You will notice a key difference when you use a tap screw: it cuts its own threads as you drive it in. Traditional screws require a pilot hole before you can install them. Knowing which screw to choose helps you avoid mistakes and saves time. If you want strong, reliable results in your next project, understanding this difference matters. Prince Fastener recommends picking the right screw for each task to get the best outcome.

Основные выводы

- Self-tapping screws make their own threads. This saves time and you do not need a pilot hole. – Traditional screws need a pilot hole first. This gives you more control but takes more time to use. – Pick self-tapping screws for fast jobs. Use traditional screws for soft or fragile materials that need gentle care. – Always match the screw type to your material for the best results. Self-tapping screws are good for wood, metal, and plastic. – Using the right screw makes your project last longer and work better. This helps your work be easier and stronger.

What Is a Tap Screw

Tap Screw Definition

A tap screw is a fastener that creates its own threads as you drive it into a material. You do not need to cut threads in advance. Self-tapping screws belong to the tap screw family. You use a tap screw when you want to join materials like metal, wood, or plastic without extra steps. Prince Fastener offers many types of tap screw for different projects. You can find tap screw options for both home and industrial use.

How Tap Screws Work

You use a tap screw by driving it into the material. The sharp tip and threads cut into the surface, forming a tight grip. Self-tapping screws need a pilot hole before you install them. Self-drilling screws, another type of tap screw, can drill their own pilot hole and tap threads at the same time. This makes installation faster and easier.

Примечание: Self-tapping screws and self-drilling screws are not the same. Self-tapping screws need a pilot hole, but self-drilling screws do not.

Here is a table to help you see the main differences:

| Особенность | Саморезы | Саморезы |

|---|---|---|

| Требование к пилотному отверстию | Requires a pilot hole | Does not require a pilot hole |

| Drilling Capability | Cannot drill through metal | Can drill through metal |

| Thread Tapping | Taps threads into the material | Taps threads while drilling |

| Типичные применения | Wood, metal, and brick | Fastening metal to metal and wood |

| Скорость установки | Slower due to pilot hole | Faster, no pilot hole needed |

| Эффективность затрат | May need extra drill bits | Saves time and money |

Общее использование

You can use a tap screw in many situations. These include:

- Securing thin sheet metal layers

- Fixing brackets into wood

- Fastening aluminum sections together

- Drilling into plastic housings or plugs

You will also see tap screw used in roofing, steel framing, HVAC work, drywall, woodworking, and DIY projects. In construction and manufacturing, tap screw helps you join panels and secure components when a pre-tapped hole is not available. Prince Fastener recommends tap screw for jobs where you need a strong hold and quick installation.

Self-Tapping Screws Overview

Характеристики саморезов

Саморезы make their own threads as you put them in. You do not need to make threads first. You can use these screws right away in many materials. This saves you time and work. These screws are less likely to break or split your project. They are safer for your work than regular screws. Prince Fastener says to use self-tapping screws when you want a strong hold and easy use.

Here is a table to help you see how self-tapping screws and regular screws are different:

| Особенность | Саморезы | Traditional Screws |

|---|---|---|

| Hole Creation | Make their own hole when you use them | Need a pilot hole before you use them |

| Internal Threading | Make threads in the material | Do not make their own threads |

| Способ установки | Go straight into the material | Need a pilot hole first |

| Risk of Damage | Less likely to damage your project | More likely to split or break things |

How Self-Tapping Screws Cut Threads

Self-tapping screws have sharp threads that cut into the material. There are two main types of self-tapping screws. Thread-forming screws push and shape the material to make threads. These work best in soft plastics or soft metals. They do not make chips, so your area stays clean. Thread-cutting screws have sharp edges that cut through hard or brittle materials. These are good for metal or hard plastic. You need a bigger pilot hole for thread-cutting screws. This lets chips come out and keeps your project safe.

Tip: Always pick the right screw for your material to get the best results.

