Screw and Nut Manufacturer

Screws and nuts are one of the basic fastening components in structural, engineering, machinery, and others. The production of fastener screws and nuts starts from raw material in a form of wire coil, which is processed in several methods and equipment to achieve its final form.

Prince fastener is one of the most trusted fastener companies that cater to the large demand for fasteners overseas. We carry an extensive experience in industrial manufacturing for over 30 years. We specialize in standard and non-fasteners such as screws, nuts, bolts, washers, nails, rods, anchors, etc.

Our company follows International standards like DIN, ISO, ASTM, etc. for fabricating industrial fasteners. Prince fastener guarantees reliable service, uncompromised quality of products, and reasonable prices of fasteners.

Read More:

Manufacturing Process

- The wire coil is straightened and cut to length

- Thread Cutting – the threads on steel are formed in a machine by rolling and cutting

- Heat Treatment – exposing the formed steel to extreme temperatures to eliminate unwanted elements and harden the steel

- Surface treatment – adding an extra layer of protection on the surface of screws and nuts to increase corrosion resistance

Read More: How Are Fasteners Created?

Manufacturing Terminologies

Machining – refers to the more advanced process of cutting and forming the screws and other fastener types through a specialized machine.

Cold Forming – is the shaping of metal elements at low or below crystallization temperature to increase their hardness, tensile strength, and corrosion resistance.

Hot Forming – the quicker process of deforming the metal above crystallization temperature for them to be malleable, increase ductility, and have great corrosion resistance.

Prince Fastener’s Screws and Nuts

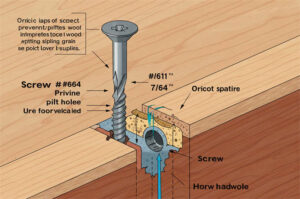

Square Slotted Self-tapping Screw

Stainless Steel Hex Nuts

Self-drilling Screw with washer

Hex Bolts and Nuts