You should look at bolt quality and if the supplier is reliable when picking bolt companies for your project. Bad fastening can lead to big problems. More than 80% of building failures happen because of bolt problems or bad suppliers. You need to pick the right bolt types and amounts for your project. A company with experience, a good name, and helpful customer support makes you trust they will give you safe and strong fasteners.

Key Takeaways

- Pick a bolt supplier with strong quality certificates. Check for ISO and ASTM standards. These help make sure bolts are safe and reliable.

- Find a company that has many bolt types and sizes. Having choices helps you get the right fasteners for your project.

- Choose suppliers with a good reputation and reviews. Good feedback means the company is reliable and gives quality service.

- Make sure the supplier has great customer support. Fast answers and help can stop your project from being late.

- Ask about how long orders take and delivery choices. Getting bolts on time is important to keep your project moving.

Selection Criteria for Bolt Companies

Quality Standards & Certifications

You need to make sure your fastener supplier follows strict rules for quality. Good fasteners come from companies that have important certifications. These certifications show the supplier cares about safety and how well their products work. You should look for these well-known standards when you choose a supplier:

- ISO 9001 Registered

- Compliance with the National Fastener Act

- AS9100:2016

- ISO 9001:2015

- API Spec 20E Monogram

- API Spec Q1 Manufacturing Certification

Many bolt companies also use international standards. These rules help you trust the bolts you buy for your project. The table below shows some important ISO standards you might see:

| ISO Standard | Description |

|---|---|

| ISO 9001 | Focuses on quality management practices to meet customer requirements and regulatory standards. |

| ISO 14001 | Provides a framework for environmental responsibility, helping manufacturers manage waste and resource consumption. |

| ISO 45001 | Ensures safe working environments and compliance with labor laws. |

| ISO 898 | Defines mechanical properties of fasteners, ensuring performance and safety criteria. |

| ISO 10683 | Specifies requirements for non-electrolytic zinc flake coatings for corrosion resistance. |

| ISO 4042 | Applies to electroplated coatings, ensuring specifications for thickness and corrosion resistance. |

| ISO 8992 | Defines general requirements for fasteners, including design and testing protocols. |

| ISO 17025 | Ensures accuracy in mechanical testing and inspection. |

Tip: Always ask your supplier to show proof of certification. This step helps you avoid problems later in your project.

Range of Bolt Types & Sizes

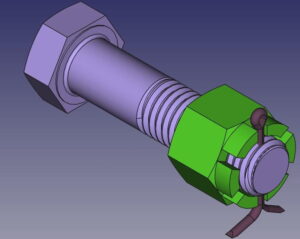

You want a fastener company that sells many kinds of bolts and fasteners. Every building job needs different bolts. A big selection means you can find the right fastener for your work. The best suppliers have many types and sizes, like:

- Carriage bolts: Used with wood and masonry, have a domed or countersunk head.

- Flange bolts: Have a built-in flange to spread out the load.

- Plow bolts: Designed for heavy-duty work, often with a square-shaped top.

- Hex head bolts: Come in many lengths and thread types, easy to use with tools.

- Square head bolts: Square heads make installation simple.

- Socket Head Cap Screws: Strong fasteners for tough mechanical jobs.

You also want a supplier who can make special fasteners for your project. Some companies offer:

- Screws, bolts, nuts, and washers for many industries.

- Custom fasteners made for your project’s needs.

- Special materials and finishes, like corrosion resistance or extra strength.

- Fast delivery to keep your project on schedule.

Having lots of choices helps you avoid delays and makes sure you get the right parts every time.

Safety and Critical Fasteners

Safety is the most important thing when you pick bolts for key parts of your build. Critical fasteners hold up buildings and keep people safe. You should check that your supplier follows strict safety rules. The table below lists some important ASTM standards for structural bolts:

| ASTM Standard | Description | Key Requirements |

|---|---|---|

| ASTM A307 | Carbon Steel Bolts and Studs | For general use, includes grades for strength. |

| ASTM A325 | High-Strength Structural Bolts | For steel connections, needs heat treatment and testing. |

| ASTM F593 | Stainless Steel Bolts | Sets rules for stainless steel, including chemical and mechanical properties. |

| ASTM F1554 | Anchor Bolts | For concrete foundations, includes different strength grades. |

| ASTM A193 | Alloy and Stainless Steel Bolting | For high-pressure and high-temperature jobs. |

Bolt companies do many tests to make sure their bolts are safe. These tests include:

- Fastener testing from raw materials to finished bolts.

- Batch testing to check every group of bolts.

