In the construction and decoration industry, drywall screws are essential fasteners used to connect gypsum boards to supporting structures. Selecting the correct drywall screw is crucial for ensuring construction quality and safety. At Prince Fastener, we focus on delivering the best fastener solutions. We understand how important it is for professional contractors and DIY enthusiasts to grasp the specifications, torque standards, materials, and installation techniques of drywall screws. This article provides critical information on drywall screws, including specifications and head diameter, torque standards, critical parameters, and how to select the appropriate length. Whether an industry expert or a novice, this guide will help you make the right choices for your project.

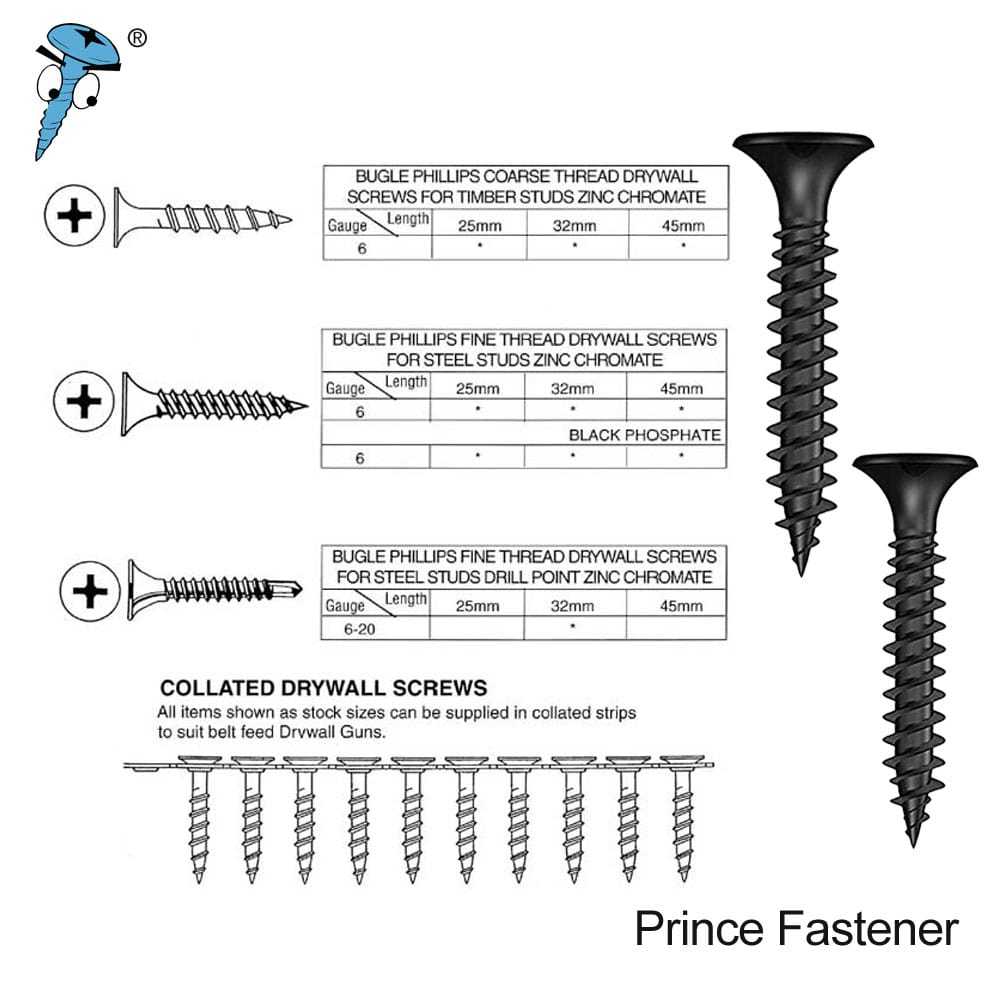

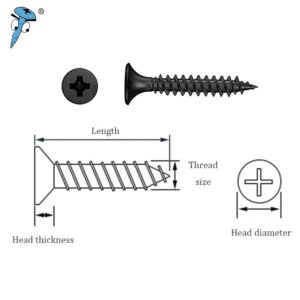

Drywall Screw Head Diameter and Specifications

For different specifications, the head diameter of drywall screws varies. Based on research, here are some standard drywall screw specifications and their corresponding head diameters:

- #6 (3.5mm) drywall screw: Head diameter is 3.5mm

- #7 (3.9mm) drywall screw: Head diameter is 3.9mm

- #8 (4.2mm) drywall screw: Head diameter is 4.2mm

- #10 (4.8mm) drywall screw: Head diameter is 4.8mm

These diameters represent the total width of the screw head, which is a crucial parameter to consider when selecting the appropriate drywall screw.

How Does Head Diameter Relate to Screw Specifications?

