The biggest difference between a truss head screw and a pan head screw is the shape and width of the head. A truss head screw has a wide, flat head. It covers more area on the surface. This helps stop thin materials from getting damaged. It also spreads out the pressure better. Both screws are best for small, light jobs. They are not strong enough for heavy building work.

Picking the right screw can make your project last longer and be safer. Look at the table below for a quick comparison:

Screw Head Type | Head Shape & Profile | Common Use | Structural Load Impact | Main Advantage |

|---|---|---|---|---|

Truss Head | Extra-wide, low-profile | Sheet metal, insulation | Light-duty only | Stops damage to thin materials |

Pan Head | Rounded, wide bearing surface | Electrical, light framing | Light-duty only | Spreads weight, saves money |

Key Takeaways

Truss head screws have wide, flat heads. They help protect thin materials. The heads spread out pressure. They fit well in small spaces.

Pan head screws have round, thick heads. These heads give a strong grip. They look neat and can be seen. They work well for wood and metal jobs.

Pick truss head screws for thin or delicate things. Use them for sheet metal and plastic. This helps stop damage and pull-through.

Use pan head screws for thick materials. They hold tight and keep the head showing and neat.

Always pick the right screw for your job. Match it to your material. Use the correct tools. Drill holes first for a strong hold.

Head Design

Truss Head Screw Features

A truss head screw has a wide, mushroom-like head. The head sits close to the surface and covers a big area. This helps spread out the pressure on the material. The screw does not stick out much, so it works well in tight spots. Sometimes the head is fully round, or it can be a little flat near the drive. Because the head is thin, it is not good for heavy jobs. The wide head helps keep thin things like sheet metal or plastic safe from damage.

Tip: Pick truss head screws if you want to stop thin materials from tearing or need a screw that fits in small spaces.

Truss head screws can be made from steel, stainless steel, or brass. Steel and stainless steel are strong and do not rust easily. Brass looks nice and also fights rust, so it is good for lights or wood projects. The wide head helps stop shaking and keeps your project steady.

Pan Head Screw Features

Pan head screws have a round, tube-shaped head with a flat bottom. The head is thicker than a truss head screw. This means it has more metal and can take more force. You get a strong grip and a tidy look because the head sits above the material. Pan head screws are great for wood, cabinets, and metal work. Use them when you want the screw to show and need it to hold tight.

Pan head screws are mostly made from steel or stainless steel. These metals help you put in the screw easily and keep it strong. Stainless steel is best if you want the screw to last and not rust, especially outside or in electric work.

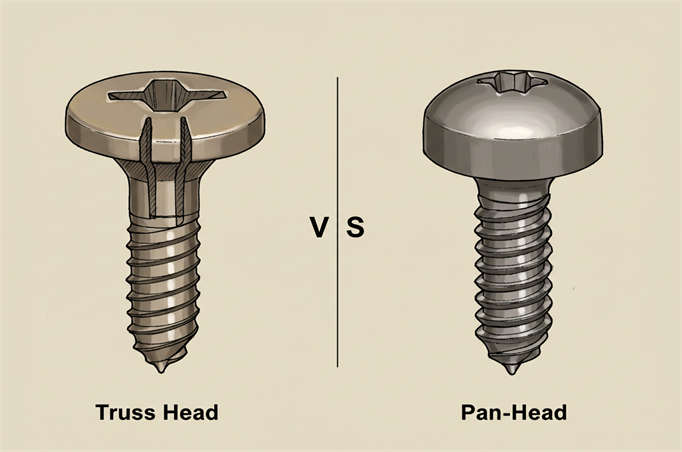

Key Visual Differences

You can tell truss head screws and pan head screws apart by their shape and how they sit.

Truss head screws have a low, wide, and a little domed head. The big surface spreads out the load and stops the screw from sinking in.

Pan head screws have a round top and a flat bottom. The head sits higher and covers less area.

Here is a quick comparison table:

Feature | Truss Head Screw | Pan Head Screw |

|---|---|---|

Head Profile | Low, wide, slightly domed | Rounded, cylindrical, flat bottom |

Bearing Surface Area | Large, spreads load | Smaller, secure hold |

Material Compatibility | Thin materials, sheet metal, plastic | Wood, cabinetry, metalworking |

Clearance Suitability | Fits tight spaces, flush finish | Sits above surface |

Washer Compatibility | Excellent, large support area | Good, but smaller support area |

Note: The low shape of a truss head screw makes it great for tight spaces. You can use it in metal lath, steel frames, or anywhere you need the screw head to stay low.

