Top 11 Self-drilling Screw Suppliers and Brands in 2022

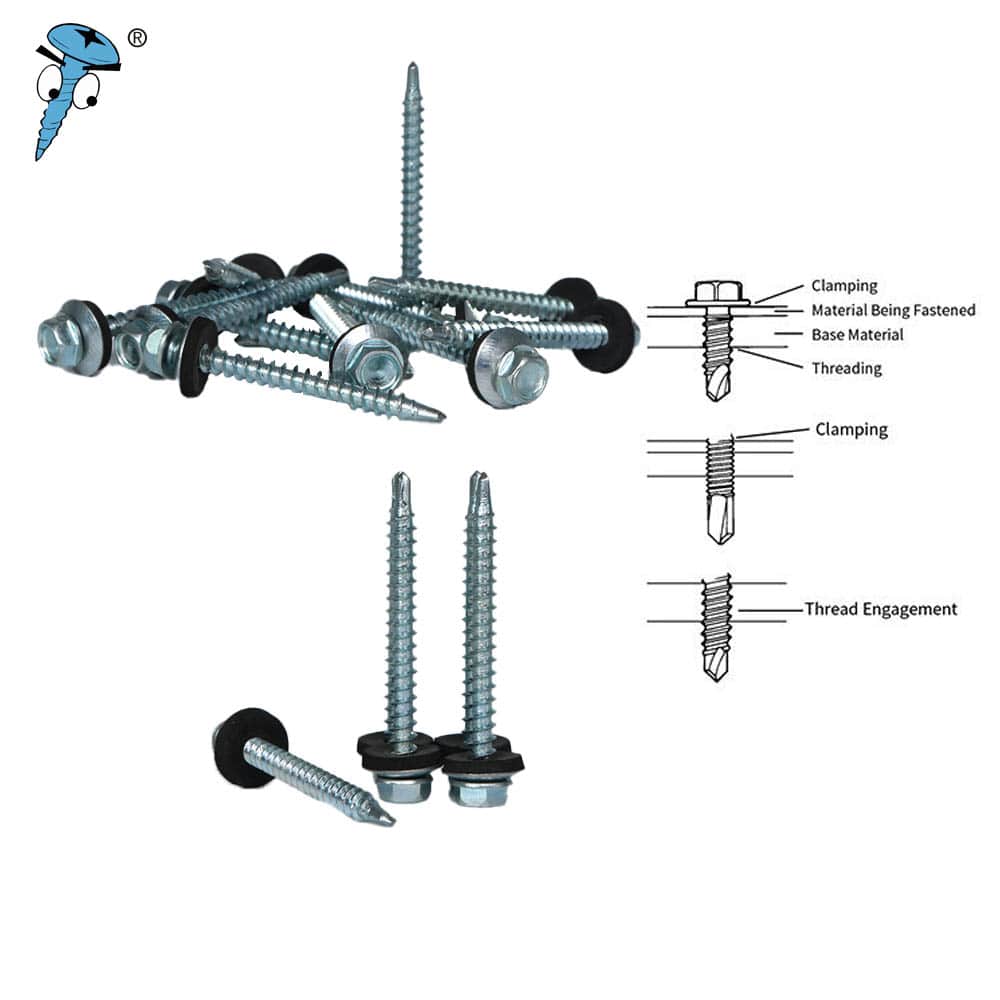

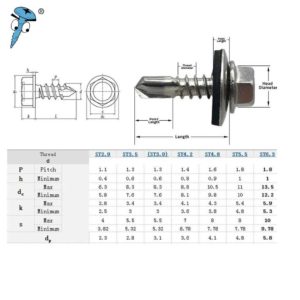

The tail of the self-drilling screw is in the shape of self-drilling or pointed tail, without auxiliary processing, it can directly drill, tap and lock on the setting material and basic material, which greatly saves the construction time. Compared with ordinary screws, its toughness and pull-out force and maintenance force are high, and it will not loosen for a long time after combination. It is easy to use safety drilling and tapping to complete the operation once. Based on detailed market research and customer feedback, we have listed 11 self-drilling screw suppliers and brands that are well accepted by customers for your reference.

