You cannot use the same torque specifications for bolts in every situation. Each bolt material and finish changes how much torque you need. Thread friction, surface finish, and even coatings like zinc plating all play a role. For example:

- A rough thread needs more torque than a smooth one.

- Lubricants can make bolts easier to tighten, but not all work the same.

- Temperature and humidity can change how the bolt behaves.

If you use the wrong torque, you risk damaging parts or causing failures.

Key Takeaways

- Torque specifications change with bolt material and finish. Always look up what each type needs.

- Lubricants lower friction, so you need less torque. Change your torque settings if you use lubricants on bolts.

- Tightening bolts too much or too little can cause big problems. It can even break parts or damage structures. Always use the right torque values.

- The K factor helps you find the right torque. It changes with the bolt’s finish and friction. Always think about the K factor when tightening bolts.

- Use a bolt torque chart to find the right torque values. This chart helps keep your projects safe and secure.

Why Bolt Finish and Material Affect Torque

Friction and Surface Treatments

When you tighten a bolt, friction controls how much force you need. The finish on the bolt changes this friction. A plain steel bolt has one level of friction. Zinc-plated or galvanized bolts have different friction. Lubrication or coatings can make bolts easier or harder to turn. These changes affect how much torque you need.

Surface roughness and coatings change how bolts work. Scientists studied how finishes change friction. Here is a table with some important findings:

| Study Title | Key Findings |

|---|---|

| The Friction Coefficient of Fasteners | Looks at how lubrication, surface treatment, and material affect friction in bolts. |

| A research method of bearing coefficient in fasteners based on the fractal and Florida theory | Shows how surface shape affects friction, contact area, and load. |

| Surface roughness effect on the torque-tension relationship in threaded fasteners | Studies how roughness changes the torque-tension link in bolts. |

You can see that surface finish changes the torque needed. Lubrication lowers friction, so you need less torque for the same force. Without lubrication, friction goes up, and you need more torque. Tightening bolts many times also changes friction. Lubricated bolts keep their force, but dry bolts lose force over time.

Different materials and finishes change torque needs. Zinc-plated and galvanized bolts need more torque than plain steel bolts. Here is a table comparing torque coefficients for bolts:

| Bolt Type | Torque Coefficient |

|---|---|

| Zinc-Plated Bolts | 0.25 |

| Galvanized Bolts | 0.25 |

| Plain Non-Plated Bolts | 0.20 |

If you use the wrong torque, bolts can be too loose or too tight. Always check the finish and material before picking the torque.

The K Factor and Its Role

The K factor helps you know how much torque you need. The formula is T = KFd. T is torque, K is the torque coefficient, F is force, and d is the bolt diameter. The K factor changes with finish, friction, and material.

- The torque-preloading link uses a constant K.

- The formula T = KFd shows how K controls torque.

- For steel bolts, K = 0.20 works for most screws and nuts.

- The K factor depends on finish and friction when tightening.

- Changes in friction and surface can make torque go up or down.

- Different loads and coatings change friction, which affects torque.

Always check torque for bolts using the K factor. Zinc-plated or galvanized bolts need a higher K than plain steel bolts. This means you need more torque for the same force. Lubrication lowers the K factor, so you need less torque.

When you pick fasteners, look at the finish and material. These things change torque needs and help you avoid problems. Using the right torque keeps bolts safe and secure.

Comparing Torque Specifications for Bolts

When you look at torque specifications for bolts, you see that they change with every combination of material, finish, and size. You cannot use one value for all bolts. Each type of bolt and nut needs its own torque. This section helps you compare the most common types and shows why you must check torque specifications for every job.

