Welcome to Prince Fastener, your trusted expert in the fastener industry for over 30 years. We specialize in providing high-quality fastening solutions for various applications, including construction, industrial manufacturing, and DIY projects.

In our fast-paced world, selecting the right fastening solution can significantly impact project success. Today, we will delve into the differences between self-drilling screws and self-tapping screws. These two types of screws, though often confused, serve distinct purposes and excel in different scenarios.

For instance, self-tapping screws are indispensable for materials like wood and plastic. They utilize their sharp threads to cut into the material and create a secure bond. In contrast, self-drilling screws are designed to tackle harder materials such as metal and concrete. With a unique drill-like tip, they eliminate the need for pre-drilling, saving you time and effort.

Understanding these differences can help you make informed decisions and achieve optimal results.

Definitions

- Self Threading Screw: This screw drives into softer materials, such as wood or light steel frames, without requiring a pre-drilled hole (although some harder materials may require a pilot hole). It relies on the friction and biting force between its threads and the material to secure itself. Our thread design allows it to effectively cut into the material and form a mating fit as you drive it in.

- Self-Drilling Screw: Also known as a self-drilling self threading screw, this type features a drill-bit-like tip. It drills its hole and taps threads into harder materials, such as metal. During installation, the tip acts like a drill, creating the appropriate size hole, and then the screw’s threaded portion taps into the material, securing the screw.

How They Work

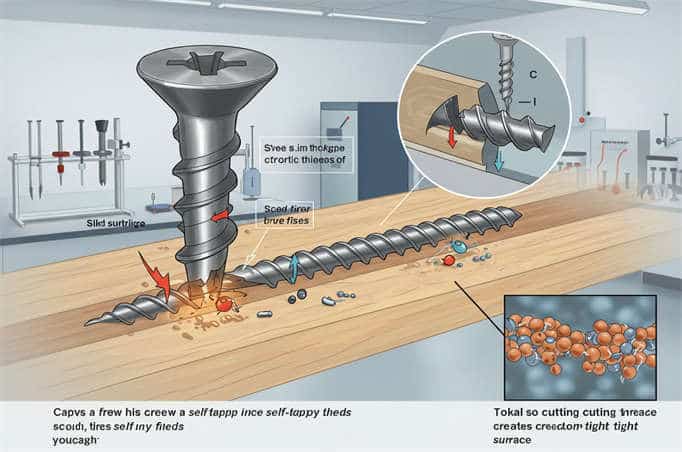

- Self-Threading Screw: Typically, you’ll start with a smaller pilot hole in the material. As you rotate the screw, the cutting edges on the threads cut into the material, causing plastic deformation. This creates a tight fit between the threads and the material, ensuring a secure hold. For example, when securing hardware to a wooden board, you’d first drill a small pilot hole, then drive in the self threading screw, and its threads will bite into the wood.

- Self-Drilling Screw: Its tip resembles a small drill. As the screw begins to rotate, the tip first drills a small hole in the material’s surface. With continued rotation, the screw’s threaded portion gradually enters this hole and cuts matching threads into the hole wall, creating an effective connection between the screw and the material. For instance, when attaching a component to a thin metal sheet, a self-drilling screw drills directly into the metal, eliminating the need for pre-drilling.

Appearance

- Self-Threading Screw: We offer these with various head shapes, commonly including flat, round, and countersunk. The threads are generally fine and run continuously from the screw’s tip to its head. For example, a flat-head self threading screw features a flat top, making it suitable for applications that require a larger bearing surface.

- Self-Drilling Screw: We also offer a range of head shapes. Its tip resembles a drill bit, featuring spiral flutes and similar structures. This tip usually has higher hardness, allowing it to withstand the stress of drilling. The threaded portion, like a self threading screw, forms the threaded connection with the material.

Suitable Materials

- Self Threading Screw: We design these primarily for softer materials such as wood, plastic, plasterboard, and light steel frames. Since they secure mainly by cutting threads into the material, they may struggle to cut into harder materials effectively. For instance, in the assembly of wooden furniture, we frequently use self threading screws to connect different wooden components.

- Self-Drilling Screw: These are ideal for various harder materials, including thin metal sheets (like colored steel or galvanized steel), concrete (with appropriate sleeves or attachments), and brick walls. You’ll find our self-drilling screws widely used in securing building exterior metal panels and mounting equipment on concrete walls.