Sonic Precision Hardware Industry (Kunshan) Co., Ltd.

Self-drilling Screw Supplier Introduction

Sonic Precision Hardware Industry (Kunshan) Co., Ltd. is the only manufacturer in China that produces “North Tower” screws. Its strong technical force, rigorous quality management system and perfect after-sales service allow customers to use it with confidence.

“Beita” brand self-drilling self-drilling screws and core pull studs form two series of complete materials and specifications, which have passed the ISO9001: 2000 certification of the American AQSR quality management system. The product has a production history of more than 30 years. Its strong technical force, “good but not expensive” is the symbol of Beita fastening series, perfect after-sales service, timely tracking of users, and won the support and trust of customers at home and abroad. The products have reached the international advanced level and are exported to more than 40 countries and regions.

North Tower’s PIAS self-drilling stainless steel screws and SUPER PIASTA stainless steel corrosion-resistant composite metal self-drilling screws are the world’s first, all stainless steel self-drilling screws, the cutting ability is better than that of milling cutters, especially the low-speed heavy cutting has reached the world’s high level . “Beita” brand self-drilling screws are made of low carbon steel, 304 stainless steel, 410 stainless steel and 550 stainless steel according to the material.

The stainless steel Beita brand self-drilling screws, of which the 550 patented stainless steel material, has high hardness, high strength, high corrosion resistance, and the salt spray test can reach more than 5,000 hours. It is a high-tech innovative product.

Beita brand self-drilling screws made of low carbon steel are coated with colorful zinc, blue white zinc and dacromet, and the corrosion resistance can stand up to 48 hours, 1000 hours to 2000 hours of salt spray test respectively.

Beita brand pull studs are made of low-magnesium alloy, high-magnesium alloy, all-iron, stainless steel series, and the head shape has semi-circle head and salad head.

Beita brand self-drilling screws have hexagonal big washer, hexagonal small washer, round head, salad head, round head washer, Weihua head, horn head, large flat head (the head can be painted according to customer requirements , hexagonal washer can be made of nylon head).

Beita brand has always adhered to the quality policy of scientific management, technological innovation and abide by the contract, and is willing to join hands with domestic and foreign enterprises to achieve a great cause. And the company still has a variety of related brand products, such as: Shuangfan, Feiyu, Darong, Jiuru……

Hebei Jinan Standard Parts Co., Ltd.

Self-drilling Screw Supplier Introduction

Welding stud manufacturer Hebei Jinan Standard Parts Co., Ltd. has strong strength, standardized management, advanced technology and excellent equipment; in 2019, it was rated as a Class A enterprise in the comprehensive evaluation of the economic performance of Yongnian standard parts enterprises; the company passed ISO9001:2000 international quality in 2005 Management system certification, passed the EU CE safety system certification in 2009 (Certificate Number M.2018.201.N8206); has won the “Hebei Province Famous Brand Product”, “Hebei Province Famous Brand Enterprise”, “Hebei Province Consumer Trustworthy Unit”, “Hebei Province Famous Brand Enterprise” “Hebei Province’s Product Quality Trustworthy Unit”, “Hebei Province’s Contract-honoring and Credit-Reliable Enterprise”, “Hebei Province’s Science and Technology Small and Medium-sized Enterprises”, “Steel Structure Industry Chain Certified Supplier”, “Hebei Province’s Leading Brand Enterprise in the Same Industry”, “Hebei Province Honorary titles such as “Key Recommended Unit of Integrity Enterprises in Hebei Province” and “Demonstration Unit of Double Guarantee of Quality and Credit”.

The company attaches great importance to the investment and development of scientific and technological research and development. In 2016, we applied for the invention patent of “cylindrical head welding stud, cylindrical head welding stud production method and production equipment” (patent number: ZL 2016 1 1040509.4, the patent term is 20 years) And the utility model patent of “cylindrical head welding stud and production equipment” (patent number: ZL 2016 2 1261677.1 patent term is ten years), which has significantly improved the efficiency of our company’s welding stud production, reduced energy consumption and improved the quality of welding studs promotion.

