Here’s a quick look at the most common types of bolts and their uses:

- Anchor bolts secure parts to concrete.

- Coach bolts tighten wood to metal.

- Hexagon bolts add strength in engineering.

- Hexagon set screws hold pieces together.

- Flanged bolts spread tension.

- Roofing bolts fit thin woods.

Choosing the right bolt keeps your project safe and strong.

Key Takeaways

- Picking the right bolt is very important for safety. Using the wrong bolt can cause your project to break. This can be dangerous.

- Each type of bolt has its own job. Hex bolts work well for building things. Carriage bolts are good for wood projects.

- Think about what the bolt is made of and how it looks. Stainless steel bolts are best outside. Galvanized steel bolts do well in bad weather.

Why Choosing the Right Bolt Matters

Safety and Strength

Picking the right bolt keeps things safe. The wrong bolt can make things dangerous. Buildings might shake or even fall down. No one wants that to happen. Here are some safety risks you should know:

- Using the wrong bolt can make things unstable.

- If the bolt is too weak or too small, it can break.

- Putting bolts in the wrong way can make them fail and cause big problems.

You should also think about quality. Bolts with special certifications work better for important jobs. Engineers learned from old mistakes and now use safer bolts. Rules help companies make bolts that are stronger and smarter. Check out this table to see how these things help keep you safe:

| Evidence Description | Implication for Safety Outcomes |

|---|---|

| Quality certifications for bolts in critical services are essential. | Makes bolts more reliable and lowers the chance of problems in important places. |

| Lessons learned from past failures lead to improved safety practices. | Stops the same mistakes from happening again by using better ways to build things. |

| Regulatory environments can impact technological advancements. | New rules can help make bolts safer by letting people invent better ones. |

Cost and Efficiency

Choosing the right bolt saves money and time. You don’t want to waste money fixing mistakes or buying new bolts. The right bolt helps your project go faster. Here’s how picking bolts affects your budget and work:

- The right bolt stops joints from breaking and keeps people safe.

- You save money by not picking bolts that are too strong or too weak.

- Choosing the best material helps your project last longer, even in tough places.

If you pay attention to bolt type, size, and material, you get a safer and stronger result. Your work gets easier and your project works better. 👍

Types of Bolts Explained

When you start a project, you see many types of bolts. Each type does a special job. Let’s look at the most common types of bolts. We will talk about their uses and what makes them different.

Hex Bolts

Hex bolts have a head with six sides. You tighten them with a wrench or socket. These bolts come in many sizes. Some are small for home repairs. Others are big for building bridges.

Typical Sizes:

- 1/4″ to 1-1/2″ diameter

- Lengths from 1/2″ to over 12″

Common Uses:

- Used for light and medium jobs like attaching brackets

- Help fix frames and parts in cars and machines

- Used in electrical and HVAC work

- Great for DIY and home repairs

- Used in construction and mechanical assembly

Material and Finish Options:

- Made from low carbon steel, medium carbon steel, high-strength alloy steel, stainless steel (304, 316), brass, silicon bronze

- Finishes include zinc plating, hot-dip galvanization, black oxide, cadmium plating, plain

| Material Options | Finish Options | Strength Ratings |

|---|---|---|

| Low carbon steel (Grade A307) | Zinc plating (clear, yellow, black) | Tensile strength: 60,000 psi |

| Medium carbon steel (Grade 5) | Hot-dip galvanization | Proof load: 85,000 psi |

| High-strength alloy steel (Grade 8) | Mechanical galvanization | |

| 304 stainless steel | Black oxide | |

| 316 stainless steel | Cadmium plating | |

| Brass | Plain finish | |

| Silicon bronze |

Tip: Pick stainless steel hex bolts for outdoor jobs. They do not rust and last longer in wet places.

Carriage Bolts

Carriage bolts have a round, smooth head. There is a square part under the head. This keeps the bolt from turning when you tighten the nut. You see these bolts in woodwork and outdoor projects.

Typical Sizes:

- 1/4″ to 3/4″ diameter

- Lengths from 1″ to 10″

Common Uses:

- Used for making furniture and woodworking

- Fasten metal parts in machines

- Used in decks and fences outside

- Attach beams and posts in buildings

- Used for car changes

Material and Finish Options:

- Made from steel, stainless steel, brass

- Finishes are zinc-plated, galvanized, plain

Carriage bolts look nice and do not catch on things. Their design makes them easy to put in.

