What Are the Different Types of Screws | The Guide to Buying the Right Screws

What is a Screw?

A screw is a type of mechanical device called a fastener that joins/affixes and holds the materials together to create a functioning assembly. Screws have replaced the conventional use of nails, they generally propose a better holding power when joining two surfaces because of the presence of threads and countersinking heads. The uses of screws have a wide range of applications in wood, concrete, metal, plastic, and other solid materials.

There are different variations of types of screws: machine screws, steel screws, concrete screws, drywall screws, chipboard screws, stainless steel screws, self-tapping screws, self-drilling screws, etc. They are also part of threaded fasteners which are non-permanent or temporary fixings typically used in interior applications.

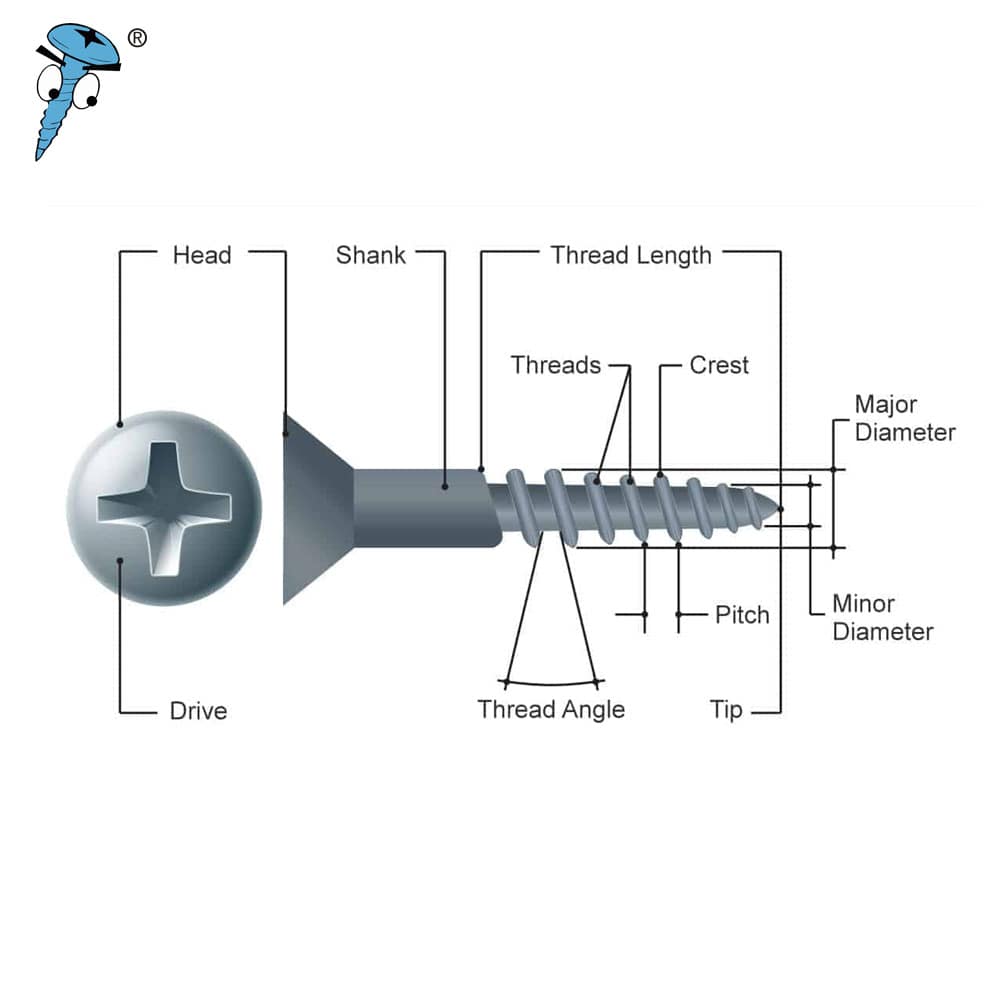

Parts of Screws

Head. The main and upper parts of the screw that has different forms for the functionality of the screws.

Drive. Located at the top part of the head of screws, there are several sizes and shapes of screw drives that can correspond to the drives of its application tool.

Thread. A helical structure that conveys rotational force in the inner or outer surface of a cylinder on screws. Screws are usually fully threaded and sometimes partially threaded. There are also different parts of threading on screws such as thread length, pitch, and crest.

Shank. the smooth surface (non-threaded shank) between the head and threads of the screw and also refers to the overall length of the screw which includes the threaded part (threaded shank). While the thickness of the screw within the shank is generally measured by minor and major diameters.

Tip/Point. The lowermost part of the screws represents the tapered point. The tip primarily touches and enters the surface of a material.

7 Common Types of Screws

The distinct difference between machine screws and the others is the threaded blunt end on the tip, usually used for fastening metal parts together.

