You want the best fastening solution for your project. The right choice depends on the material and how you plan to use it. Self tapping pan head screws work well if you need to cut threads into metal or plastic without pre-drilling. Pick a screw that matches your needs for strong, lasting results.

Основные выводы

- Self tapping pan head screws make their own threads. They work well for metal and plastic. You do not need to drill holes first.

- Pick the right screw for your material. Use self-tapping screws for metal. Use wood screws for wood. Use self-drilling screws for fast metal jobs.

- Think about rust when picking screws. Stainless steel works best outside. It helps stop rust from forming.

- Use a chart to compare screw sizes and head types. Look at thread designs too. This helps you pick the best screw for your project.

- Do not make mistakes like using the wrong screw or tool. This can make weak joints. It can also cause your project to fail.

What Are Self Tapping Pan Head Screws

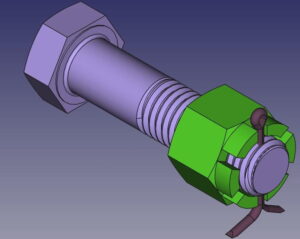

Features of Self Tapping Pan Head Screws

Self tapping pan head screws have a round, flat top. This top helps spread pressure across the surface. It keeps your material safe from harm. The screw makes its own threads as you put it into metal or plastic. The size and thread pitch decide how tight the screw holds. The head size matters too. It shows how much force the screw can take before coming out. You can pick thread forming or thread cutting styles. Thread forming is good for soft materials. Thread cutting works better for hard metals. The tip shape fits the material type. This makes putting in the screw easier and safer.

Tip: Picking the right size and thread style helps your screw hold better and last longer.

Общее использование

Self tapping pan head screws это used in many fields. Here are some common ways people use them:

- Construction: They hold sheet metal panels to frames.

- HVAC Systems: They keep ductwork and thin pieces in place.

- Automotive: They fix light parts like plastic trims.

- Electronics: They attach circuit boards and small parts.

- Machinery: They hold pieces that shake or move.

Prince Fastener has many types of these screws. You can find the best one for your job.

Плюсы и минусы

| Mechanical Property | Contribution to Secure Hold in Metal Applications |

|---|---|

| Alloy mix | Makes screws hard and strong for tough work |

| Thread design | Cuts and holds threads tight in metal |

| Tip shape | Fits metal type for better entry |

| Torsional strength | Stops twisting and breaking when you install |

| Coatings/Plating | Keeps screws from rusting and helps them stay strong |

You can put these screws in fast because you do not need to drill holes first in most thin metals. The pan head spreads pressure, so these screws work well for metal frames. Stainless steel screws do not rust, so your project lasts longer. But self tapping screws may not work in thick or brittle materials. Always pick the right screw for your material to get the best results.

Other Screw Types Explained

Self-Drilling Screws Overview

Self-drilling screws are used a lot in metalwork. They have a sharp tip that looks like a drill. You do not need to make a hole first. The screw makes its own hole and threads as you put it in. This saves time and work, especially with hard metals like steel.

- Self-tapping screws need a hole made first, but self-drilling screws do not.

- Self-drilling screws are best for metal. Саморезы are better for wood or plastic.

Tip: If you want to work faster on metal, use self-drilling screws.

Machine Screws Overview

Machine screws have the same thread all along the shaft. You use them with a nut or a hole that already has threads. These screws are good for machines, electronics, and appliances. There are many head shapes and sizes to choose from. Machine screws hold tight when you use the right nut or threaded hole.

Wood Screws Overview

Wood screws have a sharp tip and thick threads. You use them to join wood pieces together. They grip the wood well, so your furniture or cabinets stay strong. The table below shows how wood screws and self-tapping screws are different:

| Type of Screw | Typical Use Cases |

|---|---|

| Шурупы по дереву | Furniture assembly, cabinetry work, wall paneling, craft projects |

| Саморезы | Joining metal sheets, automotive repairs, HVAC ducts, assembling aluminum frames |

Sheet Metal Screws Overview

Sheet metal screws are used to join thin metal sheets. They have sharp threads that cut into metal. You can use them for HVAC, roofing, or fixing cars. The table below shows how tapping screws and drilling screws are different:

| Особенность | Tapping Screws | Drilling Screws |

|---|---|---|

| Thread Formation | Makes threads in a hole | Makes holes and threads at once |

| Процесс установки | Needs a hole first | No hole needed |

| Holding Power | Great in soft materials | Good in metal, may change in others |

| Скорость установки | Slower because of drilling | Faster, good for many screws |

Prince Fastener has many sheet metal screws for your next job.

Self-Clinching Fasteners Overview

Self-clinching fasteners give a strong hold in thin metal. You press them into a hole, and the metal locks them in place. You only need to reach one side of the metal. These fasteners can handle a lot of force and twisting.

- They are harder than the metal they go into, so they stay tight.

- The soft metal wraps around the fastener, making it secure.

- You get a smooth finish that looks nice.