Lag Bolts

Lag bolts are also called lag screws. They have a thick body and a hex head. You use them to fasten heavy wood or attach things to wood. They screw right into the wood and do not need a nut.

Typical Sizes:

- 1/4″ to 1/2″ diameter

- Lengths from 1″ to 8″

Common Uses:

- Used to hold heavy wood together

- Build decks and pergolas

- Hang shelves

- Fasten machines in factories

Material and Finish Options:

- Made from steel, stainless steel (18-8, 316), silicon bronze

- Finishes are zinc-plated, hot-dipped galvanized, plain

| Material/Finish | Corrosion Resistance Description |

|---|---|

| 18.8 Stainless Steel | Very good at stopping rust, great for outdoor use. |

| 316 Stainless Steel | Even better at stopping rust, good for salty water places. |

| Plain Finish A307 Grade A Steel | Strong and good for dry, indoor places. |

| Clear Zinc Plating | Helps steel lag bolts resist rust. |

| Hot-Dipped Galvanized Finish | Lasts longer in bad weather or wet places. |

Note: Use hot-dipped galvanized lag bolts for outdoor jobs. They last longer in rain and snow.

Eye Bolts

Eye bolts have a loop at one end. You use them to lift, anchor, or pull heavy things. The loop lets you attach ropes, chains, or cables.

Typical Sizes:

- 1/4″ to 1″ diameter

- Lengths from 1″ to 12″

Common Uses:

- Used for lifting and rigging

- Anchor equipment

- Hoist steel plates, motors, and containers

- Give lifting points on loads

Material and Finish Options:

- Made from steel, stainless steel

- Finishes are zinc-plated, hot-dip galvanized

| Safety Standard | Description |

|---|---|

| ASME B30.26 | Rigging hardware for lifting devices |

| OSHA 1910.184 | Rules for slings and rigging hardware |

| ASME B18.15 | Eyebolts size and strength standards |

| Federal Spec FF-B-575E | Bolt, hook, and forged eyebolt rules |

Always check eye bolts for cracks or damage before using. Install them the right way to stay safe.

U-Bolts

U-bolts look like the letter “U” with threads on both ends. You use them to hold pipes or tubes in place. They are common in plumbing and cars.

Typical Sizes:

- 1/4″ to 1″ diameter

- Fits pipe sizes from 1/2″ to 6″ and more

| Sizing Criteria | Description |

|---|---|

| Pipe Diameter | Measure the pipe’s outside to pick the right U-bolt width. |

| Load Requirements | Pick a bigger U-bolt for heavy loads. |

| Vibration Resistance | Use special U-bolts in cars to stop shaking. |

Common Uses:

- Hold pipes in plumbing and HVAC

- Attach exhausts and axles in cars

- Support beams and brackets in buildings

| Material | Durability Characteristics |

|---|---|

| Steel | Strong and lasts long, good for most jobs. |

| Stainless Steel | Does not rust, great for tough places. |

| Brass | Stops rust but not as strong as steel. |

| Aluminum | Light, but not as strong as steel or stainless steel. |

Stainless steel U-bolts work best outside or in wet places. They do not rust easily.

Flange Bolts

Flange bolts have a washer built in under the head. The flange spreads out the load and keeps the bolt tight. You see these bolts in cars and big machines.

| Feature | Flange Bolts | Hex Bolts |

|---|---|---|

| Head Design | Flange gives a wider surface for spreading force | Hexagonal head |

| Load-Bearing Capacity | Flange helps hold more weight | Needs washers for stability |

| Installation Precision | Needs careful alignment | Easier to install, less careful |

| Common Applications | Used in cars, building, and factories | Used in many jobs, furniture |

| Advantages | Stays tight, needs fewer extra parts | Cheap, easy to find |

| Industry | Reason for Preference |

|---|---|

| Automotive Manufacturing | Fast, safe, and stops shaking |

| Heavy Machinery | Fast, safe, and stops shaking |

Flange bolts save time. You do not need a washer, and they stay tight even when things shake.

J-Bolts

J-bolts have a hook shape like the letter “J.” You use them to anchor things in concrete. The curved end holds tight in the concrete. They are good for heavy jobs.