Manufacturing Process

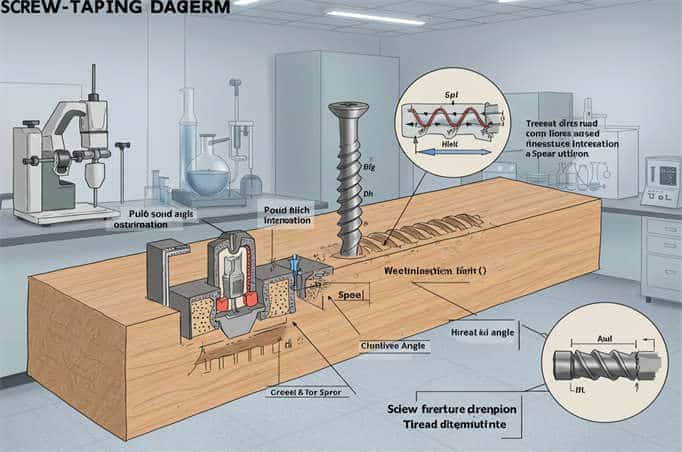

- Self Threading Screw: We produce these by forming metal wire into threaded shapes using molds. The precision of the thread processing is crucial for the screw’s fit with the material; overly tight threads can make the screw difficult to drive, while excessively loose threads will compromise the securing effect.

- Self-Drilling Screw: In addition to thread processing, the manufacturing of the drill-bit tip is critical. We employ specialized processes to create the drill-like tip, including heat treatment of the material to enhance hardness and machining of spiral flutes and other structures, ensuring the tip drills holes effectively.

Performance Characteristics

- Self Threading Screw: We ensure our self-threading screws offer excellent self-tapping performance, providing a stable fastening force in various materials. Their tensile strength depends on the screw’s material and size, performing well in general light-duty connection applications. However, without proper protective measures, they might loosen under significant impact loads or vibrations.

- Self-Drilling Screw: Since it drills its own hole and taps threads, integrating drilling and fastening functions, it offers higher construction efficiency. Furthermore, it provides excellent fastening in harder materials. Its shear and tensile strengths, with appropriate design and material selection, can meet more stringent application requirements. However, self-drilling screws can generate significant stress during drilling, demanding higher material quality and heat treatment. Otherwise, the drill bit portion might get damaged.

Self Threading vs. Self-Drilling Screws for Metal Sheet Installation

When installing metal sheets, both self-threading and self-drilling screws have their unique characteristics. The best choice depends on the specific circumstances. Here’s a detailed comparison:

Self Threading Screw

Advantages:

- Suitable for Thin Metal Sheets: Our self-threading screws typically feature sharp or blunt points, enabling their threads to cut and form threads in softer materials, such as thin metal sheets. They work well for thin metal sheets, such as steel, aluminum, or copper plates under 1.2mm in thickness, providing sufficient fastening force.

- Reusable: As long as the material remains undamaged, you can remove and reinsert our self-threading screws multiple times without significantly reducing the fastening force. The threads formed in the material remain intact for future use, which is convenient for temporary fastening or situations requiring disassembly and adjustment in metal sheet installations.

- Lower Cost: Our self threading screws generally have a lower unit price than self-drilling screws. If your installation doesn’t demand extremely high efficiency, and the metal sheet is thin and easy to work with, choosing our self threading screws offers a cost advantage.

Disadvantages:

- Limited Adaptability to Metal Sheet Thickness: For thicker or harder metal sheets, our self-threading screws struggle to cut threads, making effective fastening difficult. They are generally unsuitable for metal sheets exceeding a specific thickness, such as high-strength steel plates several millimeters thick.

- Requires Pre-Drilling Before Installation: When using our self threading screws on metal sheets, you typically need to pre-drill a pilot hole. The hole diameter must be slightly smaller than the screw’s primary diameter, which adds installation steps and time, especially when installing many screws or working in hard-to-reach areas. This process can be cumbersome.

Self-Drilling Screw

Advantages:

- No Pre-Drilling Required, High Installation Efficiency: The primary advantage of our self-drilling screws is their drill-bit-like tip, which enables them to drill and tap threads into hard materials, such as metal, without requiring pre-drilling. This directly fastens the metal sheet, significantly saving installation time, especially for large metal sheet installation projects or situations demanding high installation efficiency. This effectively improves work efficiency and reduces labor costs.

- Suitable for Various Metal Sheet Thicknesses and Hardnesses: Our self-drilling screws are compatible with a wide range of metal sheet thicknesses and hardnesses. Whether the metal sheet is thin or thick, as long as it falls within the self-drilling screw’s length and specification range, it can be effectively fastened. They also work well with more rigid metal sheets, ensuring connection stability.

- Higher Overall Strength: The threads our self-drilling screws form in metal sheets create a tight bond with the metal material, providing high tensile and shear strength. This makes the connections between metal sheets more secure and reliable, capable of withstanding greater loads and external forces. They are suitable for metal sheet installation scenarios requiring high connection strength.

Disadvantages:

- Poor Reusability: Due to their drill-tip shape, our self-drilling screws are generally not suitable for repeated disassembly and reinsertion. Once removed, the remaining hole is larger than the thread requires, and re-using them might lead to a loose connection. Therefore, they are more suitable for permanent installations.

- Relatively Higher Cost: Our self-drilling screws generally have a higher unit price than self threading screws. For large-scale installations, using self-drilling screws might increase material costs.

