You want your drywall installation to last, so you need the right screws for the job. Fine thread screw options work best when you attach drywall to metal studs. Choosing the correct size, gauge, and coating prevents damage and keeps your drywall secure. Many people make mistakes like using wood screws or placing screws too far apart, which can lead to sagging drywall or poor finishes. Pay attention to how deep you drive each screw. Drywall projects become much easier when you pick the right materials from the start.

Основные выводы

Использование fine thread screws for attaching drywall to metal studs. They grip better and prevent sagging.

Выберите right length and gauge of screws. For 1/2-inch drywall, use #6 gauge, 1-1/4 inch screws.

Select screws with a good coating, like iron phosphate, to resist rust and ensure durability.

Space screws correctly: 16 inches apart on walls and 12 inches on ceilings for a strong hold.

Avoid common mistakes like overdriving screws. Use a screw gun with a depth-setting clutch for best results.

When to Use Fine Thread Screws

Drywall and Metal Studs

You need to use fine thread screws when you attach drywall to metal studs. Fine thread screws have tightly spaced threads. These threads grip metal better than coarse threads. When you drive these screws into metal, they cut into the stud and hold the drywall firmly in place. This secure fit helps prevent the drywall from moving or sagging over time.

Many people wonder if they can use the same винты для гипсокартона for wood and metal. The answer is no. Fine thread screws work best for drywall to metal studs. Coarse thread screws are better for wood because they grip the softer material without slipping.

Here is a simple table to help you remember which screw to use:

Тип винта | Recommended Use |

|---|---|

Тонкая нить | Designed for use with metal studs. |

Грубая нить | Better for softer materials. |

Tip: Always check the type of stud before you start your drywall project. Using the right screw saves you time and prevents problems later.

Best Scenarios for Installation

You should choose fine thread drywall screws in several situations. If you work with steel framing, these screws make the job easier. You also need them when you install drywall to metal studs in basements, offices, or commercial buildings. Fine thread screws help you get a tight fit, even if the metal studs are thin.

Some projects require you to hang drywall on both walls and ceilings. Fine thread screws keep the drywall secure in both places. You can use them for standard 1/2-inch drywall or thicker panels. These screws also work well when you need to attach multiple layers of drywall to metal studs.

When you use the right drywall screws, you avoid common problems. You will not see loose panels or popped screw heads. Your finished wall will look smooth and strong. Always choose fine thread screws for drywall to metal studs to get the best results.

What Are Fine-Thread Drywall Screws

Features of Fine Thread Screws

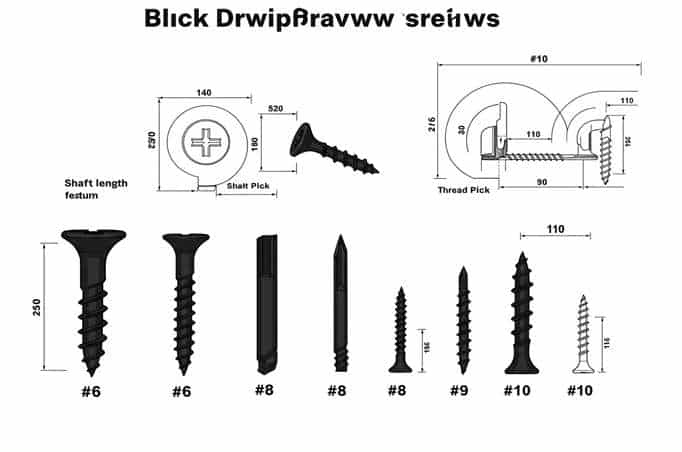

You need to know the characteristics of fine-thread drywall screws before you start your drywall project. These screws have threads that are close together. The sharp tips help you pierce metal studs with less effort. Fine thread drywall screws come in different lengths and gauges, so you can choose the right size for your drywall. Most drywall screws have a bugle head. This shape lets you drive the screw into drywall without tearing the paper surface.

Fine thread drywall screws work best with metal studs. The tightly spaced threads grip the metal and hold the drywall in place. You will see that these screws have a black phosphate coating. This coating protects the screws from rust and makes them easier to drive into drywall. When you look at the advantages of fine-thread drywall screws, you notice that they provide a strong hold and a clean finish.

Fine-threaded screws work best because drywall screws are not strong enough for the job. These screws have finer threads and sharper tips to better pierce and provide hold in metal studs.