- Metallurgical checks to find flaws inside the metal.

- Final product testing for real-world use, like checking coating thickness.

You should also know about pre-installation verification (PIV). This test checks bolts before you use them. PIV tests three bolts from each batch. If a bolt fails, the supplier must fix the problem before you continue.

Note: Always follow the manufacturer’s torque instructions and use a calibrated torque wrench. This practice helps stop bolt failures and keeps your project safe.

A careful selection process protects your build and everyone who uses it.

Experience & Reputation in Fastener Supply

Industry Experience

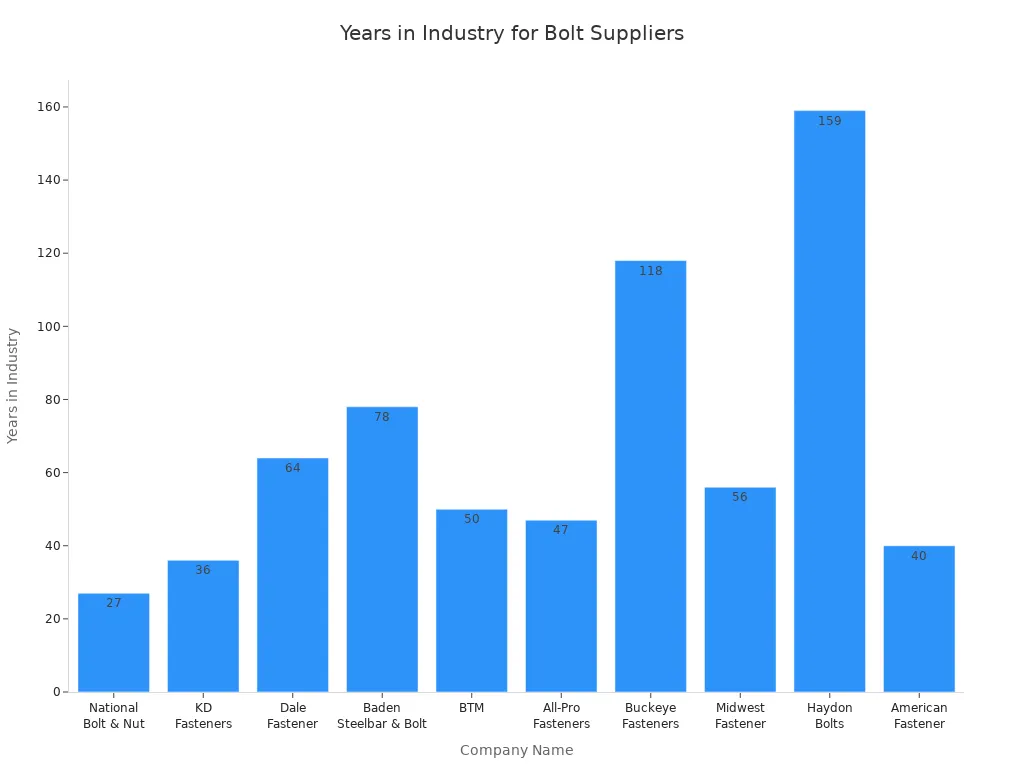

It is smart to pick a fastener company with lots of experience. A company that has worked for many years knows how to solve problems. They have helped with many different projects. For example, Prince Fastener has been helping customers for a long time. Some top bolt companies have worked for over 40 years. The table below shows how long some famous suppliers have been in business:

| Company Name | Established Year | Years in Industry |

|---|---|---|

| National Bolt & Nut, Inc. | 1996 | 27 |

| KD Fasteners, Inc. | 1987 | 36 |

| Dale Fastener Supply | 1959 | 64 |

| Baden Steelbar & Bolt Corp. | 1945 | 78 |

| BTM | 1973 | 50 |

| All-Pro Fasteners | 1976 | 47 |

| Buckeye Fasteners Company | 1905 | 118 |

| Midwest Fastener | 1967 | 56 |

| Haydon Bolts, Inc. | 1864 | 159 |

| American Fastener Technologies | 1983 | 40 |

A company with a long history can make you feel safe. You know your project will go well.

Reliability & Track Record

You want a supplier you can count on. A good fastener company uses new machines and checks quality all the time. Here are ways to tell if a supplier is reliable:

- They use modern machines to make bolts.

- They check quality at every step.

- They test bolts to make sure they are strong.

- They use smart tools to send orders fast.

- They tell you what is happening with your order.

