A socket head cap screw has a round head. It has a hexagonal hole for turning. The shaft has threads all the way down. This shape makes it strong. It is also small and fits in tight spots. Many industries use socket head screws for tough jobs, like:

- Industrial machines need screws that resist heavy loads and shaking

- Car engines and suspensions need screws that handle stress

- Building and airplanes need screws that are light and hold tight

Makers use strong metals like alloy steel and stainless steel. This lets small screws hold heavy things.

Key Takeaways

Socket head cap screws have a small, round head. The head is strong and has a hex hole. An Allen key fits into the hole. This makes it easy to tighten the screw. You can use it in tight spaces. The screw does not slip when you turn it.

These screws are made from strong materials. Some are alloy steel and some are stainless steel. These materials help the screws hold heavy things. They also stop the screws from rusting. This is good for tough places.

There are different head types for these screws. Some are standard, button, flat, or low head. These choices help with strength and looks. They also help the screw fit in small or smooth spaces.

Socket head cap screws are used in many things. You find them in machinery, cars, and electronics. They are also used for clamping. These screws save space and hold parts tight. They make fixing things easier.

Socket head cap screws are better than hex bolts. They are also better than regular cap screws. They give more turning power. They have a small shape. They do not slip easily. This makes them great for careful and hard jobs.

Socket Head Features

Head Design

Socket head cap screws have a round head with a hex hole. This shape gives some important benefits:

- The small size helps save space and fits in tight spots.

- The round head is very strong. It lets you use more force to tighten. You do not need as many screws, so it saves money.

- The hex hole lets you use an Allen key. This helps you turn the screw without slipping. It works well with strong materials.

- The round shape and set sizes (head is about 1.5 times wider than the thread, and as tall as the thread) help make the screw strong and save space.

- The barrel-shaped head is good for small spaces. It also lets you use lighter and smaller parts.

Drive Type

The hex socket drive helps you turn the screw with more force. An Allen key fits tightly in the hole. This lets you use the right amount of force. The design is good for small spaces. It also keeps nearby parts safe from damage. The tight fit between tool and screw stops slipping. This makes putting in the screw easier and safer.

Materials

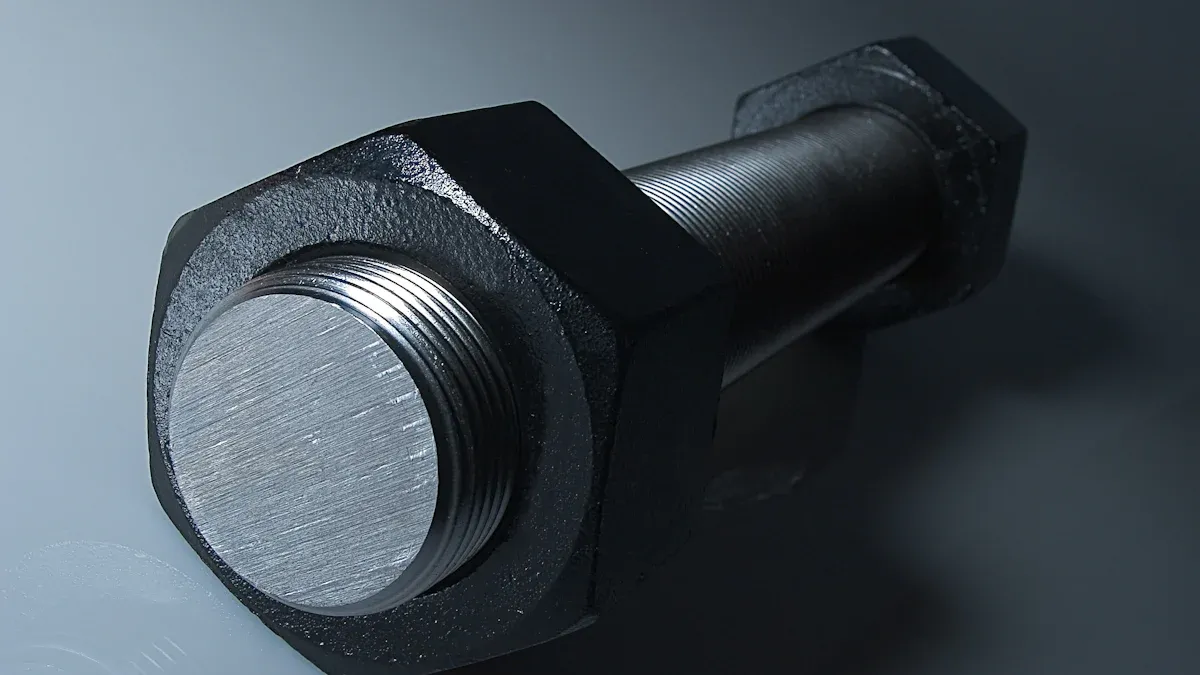

Makers use different materials for socket head cap screws. Alloy steel is used when you need strong screws. Stainless steel is used when you need to stop rust. Some screws are made from nylon or PEEK. These are good if you need light or chemical-resistant screws. Heat treated alloy steel screws are very strong. They can handle at least 170,000 psi. They often have a black finish. These screws work in hot and high-pressure places, like boilers. Stainless steel screws are not as strong but do not rust.

| Material Type | Typical Material Grades | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Reduction of Area (%) | Hardness (Rockwell) |

|---|---|---|---|---|---|---|

| Alloy Steel | C39-C45, C37-C45 | 162,000 – 180,000 | 153,000 – 170,000 | 10 | 33 | ~33 |

| Stainless Steel | B80-C33 | ~95,000 | ~30,000 | 10 | 30 | ~30 |

Tip: Heat treated alloy steel socket head cap screws often look black. This finish looks nice and helps stop some rust.

