The Importance of Drywall Screws in Engineered Decoration

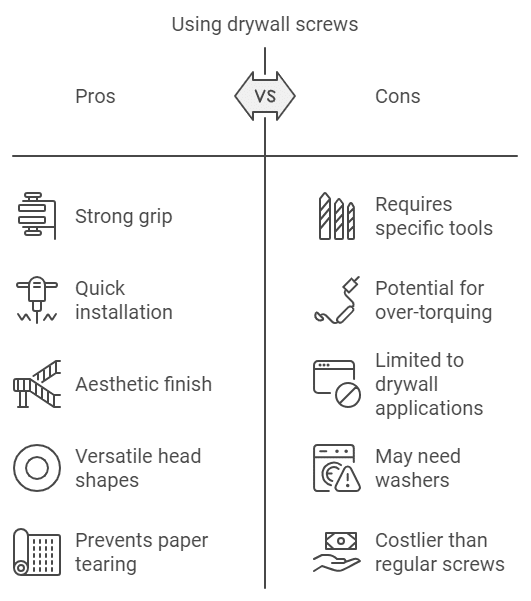

In the world of engineered decoration, drywall screws are tiny but play a vital role. They are the bridge connecting the gypsum board to the keel to ensure the wall is aesthetically pleasing and robust. Today, Prince Fastener mentions the different types of such screws, their characteristics, and how to use them properly. The article will provide helpful information whether you’re looking for ways to improve the quality of your assemblies or wondering how to provide more professional advice to users.

What are Drywall Screws?

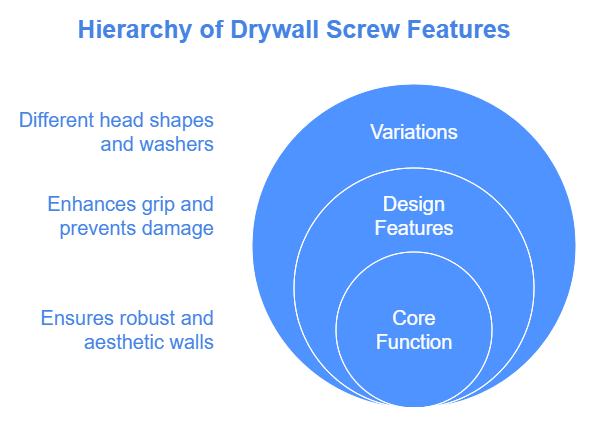

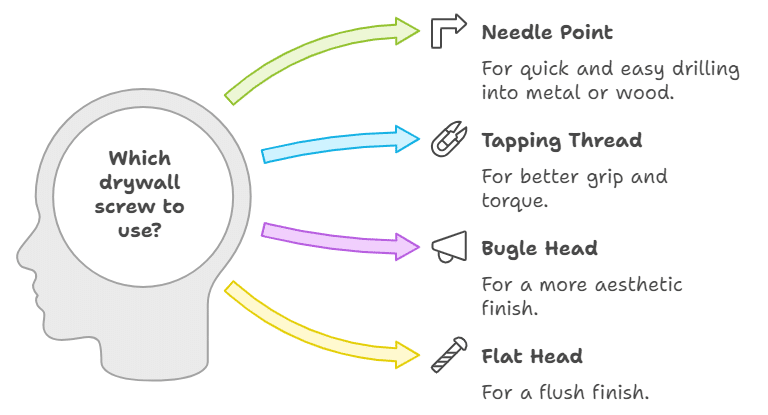

Drywall screws on plasterboard are specially designed (drywall) assembly screws. They usually have special needles (Needle Point) that quickly go over the gypsum board and drill into the metal or wood keel without tearing the paper. Drywall screws typically have 60+ degree tapping screws (Tapping Thread), which helps create a better grip when torquing. They may also have different head shapes, such as Bugle Head or Flat Head, and may or may not have washers.

What are the slotted drywall screws?

A slotted drywall screw is a type of screw that is suitable for mounting assembled hardware into wood, but a drywall anchor is applied when mounting to drywall. Slotted screws are available in hex heads, swift screws, and tops.