Materials for Self-Tapping Screws

Self-tapping screws come in many materials for different jobs. Some common types are:

- Carbon steel for strong and cheap screws

- Stainless steel for wet or outdoor places

- Alloy steels for extra strength

- Brass for electrical jobs and to stop rust

- Nylon for light weight and insulation

Companies like Prince Fastener use heat to make screws tough and strong. Some screws have zinc or PTFE coatings to stop rust and help you install them. Always choose the right screw material for your project’s needs.

Traditional Screws Explained

What Are Traditional Screws

You often see traditional screws in many projects. These screws have a simple design. You use them to join wood, metal, or plastic. Traditional screws do not cut their own threads. You need to prepare the material before you use them. Most traditional screws have a pointed tip and spiral threads. You can find them in many sizes and shapes. Prince Fastener offers a wide range of traditional screws for every job.

Процесс установки

When you use traditional screws, you must drill a pilot hole first. This step helps guide the screw and prevents the material from splitting. You place the screw into the pilot hole and turn it with a screwdriver or drill. The threads grip the sides of the hole and hold the materials together. Traditional screws give you control over the fit and depth. You can remove and reuse them if needed. Many people choose traditional screws for their reliability and ease of use.

Tip: Always match the screw size to the pilot hole for the best hold.

Here is a simple checklist for installing traditional screws:

- Mark the spot for the screw.

- Drill a pilot hole.

- Insert the screw into the hole.

- Tighten the screw with a screwdriver or drill.

Where to Use Traditional Screws

You can use traditional screws in many places. They work well in woodworking, furniture assembly, and home repairs. Traditional screws are a good choice for projects that need a strong, lasting hold. You might use them to attach hinges, build shelves, or fix cabinets. In metalwork, traditional screws help you join thin sheets or brackets. You can also use them in plastic parts when you want a secure fit. Prince Fastener recommends traditional screws for jobs where you want precision and strength.

| Application Area | Why Use Traditional Screws? |

|---|---|

| Woodworking | Strong grip, easy to adjust |

| Metalwork | Secure thin sheets or brackets |

| Furniture Assembly | Reliable and reusable |

| Home Repairs | Versatile and easy to use |

Traditional screws give you flexibility and control. You can trust them for many tasks at home or on the job.

Ключевые различия

Thread Cutting vs. Pilot Holes

When you compare self-tapping screws to traditional screws, you see a big difference in how they create threads. Self-tapping screws cut their own threads as you drive them into the material. You do not need to make threads before you start. Traditional screws need a pilot hole. You must drill this pilot hole before you use the screw. This step helps prevent the material from splitting or cracking.

Here is a table to help you see the mechanical differences:

| Особенность | Саморезы | Traditional Screws |

|---|---|---|

| Thread Creation | Creates threads while being driven into the material | Requires a pre-drilled pilot hole |

| Pre-Drilling Requirement | Не требуется предварительное сверление | Requires a pilot hole to prevent splitting |

| Приложение | Often used in outdoor applications | Commonly used in various materials, especially wood |

You can use self-tapping screws when you want to save time and skip the pilot hole step. You use traditional screws when you want more control and need to protect delicate materials. Prince Fastener recommends checking your project needs before you pick a screw.

Tools and Preparation

You need different tools and steps for each screw type. Self-tapping screws let you work faster because you do not need to drill a pilot hole in most cases. You only need a screwdriver or a drill to drive the screw. Some self-tapping screws, like self-drilling screws, go straight into the material without any extra steps. This saves you time and effort.

For traditional screws, you must prepare the material first. You mark the spot, then drill a pilot hole with a drill bit. After that, you use a screwdriver or drill to insert the screw. This process takes more time because you have to switch tools and drill the pilot hole before you can finish the job.

- Self-drilling screws: Use a high-torque drive tool, such as an electric or cordless drill. No pilot hole needed. Installation is fast.

- Self-tapping screws: Sometimes need a pilot hole, which you make with a drill bit. This adds extra time compared to self-drilling screws.

- Traditional screws: Always need a pilot hole. You must drill first, then drive the screw.

