When you pick the right stud and bolt, you keep things safe and working well. Studs and bolts hold things together, but their strength is not just about size or what they are made of. Tensile strength tells us how much pulling a fastener can take. Shear strength shows how well it can handle sliding forces. For example, bolts usually have shear strength that is about 60% of their tensile strength. Many engineers wonder if studs give better clamp force or if bolts are just as good. Each fastener has special features that change how it works in real life.

Key Takeaways

- Choose studs for heavy loads and tough conditions; bolts work well for everyday jobs and quick assembly.

- Pick materials like stainless steel for wet places and alloy steel for high heat to keep fasteners strong and long-lasting.

- Use fine pitch and deep threads to resist vibration and hold heavy loads; coarse threads fit quick, light tasks.

- Select the right bolt or stud size to match your job; too small weakens joints, too big can damage materials.

- Always install fasteners with the correct torque and matching thread systems to avoid loosening or breakage.

Stud and Bolt Basics

What Are Studs?

Studs are used in many big projects. They look like long rods with no head. Studs have threads on both ends or all over. You need nuts on each end to hold them in place. This design spreads force out evenly. It helps keep joints strong when under pressure. Studs are good for places with high tension, heat, or shaking. You see them in oil & gas, power plants, and building sites. Studs are strong and do not rust easily. This makes them great for hard jobs. You can put them in or take them out fast. This saves time when fixing things. Studs let you use different nuts. This gives you more choices for special machines.

Tip: Studs are best when you need a strong hold for heavy loads and tough places.

What Are Bolts?

Bolts have a head shaped like a hexagon. You use a wrench or socket to turn them. Most bolts have threads on just one end. This makes them easy to use in small spaces. You can put them in when you reach only one side. Bolts are good for building, machines, and cars. You can take bolts out fast to change parts. Bolts are strong enough for normal jobs and daily use.

Here is a table that shows how studs and bolts are different:

| Feature | Hex Head Bolts | Stud Bolts |

|---|---|---|

| Head Presence | Hexagonal head for wrench/socket installation | Headless rod, threaded on both ends |

| Threading | Threaded on one end | Threaded on both ends or fully threaded |

| Installation | Tightened from one side using tools | Requires nuts on both ends, installed from both sides |

| Load Distribution | Load applied via head and single nut | Uniform load distribution via dual nuts |

| Design Purpose | Versatile, easy to install in moderate conditions | Designed for heavy load, high strength applications |

| Typical Applications | Structural, mechanical equipment, moderate pressure | Heavy load, high pressure, bridge construction, machinery |

| Pressure Ratings | Suitable up to nominal pressure PN16 | Suitable up to nominal pressure PN40 |

You should know these differences before you pick a stud or bolt. Studs are stronger and last longer in hard places. Bolts are quick to use and good for simple jobs.

Material Strength

Common Materials

Studs and bolts are made from many materials. Steel and stainless steel are used a lot in cars and buildings. Steel is strong and costs less money. Stainless steel does not rust and lasts longer in wet places. You see grade 2, 5, and 8 carbon steel bolts in cars and buildings. Grade 2 is for light jobs. Grade 5 is good for cars. Grade 8 is strong for heavy loads like car suspensions.

Titanium is now used in electric cars because it is light and strong. Alloy steels like AISI 4140 and 4142 make B7 stud bolts for high heat and pressure. These alloys have carbon, chromium, and molybdenum. This helps them stay tough and not wear out fast. Bronze and brass are used sometimes, but not often.

| Material Type | Description & Usage | Sector/Application |

|---|---|---|

| Steel (Carbon Steel) | Strong, lasts long, and costs less. | Cars, Buildings |

| Grade 2 Carbon Steel | Not very strong, cheap. | General use |

| Grade 5 Carbon Steel | Used in cars. | Cars |

| Grade 8 Carbon Steel | For heavy loads. | Cars |

| Stainless Steel | Does not rust, lasts long. | Cars, Buildings |

| Alloy Steel | Very strong, good for heat. | Cars, Heavy Jobs |

| Protective Coatings | Zinc or chrome stops rust. | Cars, Buildings |

| Bronze and Brass | Used for special jobs. | Special uses |

| Titanium | Light, strong, used in electric cars. | Electric Cars |

Tip: Use stainless steel in wet or salty places. Pick alloy steel for hot or heavy jobs.