Companies like Prince Fastener do these things to give you good bolts. They also use smart ways to manage orders and fill big orders quickly.

| Strategy | Description |

|---|---|

| Supply Chain Management | Manages everything from getting materials to delivery, using technology for real-time updates. |

| Order Picking Strategies | Uses methods like batch picking to make warehouse work faster. |

| Fulfillment Partner Choice | Picks partners with good records and technology to keep orders on track. |

Customer Reviews & Online Reviews

You should read reviews before you pick a supplier. Reviews from other people tell you what the company is really like. Many people say the best suppliers give great service and products. One customer said:

The reviews and experiences that were available felt genuine, rather than paid promotions… Quality all around. You have to experience it to truly appreciate it. Machine build, design choices, advanced (useful) features, and exceptional support make this a winner all around.

Online reviews show if a supplier is good for you. They tell you about real customer stories, product quality, and how fast the company ships. You can find these reviews on websites and forums. If you see lots of good reviews for a company like Prince Fastener, you know you can trust them.

- Online reviews share real stories from buyers.

- They help you compare companies fast.

- Good reviews mean the supplier is trusted and cares about quality.

Picking a fastener company with lots of experience, a good record, and happy customers helps your project do well.

Production & Technology Capabilities

Manufacturing Capacity

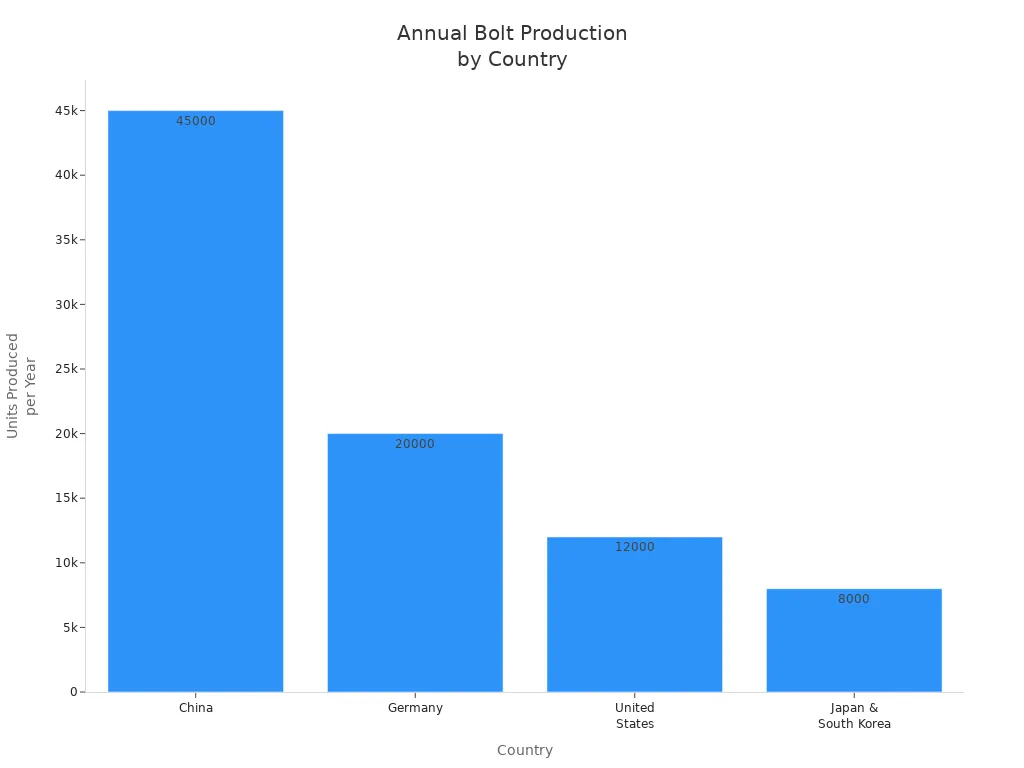

It is important to know how many bolts a company can make each year. Big bolt companies make thousands of bolts to meet needs around the world. The table below shows how many bolts some top countries make every year:

| Country | Units Produced/Year | Global Share | Market Value (USD) |

|---|---|---|---|

| China | ~45,000 | ~40% | 120 million |

| Germany | ~20,000 | ~20% | 60 million |

| United States | ~12,000 | ~12% | 35 million |

| Japan & South Korea | ~8,000 | ~15% | 20 million |

Bolt companies use smart ways to keep up with what people need. They buy new machines and use better technology. Automation and 3D printing help them make bolts faster and better. Some companies make new fasteners for special jobs. They also change their products to fit what people in different places want.

