You have an important choice when picking a bolt torque chart for your project. Each chart fits certain bolt types, materials, grades, and uses. Good torque values stop problems and keep things safe. Correct records help your work and make people trust you. You can use the quick guide to pick the right chart easily.

Key Takeaways

- Pick the right bolt torque chart for your bolt. Think about the bolt type, size, material, and where you will use it. This helps keep things safe and working well.

- Always look at the threads and lubrication before you start. Clean and oil the threads to lower friction. This helps you get the right torque.

- Use a torque wrench that is checked and works well. Follow the right order when you tighten bolts. This stops uneven stress and keeps equipment from breaking.

- Write down the torque values and project details. Keeping records helps with quality checks and fixing things later.

- Use charts from good sources or industry rules. This makes sure your numbers are right. Always check that the chart fits your bolt needs.

Quick Selection Guide

Decision Tree

You can use this decision tree to narrow down your options for a bolt torque chart. Start with the type of bolt you have. Next, check the material and grade. Then, think about the environment where you will use the bolt.

What type of bolt do you have?

- Standard hex bolt

- Socket head cap screw

- Specialty or application-specific bolt

What is the bolt size?

- Small (M6 or below / 1/4″ or below)

- Medium (M8–M16 / 5/16″–5/8″)

- Large (M18 and above / 3/4″ and above)

What is the bolt material and grade?

- Steel (Grade 5, Grade 8, etc.)

- Stainless steel

- Alloy or other materials

What is the application environment?

- Dry

- Lubricated

- High temperature

- Corrosive

Do you need to follow a specific industry standard?

- Yes (SAE, ISO, ASME)

- No

Tip: If you answer “specialty” or “yes” to industry standard, you should use a manufacturer or standard-specific bolt torque chart.

Checklist

Before you select a chart, review this checklist. It covers the most important factors engineers consider, based on industry surveys.

| Factor | Description |

|---|---|

| Size | Larger bolts need more torque. For example, M6 and M10 bolts have different torque values. |

| Bolt material | The material changes the torque needed. Stronger materials can handle higher torque values. |

| Condition of thread | Rusty or dirty threads increase friction. This can lead to inaccurate torque application. |

| Lubrication | Lubricated bolts need less torque because friction is lower than with dry bolts. |

| Thread pitch | Coarse and fine threads have different pitches. This affects the torque required. |

Check each item above before you choose a bolt torque chart. This will help you avoid mistakes and ensure you use the right values for your project.

Top 10 Bolt Torque Charts

Portland Bolt Torque Chart

The Portland Bolt Torque Chart helps you find torque values for many fastener grades and sizes. It shows you how much torque to use for different bolt sizes and materials. People often use this chart in construction and engineering jobs. The chart is a guide, so you need to think about things like mistakes, surface roughness, and lubrication when tightening bolts.

Note: Always look at the chart’s advice and change it for your own project.

| Feature | Description |

|---|---|

| Torque Values | Shows torque for many grades and sizes of fasteners |

| Bolt Torque Chart | Has torque numbers for many grades and sizes of fasteners |

Common industries using this chart:

- Construction

- Engineering

Imperial Supplies Fastener Torque Chart

The Imperial Supplies Fastener Torque Chart is good for quick checks with imperial bolts. It lists common SAE grades and gives torque for dry and lubricated bolts. You can use it for fixing, maintaining, and working in factories.

Tip: Always check the bolt grade and size before using the torque.

Fractory Metric Bolt Torque Chart

The Fractory Metric Bolt Torque Chart gives torque numbers for metric bolts. You can use it for steel and stainless steel fasteners. Many people use this chart in factories and metal shops. It helps you pick the right torque for metric bolts in machines and buildings.

Engineers Edge Torque Table

The Engineers Edge Torque Table works for both imperial and metric bolts. The table lists the highest torque for SAE Grades 1 to 8 and covers standard metric hex nuts.

| Fastener Type | Torque Value (Imperial) | Torque Value (Metric) |

|---|---|---|

| Standard Bolt Sizes SAE Grades 1-8 | Highest torque values | N/A |

| Standard Metric Torque Hex Nuts | N/A | Gives needed torque values |

This chart is good for general engineering and design.