Impact on Performance

The material you pick changes how studs and bolts work. Stainless steel is best for wet or chemical places. Alloy steel is good for high heat and heavy pressure. Carbon steel saves money for easy jobs but does not last in hard places. Titanium is strong and light for electric cars.

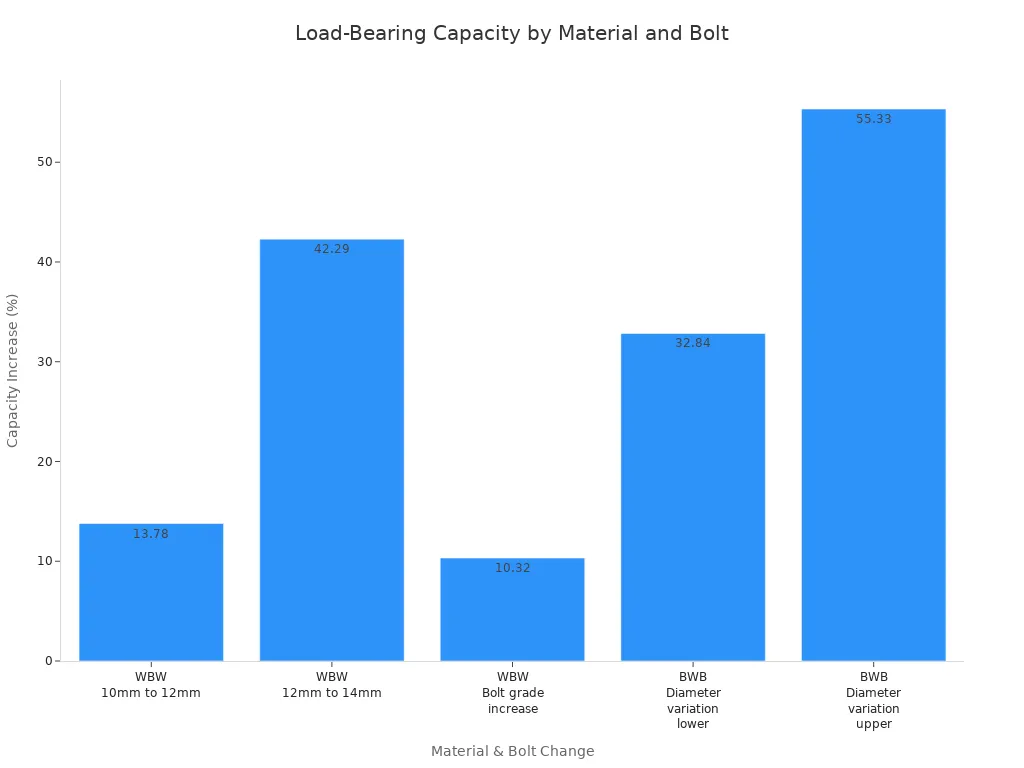

Materials change how much weight bolts can hold. Bigger bolts and higher grades hold more weight. The chart below shows how different materials and sizes make bolts stronger:

You should think about how long bolts last. Hard surfaces made by rolling help bolts last longer. Zinc plating protects bolts from rust and wear. In places with lots of shaking, pick materials that do not break easily.

The environment matters too. Rust can make bolts weak, especially if metals touch. High heat can make steel soft and less strong. Cold can make bolts break after heating. Always pick the right material for your job and place to keep things safe and strong.