The quality inspection department of our company has a complete set of quality inspection and control equipment, and a professional standard parts quality inspection and control system under the direct leadership of the general manager. Our company’s production policy is: choose better materials, use stronger equipment, and make better products! Pursue high precision and high standards, and strive to create a well-known brand of Jinan brand high-quality standard parts! The company has a number of professional production lines for standard parts such as welding studs, stainless steel self-drilling screws, steel structure bolts, high-strength bolts, and various nuts.

The company specializes in manufacturing welding studs, cylindrical head welding studs, international standard welding studs, American standard welding studs, national standard welding studs, stainless steel self-drilling screws, high-strength hexagon head bolts for steel structures, and high-strength torsional shear connections for steel structures Vice, anchor bolts, galvanized braces for steel structure, iron tower bolts, hot-dip galvanized bolts, 8.8 hexagon bolts, 10.9 hexagon bolts, 12.9 hexagon bolts. Our company’s various products are widely used in steel structure engineering, railway, highway, bridge engineering construction, hardware machinery, electronic instruments, household appliances, textile machinery, food machinery, automobile manufacturing, air compressor unit manufacturing, boiler manufacturing, tower cranes, engineering Machinery manufacturing and other industries, the products are sold all over the country and exported to more than 20 countries and regions such as Kazakhstan, Iran, Egypt, Dubai, India, Russia, etc. Jinan brand welding studs and other fasteners have high-quality material selection, strict inspection, stable quality, reasonable price, and provide product quality inspection reports.

Various products are used in various engineering constructions that require the use of welding studs and other fasteners in various design drawings. , can also be used in various key projects suitable for the use of welding studs and other fasteners; supply many large steel structure engineering companies; some products are also used in some automobile manufacturers, railway engineering bureaus, textile machinery manufacturers, food machinery factories, Agricultural machinery manufacturers and other industrial machinery manufacturing enterprises; recognized and trusted by construction units and corporate users!

The company has a high-quality enterprise management team with rich experience and is familiar with the modern enterprise system; we have a technical management team with excellent technology, standardized management and strict requirements, which can ensure the stable quality and market competitiveness of our company’s products at any time! Our company’s quality policy is: more stable, higher and stronger (that is, the quality of various standard products is more stable, the quality standard is higher, and the product market competitiveness is stronger)!

The company adheres to the business philosophy: “survive by quality, develop by reputation! Provide better service and provide more reliable products!” The business philosophy; wholeheartedly provide customers in various industries with stable quality, reasonable price and reliable quality supporting products! Mr. Zhang, the general manager of Hebei Jinan Standard Parts Co., Ltd., together with all the staff, would like to express high respect and heartfelt thanks to the old and new friends from all walks of life who have always cared and supported Jinan Company! All Jinan staffs are willing to go hand in hand with friends at home and abroad with better products and better services to create a better future!

Hongyao Technology (Zhejiang) Co., Ltd.

Self-drilling Screw Supplier Introduction

Hongyao Hardware Industry Co., Ltd.) is a fastener manufacturer registered in March 2005. The company is a dynamic team composed of a group of personnel who have been engaged in production and management for 15 years in Taiwan-funded (Jinyi) and US-funded enterprises (Textron), integrating technology and management.

Hongyao Technology (Zhejiang) Co., Ltd. (formerly Jiashan Hongyao Hardware Industry Co., Ltd.) has 50 sets of advanced production equipment manufactured by Taiwanese enterprises, with an annual production capacity of 5,000 tons, mainly including: drywall nails, fiberboard tops, self-tapping screw supplier , Hardware gaskets, hexagonal washer, furniture screws, electronic screws, automotive fasteners suppliers and other hardware fasteners.

Hongyao Hardware adheres to the principle of “honesty, quality wins”, and is determined to produce and develop fasteners. With years of accumulated experience, Hongyao Hardware has won customers and customers with high-quality products and good services. High praise! Not long after the company was established, it applied for self-export rights, and the products are exported to most countries in South America, North America, Oceania, Europe and other regions! Our company insists on continuous improvement and continuous satisfaction of customer needs as the company’s pursuit The ultimate goal of our company, we are willing to keep making progress with our customers and peers!

