If you’re wondering what are washers used for, they help bolts and screws stay secure in your projects. Washers spread out the force, which protects surfaces and adds safety. You’ll see what are washers used for in repairs around the house. Since different types of washers have specific jobs, knowing what are washers used for can help you choose the right one and make your work last longer.

Key Takeaways

- Washers help protect surfaces. They also keep bolts tight. Washers spread force so things do not get damaged when you tighten them.

- There are different types of washers. Each type has its own job. Flat washers help spread the load. Spring washers add tension. Lock washers stop things from coming loose.

- Picking the right washer makes your project last longer. Choose the washer that fits your project. This gives you the best results.

What Are Washers Used For

Washer Functions

You may ask what are washers used for when you see them in your toolbox. Washers do more than just take up space. They help keep your projects strong and safe. When you tighten a bolt or screw, washers spread out the force. This stops the surface from cracking or bending. Washers help things like furniture, bikes, and playground equipment last longer.

Check out this table to see how washers help in mechanical assemblies:

| Function | Description |

|---|---|

| Load Distribution | Washers spread the load over a bigger area. This stops the surface from getting damaged. |

| Anti-Loosening and Vibration Resistance | Washers keep bolts tight even when things shake. They help stop bolts from coming loose. |

| Sealing and Electrical Insulation | Rubber or silicone washers make seals. Nylon washers help stop short circuits in electronics. |

| Extended Equipment Lifespan | Washers lower wear and rust. They protect bolts and parts, even in tough places. |

You can see that washers do more than just hold things together. Washers help bolts stay tight, stop leaks, and protect electronics from short circuits.

Why Washers Matter

Why do washers matter in your repairs? If you do not use washers, you might damage the surfaces you want to protect. Washers spread out the force from bolts and screws. This stops materials from getting ruined. Without washers, things can crack when you tighten bolts.

Here are some reasons to always use washers:

- Washers keep your projects safe and strong.

- They stop surfaces from getting scratched or cracked.

- Washers help bolts and screws stay tight, even if things move.

- They help your repairs last longer.

When you think about what are washers used for, remember they protect, secure, and help your work last. Next time you use a bolt, remember how a washer can help.

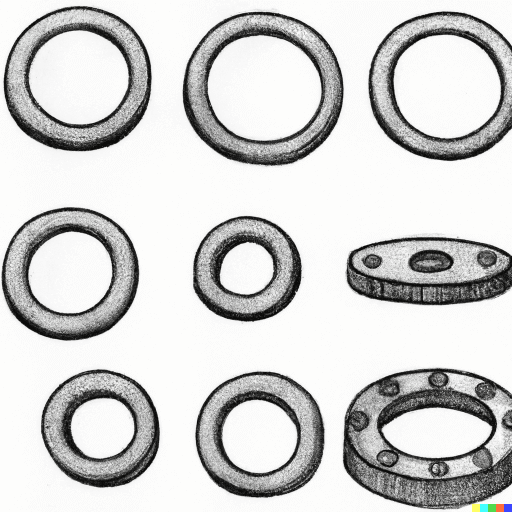

Different Types of Washers

When you open a toolbox, you might see a bunch of small metal or plastic rings. These are washers, and they come in many shapes and sizes. You’ll find that the different types of washers each have a special job. Let’s look at the three most common types of washers you’ll use in repairs and projects.

Plain (Flat) Washers

Plain washers, also called flat washers, are the most basic type. You’ll recognize them by their simple, round shape with a hole in the middle. These washers spread out the force from a bolt or screw. That means you won’t damage the surface underneath when you tighten things up.

Here’s a quick look at what plain washers do for you:

- Distribute the load so the surface doesn’t crack.

- Protect the material from scratches.

- Absorb vibrations to keep bolts tight.

- Help line up parts and keep them spaced.

- Insulate against electricity or heat.

- Seal joints to stop leaks.

You’ll find plain washers made from many materials. Some are metal, like stainless steel or brass. Others are plastic, nylon, or even rubber. This lets you pick the right washer for your project, whether you’re fixing a bike or working on electronics.

Tip: If you want to protect a painted surface or keep water out, choose a washer made from nylon or rubber.

Check out this table to see the materials you might use:

| Type of Washer | Material Options |

|---|---|

| Plain Washers | Stainless Steel, Titanium, Nylon, Brass, Fibre |

| Rubber and Nylon Washers | Rubber, Nylon |

| Metal Washers | Brass, Aluminum, Stainless Steel |

| Plastic Washers | Polyethylene, PTFE, Nylon |

Spring Washers

Spring washers look a little different. They aren’t flat. Instead, they have a curved or twisted shape. You’ll use spring washers when you need to keep tension on a bolt or screw. These washers act like tiny springs. They press against the fastener and the surface, keeping everything tight even if things shake or move.

Why do you need spring washers? Here’s what they do:

- Keep tension on bolts so they don’t loosen.

- Absorb shocks and vibrations.

- Make sure your fasteners stay secure in machines or vehicles.

- Work well in high-stress places, like engines or heavy equipment.

Spring washers are super useful in cars, trucks, and big machines. You’ll also see them in electronics, furniture, and appliances. If you want your project to stay tight and safe, a spring washer is a smart choice.

Note: Spring washers are perfect for places where things move or vibrate a lot. They help prevent loose bolts and keep everything working smoothly.

Lock Washers

Lock washers are designed to stop nuts and bolts from coming loose. You’ll see them in split, star, or coiled shapes. The special design lets lock washers grip the surfaces and hold fasteners tight. They use friction and tension to keep everything in place, even when things vibrate or shift.

Here’s how lock washers work for you:

- Create tension between the bolt and the surface.

- Increase friction so nuts and bolts don’t turn by themselves.