Benefits for Drywall Installation

You get several benefits when you use fine thread drywall screws for your drywall installation. These screws give you a secure fit, so your drywall stays flat against the metal studs. You avoid problems like loose panels or popped screw heads. Fine thread drywall screws also help you finish your drywall faster because they drive smoothly into metal.

When comparing coarse-thread and fine-thread drywall screws, you see that fine thread screws are easier to remove from wood. Some users say that fine thread screws can strip out more easily, so they may not hold as tightly in wood as coarse thread screws do. You should test the holding power of both types if you want to see which works best for your project.

Fine thread drywall screws hold drywall to metal studs.

Coarse thread screws work better for wood studs.

You need to consider the factors to consider when selecting drywall screws, such as length, gauge, and coating.

You make your drywall installation easier and stronger when you choose the right screw. Fine thread drywall screws help you get a smooth, professional finish every time.

Choosing the Right Drywall Screws

Length and Gauge

When you install drywall, you need to pick the correct length and gauge for your screws. The right choice helps you get a strong and lasting wall. For standard 1/2-inch drywall on metal studs, you should use #6 gauge, 1-1/4 inch fine thread drywall screws. This size gives you enough grip without going too deep. You can also use 1-5/8 inch screws if you work with thicker drywall or need extra holding power.

Here is a table that shows the best screw length and gauge for drywall:

Drywall Thickness | Recommended Screw Lengths | Манометр |

|---|---|---|

1/2-inch | 1 1/4-inch or 1 5/8-inch | #6 or #8 |

You want to use drywall screws that match the thickness of your drywall. If you use screws that are too short, the drywall may not stay tight against the studs. If you use screws that are too long, you might damage wires or pipes behind the wall. The #6 gauge screw is strong enough for most drywall jobs. It holds the drywall firmly to metal studs and does not bend or snap easily.

Drywall screws for metal studs use harder steel and fine threads. These features help the screws grip the metal and keep the drywall in place. The sharp tips let you pierce the steel quickly. You get a secure fit every time you drive a screw into the stud.

Drywall screws with the right gauge and length make your installation easier.

Fine thread screws work best for metal studs.

You avoid problems like loose drywall or popped screw heads.

Tip: Always measure your drywall before choosing the right type of drywall screw. This step helps you pick the best length and gauge for your project.

Coating Options

You need to think about the coating on your drywall screws. The coating protects the screws from rust and makes them last longer. The most common coating for drywall screws is iron phosphate. This coating gives you good rust resistance and helps the screws grip the drywall better. You also find zinc coatings and advanced ceramic or epoxy coatings.

Here is a table that explains the different coatings for drywall screws:

Coating Type | Описание | Corrosion Resistance Impact |

|---|---|---|

Zinc Coating | Electroplated layer of zinc that acts as a sacrificial barrier against rust and corrosion. | Provides protection against moisture and corrosive elements, suitable for indoor and outdoor use. |

Iron Phosphate Coating | Enhances adhesion properties and creates a chemical bond for increased rust resistance. | Improves long-term performance and resistance to corrosion, especially when used with other coatings. |

Ceramic and Epoxy Coatings | Advanced coatings that withstand extreme environmental conditions. | Offers superior resistance to corrosion and abrasion, ideal for high humidity or chemically exposed areas. |

You want to use iron phosphate-coated drywall screws for most indoor drywall projects. This coating keeps your screws from rusting and helps your drywall stay strong. If you work in a wet area or outside, you can use zinc or ceramic-coated screws for extra protection.

Iron phosphate coating works well for drywall on metal studs.

Zinc coating gives you extra protection against moisture.

Ceramic and epoxy coatings help in tough environments.

You make your drywall installation last longer when you choose screws with the right coating. You avoid rust and keep your walls looking good for years.

Note: Always check the coating before you buy drywall screws. The right coating helps your screws resist rust and keeps your drywall secure.

Fine Thread vs. Coarse Thread

Ключевые различия

You need to understand how fine thread and coarse thread drywall screws differ before you start your drywall project. The thread design changes how each screw works in different materials. Fine thread screws have a narrow helical shape with shallow ridges. Coarse thread drywall screws feature wide set and deep threads. These differences affect how the screws grip drywall and studs.