Material: Brass or steel

Used for applications involving drywall or drywall panels with softwood and metal. Drywall screws have cylindrical threads and tapered sharp ends.

Materials: Black phosphate

Dowel Screws

Also referred to as double-ended screws, dowel screws don’t have a head but are threaded in both ends with a smooth surface in the middle. The common use of dowel screws is to fasten pieces of wood like furniture.

Masonry Screws

Masonry screws feature a flat head for countersinking, they are used for heavy-duty applications involving concrete usually in the construction industry.

Material: Stainless steel or carbon steel

This type of screw eliminates the need for pre-drilling on the material of application. Its tapered sharp end taps right away into the surface, hence its name self-tapping screws.

Subtypes: drywall screws, wood screws, sheet metal screws

It features a highly sharp pointed end that works like a drill bit for easier installation. Self-drilling screws don’t require a pilot hole and are usually used for wood and metal applications.

Also known as particle board screws, its name is derived from its particular use in chipboard panels. They have coarse threads that cut into the material during installation.

Read More: What Are the Different Kinds of Fasteners?

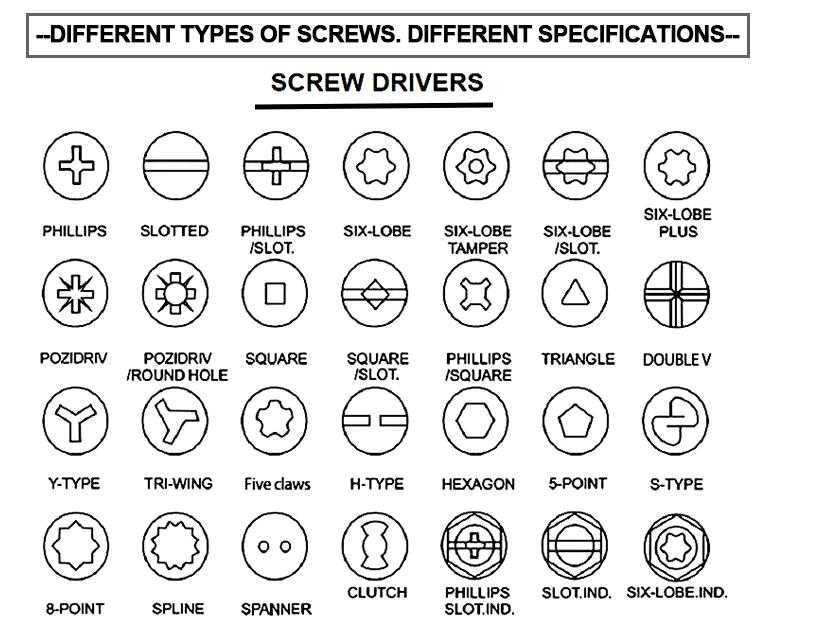

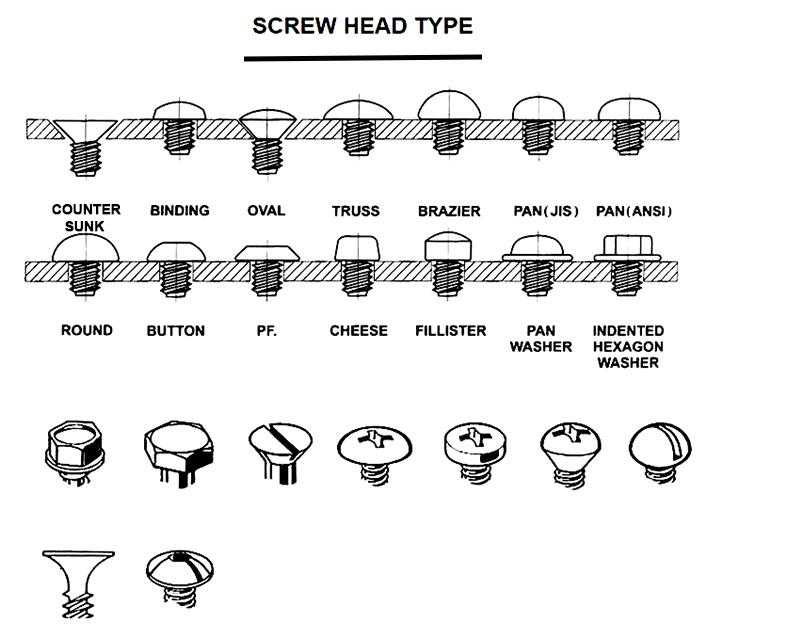

Screw Head Drives and Head Style

The head drive style or drive recess is an essential part that affects the clamping force and proper installation of screws. There are many types of head drives on screws: slotted, Torx, one-way, slotted hex, Phillips, Phillips slotted combination, Spanner, indented hex, square, etc.

There are two basic designs of the screw head: countersunk and non-countersunk. countersunk heads are mainly flat, allowing them to be buried or hidden in the surface of the application. While non-countersunk heads are the opposite, its head is fully exposed.