Thread Design

Pitch and Depth

Thread pitch and depth play a big role in how fasteners work. Pitch means the distance between each thread peak. When you choose a coarse pitch, you get fewer threads per inch. This lets you install bolts faster, but it lowers shear strength and makes them less resistant to vibration. Fine pitch threads have more threads per inch. These threads increase clamp load and help stop loosening from vibration. You get better strength and durability, but installation takes longer. Fine threads may also stick or gall if you tighten them too much.

Manufacturers look at thread pitch when they design fasteners. They test and simulate different pitches to find the best balance between load capacity, speed, and resistance to loosening. Sometimes, a small difference in pitch between the bolt and nut can make the connection last longer and resist loosening. This difference spreads the load better and reduces stress on each thread. If the pitch difference is too large, you may lose clamp force.

Thread depth matters too. Deeper threads give more contact area between the bolt and nut. This spreads the load and lowers stress on each thread. You get higher load capacity and better wear resistance. Deeper threads also help the fastener last longer, but they increase friction. Shallow threads make installation easier and reduce friction, but they cannot hold as much load.

Tip: Pick fine pitch and deeper threads for jobs with high vibration or heavy loads. Use coarse pitch and shallow threads for quick assembly and light-duty tasks.

Fit and Load

Thread fit affects how tight the bolt feels and how well it stays in place. A tight fit increases friction inside the threads. This friction helps stop the bolt from loosening when things shake or vibrate. If the fit is loose, the bolt can move and loosen over time. The tightening torque comes from friction under the bolt head and inside the threads. Most of the torque keeps the bolt locked in place. Only a small part of the torque actually pulls the bolt tight.

When you pick the right thread fit, you lower the risk of loosening. You also improve how the load spreads across the threads. Dynamic tests show that load does not just stay on the first few threads. It spreads along the whole length, especially when things move or shake. Longer and deeper threads help share the load and keep the connection strong.

New technology helps make better threads. 3D printing lets you create special thread shapes for tough jobs like gas turbines. Automation makes fastener production faster and more consistent. Some fasteners, like SCRAIL®, use unique threads to combine quick installation with strong holding power. These advances help you get stronger, more reliable connections in many industries.

| Thread Feature | Impact on Performance | Best Use Case |

|---|---|---|

| Fine Pitch | High clamp load, vibration resistance | Heavy loads, high vibration |

| Coarse Pitch | Fast assembly, lower strength | Light-duty, quick jobs |

| Deep Threads | Higher load capacity, more wear resistance | Long-lasting, tough jobs |

| Tight Fit | Less loosening, more friction | High vibration environments |

| Loose Fit | Easier assembly, higher loosening risk | Temporary or low-stress jobs |

Size and Dimensions

Diameter and Length

You need to pay close attention to diameter and length when choosing fasteners. Diameter tells you how thick the bolt or stud is. Bigger diameters mean more strength. For example, a 3/4-inch diameter bolt can hold much more weight than a smaller one. The tensile strength goes up as the diameter increases, because the stress area gets larger. You can see this in heavy machinery, where bolts and studs range from small sizes like M6 or #6 up to large sizes such as M30 or 1-1/2 inch. These sizes follow industry standards to make sure parts fit and work safely.

Here is a table showing standard size ranges for bolts and studs in heavy machinery:

| Size Type | Diameter Range | Length Increments | Thread Types | Clearance Hole Sizes | Hex Head Dimensions |

|---|---|---|---|---|---|

| Metric Bolts | M1.6 to M100 (1.6–100 mm) | Varies by length | Metric pitches | 1.8–107 mm | ASME B18.6.7M |

| Inch Bolts | #2 to 1-1/2 inch | 1/4 inch steps | UN, UNC, UNF | 0.120–1.625 inch | ASME B18.6.3 |

Length matters just as much as diameter. You measure length from the base to the connection point. Longer bolts and studs help hold heavy parts together. Shorter ones fit tight spaces, like in cars. Always double-check your measurements to avoid mistakes.