Hongyao Technology (Zhejiang) Co., Ltd. strictly controls the quality, and has introduced a variety of quality inspection equipment such as metallographic polishing machine, attack speed machine, metallographic sample inlay machine, torque tester, micro hardness tester and so on. The main products of Hongyao Hardware are:

1. Chipboard screws, coarse teeth, fine teeth, the products meet the requirements of JISB1125 and the requirements specified by customers, especially the wall panel nails with 3.5*25 fine teeth, can penetrate the 1.0MM rank board within 0.6 seconds, and within 1.5 seconds Tapping through the 1.5MM iron plate,

2. Self-tapping screws of various head types, especially the series of flat head M4, have a large production volume;

3. Furniture screws;

4. Drywall screws;

5. European screws;

6. Produce non-standard parts according to customer samples. Includes triangular screw.

Hongyao Technology (Zhejiang) Co., Ltd. (formerly Jiashan Hongyao Hardware Industry Co., Ltd.) can produce specifications from M2.9-M8.0 (4#-14#), length from 6MM to 150MM (1/4″- 6″) There are many kinds of products, and the product quality conforms to DIN, ANSI, JIS, GB and related international standards; there are many kinds of products, nearly 2000 kinds of products, sincerely looking for long-term cooperation friends, hope to accept your company’s higher challenges!scre

Shanghai Yupu Industrial Co., Ltd.

Self-drilling Screw Supplier Introduction

Shanghai Yupu Industrial Co., Ltd. was established in 2004. It is a fastener manufacturing enterprise integrating R&D, production and sales. Its products cover GB, DIN, JIS, BS, ANSI/ASME and other standards.

The company’s products include stainless steel, carbon steel, aluminum, copper and other fastener series products, which are widely used in aerospace industry, military industry, metallurgical machinery, mold industry, hydraulic assembly, chemical industry, electronics, automobile, solar energy industry, wind power, food, beverage Processing equipment, pump industry, complete sets of sewage treatment equipment, communications, construction and other industries.

The company adheres to the corporate philosophy of “people-oriented, quality first, customer first”. Continuously improve product quality, enhance the company’s competitiveness, and maximize customer satisfaction. The company regards quality as its life, and has established a complete set of quality management system, and strictly implements the ISO9001:2000 quality management certification system. At the same time, it is equipped with various advanced testing equipment and instruments such as spectrum analyzer, magnetic particle flaw detector, tensile machine, salt spray testing machine, etc., so that products at different stages can be controlled with high quality.

The company is committed to the research and production of industrial fasteners. Relying on the company’s advanced production and testing equipment. It is formed by the general manager of the company and employs 3 senior technical personnel with more than 10 years to lead the technical team. We can provide you with the most professional fastening connection solutions. Design your products at any time, provide technical support with fastener expertise, and communicate with us online through the online platform.

According to your drawings or samples, we can produce all kinds of special-shaped and non-standard fasteners, combined fasteners, special fasteners, stamping parts, mechanical parts, etc. required. With our superb production technology, we solve the problems encountered in the production of various non-standard cold heading products. And many high-precision manual, CNC lathe products, special-shaped red forging products, to achieve automatic mechanized production, to achieve the goal of timely delivery and reduce production costs.

TRC

Self-drilling Screw Supplier Introduction

Our company has been engaged in the production and research and development of stainless steel self-drilling since 2006. It covers an area of 26,640 square meters, with a workshop area of 16,000 square meters and more than 150 employees. It is located in Dafeng District, Yancheng City, east of Jiangsu.

Our company has more than 200 sets of advanced production and testing equipment from Taiwan, using imported and domestic large steel mills of high-quality raw materials, specializing in the production of various types of SUS410/SUS304/SUS316 stainless steel self-drilling screws and self-tapping screws and machine screws. The production of crystals is organized according to the relevant standards and specifications of the National Standard (GB), American Standard (ANSI), German Standard (DIN), Japanese Standard (JIS), and International Standard (ISO), with an annual production capacity of more than 15,000 tons. Crystal Management has passed the IS09001 : 2015 management system certification, and has won the title of Standard Implementation and National High-tech Enterprise.