When you pick a screw, think about what you are fastening and how much space you have. Truss head screws spread out the load and protect thin materials. Pan head screws give a strong hold and look neat on top.

Applications

Truss Head Screw Uses

You often see truss head screws in jobs where you need to protect thin or soft materials. The wide, low-profile head spreads out the pressure. This helps stop the screw from pulling through or tearing the material. You can use these screws in many places:

Installing insulation on metal or wood surfaces

Connecting girders and siding to structures

Light metal framing with aluminum or thin-gauge metal

Furniture and electronics assembly

Retrofitting lighting fixtures

If you work with plastics or thin sheet metal, a truss head screw gives you a safe and secure hold. The head covers more area, so it keeps the material from getting damaged. In the electronics industry, you might use these screws to fasten circuit boards or attach covers without cracking the plastic. In HVAC work, you can use them to secure ductwork or attach insulation panels. When space is tight, the low head profile fits well and does not stick out.

Tip: When you need to fasten something delicate or thin, choose a truss head screw for better support and less risk of damage.

Pan Head Screw Uses

Pan head screws work best when you want a strong grip and a neat look. The head sits above the surface, so you can see it. You get a secure hold, and the screw is easy to drive in. Here are some common uses:

Assembling furniture kits and building wooden shelves

Securing drywall to metal or wood studs

Attaching electrical components in panels or boxes

Fastening hardware like brackets and hinges

Joining sheet metal panels in metalworking projects

You might pick a pan head screw when you need a screw that is easy to install and gives a finished look. The head is slightly raised, so it is easy to grip with a screwdriver. In woodworking, you can use these screws to put together cabinets or shelves. In metalworking, they help join panels or secure brackets. The broad head can handle more torque, so you get a tight fit without stripping the screw.

Note: Pan head screws are a good choice when you want a visible, tidy finish and a screw that is easy to drive.

Load and Material Suitability

The shape and size of the screw head affect how well the screw works with different materials and loads. A truss head screw has a wide, rounded head that spreads the load over a larger area. This design makes it perfect for soft materials like plastics or thin sheet metal. The wide bearing surface prevents the screw from pulling through or damaging the material. You get excellent surface coverage, which is important when you work with delicate items.

A pan head screw has a smaller bearing surface but a thicker head. This gives you a strong grip and lets you use more force when driving the screw. You can use pan head screws in wood, metal, or plastic when you want a secure hold and a slightly raised finish. They work well in projects where the screw will be seen and needs to look neat.

Screw Type | Best For | Load Suitability | Material Suitability |

|---|---|---|---|

Truss Head Screw | Thin, soft, or delicate items | Light-duty, wide spread | Plastics, sheet metal, insulation |

Pan Head Screw | Visible, strong connections | Light to medium-duty | Wood, metal, cabinetry |

If you need to fasten something soft or thin, use a truss head screw to avoid damage. If you want a strong, visible connection, pick a pan head screw. Always match the screw to your material and the load it will carry.

Installation Tips

Best Practices

Installing truss head screws and pan head screws the right way helps you avoid damage and get a strong hold. You should always match the screw type to your material. For truss head screws, use them with thin or soft materials so the wide head can spread the load. If you use truss screws on thick materials, the head may not work as designed.

When you install pan head screws, keep steady pressure. Too much force can strip the drive, especially in hard wood or metal. Always check that your screws match the anchors or bolts you use. This keeps your project safe and prevents loosening.

Here are some tips to help you install screws without problems:

Use the correct driver size and type for your screw head, such as a Phillips screwdriver for Phillips screws.

Pre-drill pilot holes in hard materials. This makes driving easier and stops splitting.

Choose strip-resistant drives like Torx or square drives. These have more contact points and reduce stripping.

Keep your driver or drill at a 90-degree angle to the screw. This helps you engage the screw properly.

Start with low torque settings on power tools. Increase slowly to avoid over-tightening.

Use new, well-fitting bits. Old bits can slip and damage the screw head.

Impact drivers, such as the Dewalt brushless model, work well for driving screws without stripping. They give you controlled torque and help with tough jobs.

Tip: For truss-head screws, use a setting tool that supports the screw head on its fillets. This prevents buckling and ensures a safe, precise fit.

Tools Needed

You need the right tools for a smooth installation. The table below shows what works best for each screw type:

Screw Type | Manual Tools | Power Tools | Special Tools |

|---|---|---|---|

Truss Head Screws | Phillips, Torx, Square | Impact driver, drill | Setting tool for fillets |

Pan Head Screws | Phillips, Torx, Square | Impact driver, drill | Setting tool for full head |

Use manual drivers for delicate work or when you need more control.