Misumi Metric Bolt Torque Chart

The Misumi Metric Bolt Torque Chart helps you find torque for metric bolts made from steel and stainless steel.

| Material | Finish |

|---|---|

| Steel SWCH Equivalent | Plain Fabric |

| Stainless Steel 304 Equivalent | Plain None |

You can use this chart for robots, machines, and automation. It covers common materials and finishes, so picking the right torque is easy.

Useful Magnets Tightening Torque Chart

The Useful Magnets Tightening Torque Chart is handy for quick checks in workshops and repair shops. It gives torque numbers for many bolt sizes and materials. The chart is easy to use and helps you not tighten bolts too much or too little.

Repair Engineering Bolt Torque Chart

The Repair Engineering Bolt Torque Chart gives exact torque for fixing cars.

- The chart lists torque based on how strong the bolt and nut are.

- It makes sure you get the right clamp force for safety.

- The nut must be as strong or stronger than the bolt.

- Good thread grip is important for safe assembly.

You can use this chart for car repairs to stop bolts from breaking.

Crane Electronics Torque Guide

The Crane Electronics Torque Guide helps you manage torque with advanced tools. This guide covers many fasteners and gives tips for electronic torque tools. It is great for checking quality in factories and assembly lines.

SAE J429/ASME/ISO Standard Charts

SAE J429, ASME, and ISO standard charts give you approved torque numbers. These charts show rules for both imperial and metric bolts. Use them when your project needs to follow world standards.

Manufacturer & Application-Specific Charts

Manufacturer torque charts give exact torque for special devices and products.

- These charts match the design and materials of each product.

- General standards give wider rules, but may not fit every job.

- For example, Leviton gives a torque range for duplex receptacles, and Square D puts torque numbers on circuit breakers.

Always check the manufacturer’s advice when working with special equipment.

Bolt Torque Chart Comparison

Size Range

You need to check if the chart fits your bolt sizes. Some charts work for small bolts. Others are made for big bolts in factories. Most charts do not say the smallest or biggest size. You should look at each chart before you start your project.

| Minimum Bolt Size | Maximum Bolt Size |

|---|---|

| N/A | N/A |

Tip: Always look at the chart’s size range before you tighten bolts.

Material Coverage

Bolts can be made from many materials. The best charts show torque for ferrous and non-ferrous bolts. You can find torque for steel, stainless steel, bronze, and brass. This helps you not make mistakes when you use different materials.