Here is a table that shows the main differences:

Особенность | Грубая нить | Тонкая нить |

|---|---|---|

Дизайн резьбы | Wide set and deep | Narrow helical shape with shallow ridges |

Application Suitability | General purpose, handles obstructions better | Specific strength applications, higher tensile strength |

Resistance to Damage | More tolerant to damage, less likely to strip | More prone to galling due to higher friction |

Устойчивость к вибрации | Less effective against vibrations | More effective against vibrations |

Ease of Tapping | More material to cut | Less material to cut, easier tapping |

Fine thread screws work best for drywall attached to metal studs. You get higher tensile strength and better vibration resistance. Coarse thread drywall screws handle obstructions better and resist damage. You should use coarse thread drywall screws for drywall to wood studs because they grip softer materials well.

Tip: Always match the screw type to your stud material. This step helps you avoid stripped screws and loose drywall panels.

Лучшие примеры использования

You want to choose the right drywall screws for your project. Fine thread screws are ideal for attaching drywall to metal studs. You see these screws used in commercial buildings and offices. Fine thread screws engage with pre-formed threads in metal, giving you a strong hold. Coarse thread drywall screws work better in softer materials. You should use them when you install drywall to wood studs. These screws cut into the wood and provide a secure grip.

Fine thread screws are best for drywall on metal studs.

Coarse thread drywall screws are perfect for drywall to wood studs.

Fine thread screws can cause more damage in wood, so avoid them for wood framing.

You also need to think about cost. Fine thread screws cost slightly more than coarse thread drywall screws because of higher demand in commercial drywall projects. Both types of drywall screws cost about $5 to $10 per 1-pound box. If you buy screws in bulk, you lower the cost per screw. This tip helps you save money on large drywall jobs.

Note: Fine thread screws make your drywall installation easier when you work with metal studs. Coarse thread drywall screws give you better results in wood framing.

You get the best results when you use the right drywall screws for your material. Fine thread screws help you finish drywall on metal studs quickly and securely. Coarse thread drywall screws make drywall to wood studs strong and long-lasting.

Советы по установке

Tools for Drywall Screws

You want the right tools for attaching drywall to metal studs. Using the correct tool makes your installation smoother and faster. A drywall screw gun helps you drive screws at a steady speed and depth. This tool prevents you from overdriving or underdriving the screw, which keeps your drywall secure and the finish smooth. Many screw guns have an automatic feed, so you can work quickly on large projects.

For the best results, use these tools and screw types:

Fine thread screws with sharp points for 25 gauge metal studs.

Fine thread or dual thread screws for 20 gauge studs to prevent stripping.

Drill point screws for true 20 gauge studs or harder-to-reach spots.

Sharp screws work best for most drywall jobs. They pierce metal studs quickly, especially when you press firmly on the board. In some cases, drill point screws help you with tougher materials.

Как избежать распространенных ошибок

You can avoid many problems during drywall installation by watching for common errors. Here are some mistakes to look out for:

Stripping screws when attaching drywall to light gauge metal studs.

Using the wrong type of screws for the stud thickness.

Hitting hard spots in recycled steel studs, which can wear down screws.

Overdriving screws, which tears the drywall paper and weakens the hold.

Underdriving screws, which leaves the head sticking out and makes finishing harder.

Placing screws too close to the edge, which can crack the drywall.

Tip: Always check your screw depth. Use a screw gun with a depth-setting clutch to keep each screw at the right level.

Here is a table to help you see how screw depth affects your installation:

Consequence | Solution | |

|---|---|---|

Over-driving screws | Weakens hold, tears paper | Use depth-setting clutch on drill |

Under-driving screws | Protruding heads interfere with finishing | Check depth periodically |

Ensuring Secure Installation

You want your drywall to stay strong and look smooth. Follow these tips for effective use of each type of screw and get the best results:

Подробности | |

|---|---|

Тип винта | Use fine-thread drywall screws for metal studs as they cut into the metal without causing damage. |

Длина винта | Choose screws that penetrate at least 25 mm into the stud; 32 mm for 9.5 mm plasterboard, 38 mm for 12.5 mm. |

Дизайн головы | Use bugle head screws to ensure a flush finish and minimize damage to the drywall surface. |

Proper Screw Placement | Space screws 300 mm apart on walls, 230 mm on ceilings, and 150 mm along seams and edges. |

Installation Techniques | Drive screws perpendicular to the surface and ensure they are slightly recessed for a smooth finish. |