As a pioneer of stainless steel self-drilling screws, Jiangsu Gude Construction Machinery Co., Ltd. has established a competitive advantage in the stainless steel self-drilling screw industry:

Strength advantage 1 The registered capital is 30 million yuan (RMB).

Scale advantage 1 covers an area of 26,640 square meters and a construction area of 16,000 square meters.

Efficiency advantages—drawing, cold pier, self-drilling, tooth rolling, cleaning, vacuum nitriding heat treatment furnace, mesh belt heat treatment furnace, not only to ensure quality, but also to ensure delivery.

Service advantages 1. The company has set up more than 500 special dealers in major cities across the country, and established 4 warehousing and logistics centers.

Equipment advantages—drawing equipment, pier equipment, self-drilling equipment, tooth rolling equipment, degreasing equipment, degreasing equipment, mesh belt furnace, vacuum nitriding furnace, box tempering furnace, polishing equipment, grinding equipment, passivation equipment , drying equipment, packaging equipment, testing equipment.

Inventory advantage 1. The standing inventory is 5,000 tons, and the stainless steel self-drilling screw industry has a relatively complete production of crystal items and a large-scale inventory. Crystal Advantage One has 20 years of experience in the production and sales of stainless steel self-drilling screws, and adheres to the concept of “only high professionals can create value, speculation has no future”. Over the years, Goode has adhered to this concept and firmly instilled it in From every manager of the company to every new employee.

Jing brand advantage one “Cook” and “Qin Cheng” as well as “TRC” and “Yunfeng” Jing brand stainless steel self-drilling screws are widely used in steel structure engineering, glass curtain wall, stainless steel doors and windows, lighting covers, kitchen utensils, airports, docks, Chemical factories, power plants, solar energy industry, plastic steel doors and windows, guardrails, handrail installation and other industries have become well-known crystal brands in the stainless steel self-drilling screw industry, and the crystals are widely sold all over the world.

Although self-drilling is small, safety is a big issue. Only safety can bring peace of mind.

Choose “Goode” stainless steel self-drilling: equal to choosing peace of mind.

Prince Fastener Manufacturing Co.,Ltd.

Self-drilling Screw Supplier Introduction

Your trusted fastener manufacturer, Prince Fastener provides you with competitively priced, high-quality screws, as well as professional technical support and thoughtful service.

Prince Fastener specializes in the production of screws and nuts, self-tapping screws |, non-standard screws, bolts, and other fastener products. Prince Fastener has a wide range of products and complete specifications, which are sold all over the country and all over the world, and have a good reputation in the industry in various markets. Prince Fastener is well-equipped, well-managed, and has a sound system. It has successfully passed various national and international quality system certifications, and passed the review every year.

In addition, in order to better serve our customers and allow customers to truly experience the “one-stop” fastener procurement solution, Prince Fastener has opened a non-standard customized fastener service, dedicated to the development of non-standard parts and Supporting, ” Prince Fastener Non-standard Customization Service” has a complete service system from R&D-engineering-technology-quality control-after-sales

Prince Fastener specializes in the production of various types of screws, bolts and other fasteners. Our company has a wide variety of products, complete specifications, and product quality in line with industry and national standards, as well as American standard, German standard, Japanese standard and other international standards. The products are sold all over the country and all over the world, and have a good reputation in the industry in various markets.

Machine screws. Self-tapping screws. Drilling screws. Wallboard screws. Fiberboard screws. Hexagon screws. Non-standard screws and bolts, etc.