Tip: If you want to finish your project quickly, choose self-tapping screws or self-drilling screws. Prince Fastener offers both options for fast and easy installation.

Совместимость материалов

You must match the screw type to the material you use. Self-tapping screws work well in many materials, such as steel, stainless steel, brass, and aluminum. You can use them in construction, automotive, marine, and even medical projects. Self-tapping screws give you a strong hold in tough materials and resist corrosion when you pick the right finish.

Traditional screws also work in many materials, but you need to drill a pilot hole first. You often use them in wood, plastic, and thin metal. You get a secure fit, but you must take extra care with the pilot hole size.

- Steel: Use self-tapping screws for strength and durability. Good for construction and cars.

- Stainless steel: Pick self-tapping screws for marine or medical jobs. They resist rust.

- Brass: Choose self-tapping screws for electrical work or when you want a nice finish.

- Aluminum: Use self-tapping screws for lightweight and corrosion-resistant projects.

- Other alloys: Self-tapping screws fit high-performance needs in aerospace and medical devices.

Prince Fastener makes self-tapping screws in many materials. You can find the right screw for any job. Always check the material before you start. The right screw gives you a safe and lasting result.

When to Use Self-Tapping Screws

Best Projects for Self-Tapping Screws

Вы можете использовать саморезы in many types of building and repair projects. These screws work best when you want to save time and get a strong hold. You often see them in construction, metalwork, and modular builds. For example, you can use self-tapping screws to join steel frames, attach roof panels, or assemble metal furniture. Many builders choose them for jobs that need quick assembly and a secure fit.

Here is a table that shows where self-tapping screws shine:

| Тип проекта | Тип винта | Steel Thickness | Преимущества |

|---|---|---|---|

| Residential Housing | #10-16 Tek | 1.2 mm | Cuts installation time by 30% because you skip pre-drilling. |

| Industrial Warehouses | #14-14 Tek | 2.0 mm | Handles heavy loads for bracing and roof trusses. |

| Modular Schools | #8-18 Tek | 1.0 mm | Makes fast assembly easy with less risk of bending or damaging material. |

You can also use саморезы for HVAC systems, car repairs, and DIY projects at home. Prince Fastener offers a wide range of self-tapping screws for these needs.

Tip: Choose self-tapping screws when you want to work faster and avoid extra steps.

Advantages in Use

Self-tapping screws give you many benefits on the job. You do not need to drill a pilot hole, so you finish your work faster. This saves you time, especially if you have many screws to install. You also use fewer tools, which makes your work area safer and less crowded.

Here is a table that explains the main advantages:

| Advantage | Описание |

|---|---|

| Increased Efficiency | You skip pilot holes, so you assemble parts much faster. |

| Reduced Labor Costs | You spend less time and need fewer workers, which lowers your project costs. |

| Cost-Effectiveness | You may pay more for the screws, but you save money in the long run by working more quickly. |

You get a strong, reliable hold with less effort. Many professionals trust Prince Fastener self-tapping screws for these reasons. You can count on them to help you finish your project on time and within budget.

When to Use Traditional Screws

Best Projects for Traditional Screws

Traditional screws are helpful for many projects that need careful work. You can use them for woodworking, putting furniture together, and fixing things at home. These screws are good when you do not want to split wood or hurt soft materials. You can use traditional screws to put on hinges, build cabinets, or fix shelves. Many workers pick these screws for jobs that need a strong hold that lasts.

You can also use traditional screws when working with metal. They help you join thin metal sheets or hold brackets in place. You get a good grip if you match the screw size to the pilot hole. You can take these screws out and use them again if you need to change something. Prince Fastener has many kinds of traditional screws for all sorts of projects.

Tip: Pick traditional screws when you want to control where and how deep the screw goes.

Here are some common projects where traditional screws are best:

- Building wooden furniture

- Putting on door hinges

- Fixing cabinets

- Putting shelves together

- Holding metal brackets

Advantages in Use

Traditional screws have many good points. You can take them out and use them again, so you have more choices. You can control how tight and how deep the screw goes by making a pilot hole first. This step helps stop the wood from splitting and keeps your work safe.