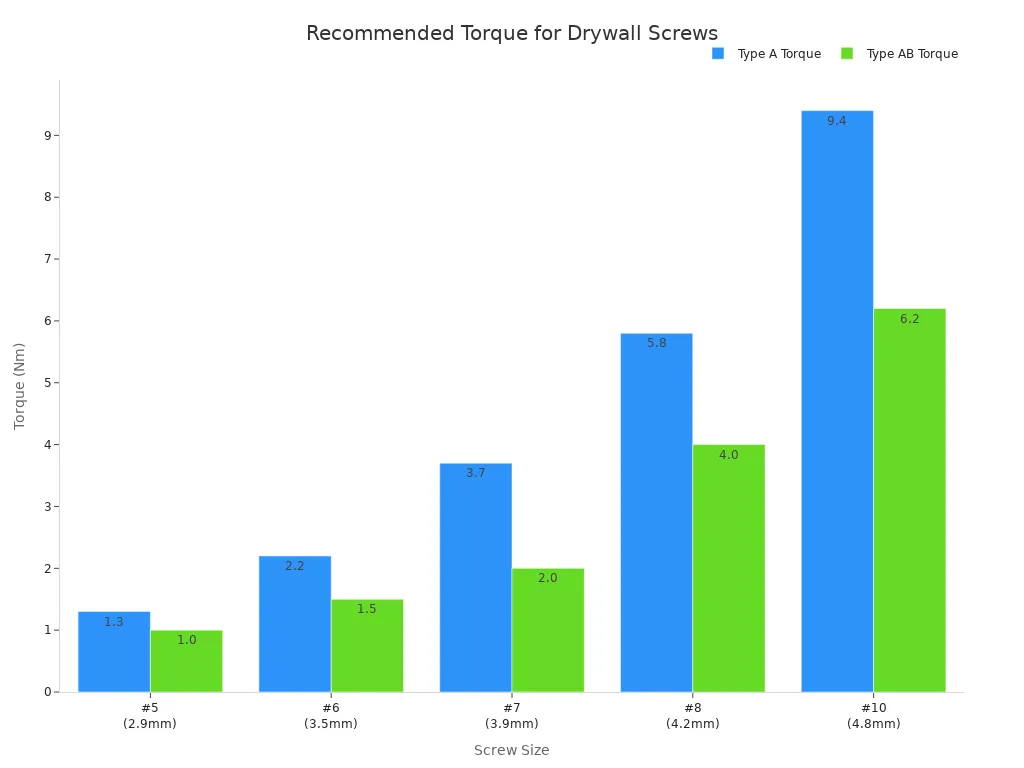

You should also pay attention to torque settings when using power tools. The right torque keeps screws from stripping or breaking. Here is a chart to guide you:

For ideal scenarios for using fine-thread drywall screws, always check the stud gauge and use the right screw type. Mark stud locations before attaching drywall. Align and fasten metal studs first. Space screws about 12 inches apart on ceilings and 16 inches on walls. Drive each screw straight in and make sure it sits just below the drywall surface. These steps improve the ease of installation and help your drywall last longer.

Remember: Careful planning and the right tools give you the best results and make the ease of installation much better.

You can make your drywall strong by doing a few things. Fine thread screws hold tight to metal studs and do not cause much damage. Pick screws that are the right length and have a good coating. This stops rust and keeps joints from getting loose. Experts say you should mark where the framing is and space screws the right way. Take out any screws you miss for a neat look. Always use the right screw for your material and put them in the right way. This helps your drywall stay in place and look nice. 👍

Часто задаваемые вопросы

What size fine thread screw should you use for 1/2-inch drywall on metal studs?

You should use #6 gauge, 1-1/4 inch fine thread screws for 1/2-inch drywall on metal studs. This size gives you a strong hold and keeps your drywall secure.

Can you use coarse thread screws with metal studs?

You should not use coarse thread screws with metal studs. Coarse threads do not grip metal well. Fine thread screws work better because they cut into the metal and hold the drywall tight.

Why do drywall screws have a black coating?

The black coating is usually iron phosphate. This coating helps prevent rust and makes the screws easier to drive into drywall. You get longer-lasting results with coated screws.

How far apart should you space drywall screws?

You should space drywall screws about 16 inches apart on walls and 12 inches apart on ceilings. Place screws closer together along seams and edges for extra strength.

What tool works best for driving drywall screws?

А винтовой пистолет для гипсокартона works best. This tool lets you set the screw depth and drive screws quickly. You get a smooth finish and avoid damaging the drywall.