Choosing Dimensions

Picking the right size keeps your structure safe. If you use bolts or studs that are too thin or short, joints become weak and may fail under load. If you choose ones that are too thick or long, you risk splitting or cracking the material. You must match the size to the job. Think about the thickness of the material and the type of application. Heavy machinery needs longer studs for stability. Space-limited jobs, like automotive work, need shorter ones.

Follow these guidelines when selecting dimensions:

- Measure from the anchoring point to the connection point.

- Double-check measurements for accuracy.

- Consider material thickness and type.

- Choose longer studs for heavy loads, shorter for tight spaces.

- Use standards like ASTM to avoid failures.

- Align and install properly to keep load-bearing capacity.

- Pick the right material for the environment.

If you use the wrong size, you risk loose joints, bent bolts, or even structural failure. Over-tightening can strip threads or crack materials. Under-tightening leads to loose connections. Always check load requirements and follow best practices to keep everything safe and strong.

Grades and Certification

Grading Systems

It is important to know grading systems before picking a fastener. These systems show how strong and dependable a bolt or stud is. The main grading systems are SAE, ISO, and ASTM. Each system uses grades or classes to show strength and best use. You can see the differences in this table:

| Grading System | Grades / Classes | Strength Range (psi) | Typical Applications | Description |

|---|---|---|---|---|

| SAE (Society of Automotive Engineers) | Grade 2, Grade 5, Grade 8 | 60,000-74,000 (Grade 2), 105,000-120,000 (Grade 5), up to 150,000 (Grade 8) | Household repairs (Grade 2), automotive/military/machinery (Grade 5), heavy machinery/aerospace (Grade 8) | Inch-sized bolts and nuts, strength shown by lines on bolt head, carbon or alloy steel |

| ISO (International Standards Organization) | Property Classes 8.8, 10.9, 12.9 | Comparable to SAE Grade 5 (8.8), Grade 8 (10.9), strongest metric (12.9) | Automotive and machinery (8.8), demanding industrial and automotive (10.9), critical engine parts (12.9) | Metric bolts and nuts, numbers on bolt head, carbon or alloy steel, alloy steel for highest class |

| ASTM (American Society for Testing and Materials) | ASTM A307 Grade A, Grade B; ASTM A193 Grades B5, B6, B7, etc. | 60,000 (A307 Grade A), up to 100,000 (A307 Grade B), various strengths for A193 grades | Construction (A307), piping and flanged joints (A307 Grade B), industrial and high-temperature applications (A193) | Standards for construction and industrial bolts, grades show strength and material |

You can look at the chart below to compare strength ranges. This helps you choose the right grade for your job.

Certification Importance

You should use certified fasteners for high-pressure or hot places. Certification standards like ASTM A193 and ASTM A194 set rules for what fasteners must be made of. These rules help bolts and studs last longer and stay strong. ISO certifications, like ISO 9001, check if the supplier makes good products. ISO 3506-1 and ISO 3506-2 check if stainless steel fasteners resist rust. Certified fasteners work well in tough places.

Certified fasteners use special materials like Inconel, Monel, stainless steel, and titanium. These materials are tested for pressure, heat, and rust. Markings and papers prove the fastener meets the rules. You can check and trace every certified fastener. This lowers the chance of failure and keeps your project safe.

ASTM standards cover many bolts and studs. They list what the fastener is made of, how strong it is, and how to test it. SAE and ISO focus on strength and markings. ASTM gives more details for special jobs. Always check for certification before using a fastener in an important place.

Tip: Pick certified fasteners for high-pressure, hot, or rusty jobs. This keeps your work safe and strong.

