tip—triangular tooth self-extruding. When screws are screwed into holes in plastic metal material, they are extruded into the

holes to form internal lines and form a reliable locking thread connection.

Prince fastener Plasterboard Screws product features

Although there are many types of Plasterboard Screws, they all have the following main characteristics:

(1) Are generally made of carburized carbon steel (accounting for 99% of the total product). It can also be made of stainless

steel or nonferrous metals

(2) The product must go through heat treatment; carbon steel Plasterboard Screws must go through carburizing treatment, stainless steel Chipboard Screw must go through reliable solution hardening treatment, and make the Chipboard Screw meet the standard requirements of mechanical properties and performance.

(3) The product has a high surface hardness and good core toughness. That is, “soft inside and hard outside” is the Prince fastener Plasterboard Screws to meet the requirements of performance

(4) The surface of the product needs surface protection treatment, generally electroplating treatment. Some products require phosphate treatment (phosphating) on the surface, such as wallboard Screw for phosphating.

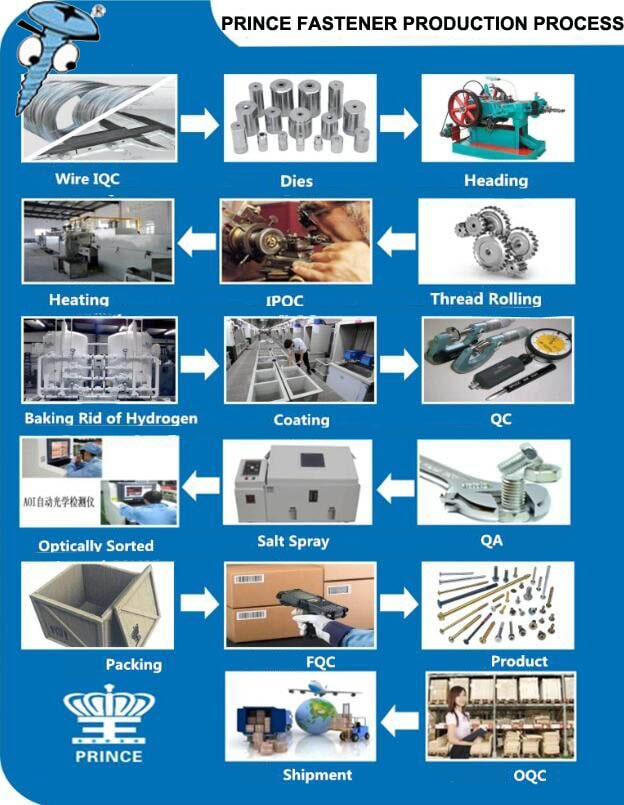

(5) Adopting a cold heading process for production. It is recommended to use a high-speed mean heading machine, high-speed wire rolling machine, or high-speed planetary wire rolling machine to ensure product quality. Such production of Chipboard nail head molding, thread quality is high.