What are the two types of slotted drywall screws?

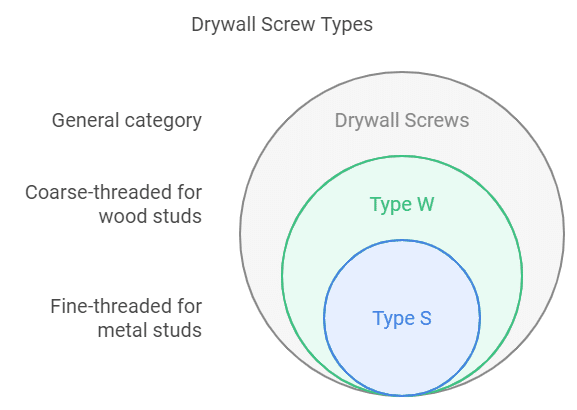

Drywall screws, also known as drywall screws, typically come in two main types: a fine-threaded drywall screws(type S) designed specifically for metal studs and a coarse-threaded drywall screw (type W) designed for wood studs. These two types of drywall screw are divided according to the size and length of the screw threads to adapt to different use scenarios and materials.

Delicate Thread Drywall screws (Type S): These drywall screws have thin screws and are generally used to fasten gypsum board to metal studs. Because of the high toughness of the metal, thin screws can better grip the metal surface and make a solid connection. The tops of these screws are designed to be sharp, making it easier to get a good grip on the metal surface.

Coarse Thread Drywall screws (Type W): These drywall screw have thicker screws and are suitable for fixing gypsum boards to wooden studs. Wooden keel is less intense, so the use of thick screws can provide more bite to ensure the stability and variability of the gypsum board. These screws are generally long and thin to accommodate the characteristics of the wood.

When picking slotted drywall screws there is also best length drywall screw for drywall to consider, which usually lies in the thickness of the plasterboard and whether there are two layers of plasterboard. For example, a single layer of gypsum board may require shorter screws, while two layers of gypsum board must have longer screws to ensure that they pass through all the layers and are securely fixed to the keel. It is also essential to design the head of the wallboard screws, commonly known as Bugle Head (Bugle Head), Friendly Head (Flat Head), etc., to ensure that the screws can be placed quickly into the gypsum board without damaging the surface of the wood.

How do I apply slotted drywall screws in dry test walls?

The following steps must be followed to apply slotted drywall screws in dry test walls (plasterboard walls).

Measurement and identification: First of all, the position of equipment (e.g., light fittings, gas sensors, etc.) must be accurately measured and identified on the plasterboard.

Grooving: A utility tool is used to groove the gypsum board. The depth and total width of the groove should be clearly defined based on the specifications of the slotted drywall screws. According to the web search, the grooving depth should not exceed 1/4 of the wall thickness, and the pipe grooving should not be less than 300mm from the window or door opening.

Assembling slotted drywall screws: Insert the slotted drywall screws into the slots. The wall plate screws usually have preset holes for large equipment.

Large equipment: Bias the equipment towards the holes in the slotted drywall screws, and fix the equipment to the wallboard with screws or other standard parts.

Check and adjust: After the installation is completed, check the solidity of the equipment and adjust it accordingly to ensure that the system is assembled neatly and solidly.

Seam plugging and repair: If there is damage to the gap in the grooving and installation, be sure to use unique repair materials to scrape flat and carry out anti-cracking solutions.

Clearing: Finally, clear the wall to eliminate excess dust and debris.

Note that trenching should be done in such a way as to prevent piping and structural components, such as rebar, from the wall. In addition, for wet and cold, cold, or high humidity regions, you should choose gypsum boards suitable for humid environments, such as waterproof gypsum boards. Safety codes and operating standards should also be followed during installation to ensure safe construction.

Based on today’s discussion, Prince Fastener hopes you have a more comprehensive understanding of slotted drywall screws. These simple components are the key to quality assurance and customer satisfaction. Whether selecting a suitable material or giving installation instructions, it’s essential to grasp the details daily. Prince Fastener believes that continued learning and mastery of this expertise will allow us to serve our customers better and enhance the competitiveness of our business.