Installation and Torque

Proper Installation

You must be careful when you put in bolts and studs. This helps keep joints strong. If you hurry or use the wrong tool, you can hurt the threads. This makes the fastener weaker. Some people mix metric and imperial fasteners. This is a mistake. It causes a bad fit and loose joints. Always check that the threads and sizes are the same before you start. If the mold is not lined up or the plate is too thick or thin, you get problems. These mistakes can bend threads, make joints loose, and lower strength.

Here are some mistakes you should not make:

- Mixing metric and imperial fasteners

- Picking the wrong thread pitch or size

- Using punch speed that is too high

- Not checking plate thickness or hole size

- Skipping checks and not calibrating tools

You need to use the right clinching pressure, punch speed, and holding time. These steps stop parts from bending and keep joints steady. Check your work often with alignment tools and thickness gauges. This helps you find problems early. If you see a damaged stud, take it out and put in a new one. This brings back the strength.

Tip: Always use fasteners from the same system. Double-check that threads fit before you install them.

Torque and Strength

Torque is how hard you turn a bolt or stud to make it tight. The right torque keeps the joint safe and stops it from failing. If you do not use enough torque, the joint can get loose, leak, or break when things shake. Too much torque can stretch the fastener, strip the threads, or break the material. You must use the torque that matches the size and grade.

Here is a table with good torque values for car bolts:

| Bolt Size | Grade 2 (Coarse) | Grade 5 (Fine) | Grade 8 (Plain) | 18-8 Stainless (Fine) |

|---|---|---|---|---|

| 1/4″ | 4 lb-ft | 10 lb-ft | 12 lb-ft | 10 lb-ft |

| 1/2″ | 37 lb-ft | 90 lb-ft | 90 lb-ft | 90 lb-ft |

| 1″ | 210 lb-ft | 644 lb-ft | 909 lb-ft | 909 lb-ft |

You should use a torque wrench that is checked and works well. Follow the right order when you tighten bolts. If you use too little or too much torque, the fastener can fail. Not using enough torque is worse. It lets the joint come apart and puts stress on the fastener. Too much torque makes the fastener wear out faster or break right away.

Do these things to lower the chance of failure:

- Use the right torque for the fastener’s size and grade.

- Tighten bolts in the correct order.

- Get threads ready and use oil if needed.

- Make sure your tools are working right.

Note: The right torque keeps joints tight and stops them from wearing out. Always use the numbers the maker gives for best results.

If you learn about the five main facts of stud and bolt strength, you can make things safer and more reliable. Look at the table below to see how each fact helps keep mechanical parts safe:

| Key Factor | Impact on Safety |

|---|---|

| Material Properties | Sets safety margins |

| Manufacturing Process | Ensures quality and reliability |

| Type of Stress | Prevents failure |

| Service Conditions | Reduces risk of degradation |

| Part Shape | Maintains load integrity |

Check material, grade, thread design, size, and how you install before picking fasteners. Always pick products that follow industry rules and use good methods for tough jobs. Smart choices help protect your work and keep people safe.

FAQ

What is the difference between tensile strength and shear strength?

Tensile strength shows how much pulling force a fastener can handle before breaking. Shear strength measures how well it resists sliding forces. You need to check both when you pick studs or bolts for your project.

How do I know which grade of bolt to use?

You should look at the job’s load and environment. Higher grades mean stronger bolts. For heavy loads or high heat, pick Grade 8 or ISO 10.9. For light jobs, Grade 2 or ISO 8.8 works well.

Why does thread pitch matter?

Thread pitch affects how tightly you can clamp parts together. Fine pitch threads give better grip and resist vibration. Coarse pitch threads install faster but may loosen more easily. You should match pitch to your job’s needs.

Can I mix metric and imperial fasteners?

You should never mix metric and imperial fasteners. Mixing them causes poor fit and weak joints. Always use the same system for all bolts, studs, and nuts in your project.

What happens if I use the wrong torque?

Using the wrong torque can damage threads or make joints loose. Too little torque lets parts move and fail. Too much torque can break the fastener. Always follow the recommended torque for each size and grade.