Standards

Socket head cap screws must follow strict rules to be safe and work well:

- ASTM A574 says screws must use strong alloy steel and be heat treated. This is for screws from 0.060 to 4 inches wide.

- ASME B18.3 gives the main size and shape rules. It covers things like body width, head width, head height, hex hole size, and thread length.

- Threads must match special thread rules. Class 3A is for screws up to 1 inch. Class 2A is for bigger screws.

- The surface must be smooth. There are rules for how smooth the fillet, head, and threads must be.

- Some screws do not need marks to show what they are made of. This is true for alloy steel screws under ASTM A574.

Mechanical Properties

Socket head cap screws are very strong. They are stronger than many other screws. They can handle more force and hold things tight. Alloy steel screws can handle at least 170,000 to 180,000 psi, depending on size. Stainless steel screws are not as strong but do not rust. The small shape lets these screws be stronger than bigger bolts made from weaker metals.

| Diameter (inches) | Minimum Tensile Strength (ksi) |

|---|---|

| ≤ 0.500 | 180 |

| > 0.500 | 170 |

Socket head cap screws do not slip out as easily as other screws. Their shape lets you use more force and put them in tight. These screws meet ASTM A574 and ASME B18.3 rules. This means they work well in tough jobs.

Socket Head Types

Standard

Standard socket head cap screws have a round, tube-shaped head. There is a hex hole inside the head. The head is about one and a half times as tall as the thread is wide. This head is smaller than most other machine screw heads. When you put the screw in, the head sits inside a special hole. This makes the top flat with the surface. This design lets you use more force to tighten the screw. You do not need as many screws, so it saves weight and money. The strong head works well for tough jobs where strength matters.

Note: The hex hole inside the head helps workers use these screws in small spaces where a wrench will not fit.

| Screw Type | Head Dimensions | Load Capacity / Strength Grades | Key Features |

|---|---|---|---|

| Standard Socket Head Cap | Cylindrical, head height ~1.5x thread diameter | High tensile: 8.8, 10.9, 12.9 | Flush in counterbored hole, high shear strength, heavy-duty use |

Button

Button socket head cap screws have a round, low head. The wide bottom spreads out the force over more space. These screws look nice and are good when looks are important. They also stop parts from getting caught on the screw. Many jobs use button head screws, like:

- Automotive: Used for engine parts and inside cars

- Aerospace: Used in planes and spaceships

- Manufacturing: Used in machines

- Electronics: Used for circuit boards and cases

| Industry | Typical Applications and Features |

|---|---|

| Automotive | Holds engine parts, low head design |

| Aerospace | Light and strong fastening |

| Manufacturing | Strong hold with a neat look |

| Electronics | Small fasteners for circuit boards |

Flat

Flat socket head cap screws have a flat top that sinks into the material. The head sits even with the surface when put in. This gives a smooth finish. The design stops things from catching on the screw. It also keeps the assembly safe and strong. Flat head screws are great for wood, metal, and furniture. The flat fit makes the finished product look better.

- The sunken head lets the screw sit flat with the material.

- The smooth top stops things from catching.

- These screws help make things look neat and smooth.

Low Head

Low head socket head cap screws have a head that is about half as tall as standard ones. The short head saves space and weight in small builds. Even with a smaller head, these screws are still strong. Designers use low head screws in machines and equipment where there is not much room. The small size and clean look are good for tight designs.

Tip: Low head screws fit in places where standard socket head screws are too tall.

Socket Head Applications

Socket head cap screws are used in many industries. Their small size and strength help in tight spaces and hard jobs. Engineers pick these screws when things must stay together and last a long time.

Machinery

Machines use socket head cap screws to hold parts together. There is not much space around moving parts. The round head and hex hole let you put them in small spots. Wrenches do not fit in these places. Workers use these screws for gears, covers, and motors. The strong metal keeps machines from coming apart or shaking loose. It is easy to take out and put back these screws. This helps fix machines faster.

Note: These screws sit flat with the machine. This stops things from catching and keeps surfaces smooth. It makes machines safer for workers.

Automotive

Car makers use socket head cap screws for engines and frames. These screws are strong and spread force out. This keeps parts safe from damage. The hex hole stops slipping and lets you turn hard. This keeps parts from moving or breaking. Some screws have special locks to stop shaking loose. This is important for cars that move a lot.