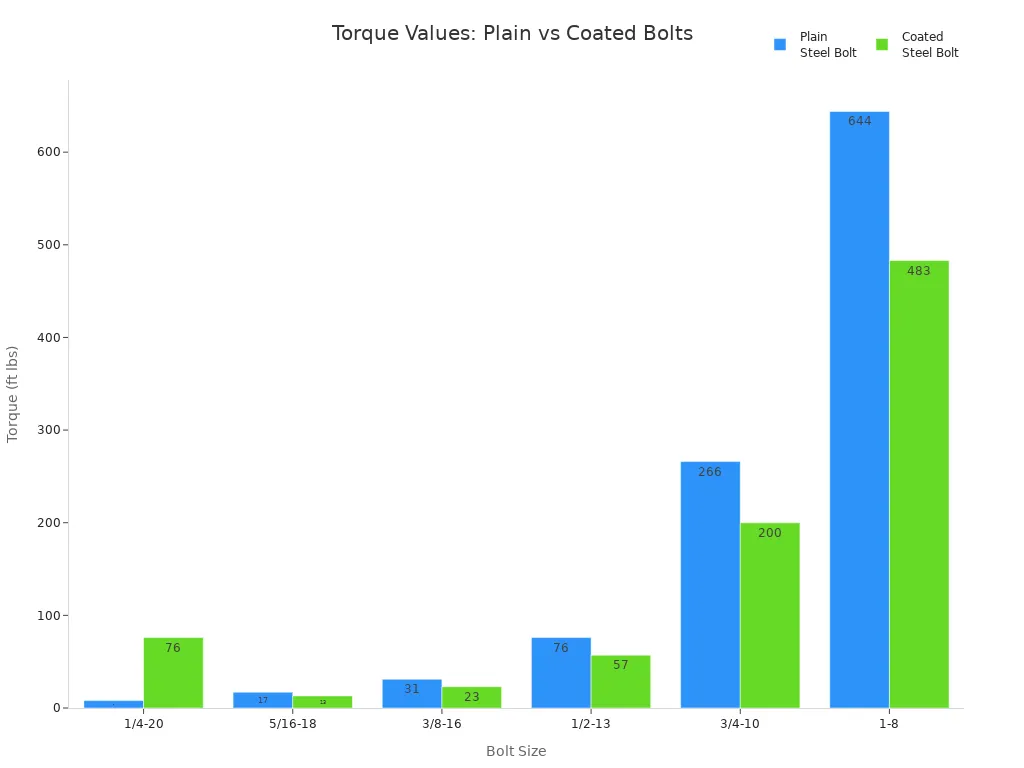

Steel Bolts—Plain vs. Coated

Steel bolts come in many finishes. The most common are plain, zinc-plated, and galvanized. Each finish changes the friction between the threads. This change affects how much torque you need to tighten the bolt. For example, a plain steel bolt has more friction than a coated one. You need more torque to reach the same tension.

Here is a table that compares torque values for plain and coated steel bolts of the same size and grade:

| Bolt Size | Plain Torque (ft lbs) | Coated Torque (ft lbs) |

|---|---|---|

| 1/4-20 | 8 | 6 |

| 5/16-18 | 17 | 13 |

| 3/8-16 | 31 | 23 |

| 1/2-13 | 76 | 57 |

| 3/4-10 | 266 | 200 |

| 1-8 | 644 | 483 |

You can see that coated bolts need less torque than plain bolts. The coating acts like a lubricant. It lowers friction and makes the bolt easier to tighten. If you use the wrong torque, you might not get the right clamping force. Always check the torque specifications for bolts before you start.

Stainless Steel and Alloy Variations

Stainless steel bolts and alloy bolts have different properties from regular steel. Stainless steel resists rust, but it can gall or seize if you do not use the right torque. Alloy bolts can handle higher loads, but they also need special torque values. The material changes how the threads grip each other.

You must know the grade and type of bolt you use. For example, ASTM A325 and ASTM A490 are two common standards for structural bolts. ASTM A325 bolts use heat-treated steel. ASTM A490 bolts use alloy steel and can handle more force. Each standard has its own torque specifications. You find these values in torque charts that list bolt diameter, grade, and minimum tensile strength.

| Standard | Bolt specifications | Bolt diameter | Minimum tensile strength |

|---|---|---|---|

| ASTM A325 | Standard specification for structural bolts, steel, heat-treated | ½ to 1 in. >1 to 1½ in. | 120,000 psi 105,000 psi |

| ASTM A490 | Standard specification for structural bolts, alloy steel, heat-treated | ½ to 1½ in. | 150,000 psi |

| ASTM A193 B7 | Standard specification for alloy-steel and stainless steel bolting for high temperature or high-pressure service and other special purpose applications | Up to 2½ in. >2½ to 4 in. | 125,000 psi 115,000 psi |

The NASA Fastener Design Manual says you must adjust torque values based on the friction between the threads. This friction changes with different materials and lubricants. If you use stainless steel bolts, always check the torque specifications for bolts and use the right lubricant to avoid damage.