Impact drivers with torque control help prevent stripping, especially with truss head wood screws or screw truss applications.

Always use bits that match the screw head exactly. This keeps the head from getting damaged.

Note: Pre-drilling pilot holes is important for hard materials. It makes driving easier and protects your project.

Industry experts, such as those at the Woodworking Network, recommend using impact drivers and matching bits for best results. Following these steps helps you install truss head screws and pan head screws safely and securely.

Choosing the Right Screw

Project Scenarios

You face many choices when starting a project. The right screw depends on what you want to build. If you work with thin sheet metal or plastic, truss head screws help prevent damage. These screws spread out the load and keep soft materials safe. For example, you might use truss-head screws to attach insulation or secure ductwork. When you need a screw that sits low and does not stick out, a truss head wood screw works well.

If you build furniture or work with thicker wood, pan head screws give you a strong grip. These screws hold shelves, cabinets, and metal brackets in place. You see the screw head, but it looks neat and finished. Pan head screws also work in electrical panels and metalworking projects.

Selection Factors

You should think about load, material thickness, and appearance before picking a screw. The table below shows how these factors affect your choice:

Project Requirement | Truss Head Screws | Pan Head Screws |

|---|---|---|

Load Distribution | Wider, flatter head distributes load over a larger surface area, reducing pull-through risk, ideal for thin or soft materials. | Smaller, domed head with deep drive offers strong, secure grip, better for thicker materials where pull-through is less a concern. |

Material Thickness | Suitable for thin materials like sheet metal or plastic due to broad bearing surface. | Better suited for thicker materials due to strong grip and deeper drive. |

Appearance | Low-profile, less obtrusive, aesthetically pleasing, suitable when clearance is limited. | More pronounced, rounded head that is visible and provides a clean, finished look. |

Installation | Requires ensuring material is thin enough for load distribution; often used where flush finish is important. | Requires consistent pressure during installation to avoid stripping; preferred when screw head visibility is desired. |

Additional Notes | Customizable for specific load and aesthetic needs; ideal for applications needing a smooth finish. | Versatile in woodworking and metalworking; cylindrical shape helps maintain material integrity. |

Tip: Always match the screw to your material and the job you want to do. For thin or delicate items, truss screws protect your work. For thicker or visible projects, pan head screws give you strength and a clean look.

Common Mistakes

Many people make simple mistakes when choosing screws. You might pick a screw truss for thick wood, but the wide head will not grip well. The screw could loosen over time. If you use pan head screws in thin sheet metal, the head might pull through and damage your project.

Some people forget to check the material thickness. Others do not think about how the screw will look when finished. You should also avoid using the wrong driver bit. This can strip the screw and make it hard to remove.

Do not use truss head screws for heavy loads or thick materials.

Avoid pan head screws in soft or thin materials if you want to prevent pull-through.

Always pre-drill pilot holes for hard materials.

Remember: The right screw makes your project last longer and look better. Take time to choose the best option for your needs.

Picking truss head screws or pan head screws can change how safe and strong your project is. Truss head screws help spread weight on thin materials. Pan head screws hold tight on thick surfaces. Using the wrong screw can cause loose parts and damage. You might need to fix things and spend more money. Experts say you should test if the screw fits and check if it works with your material. Think about how much weight the screw needs to hold before you start. Always use the right screw for your project. If you are not sure, look at your hardware or ask someone who knows. 🛠️

FAQ

What is the main benefit of using truss head screws?

Truss head screws spread pressure over a wide area. You can use them to protect thin materials like sheet metal or plastic from damage. The large head keeps your project safe and secure.

Can I use truss-head screws for heavy-duty projects?

You should not use truss-head screws for heavy-duty jobs. These screws work best for light-duty tasks. The wide, thin head cannot handle high loads. For strong connections, choose a different screw type.

When should I pick a pan head screw instead of a truss head screw?

Pick a pan head screw when you need a strong grip and a neat, visible finish. Pan head screws work well in wood, cabinetry, and metal projects. They hold tight and look clean on the surface.

Do I need a washer with a truss head wood screw?

You often do not need a washer with a truss head wood screw. The wide head already spreads the load. If you want extra support, you can add a washer, but it is not required for most light jobs.

Are truss screws and screw truss the same thing?

No, truss screws and screw truss are not the same. Truss screws refer to the type of screw with a wide head. “Screw truss” usually means a part of a roof or building structure. Always check your project needs before choosing.

Tip: Always match your screw type to your material and load for the best results.