The head diameter of a drywall screw is closely related to its specification. A screw’s specification refers to its diameter, length, and other dimensions. For drywall screws, the specification usually indicates the screw diameter, while the head diameter reflects the screw’s head size.

- Relationship between specification and diameter:

- The larger the specification number, the smaller the screw diameter. For example, a #14 screw has a smaller diameter than a #12 screw.

- Conversely, the smaller the specification number, the larger the head diameter. For example, a #10 screw has a larger head diameter than a #12 screw.

- Relationship between head diameter and size:

- The head diameter is generally proportional to the screw specification. As the screw size increases, the head diameter also increases.

- This design ensures sufficient torque application and load-bearing capacity as the screw size increases.

Practical Application:

When choosing the right drywall screw, consider both its specification and head diameter to ensure it meets specific project requirements, such as torque spacing and tightening force.

Related read:fastener used in securing pipes

Torque Standards for Different Drywall Screw Sizes

Below are the torque standards for various drywall screw specifications:

- #5 (2.9mm) drywall screws:

- Type A: 1.3 Nm

- Type AB: 1.0 Nm

- #6 (3.5mm) drywall screws:

- Type A: 2.2 Nm

- Type AB: 1.5 Nm

- #7 (3.9mm) drywall screws:

- Type A: 3.7 Nm

- Type AB: 2.0 Nm

- #8 (4.2mm) drywall screws:

- Type A: 5.8 Nm

- Type AB: 4.0 Nm

- #10 (4.8mm) drywall screws:

- Type A: 9.4 Nm

- Type AB: 6.2 Nm

These torque values represent the minimum required torque for drywall screws. The exact torque may vary in practical applications depending on specific conditions and requirements. Always refer to the product’s technical specifications or the manufacturer’s recommendations for proper torque settings.

Other Key Parameters to Consider

When selecting and using drywall screws, apart from torque standards, pay attention to these critical parameters:

- Head shape and design of drywall screw:

- The screw head must be smooth to fit perfectly with the drywall surface. Sharp tips are essential to ensure proper penetration, especially for light steel framing.

- Angle of drywall screw:

- The screw head angle is typically 22-26 degrees, ensuring smooth installation without tearing or cracking.

- Axial alignment of drywall screw:

- Check for axial alignment by standing the screw upright on a flat surface to ensure it is straight.

- Cross recess of drywall screw:

- The cross recess must be centred to prevent wobbling during installation with power tools.

- Materials of drywall screw:

- Common materials include steel, stainless steel, and zinc or phosphate coatings, which enhance corrosion resistance in humid environments.

- Surface treatment of drywall screw:

- Surface treatments, such as Dacromet, phosphating, blackening, soap phosphating, and galvanizing, significantly impact torque values. Surface lubrication also affects performance.

- Screw type :

- The screw thread must be sharp and thick enough to grip the drywall firmly and ensure tight installation.

- Length of drywall screw:

- Choose the best length drywall screw for drywall to ensure it penetrates the material behind the drywall without causing damage.

- Spacing of drywall screw:

- Proper screw spacing prevents loosening or warping, ensuring even pressure distribution.

- Installation techniques of drywall screw:

- Use suitable power tools and bits to ensure the screw head is 2-3mm below the drywall surface for secure installation.

How to Choose the Right Drywall Screw Length

When selecting the appropriate length of drywall screws, consider the following factors:

- Drywall thickness:

- The screw length should exceed the drywall thickness by at least 10mm to ensure proper penetration and secure attachment.

- Backing material:

- If the drywall is backed by wood or metal studs, ensure the screw penetrates deep enough into the studs for structural stability.

- Number of drywall layers:

- For double-layer drywall, use longer screws to ensure both layers are firmly attached.

- Specific use case:

- For example, when securing 1/2-inch drywall to wood studs, use screws at least 1 1/4 inches long. For 5/8-inch drywall, screws of 1 5/8 inches or 2 inches may be needed.

- Local standards and requirements:

- Refer to regional construction standards and practices for guidance on screw length.

- Screw type:

- Coarse-thread screws are suitable for wood studs, while fine-thread screws are ideal for metal studs.

By considering drywall thickness, backing material, and specific application scenarios, you can select the correct screw length to ensure a secure and durable installation.

Partner with Prince Fastener for Reliable Drywall Solutions

By understanding drywall screw specifications, head diameter, torque standards, and installation techniques, you can ensure your projects are both secure and long-lasting. Prince Fastener is your trusted partner in providing fasteners that meet international quality standards.

Our commitment to innovation and precision ensures that our drywall screws prevent issues such as board loosening or warping while maintaining even pressure distribution. Whether you’re working on a professional construction project or a DIY task, we’re here to provide reliable solutions tailored to your needs.

Thank you for choosing Prince Fastener. We look forward to supporting your future construction projects and building more robust, durable structures together.