrete screws.

Self-drilling Concrete Screws Sample Fee

It is in no trouble that we can provide a free sample of self-drilling concrete screws to our clients for them to inspect the quality beforehand and know the kinds of screws that Prince fastener can supply. The free samples of self-drilling concrete screws or other products can be managed with only the shipping costs to be afforded by the customer.

Custom Clearances Costs

The overall costs of custom clearances and other miscellaneous fees to be paid and included in the quotation of your products.

Want to cooperate with Fastener factory?or you want to get custom fastener?

Prince Fastener Is Here for Creating Quality Screws With Competitive Costs for You,and Offer the Technical Supports and Exclusive Services for Your Business.

Estimated Self-drilling Concrete Screws Production and Delivery Time

For us to cope with the rising demand in the industry for self-drilling concrete screws, our machinery and factory production are ready to sustain in increasing our capacities to achieve the desired goal and requirements from enterprises. The processing of production and distribution are pre-determined in the following steps.

Self-drilling Concrete Screws Design and Manufacturing

Prince fastener is equipped with several high-quality machineries from Taiwan to ensure 100% satisfaction from our self-drilling concrete screws and fastener products they undergo through testing machines, hardness machines, cutting machines, grinding machines, box burying machines, and tensile machines.

Packing and Packaging Time of Screws

After every production, we take time to put the screws in organized packaging of pp bags or small white boxes before its finally packed into boxes and ready to be shipped out or sold to retailers.

Exportation and Custom Clearance Time

Prince fastener has a wide experience of shipping outside China to cover the worldwide demand for self-drilling concrete screws. Shipment of the final products will take time and is done via air or sea transport.

Local Logistics and Import of fastener

Local logistics will be handling of the delivery of the package to the desired destination, once the hauling of the self-drilling concrete screws at your local port will be done

The following video will show how the major production factory of Prince fastener works in batches of making special screws for different brands.

Prince fastener production process

Basic concepts of Prince Fastener screw production

1、Prince Fastener Manufacturing screw can be divided into: cold heading, hot machining (turning, milling, etc.)

2、Cold heading is the use of plastic metal, by using cold mechanical pressure or drawing, reaches the metal solid deformation of.

3、Hot upsetting is the material after heating and pressure processing make the shape of the material to meet the

designrequirements.

4、Prince Fastener Machining is a small batch of special or special bolts of the six corners of the head is turned into after the milling.

5、 Screw bolt thread: mechanical and manual threading, similar to die.

6、 Milling tail: generally completed by the end of the Prince Fastener cutting machine.

7、 The difference between cold and hot upset: cold heading bolts` surface are more beautiful, dozen red bolt surface oxide skindoes not look good; cold heading high production is efficiency; general Prince Fastener M24 bolts will need to play red;

Analysis of the causes of the phenomenon and the causes of the forming process

1、Eccentric: two red and improper installation and adjustment machine.

2、Minow: a poor installation and improper Prince Fastener adjustment machine at.

3、Head is not round: the choice of a die or a punch forming is not enough.

4、Play the mode of crack: crack or die R angle, so that the model is hit by the two collision.

5、Head double: bad punch.

6、Flash: a bad, punching molding is mainly between punch and die hole clearance is too large or too short by red bars.

7、Crack angle: the punch needle burst or two punch and punch is not heavy.

8、Head cracking: material, or a die using error (such as pan head Hexagon washer head of a die), and lubricating oil.

Analysis of adverse phenomena and causes of common rolling

1、Processing crack: tooth plate and adjust the Prince Fastener old machine.

2、Blunt tail: the machine is not properly adjusted, the tooth plate is too old.

3、Crooked tail: the control screw on the seat board seat is too tight.

4、Tail: tooth wear plate and improper adjustment machine.

Searching for Self-drilling Concrete Screws made in China?

Prince Fastener is a well-established leading hardware factory in China whose specialization is focused on the development, production, and sales of non-standard fasteners and standard fasteners be it in customized requirements to be as competitive with the big brands in the industry. We have been recognized as a leading manufacturer of self-tapping and other fastener screws among of the rest distributors in China.