Nut Material and Thread Pitch Effects

The nut you use with a bolt also changes the torque you need. Nut material, size, and finish all affect the torque-tension relationship. If you use a soft material like aluminum, you need less torque than with a hard steel nut. Thread pitch also matters. Fine threads need less torque than coarse threads for the same clamping force.

Tip: Always match the nut material and thread pitch to the bolt. This helps you get the right torque and keeps your fasteners safe.

Here are some factors that change the torque you need:

| Factor | Description |

|---|---|

| Material | Different materials have varying mechanical properties affecting torque-tension relationship. |

| Size | The size of the bolt and nut can influence the required torque. |

| Plating and Surface Finish | These can alter friction and thus the torque needed for proper tension. |

| Thread Lubricants | Lubrication can reduce friction, affecting torque requirements. |

| Corrosion and Wear | Deterioration can change the effective torque needed for a secure joint. |

- Different materials have different strength and hardness.

- Aluminum nuts need less torque than steel nuts.

- Polycarbonate screws need much less torque than hardened steel screws.

- Lubrication always lowers the torque needed.

You must always check the torque specifications for bolts, nuts, and fasteners. Never guess. Each combination of bolt, nut, and finish needs its own torque. This keeps your connections strong and safe.

Using a Bolt Torque Chart

How to Read a Bolt Torque Chart

A bolt torque chart helps you find the correct torque for your bolts. You use it to match the bolt size, material, and grade with the recommended torque values. This chart is a key tool for anyone working with bolts. You must know how to read it to avoid mistakes.

Here is a simple process to follow:

- Find the bolt diameter and thread pitch in the chart. These details affect the torque needed.

- Check the bolt grade and material. Different grades and materials need different torque specifications.

- Look for the recommended torque values for your bolt. The chart lists these values for each combination.

- Notice if the chart mentions lubrication. Lubricated bolts need less torque than dry bolts.

- Use the standard torque formula: T = DFK. D is the diameter, F is the force, and K is the k-factor. The k-factor changes with lubrication and finish.

Tip: Always use the bolt torque chart for every job. Never guess the torque. The chart helps you avoid over-tightening or under-tightening.