| Bolt Grade | Material Type | Torque Values |

|---|---|---|

| Grade 2 | Ferrous | Various |

| Grade 5 | Ferrous | Various |

| Grade 8 | Ferrous | Various |

| 18-8 Stainless Steel | Non-Ferrous | Various |

| Bronze | Non-Ferrous | Various |

| Brass | Non-Ferrous | Various |

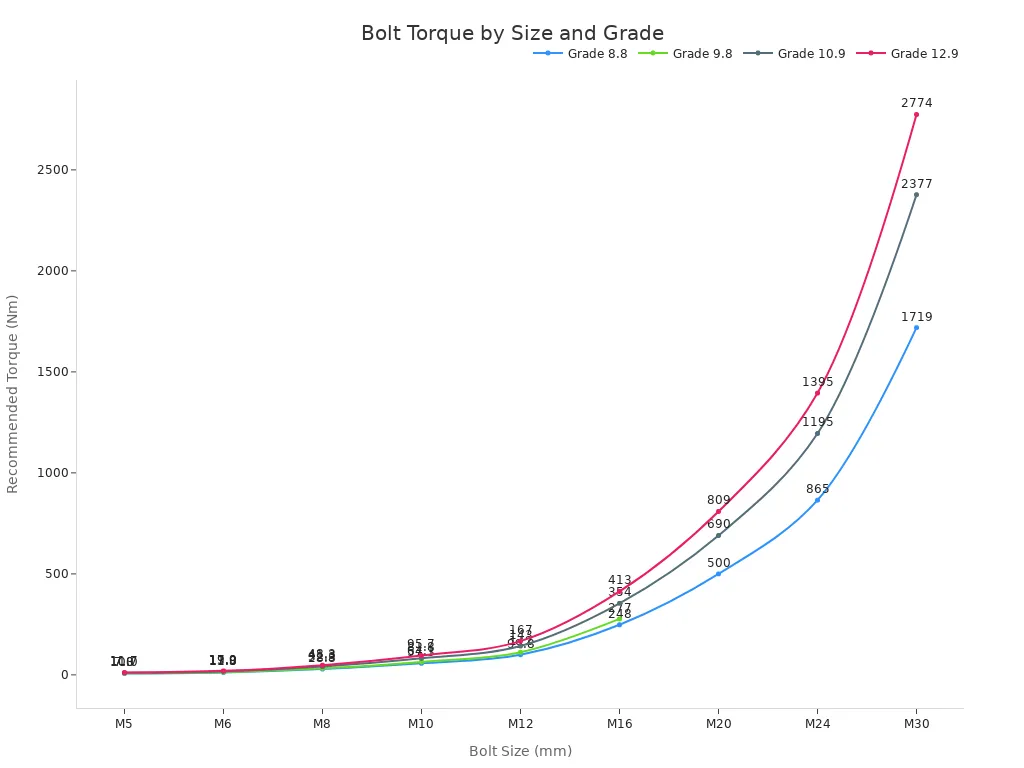

Grade Coverage

The grade of a bolt changes how much torque you need. Good charts show values for grades like 8.8, 9.8, 10.9, and 12.9. You can match the grade to the torque to keep things safe.

| Bolt Grade | Maximum Tightening Torque (Nm) |

|---|---|

| Grade 8.8 | Different values for each size |

| Grade 9.8 | Different values for each size |

| Grade 10.9 | Different values for each size |

| Grade 12.9 | Different values for each size |

Ease of Use

You want a chart that is quick and easy. Some charts have digital calculators. You type in the bolt size and grade to get torque. These tools can work on phones, so you can use them anywhere.

| Feature | Description |

|---|---|

| Digital Calculator | Lets you enter bolt info and get torque fast. |

| Mobile Compatibility | Digital calculators may work on phones or tablets. |

Note: A simple bolt torque chart helps you work faster and makes fewer mistakes.

Choosing a Chart

Project Requirements

You should always start by looking at your project’s needs. Think about what you are building or fixing. Some projects need to follow strict industry standards. Others may allow more flexibility. If you work on bridges, machines, or vehicles, you must use charts that match those rules. Write down the bolt sizes, the number of bolts, and any special instructions. This step helps you avoid mistakes later.

Material & Grade

Bolt material and grade change the torque you need. Stronger bolts can handle more force. We can see this in the table below. For example, an M10 bolt in grade 8.8 needs 57.3 Nm, but in grade 12.9, it needs 95.7 Nm. Always match the chart to your bolt’s grade and material.

| Bolt Size (mm) | Grade 8.8 (Nm) | Grade 9.8 (Nm) | Grade 10.9 (Nm) | Grade 12.9 (Nm) |

|---|---|---|---|---|

| M5 | 7.0 | 7.8 | 10.0 | 11.7 |

| M6 | 11.8 | 13.3 | 17.0 | 19.9 |

| M8 | 28.8 | 32.3 | 41.3 | 48.3 |

| M10 | 57.3 | 64.1 | 81.8 | 95.7 |

| M12 | 99.8 | 112 | 143 | 167 |

| M16 | 248 | 277 | 354 | 413 |

| M20 | 500 | N/A | 690 | 809 |

| M24 | 865 | N/A | 1195 | 1395 |

| M30 | 1719 | N/A | 2377 | 2774 |

Tip: Always check both the size and grade before you use a torque value.