Production Equipment

The important part of producing the special screws is having the best type of equipment capable of producing the quality that the mechanical industry mostly needs. Prince fastener has the advantage of manufacturing according to the requirements of the worldwide demand with the machinery that is introduced from Taiwan. There is a total of more than 100 production equipment that are capable to fully produce in maximum quantity with a monthly capacity of 600 tons and annual production of more than 6000 tons. Some of these machines are namely, head making machines, thread rolling machines, net furnaces, testing machines such as salt spray machines, 3D projectors, hardness testers, and so on.

The Team Who Collaborates in Innovation

The main priority we give focus is meeting customer satisfaction in every way possible, that is why Prince fastener as a leading manufacturer and distributor of self-drilling concrete screws continually improves on developing different innovations in the production of excellence and technology of our facility. Our factory follows a proven method of checking the fastener screws effectivity and resistance with a large number of testing type of equipment such as a projector, salt spray tester, accelerometer, center height tester, torsion tester, film thickness tester, spectrometer, and a highly qualified technical team that works hard to meet the needs of each customer requirement. We also make sure to cater to every inquiry our company will have hence the availability of our customer line in 24/7 service. To contact us directly you may send a message at this link.

The Factory, Machinery, and Proficiency

In the wide industry of manufacturing, Prince Fastener never fails to improve the progress of development in every aspect. Undoubtedly, our expertise is exceptional in showing value and a level of excellence.

Our organization is internationally accredited and acknowledged to be one of the rapid manufacturers in China for different screws having the use of top-tier equipment originating from Taiwan. This method of exceptional craftsmanship is to ensure production of custom self-drilling screws is met perfectly by the prince fastener.

The high degree of competence we exhibit in the production of custom self-drilling screws is to strongly enterprise that our resources will never cease to please the trading in the market. With our competitive prices, prince fastener can achieve repeat orders from big brands and clients, supplying them with the highest quality of custom self-drilling screws. In the large-scale selection that these fastener screws can take we have produced numerous types in sizes, forms, applications, usage, and kinds that have matched up to the main requirements that customers look for especially in making custom self-drilling screws.

Dynamically, as the vast count of domestic fastener manufacturers keeps rising, the market share in percentage has a low concentration, therefore, making the leading enterprises of custom self-drilling screws strive to obtain high-quality competence to monopolize the production of fastener products.

Understanding How to Establish the Custom Self-Drilling Screw Business

Like the demand for furniture making, the upsurge growth of mechanical fastener industries continues to improve as its significant use to derive final product results is essential.

To come about the choice of fastener products, the things to consider should start with examining supply chain solutions. This is where Prince Fastener emerges to be of service, the custom self-drilling screws have their advantages to propose. It is mainly applied to several different industries including furniture making, electronic types of equipment, construction, automotive, appliances, and even in the medical field. The usage of custom self-drilling screws covers standard components such as glass, wood, metal, metal sheets, concrete, brass, etc.

As aforementioned the importance of custom self-drilling screws, it is also a principal key point to evaluating the factors that can contribute to the business you will build. Deep research will be the cue to establish and execute the plan later on. To help in understanding the market value of custom self-drilling screws you have to innovate the following in order; market research, business plan, funding, location, business structure, and registration of the business as well as securing registration and tax requirements. We have collected reliable information from this website to showcase some important details when you are starting up your own business.

Once completed it will take motivation to keep sourcing the market niche and developments. Prince fastener comes vigorously to help with the tasks that come up against the supply of custom self-drilling screws. We will communicate and take you through the process of fulfilling the demand when either you are feasibly selecting the kind of fastener from our catalog, seeking engineering help, or consulting for the purchasing needs of custom self-drilling screws, Prince fastener will ensure firm service and maintain the best quality of serving you. With our commitment and sincerity to organizations and customers, we assure the utmost loyalty of service will be provided from day one. As a company that has excelled among other corporations in the production of custom self-drilling screws and stainless steel screws, it is gratifying to share the details of how we won the ranking and to have the product qualification rate of 100% among the other manufacturers in China. Stainless steel and custom self-drilling screws leading factory in China.

