The Complete Guide of Chipboard Screws

The evolving development of composite materials to harbor the massive demands on products has brought a versatile sheet board for wide usage in construction and furniture making. Chipboard or particle board is presently used in various furniture or household applications like flooring and renovations in sheds, gardens, and buildings. This manufactured type of wood has rapidly caught the heed of many consumers due to its cheap and convenient character. It is highly preferred for woodworking such as furniture making because of its versatility. But what makes them more functional part is the components that are used to connect them in strong and reliable assembly.

The evolving development of composite materials to harbor the massive demands on products has brought a versatile sheet board for wide usage in construction and furniture making. Chipboard or particle board is presently used in various furniture or household applications like flooring and renovations in sheds, gardens, and buildings. This manufactured type of wood has rapidly caught the heed of many consumers due to its cheap and convenient character. It is highly preferred for woodworking such as furniture making because of its versatility. But what makes them more functional part is the components that are used to connect them in strong and reliable assembly.

In the vast types of fasteners, a well-matched device works in harmony with particle boards, and the chipboard screws. Although wood screws can be used along with the material of particle boards, chipboard screws are designed to suit its needs. Chipboard screws have sharp point tips and threads that can precisely work in the condition of the material of the chipboard. Its thread can be cut efficiently without damaging the internal structure of the board sheet. Additionally, with the right selection of size in chipboard screws it can enable a perfect holding of parts together because of its coarse threads.

Definition of Chipboard Screws

Chipboard screws, also known as particleboard screws are a variation of self-tapping screws specifically designed for use with chipboard, particleboard, MDF (medium-density fiberboard), and similar materials. They have full or partial coarse threads that allow significant efficiency in the installation process and strong holding power of parts. Most often, chipboard screws have a bronze or yellow appearance that provides aesthetics or decorative look in applications. The common head style of the screw is flat type that allows a smooth finish where the screw can sit flush within the surface. Moreover, chipboard screws can be made of varying materials like stainless steel and other types of steel which undergo treatments to enhance their durability and corrosion resistance.

General Applications of Chipboard Screws

The availability of variations in sizes and form of chipboard screws has presented widespread use for their effectiveness in different applications. Some of the most common examples of applications of chipboard screws include the following:

- Woodworking Projects: As designed to match the requisite condition of particle boards, chipboard screws are necessary components that can complete most woodworking projects, particularly in constructing furniture, cabinets, and other wooden structures. Unlike traditional nails, they offer better results in the connection of parts because of their structural features and elements. Their coarse threading provides excellent grip of materials to provide a sturdy and durable connection.

- Carpentry and Framing: Carpentry becomes more secure with the help of chipboard screws by eliminating loose connections of different assemblies and framing permits a good chance of reduced stripping when associated with secured devices. Chipboard screws are known to bite into the material that creates a robust connection which is a primary requirement in carpentry and framing fastening.

- Drywall Installation: With the crucial task of choosing the appropriate length and gauge on chipboard screws, drywall installations can be secured to the walls or ceilings.

- Home Improvements: Knowing the sturdy and convenience of chipboard screws in many construction-related applications, home improvement projects can be easily glamorized with their aesthetic look. Various DIY improvements in the home like shelves, panels, and furniture are ideal employment of chipboard screws because of their natural elegant finish but also for secured and tight connections of parts.

- Outdoor Applications: Many outdoor projects can also depend on chipboard screws because of their good corrosion resistance. Their properties allow them to survive outdoor weather conditions such as rain, heat, and cold temperatures. They are ideal and suitable in applications for constructing decks, fences, and other exterior structures.

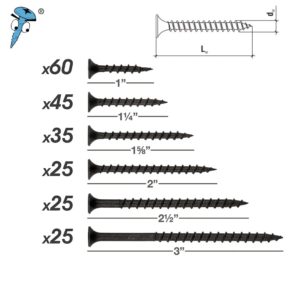

Sizes of Chipboard Screws

Chipboard screws come in a range of sizes to accommodate different thicknesses of materials and project requirements of a multitude of kinds. The sizes are typically specified using two main parameters: length and gauge which are defined as follows:

- Length: The length of chipboard screws is measured from the tip to the end of the threaded portion or the whole body from point to point. When selecting the appropriate length, ensure that the screw is long enough to penetrate both materials to provide sufficient thread engagement without protruding on the other side.

- Gauge: The gauge refers to the diameter of the screw. The common gauges for chipboard screws include #6, #8, #10, and #12. Thicker materials for connection generally require larger gauge screws for optimal performance and better security.

Choosing the Right Chipboard Screw for Your Project

Allow success in fastening by choosing the right chipboard screw for your project, proper consideration of the following factors will guide your selection:

- Material Thickness: Measure and select a screw length that allows for proper penetration through both materials being joined.

- Weight-Bearing Capacity: For load-bearing applications, choose a screw with a larger gauge and length to ensure a secure and durable connection.

- Environmental Conditions: In outdoor or high-moisture environments, opt for chipboard screws made from corrosion-resistant materials.

- Type of Wood: Different woods have varying densities. Adjust the screw size accordingly to achieve optimal holding power.

The indispensable use of chipboard screws in construction projects and woodworking offers more than just security but also reliability and versatile solution for joining wood products, especially engineered wood like particle board. There are a variety of sizes of chipboard screws to accommodate various project requirements.

Want to purchase wholesale chipboard screws? Know more about the components and fastening essentials with the professionals – Prince Fastener Manufacturing Co., Ltd. We offer high-quality chipboard screws and a diverse range of fasteners for different industry applications.