Prince Fastener Standard Parts Manufacturing Nantong Co., Ltd. is headquartered in Shanghai, and its production base is located in the beautiful Haian, Nantong, Jiangsu. The company has a wide variety of products and complete specifications, which are sold all over the country and all over the world, and have a good reputation in the industry in various markets. The company mainly produces and operates various types of self-tapping screws, self-tapping self-drilling screws, fiberboard screws, wallboard screws, machine screws, non-standard series (non-standard customized services), engineering fasteners, stainless steel fasteners, etc., and With a complete quality system, we have been committed to serving the world’s major distributors and end customers. At the same time, we can customize various types of fasteners, non-standard parts, etc. according to the requirements of manufacturers, and provide overall fastener solutions for all walks of life. , truly realize the “one-stop” fastener procurement for enterprises, which is convenient and fast. Products are widely used in various fields, such as: construction machinery, electrical equipment, construction and decoration, household items, leisure products, electrical appliances, toys, aviation, automobiles and spare parts. The company has excellent equipment, perfect management and sound system. It has a professional technical team and more than 30 years of technical experience in the fastener industry. It has exquisite craftsmanship and mature technology. The integrity, strength and product quality of Prince Fastener standard parts have always been widely praised in the industry.

Prince Fastener adheres to the corporate tenet of “steady development, development of the future, strengthened management, and perfection”, and has created the characteristic operation and management concept of “strict factory management, people-oriented, and optimized management”, and provides customers with “schematic design”. , technical support, operation and maintenance, continuous service” as one of the value-added services. Welcome customers, all colleagues to visit our company to negotiate and order, we will serve you wholeheartedly, and sincerely look forward to cooperating with you!

Jiarui Hardware (Jiangsu) Co., Ltd.

Self-drilling Screw Supplier Introduction

Jiarui Hardware (Jiangsu) Co., Ltd. is a professional manufacturer of stainless steel self-drilling screws. The company is located in the economically developed Yangtze River Delta, Hexing Industrial Park, Chunjiang Town, Xinbei District, Changzhou, covering an area of 20,000 square meters. It is adjacent to the Beijing-Shanghai high-speed railway “Changzhou North Station” in the east, the 338 Provincial Highway in the south, the Beijing-Hangzhou Grand Canal, 10 kilometers away from Changzhou Airport in the west, and the Changzhou Port, a national first-class port, in the north. The location is very convenient.

The company has introduced advanced production technology from Germany, specializing in the production of stainless steel self-drilling screw products. The company has a team with professional technology, skilled and innovative, and has introduced 20 sets (sets) of professional production equipment imported from Taiwan and supporting testing. Equipment and products are made of high-quality stainless steel series materials to ensure the quality of each product.

The company strictly controls all aspects from raw materials, production, inspection, packaging, etc. Always pursue the continuous improvement of quality and the more perfect service. Being wise and enterprising, pioneering and innovating is the eternal theme of “Jiarui”; “relying on technological development, striving for excellence to create high-quality products” is the goal pursued by “Jiarui”, and has won many domestic and foreign customers with the service tenet of “quality first, customer first” trust and support!

Guangdong Kuabiao Construction Technology Co., Ltd.

Self-drilling Screw Supplier Introduction

Guangdong Kuabiao Construction Technology Co., Ltd. The original (Dongguan Kuabiao Stainless Steel Fastener Co., Ltd.) was established in 2005, mainly producing and selling self-tapping and self-drilling screws. The company also established a bimetal composite screw production workshop in 2013, which is a domestic bimetal composite screw manufacturer.The annual output of 1 billion screws is about 3,000 tons, which are mainly used in high-corrosion-resistant buildings and supporting facilities.

According to the increasing market demand of the company’s screw products, the production efficiency is far from meeting the needs of customers. Therefore, in 2018, the beautiful Vientiane Industrial Park, Yangdong District, Yangjiang City was selected to invest in a new production base covering an area of 20,000 square meters. In January 2021, the whole factory will be relocated to the new factory. After the relocation, the production efficiency will be greatly improved. We will continue to improve and innovate, and provide customers and friends with better products and better after-sales service!

Handan Shuangzi Metal Products Co., Ltd.

Self-drilling Screw Supplier Introduction

Handan Shuangzi Metal Products Co., Ltd. is an enterprise that manufactures self-drilling and self-tapping screws.

Since its establishment, the company has been committed to the production and research and development of self-drilling wires; the company has invested in the introduction of advanced Taiwanese equipment, and hired technical expertise in hexagonal forming, tail clipping, wire rolling, carburizing, galvanizing, pad threading, packaging and other processes. Teacher, we strive for perfection in every link.