Application Environment

The place where you use the bolt changes the torque you need. High heat, moisture, or chemicals can affect how tight the bolt stays. For example, bolts in hot engines or wet areas may need different torque. The table below shows how the environment can change your results.

| Environmental Factor | Impact on Torque Application |

|---|---|

| Temperature | Fluctuations can cause thermal expansion or contraction, affecting clamping force and torque effectiveness. |

| Humidity | Can lead to corrosion, altering friction characteristics of threads. |

| Chemical Exposure | Degrades lubricants, impacting their effectiveness and required torque for secure connections. |

Note: If you work in tough environments, pick a chart that covers those conditions.

Chart Accuracy

You want a chart that gives you reliable numbers. Look for charts from trusted sources or industry standards. Some charts include extra notes for special cases. Always double-check the numbers and make sure the chart matches your bolts and your project. Using the right bolt torque chart helps you avoid failures and keeps your work safe.

Mistakes & Tips

Common Errors

You might make mistakes when using bolt torque charts. These mistakes can make things unsafe or break equipment. Here are some common problems:

- Galling and seizing happen when stainless steel or aluminum fasteners stick together from friction. You cannot separate them easily.

- Tool inaccuracy happens when torque wrenches are not calibrated. This gives wrong torque numbers.

- Tightening bolts in the wrong order causes uneven stress. The joint can bend or break.

- Friction changes if threads are dirty, damaged, or dry. Even if your wrench shows the right number, the real torque may be different.

- Over-torquing stretches bolts too much. This makes them weak and they might snap.

- Under-torquing does not make enough clamping force. The joint can get loose later.

- Uneven torque on many bolts gives different clamping pressure.

Tip: Always check your tools. Follow the right tightening order. Clean and oil threads before you put bolts together.

Best Practices

You can get better results by using good methods. Pick a bolt torque chart that matches your bolt type, material, and grade. Write down every torque value and keep records for later.

- Use a calibrated torque wrench for each job.

- Clean and oil threads to lower friction and get the right torque.

- Tighten bolts in the right order to spread stress evenly.

- Check the bolt grade and size before you use torque.

“K is your friction variable. It stays the same, but it can change because K depends on finishes like black oxide or zinc plating. Are you using moly lube or copper anti-seize? Even threadlockers can work as a lubricant at first.”

“The equation works well, but you should check each job to find the best torque value.”

The T = KDP formula helps you figure out torque. K means the friction factor, which changes with lubricants, coatings, and thread condition. You need to think about these things to get the right clamp load. Friction changes how torque and clamp force work together. Always look at your job and change torque values if needed.

Note: Using the right torque keeps your bolts safe and strong. Good records help with quality checks and future repairs.

You should pick a bolt torque chart that fits your project. Match the chart to the material, grade, and how you will use the bolt. Always check where the chart comes from and read the instructions. This helps stop leaks and keeps things working well. Use digital tools that show results right away for better accuracy. After you put everything together, check the torque with a Torque Auditing program. Make sure your tools are calibrated and use trusted services for this. Write down all your work and keep good records. Get ready for audits by looking over your steps often.

FAQ

What happens if you use the wrong bolt torque chart?

If you use the wrong chart, bolts might be too loose or too tight. This can make bolts break, cause leaks, or make things unsafe. Always pick a chart that matches your bolt’s size, grade, and material.

Can you use a metric torque chart for imperial bolts?

You should not use a metric chart for imperial bolts. Metric and imperial bolts use different sizes and rules. Always use a chart that matches your bolt’s measurement system.

How often should you calibrate your torque wrench?

You should check your torque wrench every 5,000 uses or once a year, whichever comes first. Checking it often helps you use the right torque and keeps your work safe.

Do lubricated bolts need less torque?

Yes, bolts with lubrication need less torque. Lubrication makes bolts turn easier, so you do not need as much force. Always see if the chart gives numbers for lubricated or dry bolts.