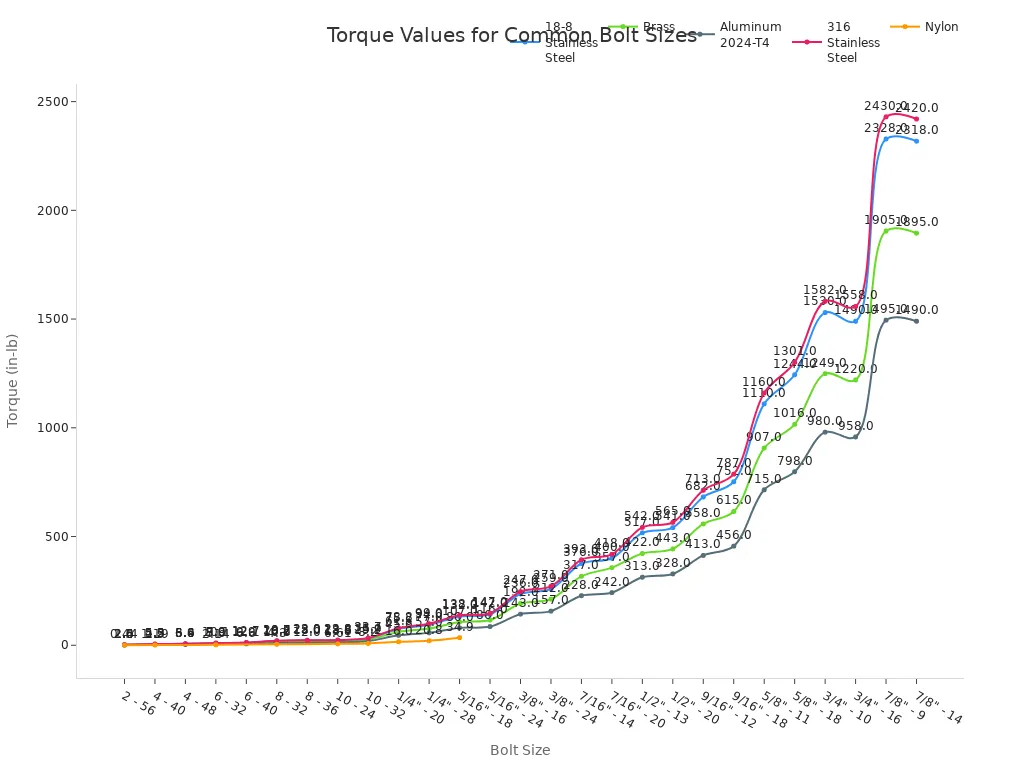

Typical Values by Size and Grade

You see many types of bolts in a standard bolt torque chart. The chart lists torque for sizes from 4 to 10 in inch-pounds and for sizes 1/4″ and up in foot-pounds. It covers Grade 2, 5, and 8 plated bolts. The diameter and thread pitch change the torque needed. Larger bolts need more torque. Fine threads need less torque than coarse threads.

The chart below shows typical torque specifications for common bolt materials and sizes:

| Bolt Size | 18-8 Stainless Steel | Brass | Aluminum 2024-T4 | 316 Stainless Steel | Nylon |

|---|---|---|---|---|---|

| 2 – 56 | 2.5 | 2.0 | 1.4 | 2.6 | 0.44 |

| 4 – 40 | 5.2 | 4.3 | 2.9 | 5.5 | 1.19 |

| 6 – 32 | 9.6 | 7.9 | 5.3 | 10.1 | 2.14 |

| 8 – 32 | 19.8 | 16.2 | 10.8 | 20.7 | 4.30 |

| 10 – 24 | 22.8 | 18.6 | 13.8 | 23.8 | 6.61 |

| 1/4″ – 20 | 75.2 | 61.5 | 45.6 | 78.8 | 16.00 |

| 5/16″ – 18 | 132.0 | 107.0 | 80.0 | 138.0 | 34.90 |

| 3/8″ – 16 | 236.0 | 192.0 | 143.0 | 247.0 | N/A |

| 1/2″ – 13 | 517.0 | 422.0 | 313.0 | 542.0 | N/A |

| 3/4″ – 10 | 1530.0 | 1249.0 | 980.0 | 1582.0 | N/A |

The torque values in the bolt torque chart are starting points. You may need to adjust them for special conditions or lubrication. Always check the chart before you tighten any bolt. The diameter and thread pitch change the clamp load and friction. This affects the torque you need. Using the bolt torque chart helps you get safe and strong connections every time.

Accurate Torque Application in Practice

Manufacturer Specs and Industry Standards

Always start with the manufacturer’s specs for torque. These specs tell you how tight to make each bolt, nut, and fastener. Manufacturers test their products. They know how different materials and finishes change the torque needed. Industry standards like ASTM or ISO also help you pick the right torque. These standards set torque at about 75-80% of the bolt’s yield point. This stretches the bolt enough to hold tight but does not break it.

When you tighten a bolt, you make it stretch and twist. Engineers use about 90% of the yield strength for best results. This keeps the bolt strong but safe. Always check the bolt torque chart and compare it to the manufacturer’s advice. Remember, torque specs are guides. Lubricants, coatings, and how you install bolts can change the torque needed. Testing bolts in real life helps you find the right torque.

Tips for Real-World Fastening

Getting the right torque in real life needs more than a chart. You need good tools and smart habits. Here are some tips:

- Calibrate your torque wrench before you use it. Do this every time or at least twice a year. This keeps your readings correct.

- Set your torque wrench to match the recommended torque for your bolts.

- Clean the threads on bolts and nuts before tightening. Dirt or rust can change the torque needed.

- Take care of your tools so they do not get damaged.