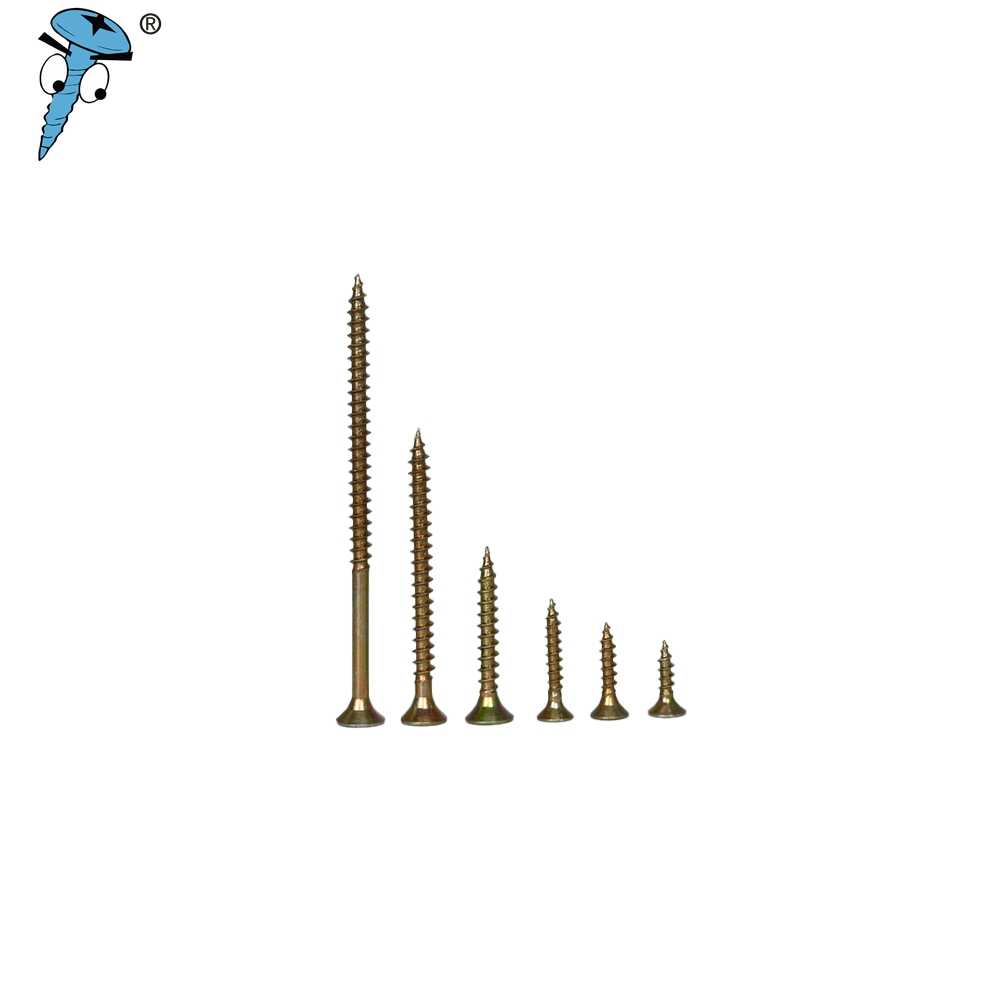

What is chipboard screw?

A chipboard screw is a product that has undergone heat treatment and is suitable for the installation of electric tools. It is mainly used for connection and fastening between wooden plates and thin steel plates. Chipboard screws are currently used to replace wood screws in many fields and are widely applied now. It can replace the use of ordinary wood screws (wood screws are not heat). At the same time, the wood screws are currently first proposed by the navigation standard to produce the production of rods, which not only saves materials, but also has a sharp thread.

What is best screw for chipboard?

Some of the most typical ones are chipboard screws and self-tapping deck screws. These are helpful as screws for particle board. Chipboard screws are pretty comparable to standard screws. However, one notable difference is that their grooves are typically asymmetrical to allow for better resistance against pull-out.

What are chipboard screws made of?

Chipboard screws, also named particleboard screws, are self-tapping screws with thin shafts and coarse threads. They are made of stainless steel or carbon steel and then galvanized. Chipboard screws of different lengths can be used in a variety of applications.

Are chipboard screws the same as wood screws?

The main difference between woodscrews and chipboard screws lies in the threads which, on a chipboard screw, run all the way along the screw’s length to the underside of the head. This makes chipboard screws particularly useful where an extra-strong hold is required, such as when installing garden decking.

Chipboard screwsare a product that has been heated, suitable for installation of electric tools. It is mainly used in the connection and fastening between wooden plates, wooden plates and thin steel plates. To a large extent, it can replace the use of ordinary wood screws.

In the entire fastener industry, this product is a variety as important as drywall screws and huge sales. It is widely used in furniture manufacturing industries, but the use of the DIY market is still limited. At present, domestic consumers purchase this variety in building materials supermarkets, mainly used to install guide rails, hinges (such as*16, etc.), combined with fish -like expansion installation (such as 4*40, etc.), and replacement of wood screw installation and making furniture and cabinets. The Chipboard screws screw that is added to the tooth pattern is an improved product for ordinary Chipboard screws screws. It is mainly optimized from the design of the thread, pursuing higher drilling speed, and solving the use of hard wood to use easily caused The problem of cracking is high in technical content.

What is particle board vs MDF?

MDF has a smooth finish as it consists of wood grains that are of the same size. Particle-boards do not have a smooth surface as they consist of wood shavings and chips.

What type of screw should I use on particle board?

Particle Board Screws are the same as a coarse thread drywall screw but available in shorter lengths than standard drywall screws. They feature a bugle head, spaced threads, extra sharp point, and black phosphate finish.

Can you use chipboard screws in MDF?

And you need to use the right materials. For consumables, Allfasteners have the range and expertise to help you get any building job done. For different types of timber, there are different types of fasteners. For very soft timbers, MDF or chipboard, you need to use chipboard screws.

What is the difference between chipboard screw and drywall screw?

Both drywall screws and chipboard screws have countersunk, half countersunk, and round head designs. The grooves of drywall screws are deeper and look better. Under normal circumstances, it is half-toothed, while fiberboard screws are generally full-toothed.

What is the difference between chipboard screw and self tapping screw?

What is Chipboard screws?

Chipboard screws are a product that is armal processing and suitable for installation of electric tools. It is mainly used for connection and fastening between wooden plates, wooden plates and thin steel plates.

Chipboard screwsare currently used to largely use the use of wood screws. Its application is very wide and sells very large in China.

What is Self tapping screws?

