Screw Head Types

Screw Head Types | Know the Different Screw Head Styles

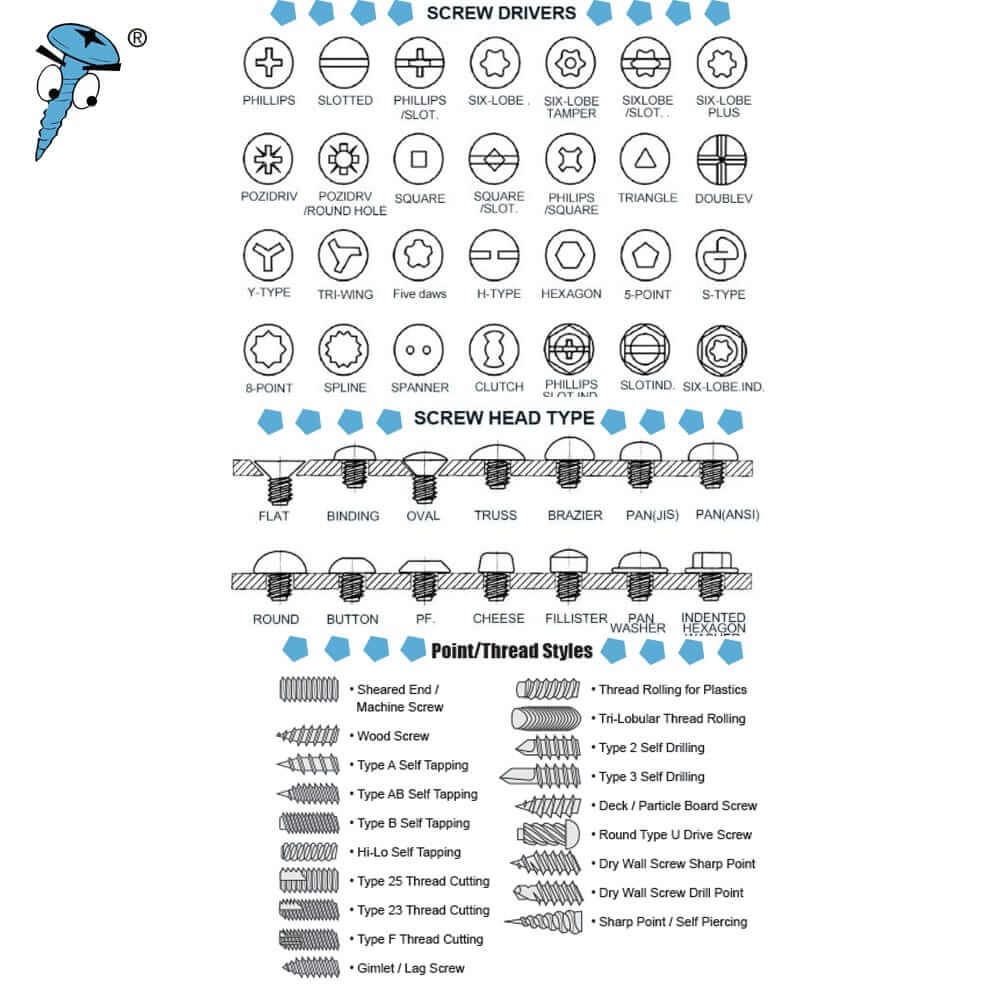

When people say ‘screws’ some still think that there are not many distinguishable features of the different kinds. Actually, screw heads are much more complex than we thought. There are many different kinds of head styles and screw drive that makes them a lot more effective in assemblies.

Screw head types have several forms that affect the utmost functioning of screws. With the variety of kinds of fasteners or screws, the implication of its overall body has further features to know before you can decide on which type is the right one. Let’s have a look at the many different kinds of head types of screws and their drives.

What Are the Different Screw Head Types?

To simplify the choices of screw head types there are two main categories that consist of different classifications in meeting the exact type of screw you need. The two basic categories are; countersunk and non-countersunk heads.

Countersunk head – is where the head of screws are resting flush in the surface of the material preventing the head to protrude beyond and cause unwanted damage or accident. It mainly consists of flat, oval, and bugle types of head screws. Non-countersunk heads – when they have full exposure to the application material. This category consists of the most variety of types such as button, fillister, flange, hex, pan, round, socket, truss, etc.

Read more:

What Are the Screw Drive Types and Their Uses?

Screw drive style or drive recesses are indications of the right tool to use during the installation and removal of screws. There are various ranges of drive recesses on screws designed for beneficial capabilities including stability, reliability, high torque, and prevention of possible tampering. The common types of screw drive styles are;

Hex (External)

Hex or hexagon requires wrench or socket tools in a hexagonal shape. The shape provides the advantage of easier turning of the screw head from the outside.

Hex (Internal)

The internal hexagonal shape of hex screws needs an Allen wrench with a matching internal hex shape.

Hex Tamper-resistant

Having a tamper-resistant feature hex screws have a small pin at the center of the socket drive, requiring a special tool during installation and removal.

Phillips

This drive is one of the most common screw recesses that is characterized by a pointed tip and round corners Phillips screws. The design can be driven by standard screwdrivers in corresponding sizes.

Slotted

Slotted drive screws are the next common type from Phillips. They can be used in most applications since they are driven by flathead screwdrivers and requires little to moderate torque.

Square

As the name implies, square recesses are square-shaped socket that allows a non-slip insertion of the screws using a slightly tapered tool.

Pozidriv

This type of screw drive is similar to Phillips screws. It consists of eight contact points providing more stabilization during installation.

Torx

A popular type of screw drive used for an application that requires tamper resistance is the Torx screw drive. The recess has six unique points making it known by its other name six-lobe screw. This screw drive is mostly used in the construction and manufacturing of electronic products.

Torx Plus

It’s simply a Torx design but with a larger contact area for the driving tool. Torx plus allows higher torque on driving the screws making it an easier and quicker process.

Tri-wing

This type of drive is a rare groove for screws. Tri-wing have 3 slightly curved grooves in sizes which can be either slotted or Phillips. When using a tri-wing screw the deep grooves enable the driver to have more force during torque.

Spanner

Screws with spanner drive have features of two slots that lock into the screwdriver or drill bit when installed. They propose a decorative final look and mostly the advantage of being tamper-proof.

Learn More About Screws and Fasteners With Prince Fastener

With a reliable fastener supplier and manufacturer like Prince Fastener, we can offer a wide variety of types, shapes, sizes, and forms of the different types of mechanical and industrial fastening devices. We specialize in helping you with the crucial and demanding needs of your projects. Whether it is a standard or non-standard fastener, we can manufacture it accordingly to your requirement and design.

Contact us now to discuss the difficulties of your fastening needs with us. You can browse the variety of selections of our fastener products at this link.