We uphold high-quality products and give back to the majority of users and merchants.

In the process of operation, we always put the growth of customers to have the strength of double purple. Therefore, we have always adhered to the tenet of operating with integrity, being anxious about the needs of customers, and using humanized communication methods to promote high-quality products and win the trust of customers.

Main products: Self-drilling wire series: self-drilling wood screws, countersunk head self-drilling, hexagonal self-drilling wire (hexagonal large flange self-drilling wire 4.5 thick, 4.8 thick, 5.5 thick) Washer head self-drilling wire, blue and white zinc self-drilling wire Drill, self-drilling wire for your faucet, self-drilling wire for pan head, self-drilling wire for flat round head, phosphating drywall nails, metal composite pads, rivets, sleeves, saddle pads, etc.

Shanghai Morul Metal Products Co., Ltd.

Self-drilling Screw Supplier Introduction

Shanghai Morul Metal Products Co., Ltd. was established in 2010. It is a fastener enterprise integrating production, processing and trade. At the same time, it is the sole agent of South Korea (Co., Ltd.) for the sales of Magni Metal Magni Coated Nails in the Chinese market.

Korea (Co., Ltd.) Myungwa Metal was founded in 1961 and mainly produces screws for automobiles, electronics and home appliances. The very first self-drilling screw and rivet (Blind Rivet) were developed in 1980. Its business scope has been expanded to steel structures and machine assembly of the entire product, and all the company’s products are in assembly line operations. At present, through continuous quality development and research, more than 200 domestic and foreign patents and certifications have been obtained. The self-drilling screw we developed is the fastest in the world, penetrating 12mm thick steel plate in 10 seconds. The annual production capacity is 10,000 tons, occupying 80% of the Korean market, and exported to Europe, America, Japan, Southeast Asia and other countries.

“Based on integrity”, providing customers with satisfactory products and services, and achieving a win-win goal with upstream and downstream customers, is the eternal pursuit of Moruer Metal. The company is committed to improving and perfecting the existing quality management system in accordance with the GB/T19001-2000 standard, strictly following the quality policy of “safe and reliable design, meticulous manufacturing, timely and effective service, and endless pursuit”, and constantly enhances the company’s overall competitiveness.

Handan Jingrun Hardware Products Co., Ltd.

Self-drilling Screw Supplier Introduction

Since its establishment, Handan Jingrun Hardware Products Co., Ltd. has been focusing on the production and operation of high-quality fasteners. It has advanced production equipment, rich production experience, complete testing equipment, professional technical team, and standardized production management. It has passed IS09001 :2015 quality management system certification, Jingrunlong always chooses high-quality materials and molds, focusing on national standard (GB), international standard (ISO), American standard (ANSI), German standard (DIN), Japanese standard (JIS), factory standard, etc.

All kinds of high-strength self-tapping screws | self-tapping, self-drilling screws | self-drilling screws (also known as self-drilling and self-drilling screws, self-drilling Drill self-drilling screws, dovetail screws) and other products; product categories include various countersunk head self-drilling screws, pan head self-tapping screws, countersunk head self-drilling screws, pan head self-drilling screws, hexagonal flange self-drilling screws, Washers head Self-drilling screws, hexagonal wood screws, countersunk head fiberboard screws, guide screws, etc. The products are widely used in color steel plates, light steel structure engineering, steel and aluminum doors and windows, advertising, refrigeration and air conditioning, home appliance manufacturing, enameled steel plates, wooden house furniture, aluminum Curtain wall, decoration, etc., are exported to Europe, the United States, Japan and other countries.

Jingrunlong has always kept in mind the management mission of “dedicating quality products, serving customers, and achieving employees”, and is committed to uniting the hearts of people with aspirations for common development, creating a harmonious and progressive management atmosphere, creating a market reputation for integrity and professionalism, and aspires to be proud of employees and trusted by customers. , The first brand in China’s fastener industry respected by the society. Welcome new and old customers to call and write, discuss cooperation, and create a better tomorrow with you!