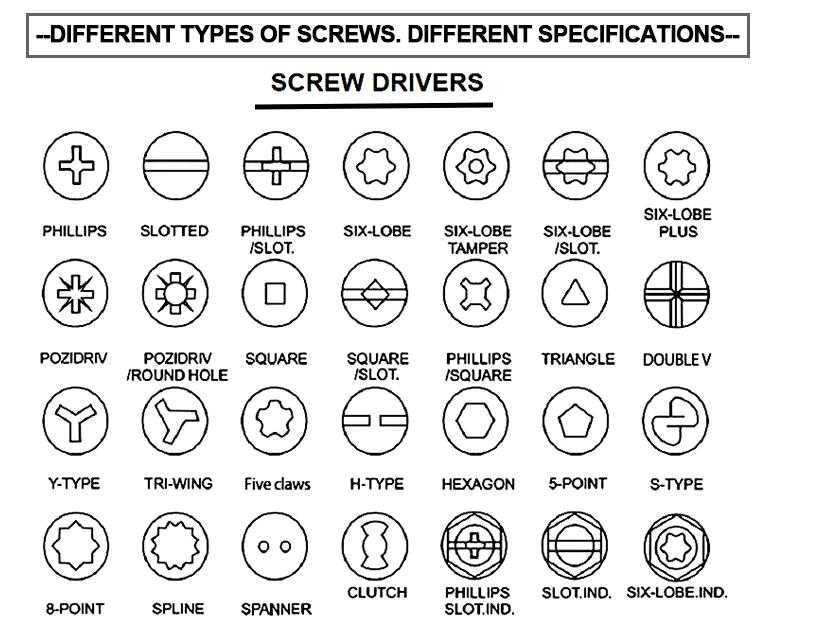

Self tapping screws nail is also called Self tapping screws screws. It is one of the types of threaded fastening in the pre-drilling hole of metal or non -metal materials. There are depression, head, etc.

Self-tapping screw

The difference between Chipboard screwsand Self tapping screws nails

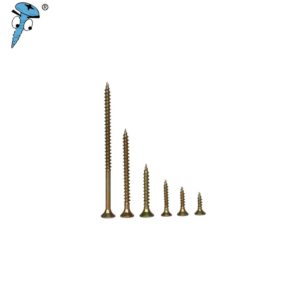

Chipboard screws are currently used to replace wood screws to a large extent. It is widely used in China. The Chipboard screwswith a deep -headed head, a semi -immersed head, round head, etc. The thread rises in a single line spiral, generally the whole teeth, with 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 6mm and other specifications. 5mm, 6mm. The technical content of the Chipboard screwsis high, and the nails are not easy to crack. The cracking problem in some hard wood can also be solved by using the threading of ordinary Chipboard screwsto be resolved. Chipboard screwsare suitable for wooden materials and are suitable for electric tool installation. It is currently mainly used in furniture manufacturing, cabinets and other fields.

Self tapping screws nails are generally used for wooden materials and thin metal boards. Self tapping screws screw thread rises on the screw, but the thread is smaller than the chipboard screws, and the surface of the thread has high hardness. Therefore, in the thin metal plate connection, the inner thread is attacked in the thread bottom of the connector to form a connection.

First of all, from their diameter, the diameter of the Chipboard screws includes six specifications of 3 mm, 3.5 mm, 4 mm, 4.5 mm, 5 mm, and 6 mm. Among them, 4 mm, 5mm, and 6 mm are the most common. The diameter of the drywall screws screw does not have so many specifications, only 3.5 mm. The drywall screws screws and fiber plates have the design of the head, semi -immersive head, and round head. In general, it is semi -teeth, and the fibrous board screw is generally full tooth. The biggest feature of the drywall screws screw in appearance is the shape of the horn head. If it is divided according to the thread, it can also be divided into two types of single -line coarse wall screws and double -line fine dental wall screws.

What appliacations for chipboard screws?

In the entire fastener industry, this product is a variety as important as drywall screws screws and huge sales. It is widely used in furniture manufacturing industries, but the use of the DIY market is still limited. At present, domestic consumers purchase this variety in building materials supermarkets, mainly used to install guide rails, hinges (such as 3.5*16, etc.), combined with fish -like expansion installation (such as 4*40, etc.) Essence The quality is better. It is better to choose the element card produced by the Shanghai Hangou Standard Metric Performing Article Factory. The quality packaging prices are more economical and affordable. Adding claws and cutting Chipboard screws screws are improved products for ordinary Chipboard screws screws. It is mainly from the thread The design is optimized, the pursuit of higher drilling speed, and solving the problem of using cracking on hard wood, which is easy to cause cracking. The technical content is high.

The application range of chipboard screws in the furniture manufacturing industry is relatively wide. It is a product similar to dry wall plates, and its sales are relatively large. In the building materials market, domestic consumers are more popular with it. It has many applications in installing rails, hinges, fish -like expansion installations, and wood screw installation and making furniture. Among them, the best manufacturer of chipboard screws is Prince Fastener The chipboard screws produced by this company are worth choosing in terms of quality and price. After the reconstruction of ordinary fiber board screws, it will become claws and cut tail chipboard screws. It is mainly transformed in the design of the thread. In this way, the problem of cracking caused by hard wood will be solved.