Knowing Private Label Brand for the Better

The familiar question that anyone with limited knowledge of the process of enterprises and business will be, what is a private label? For many in the retail industry private label is an opportunity in expanding the profit margin and decrease the cost of production. Much known companies today considers the idea of private label brand or also known as ODM (Original Design Manufacture) and some are already dependent on manufacturers in different kinds of the industry may it be frozen foods, household products, cosmetics, beverages, clothing, personal care, pet food and accessories, mechanical accessories, etc.

The concept of Private Label or Original Design Manufacturer (ODM) isn’t a new task for Prince fastener. We have been in a great amount of deals in supplying fastener screws and self-drilling concrete screws to uncountable brands or private companies. Among these documented countries that trust the quality of Prince fasteners service and the type of our self-drilling concrete screws are the following; Hong Kong, Korea, Japan, Australia, UK, Europe, the Middle East, North America, South America, Southeast Asia, and Africa.

Our fastener screws have passed accreditation in product standards of DIN, ISO, GB types, ASME/ANSI, BS, JIS, and AS. Prince fastener has the outermost confidence in the self-drilling concrete screws and other special screws we produce in mass can support professional evaluation as we can be a one-stop-shop for all of your fastener needs.

The advantages that come with a contract on a private label brand are the overall control in production, pricing, branding, and adaptability to the present demand of your manufactured products in the niche market. Although it all sounds too good there are also disadvantages or problems you can encounter in private label brands, manufacturer dependency and difficulty in building brand loyalty are some instances. Consumers may often choose the well-established brand that came before you and whenever your manufacturer is dealing with problems on their own your production may become well affected too. That is why it is an important decision to do very informative research on private labels and a prospective manufacturer to choose.

Need Special Screws for your Clients or Projects?

Prince Fastener has the experience of producing more than 500 billion screws for more than 1,000 different companies over the time of 30 continuous years into customizing fastener products, with approximately 4,800 types of screws while the annual sales volume of construction screws, furniture screws, and electronic screws exceeds 2000 tons and other related fastener products that are under strict standard requirements of our customers.

However, Prince Fasteners’ main products include the production of plasterboard screws, chipboard screws, self-tapping screws, self-drilling screws, self-drilling concrete screws, blind rivets, coil nails, common nails, concrete nails, plastic strip nails, ST nails, various shaped nails, bolts, nuts, washers, threaded rods, anchor rods, etc. Other than the aforementioned fasteners we also offer OEM and ODM or private label brands on a client’s proposed design plan. With the series of sourcing challenges throughout the fastener manufacturing industry, in Prince fastener we are proud to cater to custom orders, as a fastener factory direct supplier, having in-time delivery, and outstanding service within the reach of our clients in a common goal of having a maximized record in revenue.

As a professional self drilling screws supplier, we can assure the best possible quality of goods and service to our clients, so we suggest that contacting us for more information or an inquiry is the suitable next step on the start of manufacturing business together.

The Complete FAQ guide about Self-drilling Concrete Screws

Quick Index

- Do I need to pre-drill a hole for self-drilling concrete screws?

- What other names are self-drilling concrete screws called?

- How to install self-drilling concrete screws?

- What drill bit should I use for the application of self-drilling concrete screws?

- Are self-tapping and self-drilling concrete screws the same?

- Can you drill in concrete without using a hammer drill?

- What’s the difference between self-drilling concrete screws and a concrete anchor?

- What differentiates private label and white label brands?

- Are private label products legal?

- How do I start a private label fastener brand?

- Is there a commonly known example of a private label brand?

- Can Prince fastener sustain a private label for the long term?

- Is private label the same as ODM?

- What advantages does private label have?