The table below shows how self-clinching fasteners and self-tapping pan head screws compare:

| Особенность | Self-Clinching Fasteners | Self-Tapping Pan Head Screws |

|---|---|---|

| Установка | Only need one side | Need both sides |

| Прочность | Very strong and resists twisting | Can bend under pressure |

| Aesthetic Appeal | Looks neat and clean | May not look as nice |

| Обслуживание | Needs no extra care | Might need to be checked sometimes |

| Application Suitability | Best for thin metal sheets | Works but may not last as long |

If you need strong fasteners for thin metal, self-clinching fasteners from Prince Fastener can help you finish your project.

Self-Tapping Screws vs Other Fasteners

Application Differences

You need to know where each fastener works best. Self tapping pan head screws иметь unique design. The pan head spreads pressure and protects your material. You often use these screws in sheet metal work. Electricians use them for secure attachments. Builders choose them for roofing sheets and metal siding.

Саморезы save time in metalwork. You do not need to drill a hole first. These screws work well for steel frames and roofing. Machine screws fit machines and electronics. You use them with nuts or threaded holes. Wood screws hold wood pieces together. They grip wood tightly. Sheet metal screws join thin metal sheets. You see them in HVAC and car repairs. Self-clinching fasteners lock into thin metal. You press them in, and they stay tight.

Tip: Pick the screw that matches your project. Each type has a special use.

Совместимость материалов

Choosing the right screw depends on your material. Self tapping pan head screws work best in metal and plastic. You find them in stainless steel for corrosion resistance. The table below shows features of a common self-tapping screw:

| Особенность | Описание |

|---|---|

| Материал | 18/8 stainless steel for corrosion resistance |

| Тип | Self-tapping, thread-rolling screws |

| Dimensions | #10-24 x 1/2″ |

| Тип вождения | Tri-Lobe drive for secure engagement |

| Приложение | Ideal for metal-to-metal assemblies |

You can choose zinc-plated screws for dry interiors. Use 304 stainless steel for most outdoor jobs. Pick 316 stainless steel for coastal or chemical areas.

Self-drilling screws work in both wood and metal. Machine screws need a threaded hole or nut. Wood screws only work in wood. Sheet metal screws fit thin metal. Self-clinching fasteners need soft, thin metal to lock in place.

Процесс установки

You want your job to go smoothly. Self tapping pan head screws make their own threads in softer materials. You do not need to drill a hole in wood. In sheet metal, you should drill a pilot hole first. Self-drilling screws do both jobs. They drill and tap as you drive them in. You save time with self-drilling screws.

Machine screws need a nut or a threaded hole. You must line up the parts before tightening. Wood screws go straight into wood. You may drill a small hole for hard wood. Sheet metal screws need a pilot hole in metal. Self-clinching fasteners press into a hole. The metal wraps around the fastener and locks it in place.

Performance Comparison

You want strong and lasting results. Self tapping pan head screws hold well in metal and plastic. They resist rust if you pick the right material. Self-drilling screws work fast and hold tight in metal. Machine screws give a strong hold with nuts. Wood screws grip wood and keep furniture sturdy. Sheet metal screws join thin metal sheets. Self-clinching fasteners give a neat look and strong hold in thin metal.

Environmental factors matter. Moisture and temperature changes can weaken fasteners. Stainless steel resists rust in wet places. Carbon steel costs less but may rust. Galvanic corrosion happens when you mix metals in salty water.