Typical Sizes:

- 3/8″ to 1″ diameter

- Lengths from 4″ to 24″

Common Uses:

- Anchor equipment and machines

- Hold poles and towers

- Used for fixing and repair

- Fasten columns and beams to concrete

| Factor | Description |

|---|---|

| Size | Bigger bolts hold more weight. |

| Material | Stronger materials last longer and work better. |

| Burial Depth | Should be deep enough to hold tight in concrete. |

| Strength Selection | Use high-strength bolts for heavy equipment. |

Pick the right size and material for your J-bolts. Bigger and stronger bolts hold more weight.

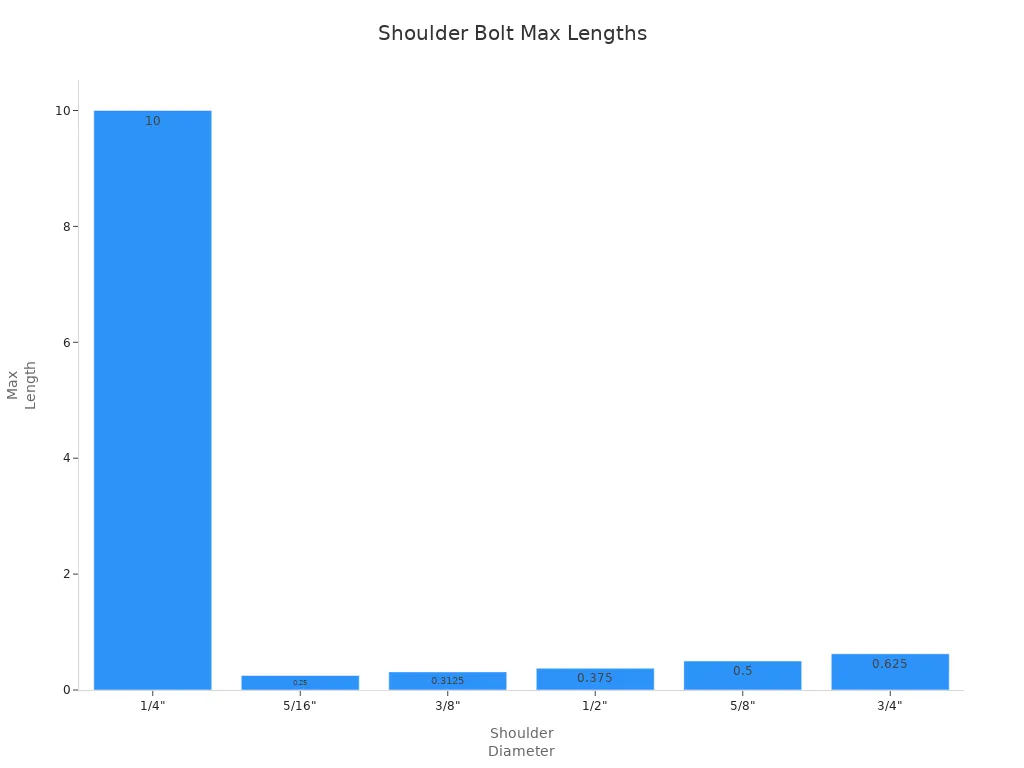

Shoulder Bolts

Shoulder bolts are also called stripper bolts. They have a smooth part between the head and threads. This part acts as a shaft or pivot.

Typical Sizes:

- Shoulder diameters: 1/4″ to 3/4″

- Lengths: 1/4″ to 10″

| Shoulder Diameter | Max Length | Min Length | Max Thread Neck | Min Thread Neck | Basic Diameter | Min Diameter | Max Diameter | Min Diameter |

|---|---|---|---|---|---|---|---|---|

| 1/4″ | 10 | 24 | 0.142 | 0.133 | 0.083 | 0.023 | 0.017 | 0.375 |

| 5/16″ | 1/4 | 20 | 0.193 | 0.182 | 0.100 | 0.028 | 0.022 | 0.438 |

| 3/8″ | 5/16 | 18 | 0.249 | 0.237 | 0.111 | 0.031 | 0.025 | 0.500 |

| 1/2″ | 3/8 | 16 | 0.304 | 0.291 | 0.125 | 0.035 | 0.029 | 0.625 |

| 5/8″ | 1/2 | 13 | 0.414 | 0.397 | 0.154 | 0.042 | 0.036 | 0.750 |

| 3/4″ | 5/8 | 11 | 0.521 | 0.502 | 0.182 | 0.051 | 0.045 | 0.875 |

Common Uses:

- Used in machines

- Acts as guides, shafts, pivots, or spacers

- Used in pulleys and transmission systems

- Used in molds for stamping and injection

Use shoulder bolts when you need parts to slide or spin smoothly.