| Strategy | Description |

|---|---|

| Investment in advanced technologies | Companies are adopting automation and 3D printing to enhance production efficiency and capacity. |

| Innovation in product offerings | Manufacturers are developing fasteners with improved durability and precision to meet diverse needs. |

| Adaptation to regional needs | Companies are tailoring their products and practices to align with specific market demands. |

Customization Options

Sometimes you need bolts that are not regular. Many suppliers can make custom fasteners for special projects. You can ask for different sizes, grades, or types. How long it takes depends on what you need. If you order a lot, your order might be done faster. Special sizes or grades can take longer because they need extra work.

| Factor | Description |

|---|---|

| Quantity | The number of fasteners ordered can significantly impact lead time. |

| Size | Different sizes may require different manufacturing processes, affecting lead time. |

| Grade | The material grade can influence the complexity of production and thus the lead time. |

| Type of Fastener | Various types of fasteners have unique manufacturing requirements, leading to different lead times. |

| Expedited Orders | Customers can request faster delivery, which may incur additional costs. |

Tip: Ask your supplier about custom options early. This helps you plan your project and avoid delays.

Lead Times

You want your bolts to arrive when you need them. Getting bolts on time keeps your project going. Most suppliers tell you how long your order will take. Lead times can change based on the size, type, and grade of your bolts. Fast delivery is important if you need bolts quickly. Many companies use tracking apps to show where your order is. You get updates about shipping and delivery. This helps you know when your bolts will get to you.

- Delivery and lead times are important when you pick a supplier.

- Real-time tracking gives you updates on your order.

- Apps like Tandem Workflow let you see shipping progress and get invoices quickly.

Note: Always check lead times before you order. Good communication helps you avoid problems and keeps your build on schedule.

Customer Support from Bolt Companies

Responsiveness

You need quick answers when you talk to a fastener supplier. Good customer support means you get help right away. Bolt companies use smart tools to answer questions fast. They use real-time data, AI, and automation to help you. These tools make things easier and faster for you. The table below shows how they do this:

| Strategy | Description |

|---|---|

| Real-time data integration | Uses many data sources to help you get answers faster. |

| AI-driven decision making | Analyzes trends to give you better and more accurate support. |

| Automation of routine tasks | Handles simple jobs so people can focus on your special needs. |

| Personalized customer interactions | Gives you help that fits your project and makes you feel valued. |

| Streamlined communication processes | Keeps you updated about your order and any changes. |

Many companies make it easier to get quotes and order bolts. You get better results and faster service.

Technical Assistance

You want a fastener company that helps you plan your project. Customer support teams give advice and answer questions. They help you pick the right bolts for your job. They make sure you follow safety rules. Here are ways they help you:

- Quality assurance checks that your bolts are strong and safe.

- Supply chain reliability means you get your bolts on time.

- Help with industry standards keeps your project safe and legal.

- Cost-effectiveness gives you good prices without losing quality.

- Customization options let you order special bolts for your job.

- Technical support helps you choose and install fasteners.

- New technology makes your project easier and faster.

You can trust your supplier when you get this kind of help.

After-Sales Service

Customer support does not stop after you buy bolts. You need help if you have questions or problems later. Top suppliers like Fastenal, McMaster-Carr, and Grainger give strong after-sales service. They do this in many ways:

- They use strict quality control to make sure you get good products.

- Their customer service teams answer your questions and give expert advice.

- They ship fast and make it easy to find what you need on their websites.

- They offer personal service and help you solve problems.

- They train their teams to help you with any issue.

You can read reviews to see how well a supplier helps customers after the sale. Good after-sales service means you get help every step of the way.

Pricing & Contract Transparency

Competitive Pricing

You want to save money on your project. A good fastener company gives fair prices. This helps you stick to your budget. Many things can change the price of bolts. These things are:

- Material quality

- Size of the fastener

- Type of coating

- Manufacturing processes

- Industry standards

- Market trends

- Customization needs

A smart supplier knows how the market works. They help you find the best mix of price and quality. You should check prices from different companies. This makes sure you pay a fair price. Good pricing does not mean the cheapest bolts. It means you get strong and safe bolts for a fair cost.

Clear Quotes & Billing

You need to know what you are paying for. Clear quotes and bills stop surprises. The best companies show all costs before you buy. They do not hide fees or add extra charges later. Pick companies that use simple and easy quotes. The table below shows what you should look for:

| Feature | What It Means |

|---|---|

| Transparent Pricing | No hidden fees or confusing charges |

| Hidden Cost Elimination | Stable prices without sudden increases |

| All-Inclusive Technology | Tools and support included in the price |

| Returns Processing | Clear, flat-rate fees for returns |

Tip: Always ask for a full quote before you order. This helps you plan your money and stops problems.