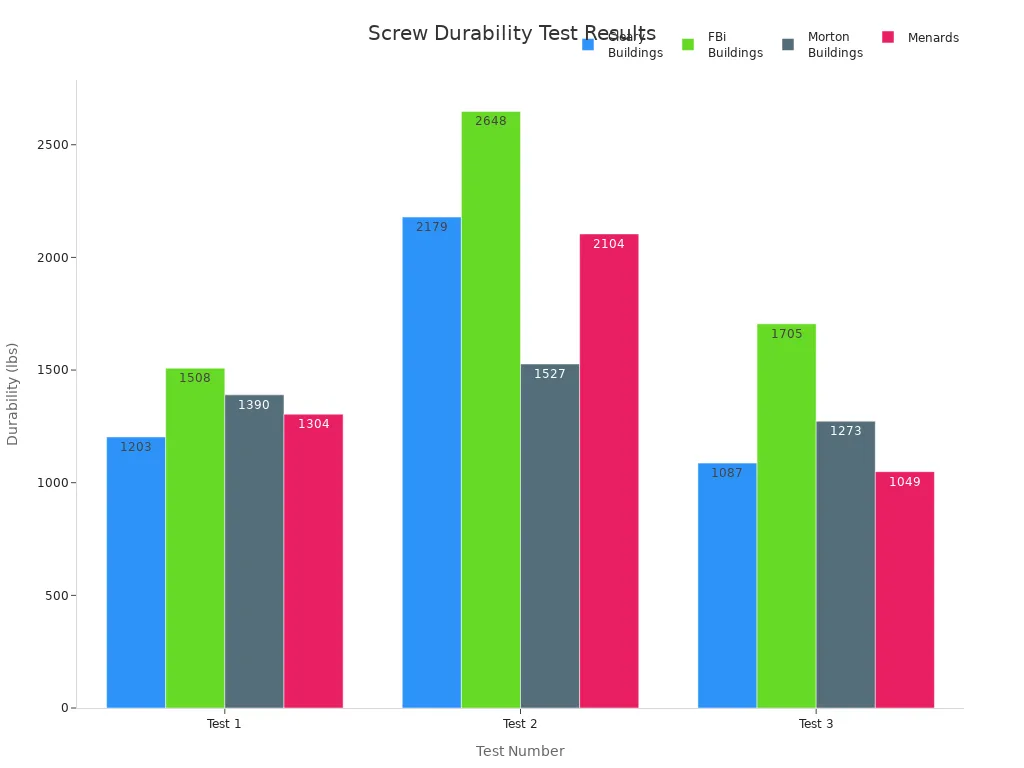

You can see how different screws perform in lab tests. The chart below shows how much force screws from different brands can handle:

Corrosion-resistant fasteners keep your project strong over time. You must choose the right screw for your environment.

Prince Fastener offers a wide range of screws for every need. You can find self tapping pan head screws, self-drilling screws, and more for your next project.

A detailed comparison helps you see the key differences. Self tapping pan head screws work best in metal and plastic. Self-drilling screws save time in metal. Machine screws fit machines. Wood screws grip wood. Sheet metal screws join thin metal. Self-clinching fasteners lock into thin metal and look neat.

Выбор правильного винта

Decision Matrix

You want to pick the best screw for your project. A decision matrix helps you compare options and make a smart choice. Look at the table below to see how different factors affect your decision:

| Фактор | Почему это важно |

|---|---|

| Размер винта | Larger screws hold more weight. Smaller screws fit tight spaces. |

| Тип головы | Pan heads spread pressure. Flat heads sit flush. |

| Дизайн резьбы | Fine threads grip metal. Coarse threads work in wood. |

| Тип нити | Box, buttress, unified, or square threads change how the screw holds. |

| Drill Point Type | Some screws need a pilot hole. Self-drilling screws make their own hole. |

| Устойчивость к коррозии | Stainless steel resists rust. Zinc-plated works indoors. |

| Cost and Labor Savings | Easy-to-use screws save time and money. |

| Environmental Suitability | Some screws work better outdoors or in wet places. |

| Compatibility with Materials | Match the screw to metal, wood, or plastic for best results. |

Совет: Prince Fastener offers a wide range of screws. You can find the right size, head type, and material for your job.

Советы по выбору

You want your project to last. Follow these tips to choose the right screw:

- Check the material you are joining. Use self tapping pan head screws for metal or plastic. Pick wood screws for wood.

- Look for corrosion resistance. Stainless steel screws work well outdoors or in wet places.

- Match the screw size to your load. Bigger screws hold more weight.

- Choose the right head type. Pan heads protect your material. Flat heads give a smooth finish.

- Test for compatibility. Some metals react with each other and cause rust.

- Use screws that meet industry standards. ASTM C1513 and AISI S200 help you pick safe screws for steel connections.

- Think about cost and labor. Self-tapping screws save time and reduce tool wear. You spend less on maintenance and replacements.

- Ask for help if you are unsure. Prince Fastener can guide you to the best screw for your needs.

Note: A construction team saved time and money by using self-tapping screws for roofing. These screws resist rust and need fewer replacements.

Ошибки, которых следует избегать

You want to avoid problems in your project. Watch out for these common mistakes:

- Picking the wrong screw type can cause weak joints or damage.

- Using the wrong tool may break the screw or leave it loose.

- Over-tightening or under-tightening leads to poor connections.

- Ignoring moisture, chemicals, or temperature can make screws fail early.

- Using a wood screw in metal gives poor grip.

- Drywall screws rust outside.

- Breakage under stress happens if you choose the wrong screw.

- Weak connections and project failures come from bad screw choices.

⚠️ Always match the screw to your material and environment. Proper selection keeps your project strong and safe.

You make the best choice when you match your screw to your project. Self tapping pan head screws work well for metal and plastic. Other fasteners fit different needs. Always think about your material, how you will use the screw, and how you will install it.

- Fasteners that match your materials last longer and prevent problems.

- Knowing your installation needs helps you work faster and get better results.

Prince Fastener gives you many options. Use the decision matrix and tips to pick with confidence.

Часто задаваемые вопросы

What makes self tapping pan head screws different from regular screws?

Self tapping pan head screws cut their own threads as you drive them in. You do not need a pre-threaded hole. Regular screws need a pre-made thread or nut.

Can you use self tapping pan head screws in wood?

You can use them in soft wood, but wood screws work better. Wood screws have deeper threads for a stronger grip. Prince Fastener offers both types for your projects.

How do you pick the right screw size?

You should match the screw size to the thickness of your materials. Use a screw that is long enough to hold both pieces together without poking through.

Do self tapping screws need special tools?

You can use a standard screwdriver or drill. Make sure you use the correct bit for the screw head. This helps you avoid stripping the screw.

Where can you buy quality self tapping pan head screws?

You can find high-quality self tapping pan head screws at Prince Fastener. The company offers many sizes and materials for different jobs.