1. Do I need to pre-drill a hole for self-drilling concrete screws?

A self-drilling concrete screws doesn’t need a pre-drilled hole for the reason that the tip of a self-drilling concrete screw includes a drill bit end that allows you to create an easy installation access. However, you can also do a pre-drilled hole if you want a marker for drilling into a concrete surface.

2. What other names are self-drilling concrete screws called?

Self-drilling concrete screws are also commonly known as masonry screws, consert screw, confast screw, Tapcons, and masonry anchors. These types of concrete fastener differ in functionality and effectivity on application so it will be important to know what kind of screw you will need.

3. How to install self-drilling concrete screws?

Self-drilling concrete screws is one of the easiest fastener screw to use, once you have the correct length size and kind of screw you can either pre-drill a hole or not, insert the screw in the desired base material and rotate the drill with the use of a tool. Make sure that the pressure you give into drilling will sustain the efficiency of installation and check for possible other issues after the application.

4. What drill bit should I use for the application of self-drilling concrete screws?

Common sizes in diameters of Prince fastener self-drilling concrete screws in whole numbers and down to inches vary from #6 to #14 and 1/4″. The lengths span from regarding 3/8″ to 6″. Once you selected the length size of your choice,keep in mind that the drill bit purpose and threads should always be longer than the entire thickness of the material being fastened of fixed together.

5. Are self-tapping and self-drilling concrete screws the same?

The two screws basically almost have the same features but they only differ in the application process because a self-tapping screw will need a pilot hole to tap into surfaces whereas self-drilling concrete screws conveniently gives the easy installation on concrete and masonry.

6. Can you drill in concrete without using a hammer drill?

The usage of a hammer drill wasn’t available in the early years, many people suggested the use of a first conventional power drill which can be hard work and slow in process, also the use of any regular drill with a concrete bit will do the work of drilling into concrete.

7. What’s the difference between a self-drilling concrete screws and a concrete anchor?

Concrete anchor are also like nail anchors and the bolt is not threaded that gives it the ultimate advantage of speed in use. There are also different types of a concrete anchor with different purpose and functionality. However, self-drilling concrete screws cuts into concrete and unlike any other fastener screws they are removable yet they stick solid to concrete base material.

8. What differentiates private label and white label brands?

Private label or private label brand is a product or service that are outsourced to another company for exclusivity advantages. Whereas a white label brand are created by manufacturers for multiple clients and retailers, they are mainly modified to generic brand and other times can be customized accordingly depending with the manufacturer.

9. Are private label products legal?

The entire process of private labeling is legal because the products produced by manufacturers are sold under contract to private label firms leaving them a maximize margin in profit.

10. How do I start a private label fastener brand?

There are few steps to consider to start your private label brand enterprise, but more importantly is to find a good manufacturer that can cater to your specifications and demand. Prince fastener comes in handy to that situation, you can directly inquire with us about starting your private label brand with self-drilling concrete screws or other fastener materials.

11. Is there a commonly known example of a private label brand?

Many known brands today are unknowingly under a private label brand, the famous example for that would be Apple company who is under contract with the biggest manufacturer in China, the Foxconn to produce the modifications they require in Apple products. With Prince fasteners flexibility in service, private label brand is also offered to our clients as a profitable business dealing with self-drilling concrete screws or fastener products and related materials for use.

More examples and private label information can be found in this link.

12. Can Prince fastener sustain private label for the long term?

Prince fasteners has envision a life-long commitment and loyalty to our clients hence the possibility of sustainability and efficiency will always be in top priority in our service. We will be gratified to keep the service in the longest time that we can cater to our clients as we value customer satisfaction more than anything else.

13. Is private label the same as ODM (Original Design Manufacturer?

Private label is generally a purchase of ODM (Original Design Manufacturer) which is the main idea of manufacturing a well produced goods in design provided by the client and developed by the company to be turned into a profitable retail brand.

14. What advantages does private label have?

To sum up the advantages that private labeling can provide, the retailers for this kind of branding often look into control of over production, control in pricing, adaptability, control of the branding, as well the product profitability. The definitive explanation of the following can be found in this link.