Elevator Bolts

Elevator bolts have a flat, wide head and a square neck. You find them in conveyor systems and big machines. The flat head sits flush so it does not catch on moving parts.

Typical Sizes:

- 1/4″ to 3/8″ diameter

- Lengths from 1″ to 6″

| Application | Design Feature Description |

|---|---|

| Attaching components to shotcrete and gunite equipment | Square neck keeps the bolt from turning during installation. |

| Ensuring secure and reliable equipment assembly | Strong build helps the bolt last during tough jobs. |

| Maintaining equipment integrity during operations | Zinc plating helps stop rust, good for inside and outside use. |

| Material Type | Finish Type |

|---|---|

| Carbon Steel | Plain (natural black color) |

| Zinc-Plated Carbon Steel | Zinc plating |

| Stainless Steel | Does not rust |

| AISI 1006-1050 Steel | Plain or Zinc Chromate finish |

Elevator bolts work best in conveyor belts and moving machines. Their flat heads help things move smoothly.

Sex Bolts

Sex bolts are also called barrel bolts. They have a male and female part that screw together. You use them to fasten panels or materials where both sides need to look smooth.

Typical Sizes:

- 1/4″ to 1/2″ diameter

- Lengths from 1/4″ to 4″

| Industry/Application | Description |

|---|---|

| Crafts | Used for stacking wood, plastic, or fabric in albums. |

| Signage and Displays | Fasten panels for strong but removable signs. |

| Modular Assembly | Attach parts in DIY projects, easy to change. |

| Architectural Hardware | Mount kickplates, hinges, and bars on doors for safety. |

| Electronics and Appliances | Put together circuit boards and control panels for easy fixing. |

| Leather Goods and Fashion | Connect belts and purses, easy to swap parts. |

| Material | Finish Options | Corrosion Resistance | Best For |

|---|---|---|---|

| Brass | Polished, antique, lacquered | Very good (natural patina) | Decorative, leather goods, marine |

| Stainless Steel | Polished, brushed, black oxide | Very good (all conditions) | Outdoor, marine, food service |

| Aluminum | Anodized (many colors), natural | Good (anodized) | Light jobs, colored |

| Steel | Zinc, nickel, black oxide, chrome | Okay (with finish) | Indoor, general use, cheap |

| Nylon | Natural (white), black | Very good (not metal) | Electrical insulation, light jobs |

Sex bolts are great when you want both sides of your project to look neat.

Machine Bolts

Machine bolts have a square or hex head and a partly threaded shank. You use them with a nut to clamp things together. They are strong and good for heavy jobs.

Typical Sizes:

- 1/4″ to 1″ diameter

- Lengths from 1″ to 8″

| Feature | Machine Screws | Bolts |

|---|---|---|

| Engagement Method | Go into internal threads | Use a nut to clamp |

| Threading | Fully threaded | Partly threaded |

| Load Bearing | Not good for high stress | Good for jobs with lots of stress |

| Installation Tools | Use screwdrivers | Use wrenches on the head and nut |

Common Uses:

- Attach boards and panels

- Used in making things, cars, electronics, and buildings

- Used in machine assembly

When you need a strong connection, machine bolts are a good choice for many bolt jobs.

Now you know the most common types of bolts and their uses. Each type has its own strengths. Pick the right one for your project. The right bolt makes fastening easier and keeps your work safe and strong.

Bolt Types Chart

Picking the right bolt can seem hard. A bolt types chart makes it easy. You can look at this chart and compare bolts fast. It helps you choose the best bolt for your project. You might be building a deck, fixing a machine, or hanging something heavy.

| Bolt Type | Head Style | Common Sizing | Best For / Main Uses | Key Difference |

|---|---|---|---|---|

| Hex Bolts | Six-sided hex head | 1/4″–1″ dia; 1″–12″+ length | Construction, machinery, furniture | Easy to grip with a wrench |

| Carriage Bolts | Smooth round head, square neck | 1/4″–3/4″ dia; 1″–10″+ length | Wood projects, flush surfaces | Won’t spin when tightened |

| Lag Bolts | Large hex head, coarse threads | 1/4″–1/2″ dia; 1″–12″+ length | Heavy wood, decks, outdoor structures | No nut needed, screws into wood |

| Eye Bolts | Loop at one end | 1/4″–1″ dia; 1″–12″ length | Lifting, rigging, anchoring | Lets you attach rope or cable |