Traditional screws are also strong and last a long time. The table below shows how traditional screws and socket screws are different:

| Особенность | Traditional Screws | Винты с головкой под торцевой ключ |

|---|---|---|

| Strength Variability | Changes a lot depending on the material | Usually stays the same in strength |

| Application Suitability | Good for light and heavy jobs | Mostly for heavy-duty jobs |

| Устойчивость к коррозии | Changes; you can get stainless steel or coated screws | Often has better coatings to stop rust |

You can pick traditional screws made from many materials, like stainless steel or coated screws, to fit your project. Prince Fastener says to use traditional screws for jobs that need a strong hold and easy changes.

Note: Always pick the right screw material for your project to help stop rust and make it stronger.

You can count on traditional screws for small fixes or big builds.

Pros and Cons Comparison

Self-Tapping Screws: Pros & Cons

Self-tapping screws are simple to use. You can put them in fast, so you save time. Most of the time, you do not need to drill a pilot hole. This lets you work quicker and use fewer tools. Self-tapping screws hold tight in many materials. If you need to change something, you can take them out easily.

Here is a table that lists the main pros and cons:

| 👍 Pros | 👎 Cons |

|---|---|

| Easy to use | Can cause tooth injuries if misused |

| Fast installation | May loosen over time |

| Lower risk of splitting or damaging material | Not always suitable for soft materials |

| High stability and precise alignment | |

| Minimal hardware needed | |

| Quick and painless removal |

Prince Fastener says self-tapping screws are great for fast and strong work. You can use them for metal jobs, building, and home projects.

Traditional Screws: Pros & Cons

Traditional screws give you more control and choices. You can use regular tools to put them in. It is easy to adjust or take them out if you need to. Many people pick traditional screws because they cost less. They are good for careful work that needs steps.

Плюсы:

- Cheap for most jobs

- Work with tools you already have

- Step-by-step use helps stop damage

- Good for soft or delicate materials

Конс:

- Takes longer to install

- You must drill a pilot hole first

- Too much force can break your project

Prince Fastener has many traditional screws for sale. You can use them for woodwork, making furniture, and repairs that need careful work.

Think about these pros and cons before you pick a screw. The right screw helps you do your project well every time.