Flexible Terms

Every project is not the same. You might need special contract rules for your job. Many suppliers give flexible choices to help you. These can be:

| Component | Description |

|---|---|

| Minimum purchase obligation | You agree to buy a certain amount of goods |

| Payment terms | Sets when and how you pay |

| Delivery flexibility | Lets you change delivery times if your project changes |

| Penalty clauses | Explains what happens if someone does not follow the contract |

| Make-up provisions | Lets you get goods you paid for but did not receive yet |

Flexible rules help you run your project well. You can talk with your supplier to set rules that fit your time and budget.

Choosing the Right Fastener Supply Company

Matching Product Type & Quantity

You need to match the right bolt type and quantity to your project. Start by looking at your building plans. Write down what kinds of bolts you need and how many. If you use the wrong type or run out, your project can stop. Many project managers use a vendor-managed inventory system. This system helps you get the right bolts when you need them. You do not have to worry about running out or ordering too much. The engineering team from your fastener supplier can help you choose the best bolts for each part of your build. They know which bolts work best for different jobs. This support saves you time and money.

Tip: Always ask your supplier if they offer inventory management or engineering support. These services help you avoid mistakes and keep your project on track.

Step-by-Step Selection Process

You can follow a simple process to pick the best fastener supply company for your needs. This process helps you make smart choices and avoid problems.

List Your Needs

Write down the types and sizes of bolts you need. Include any special materials or coatings.Check Quality Control

Make sure the company tests raw materials and finished bolts. Ask about their quality checks.Review Production Capacity

Find out if the company can make enough bolts for your project. Ask how fast they can deliver.Look at Customer Service

Choose a company that answers your questions quickly. Good support means fewer delays.Check Certifications

Ask for proof of industry certifications. These show the company meets safety and quality rules.Evaluate Technology and Customization

See if the company uses new machines and offers custom bolts. This helps if you need special fasteners.Read Reviews

Look for customer reviews online. Good reviews mean the company is trusted.Compare Prices and Terms

Ask for clear quotes. Make sure you understand all costs and contract terms.

Note: Work with suppliers who have a strong record of meeting deadlines. This builds trust and gives you reliable supply for your project.

Questions to Ask Suppliers

Before you choose a fastener supply company, ask these key questions. Their answers will help you decide if they are the right fit.

- What quality control steps do you use for your bolts?

- Can you meet my order size and delivery schedule?

- What industry standards and certifications do you follow?

- What materials do you use for your fasteners?

- How do you handle customer service and support?

- Do you offer help with choosing the right bolts for my project?

- Can you provide custom fasteners if I need them?

- How do you handle problems or returns after the sale?

You should write down the answers and compare them. This makes it easier to see which company gives you the best value and support.

| Checklist for Choosing a Fastener Supplier |

|---|

| List your bolt types and quantities |

| Check quality control and certifications |

| Review production and delivery capacity |

| Evaluate customer service |

| Ask about technology and customization |

| Read customer reviews |

| Compare prices and contract terms |

| Ask key questions before you decide |

Remember: The best fastener supply company will help you match the right product to your needs, offer strong support, and deliver on time. Careful planning and smart questions lead to a successful build.

You want your project to turn out great. Look for good quality and many bolt choices. Pick a supplier you can trust. Make sure they give strong support. Always read what other people say before you choose. Use this checklist:

- Make sure they have the right certifications and follow safety rules

- Pick bolts that fit what you need for your job

- Ask how fast they deliver and if they help you after you buy

- Look at prices and read the contract before you agree

Spend time looking up and comparing companies. Safety and trust are the most important things.

FAQ

What certifications should you check before buying bolts?

You should look for ISO 9001, ASTM, or API certifications. These show the company follows strict quality and safety rules. Always ask for proof before you order.

How do you know if a bolt supplier is reliable?

Read customer reviews and check how long the company has been in business. Reliable suppliers answer questions quickly and deliver on time.

Can you order custom bolts for special projects?

Yes, many suppliers offer custom fasteners. You can ask for special sizes, materials, or coatings. Tell the supplier your needs early to avoid delays.

Why does bolt quality matter for your project?

High-quality bolts keep your build safe and strong. Poor bolts can cause failures or safety risks. Always choose bolts that meet industry standards.

What should you do if you receive the wrong bolts?

Contact customer support right away. Good suppliers help you fix mistakes fast. Keep your order details and ask about returns or replacements.