For thin metal sheets, temporary fastening, strict cost control, and when installation efficiency is not a primary concern, our self-threading screws are a suitable choice. However, for thicker or harder metal sheets, high installation efficiency, and permanent fastening requirements, our self-drilling screws are the superior option.

Cost Differences: Self Threading vs. Self-Drilling Screws

Here’s an overview of the cost differences between our self threading and self-drilling screws:

Unit Price

- Self-Threading Screw: Generally, our self-threading screws have a relatively lower price, typically ranging from a few cents to a few dollars each. For example, 100 pieces of our M3x6 Phillips pan head self threading screws sell for around USD 0.67, making the unit price approximately USD 0.0067 per piece.

- Self-Drilling Screw: Our self-drilling screws are relatively more expensive. For instance, 100 pieces of our M3x8 self-drilling screws sell for approximately USD 1.81, resulting in a unit price of USD 0.018 per piece. Our M4x10 self-drilling screws sell for approximately USD 2.08 for 100 pieces, with a unit price of $0.02 per piece.

Overall Usage Cost

- Self Threading Screw: When considering the cost of pre-drilling during installation, the overall cost will increase. For example, using our self threading screws on a 1.2mm thick plate requires pre-drilling pilot holes, which adds labor and time costs to the drilling step.

- Self-Drilling Screw: Our self-drilling screws eliminate the need for pre-drilling. They directly drill and tap, saving time and labor costs associated with the drilling process, thereby reducing the overall usage cost to some extent.

Factors Influencing Cost

- Material: Our carbon steel self threading and self-drilling screws are lower in price, while our stainless steel versions are more expensive. For instance, our 316 stainless steel self-drilling self threading screws can be 20%-30% higher in price than our carbon steel ones.

- Specifications: Larger specifications mean higher prices. For example, our M12 carbon steel Phillips self-drilling self threading nail costs approximately USD 0.14 per piece, whereas our M3x6 Phillips pan head self-threading screw is priced at around USD 0.0067 per piece.

- Manufacturer and Brand: Our screws, sourced from Prince Fastener, a reputable brand, may have higher prices, but we guarantee quality and excellent after-sales service.

- Purchase Quantity: Buying in bulk significantly reduces costs. The larger the purchase quantity, the lower the unit price per item.

Price Difference: Stainless Steel Self Threading vs. Self-Drilling Screws

Here’s an analysis of the price differences between our stainless steel self threading and self-drilling screws:

Stainless Steel Self Threading Screw Prices

- Stainless Steel Phillips Countersunk Head Self-Threading Screws: For example, our GB846-SUS-2.9-6.5 specification from Prince Fastener sells for approximately USD 10.90 for 500 pieces, resulting in a unit price of about USD 0.021 per piece. Our GB846-SUS-3.5-16 specification is priced at roughly USD 35.40 for 1,500 pieces, with a unit price of USD 0.023 per piece.

- Stainless Steel Hex Flange Head Self Threading Screws: Taking our MISUMI economical DIN7504K as an example, 350 pieces sell for about USD 23.20, with a unit price of approximately USD 0.066 per piece. 2000 pieces sell for around USD 87.00, with a unit price of approximately USD 0.043 per piece.

Stainless Steel Self-Drilling Screw Prices

- Stainless Steel Phillips Pan Head Self-Drilling Screws: For instance, our economical self-drilling self-threading screws from Prince Fastener sell for approximately USD 1.65 for 100 pieces, resulting in a unit price of about USD 0.016 per piece. 1000 pieces sell for roughly USD 5.38, with a unit price of about USD 0.005 per piece.

- Stainless Steel Hex Flange Head Self-Drilling Screws: Our hex flange head self-drilling self threading screws from Prince Fastener are priced at approximately USD 14.20 for 500 pieces, with a unit price of USD 0.028 per piece. 2000 pieces sell for around USD 35.40, with a unit price of approximately USD 0.017 per piece.

Reasons for Price Differences

- Production Process: Our stainless steel self-drilling screws require a drill-bit-like structure at the tip, making their production more complex and costly than that of self threading screws, which leads to a higher price.

- Material and Treatment: Self-drilling screws demand higher standards for hardness and toughness. We use high-hardness stainless steel for these and subject them to special heat treatments, which increases costs and, consequently, prices.

- Functionality and Usage Scenarios: Our self-drilling screws integrate drilling and tapping functions, eliminating the need for pre-drilling and offering high construction efficiency. We frequently use them for fastening hard materials, such as metal plates, which require higher material and processing standards, resulting in a higher price.

Prince Fastener takes pride in offering a comprehensive range of self-tapping and self-drilling screws to suit diverse needs. Our stainless steel self-tapping screws provide excellent corrosion resistance for outdoor applications, while our self-drilling screws are designed for high-strength performance in demanding environments.

We also provide top-notch customer service. Our team is ready to answer your questions and help you select the right products. If you are looking for reliable and durable fasteners, look no further than Prince Fastener. We are committed to delivering high-quality products and excellent service. Thank you for choosing Prince Fastener.