| U-Bolts | U-shaped with threads on both ends | Fits 1/2″–6″+ pipe sizes | Securing pipes, automotive, HVAC | Wraps around pipes or tubes |

| Flange Bolts | Hex head with built-in washer | 1/4″–1″ dia; 1″–8″ length | Automotive, heavy machinery | Spreads load, no washer needed |

| J-Bolts | J-shaped hook | 3/8″–1″ dia; 4″–24″ length | Anchoring to concrete, poles, towers | Curved end holds in concrete |

| Shoulder Bolts | Cylindrical shoulder | 1/4″–3/4″ dia; 1/4″–10″ length | Pivots, guides, moving parts | Acts as shaft or spacer |

| Elevator Bolts | Flat, wide head, square neck | 1/4″–3/8″ dia; 1″–6″ length | Conveyor belts, machinery | Flat head sits flush |

| Sex Bolts | Barrel and screw (male/female) | 1/4″–1/2″ dia; 1/4″–4″ length | Panels, signs, furniture | Smooth finish on both sides |

| Machine Bolts | Square or hex head | 1/4″–1″ dia; 1″–8″ length | Metal-to-metal, heavy-duty assembly | Needs nut, partly threaded |

Tip: Keep this chart close by. It saves time and helps you not make mistakes when you buy fasteners.

You can check this chart fast to see which bolt works for your job. If you are not sure, look at the “Best For” and “Key Difference” columns. They help you pick the right bolt every time.

Choosing the Right Bolt for My Project

Assessing Project Needs

You want your project to last and stay safe. Start by thinking about what you need the bolts to do. Ask yourself: Will the bolts hold heavy wood, metal, or something else? Are you working outside or inside? Some bolts, like coach bolts, work best for joining wood to metal. Others, such as hex bolts, fit heavy-duty applications. If you need fastening for furniture or outdoor decks, coach bolts are often best for strength and easy installation.

Here’s a quick checklist to help you pick the right bolt for my project:

- What materials are you joining?

- How much weight will the bolts support?

- Will the bolts face rain, heat, or chemicals?

- Do you need the fastening to look neat or just stay strong?

- What tools do you have for installation?

Tip: If you’re unsure, reach out to experts like Prince Fastener. They can help you match bolts to your applications.

Matching Materials and Finishes

Bolts come in many materials and finishes. Steel bolts are strong and work well for most fastening jobs. Stainless steel bolts resist rust, so they’re best for outdoor applications. Brass bolts look nice and suit decorative fastening. You’ll see coach bolts in galvanized finishes for extra protection outside. Always match the bolt material to your project’s environment.

| Material Type | Best For | Common Applications |

|---|---|---|

| Steel | Indoor strength | Machinery, furniture |

| Stainless Steel | Wet or outdoor places | Decks, fences, marine |

| Brass | Decorative fastening | Signs, crafts |

| Galvanized Steel | Weather resistance | Outdoor structures |

Choose a finish that protects your bolts from rust and wear. Zinc or galvanized coatings work best for most outdoor fastening.

Sizing and Strength Tips

Size matters when you pick bolts. The right diameter and length keep your fastening secure. Coach bolts come in sizes for small crafts or big beams. Always check the strength grade. Higher grades mean the bolts can handle more weight. For heavy applications, use bolts with a strong grade and longer length. Short bolts may not hold well in thick materials.

- Use longer bolts for thick wood or metal.

- Pick a diameter that matches the load.

- Check the strength grade before buying.

- For safety, never use bolts that look damaged.

If you want your fastening to last, choose bolts that fit your materials and project needs. Prince Fastener offers guides to help you select the best for your applications.

You now know how different bolts work for your projects. Use the chart and tips to make smart choices. If you face tricky jobs, check with experts or manufacturer guides.

- Think about your project’s needs, like load and environment.

- Look up industry standards.

- Pick the right material.

- Ask fastener specialists for advice.

FAQ

What are the most common bolt head styles?

You will see hex, round, square, and flat heads. The most common bolt head styles help you pick the right bolts for your fastening jobs.

How do I choose bolts for different applications?

You should look at the load, environment, and materials. Some bolts work better for outdoor applications. Others fit indoor projects. Always match bolts to your fastening needs.

Can I reuse bolts after removing them?

You can reuse bolts if they look undamaged. Check for rust or wear. Damaged bolts may fail during fastening. New bolts give you better safety for most applications.