- These screws let you use more force and need fewer screws.

- The head sits flat, so it looks nice and is safer.

- Stainless steel and alloy types do not rust or get damaged by heat.

- Checking and cleaning the screws helps them last longer and work well.

Engines, suspensions, and frames use these screws because the heads are small. This helps fit them in tight places. The screws do not stick out, so they do not hurt people or hit other parts.

Electronics

Electronics makers use socket head cap screws for small devices. The small head and hex hole help in tight spots. This is good for circuit boards, cases, and robots. The low head keeps parts smooth and looking nice.

- The hex hole stops slipping and makes it easy to put in.

- Strong metals like alloy steel and titanium make the screws last.

- Fewer screws are needed because they hold tight, saving space and time.

- The flat head stops the screw from getting in the way of other parts.

Black finishes and stainless steel help with heat and stop rust. This is good for electronics that get hot or are in tough places. Alloy 330 screws work well when things get hot and cold.

Clamping & Fixturing

Factories use socket head cap screws to hold things steady. The screws are strong and can be turned tight. The small head fits in small spaces and helps line up parts.

- The screws keep things from moving during work.

- They help put parts in the same place every time.

- Flat surfaces need screws that hold tight.

- Even pressure helps clamp things better.

- Special locks stop screws from shaking loose.

Some clamp systems use these screws to get very exact placement. The screws are made to fit just right and give the same force each time. They work with special bushings and inserts. This lets workers change setups fast. The screws can be made from steel, stainless steel, or aluminum, depending on the job.

Tip: Ask experts or special stores to help pick the best socket head cap screw for your clamping needs.

Comparison with Other Fasteners

Socket Head vs. Hex Bolt

Socket head cap screws and hex bolts do similar jobs. But they look different and are put in differently. Socket head cap screws need an Allen wrench or a power tool. This stops the tool from slipping out. It also helps stop the screw from getting stripped. You can use more force with these screws. This means you do not need as many screws. The round, small head saves space and fits in tight spots. These things make them easy and safe to use in factories.

Hex bolts have a six-sided head. You need a wrench or socket to turn them. People use them with nuts. They are good for building things where strength is most important. Hex bolts are made by heating and shaping metal. The big head takes up more room. This can be a problem in small spaces. Hex bolts are strong and work well in big machines and buildings.

Tip: Use socket head cap screws when you need to fit in small spaces or need more force. Pick hex bolts for big builds and heavy loads.

Socket Head vs. Cap Screw

Socket head cap screws and regular cap screws are not the same. The heads and the way you turn them are different. Socket head cap screws have a round head with a flat top. There is a hex hole inside. This lets the screw sit flat and lets you use more force with an Allen key. The small head is good for tight spaces.

Regular cap screws are also called hex head cap screws. They have a hex head on the outside. You use a wrench or socket to turn them. The big head does not sit flat and takes up more space. These screws are good for tough jobs like building and machines.

| Feature | Socket Head Cap Screws | Traditional Cap Screws (Hex Head Cap Screws) |

|---|---|---|

| Head Design | Cylindrical head with flat top | Hexagonal external head |

| Head Dimensions | Diameter ~1.5× thread size; height = thread size | Larger external hex head, no internal recess |

| Drive Type | Internal hexagonal recess (hex socket) | External hex head for wrench or socket drive |

| Drive Tool | Allen key (hex wrench), resists cam-out better | Wrench or socket tool |

| Installation Advantages | Higher torque, compact profile, flush mounting | Standard wrenching, less compact head profile |

| Variations | Low head, flat head, button head, shoulder screws | Typically only hex head external drive |

Socket head cap screws are very strong and look neat. They are best for careful builds and places you can see. Cap screws are strong and good for hard jobs. Both types can have a flange to spread out the force and stop damage.

Socket head cap screws are strong and small. They fit in tight spaces easily. You can put them in without trouble. These screws use tough metals and come in many head shapes. This makes them good for machines, cars, electronics, and planes.

- You do not need as many screws or holes. This makes things lighter and easier to build.

- The hexagonal drive helps stop slipping. It also makes fixing things faster.

- Special finishes help the screws last longer and stop rust.

If you want to learn more, you can read guides about screw types, rules, and materials. You can also ask experts for help if you have questions.

FAQ

What tool works best for installing socket head cap screws?

An Allen wrench or hex key fits the hex hole in the screw head. This tool gives a tight grip and helps apply the right force. Power drivers with hex bits also work well for faster assembly.

Can socket head cap screws resist rust?

Stainless steel socket head cap screws resist rust. Alloy steel screws with special coatings also help stop corrosion. For wet or outdoor places, stainless steel gives the best protection.

Are socket head cap screws stronger than regular bolts?

Yes. Socket head cap screws use high-strength materials and have a compact head. They handle more force than many regular bolts of the same size. This makes them a top choice for heavy-duty jobs.

Where should someone use flat socket head cap screws?

Flat socket head cap screws work best when a smooth surface is needed. They sit flush with the material. Builders use them in furniture, electronics, and machines to prevent snagging and create a neat finish.