- Use the right torque tool for each job. The table below shows common types:

| Type of Torque Wrench | Accuracy Characteristics |

|---|---|

| Click Wrenches | Same accuracy as beam wrenches. |

| Beam Wrenches | Highly accurate readings, easy to maintain. |

| Digital Wrenches | Highly accurate, pre-calibrated, can store multiple settings. |

Follow ISO rules for how often to calibrate your tools. Always use the right torque for your fasteners. Think about the material and finish. Lubricants lower friction, so change your torque if you use them. Using the right torque stops problems like loose bolts or damaged threads. It also keeps corrosion resistance. When you follow these steps, your bolts stay tight and last longer.

Risks of Incorrect Torque Specifications

Over-Tightening and Under-Tightening

Big problems happen if you do not use the right torque. If you tighten a bolt too much, you can hurt the threads. This is worse for soft materials like aluminum or plastic. You might see cracks or bent parts. Sometimes, you do not notice these problems until something breaks.

The report says the grip length was short. This made bolts too tight. It suggests that important connections should be checked by an outside expert. HSFG bolts with special washers or TCBs should be used to stop these problems.

If you tighten bolts too much, they stretch too far. This makes them weaker and easier to wear out. You might have to fix or replace things more often. Safety problems can happen if parts do not work right.

Here is a table with the main risks:

| Consequence | Description |

|---|---|

| Structural Damage | Too much tightening can break parts in machines. |

| Reduced Load-Bearing Capacity | Bolts can stretch too much and get weaker. |

| Material Deformation | Tightening too hard can bend or crack metal. |

| Increased Wear and Tear | Parts wear out faster when bolts are too tight. |

| Potential Component Failure | Bolts can fail if they are not tightened right. |

If you do not tighten bolts enough, they can come loose. Shaking or vibration can make threads turn and lose grip. Over time, parts can settle and bolts lose their hold. Changes in temperature can also make bolts lose tightness.

| Mechanism | Description |

|---|---|

| Self-loosening due to vibration | Shaking makes threads move and bolts get loose. |

| Plastic deformation | Parts can change shape and bolts lose their grip. |

| Differential thermal expansion | Heat or cold can make bolts and parts move and lose tightness. |

Finish-Specific Failure Modes

Thread friction changes with every finish. If you do not use the right torque, special problems can happen. Zinc coatings change how threads slide, so you must change the torque. If you do not, bolts can come loose or break.

- Rust can make bolts lose grip, which is needed to keep things together.

- Strong bolts can crack from stress or chemicals.

- Too much rust makes bolts weaker, especially strong ones.

- Zinc coatings change how threads slide, which changes torque.

- You may need to change torque because coatings add friction.

Here is a table of common failure modes:

| Failure Mode | Consequences | Real-World Example |

|---|---|---|

| Under-Torquing | Bolts get loose, parts break, leaks happen | Bridge bolts not tight enough |

| Over-Torquing | Bolts break, threads strip, parts get damaged | Car wheel nuts too tight bend brake rotors |

| Incorrect Torque Application | Wrong order, friction changes, tool mistakes | Cylinder head bolts tightened wrong |

| Material Selection Issues | Wrong material, not strong enough | Aluminum bolts used where it gets very hot |

You must always think about thread friction when you set torque. Each finish changes how threads grip. If you use the wrong torque, bolts can fail, leak, or cause safety problems. Always check torque for every bolt and finish to keep things safe.

You must pick the right torque for each bolt material and finish. This helps keep things safe and strong. Always look at torque charts and instructions before you tighten bolts.

- Use a torque wrench that is checked for accuracy.

- Put on lubrication to make bolts easier to turn.

- Tighten bolts in the right order and check them again if needed.

Using the correct torque keeps machines safe, saves money on repairs, and stops dangerous problems.

FAQ

What happens if you ignore torque specifications?

You risk damaging parts or causing bolts to fail. Machines may break or become unsafe. Always check torque specifications before tightening bolts.

Do coated bolts always need less torque?

Coated bolts often need less torque because coatings reduce friction. You should always check the chart for your specific bolt and finish.

Can you use the same torque for all bolt sizes?

No. Each bolt size needs its own torque. Use a chart to find the correct value for each size and material.

Why does lubrication change the torque needed?

Lubrication lowers friction between threads. You need less torque to reach the same clamping force. Always adjust torque when using lubricants.

How do you find the right torque specifications for your bolts?

You can use a bolt torque chart or check the manufacturer’s instructions. These sources give you the correct torque for your bolt type, size, and finish.