- Bite into the surfaces for extra grip.

- Resist loosening from vibration or temperature changes.

Split lock washers, also called helical spring washers, have a cut and twisted shape. This lets them push outward and grip the surfaces better. You’ll use lock washers in cars, machines, and anywhere you need a secure connection.

Tip: If you want to keep a bolt tight in a moving part, use a lock washer. It’s one of the best types of washers for stopping things from coming loose.

Other Types of Washers

You might also see specialized washers, like split lock, sealing, square, or wave washers. Each has a unique shape and job. For example, sealing washers keep water out, and square washers stop bolts from turning. But for most projects, you’ll use plain, spring, or lock washers.

Here’s a table showing some common types of washers and their purpose:

| Type | Description | Purpose |

|---|---|---|

| Flat | Circular, two flat sides | Distributes force, protects surfaces |

| Lock | Split, coiled, or star shapes | Prevents loosening of fasteners |

| Conical | Pressed into a cone shape | Absorbs vibration and shock |

| Square | Flat, square shape | Prevents rotation, resists corrosion |

| Sealing | Made of softer materials, round shape | Forms a seal, reduces noise/vibration |

When you know the different types of washers, you can pick the right one for your project. The purpose of a washer is to protect, secure, and make your work last longer. Next time you grab a bolt, think about which washer will help you get the best results.

Types of Washers in Everyday Use

Common Uses

Washers are used in many places every day. When you fix things at home, you often use washers. These small rings help keep bolts tight on furniture. They also keep screws secure on your bike. Washers make sure appliances work safely. They protect surfaces from getting damaged. You use washers when you need even pressure, like hanging shelves or building a deck.

For home improvement, there are different types of washers. Electric high pressure washers are popular for cleaning patios or driveways. They are simple to use and need little care. This makes them good for light or medium jobs. Gas-powered high pressure washers are best for tough jobs. They clean big areas and remove hard stains. Battery-powered high pressure washers are becoming more common. They are easy to carry and use. You can clean quickly around the yard or garage.

In cars, washers help stop leaks and keep parts tight. You use washers when strong pressure is needed, like in engines or brakes. Spring washers are important when things shake and bolts might loosen. In building work, flat washers protect surfaces and help with electrical insulation. You use them to stop rust and spread weight evenly.

Real-World Examples

Let’s see how washers help in real life. When you build a bookshelf, flat washers keep screws from hurting the wood. If you fix your bike, washers keep bolts tight so they don’t come loose. In car repairs, spring washers keep engine parts safe, even when the car shakes.

Washers are used for building fences, putting up playground equipment, and setting up electronics. In construction, washers spread weight and protect beams. In plumbing, sealing washers stop leaks and keep water in. You use washers in electrical work to stop short circuits and keep wires safe.

Tip: When you start a project, think about where washers can help. Using the right washer makes your work last longer and keeps things safe.

Washers are everywhere, helping in many ways. Whether you fix, build, or clean, you need washers to do the job well.

Washer Comparison

Key Differences

You might wonder how plain, spring, and lock washers really stack up. Each type has its own job and works best in certain situations. Check out this table to see how they compare:

| Feature | Flat Washer | Lock Washer | Spring Washer |

|---|---|---|---|

| Primary Function | Distributes load | Prevents loosening from vibration | Maintains tension, absorbs vibration |

| Vibration Resistance | Low | High | High |

| Elasticity | None | Minimal (split type only) | High |

| Best Use Case | Protects surfaces, support | Machinery, dynamic assemblies | Bolted joints under vibration or load |

Flat washers work best when you want to protect surfaces or spread out force. Lock washers shine in machines or places that shake a lot. Spring washers keep bolts tight when things move or shift.

When you buy washers in bulk, you’ll notice price differences. Plain washers cost the least, so they’re great for simple jobs. Lock washers cost a bit more and work well in medium-vibration spots. Spring washers cost the most but are worth it for high-vibration jobs.

Choosing the Right Type

Picking the right washer can make your project last longer. Here are some tips to help you choose:

- Think about what your project needs. If you want to stop a bolt from coming loose, go for a lock washer. If you need to keep tension in a joint that moves, pick a spring washer.

- Match the washer size to your bolt. The inner hole should fit the bolt, and the outer edge should cover the area you want to protect.

- Check the environment. Stainless steel washers work well in wet or harsh places. Nylon washers are good for electronics or when you need insulation.

- Don’t reuse old washers. They can wear out and lose their grip.

- Avoid over-tightening. This can bend the washer or damage your project.

If you work with different types of fasteners, always check which washer fits best. Using the right washer helps you avoid common mistakes, like using the wrong size or type. You’ll get a safer, stronger result every time.

Tip: Regularly check your washers and bolts. Tighten them if needed and replace any that look worn out.

You now know flat, spring, and lock washers each have a special job. Check this table before you choose:

| Washer Type | Purpose | Wrong Choice Consequence |

|---|---|---|

| Flat | Spread load, protect surfaces | Joint failure |

| Spring | Keep tension, fight vibration | Loose parts, safety risk |

| Lock | Stop loosening in machines | Assembly failure |

Tip: Always match the washer to your project’s needs. The right washer keeps things safe and strong!

FAQ

What washer should you use for wood projects?

You should pick a flat washer. It spreads the force and protects the wood from cracking or scratching.

Can you reuse washers after taking them off?

No, you should not reuse washers. Old washers lose strength and may not hold bolts tight. Always use a new washer.

How do you know which washer size fits your bolt?

| Bolt Size | Washer Inner Diameter |

|---|---|

| 1/4″ | 1/4″ |

| 3/8″ | 3/8″ |

| 1/2″ | 1/2″ |

Check the bolt size. Match it to the washer’s inner hole.