Выбор правильного винта

Факторы, которые необходимо учитывать

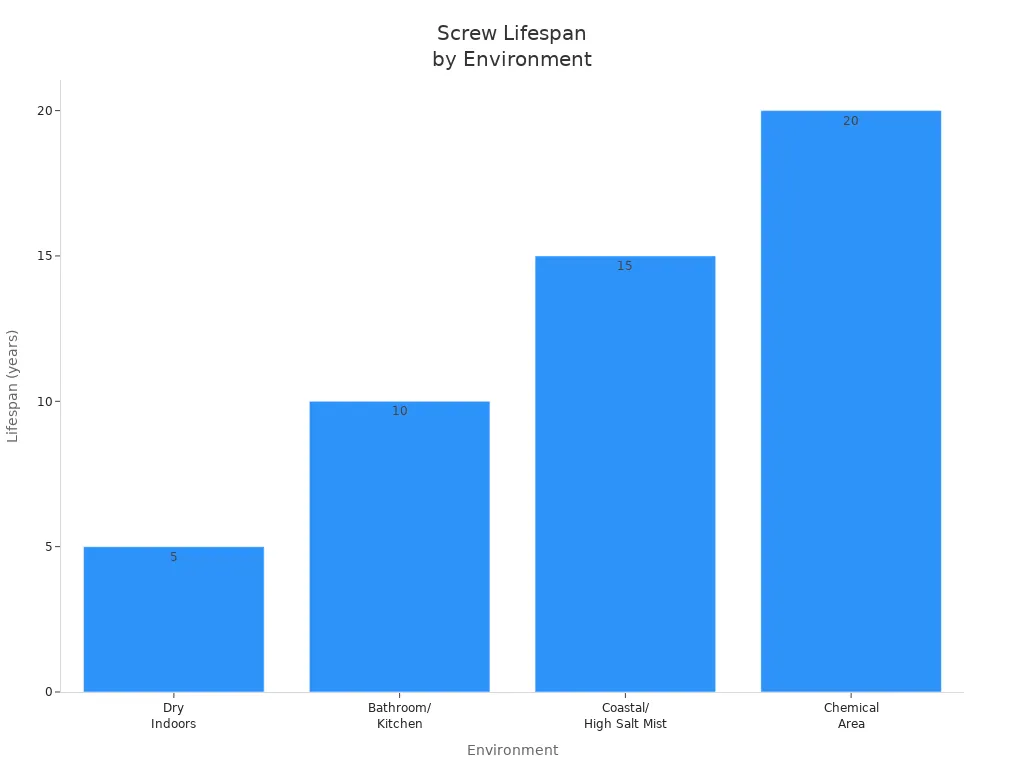

You need to think about a few things before picking a screw. The place where you use the screw is important. If you work inside and it is dry, carbon steel screws with a galvanized or white zinc finish last about 3 to 5 years. In bathrooms or kitchens, 304 stainless steel with passivation treatment can last more than 10 years. If you live near the ocean with salty air, you need 316 stainless steel and electrolytic polishing. These can last up to 15 years. In places with chemicals, titanium alloy screws with anodic oxidation last 20 years or more.

| Environment | Рекомендуемые материалы | Обработка поверхности | Продолжительность жизни |

|---|---|---|---|

| Dry Indoors | Углеродистая сталь | Galvanized, White Zinc | 3–5 years |

| Bathroom/Kitchen | 304 нержавеющая сталь | Passivation Treatment | 10+ years |

| Coastal/High Salt Mist | Нержавеющая сталь 316 | Electrolytic Polishing | 15+ years |

| Chemical Area | Titanium Alloy | Anodic Oxidation | 20+ years |

You also need to know what material you want to join. Some screws are better for wood, metal, or plastic. Prince Fastener has many screws for every place and material. You can always find the right screw for your job.

Practical Selection Tips

Picking the right screw for your material makes your project easier. Here are some tips that experts use:

- Шурупы по дереву: Use coarse threads and sharp points. These go into wood easily.

- Machine Screws: Pick fine threads for machines or electronics. These fit into tapped holes or nuts.

- Винты для листового металла: Choose self-tapping screws with threads all the way down for metal sheets.

- Deck Screws: Pick screws that do not rust for outdoor decks. These stop wood from splitting.

- Drywall Screws: Use bugle head screws so you do not rip drywall paper.

- Concrete Screws: Use strong screws made for concrete or bricks.

Tip: Always pick a screw that matches your project. Good brands like Prince Fastener help you get great results every time.

Check the screw’s material, coating, and thread type before you buy. This helps you avoid problems and makes your work last longer. If you follow these tips, you will always pick the right screw for your job.

You now understand how саморезы и traditional screws are different. Look at the table below for a quick review:

| Особенность | Саморезы | Traditional Screws |

|---|---|---|

| Hole Creation | Makes its own hole | Needs a pilot hole |

| Резьба | Creates internal threading | Does not create threading |

| Risk of Damage | Lower risk | Повышенный риск |

Picking the right screw helps your project stay safe and strong. Here are some tips to remember: Match the screw type to your material and how much weight it needs to hold. Use good screws from Prince Fastener so your work lasts longer.

Easy decision guide:

- If you want a quick job in soft stuff, use self-tapping screws.

- If you need to be careful or work with delicate things, pick traditional screws.

Choose the right screw and your project will last longer and look nicer.

Часто задаваемые вопросы

What is the main difference between self-tapping screws and traditional screws?

Саморезы cut their own threads as you drive them in. Traditional screws need a pilot hole before you use them. You save time with self-tapping screws. Prince Fastener offers both types for your projects.

Can I use self-tapping screws in wood?

Yes, you can use self-tapping screws in wood. They work well for soft and hard woods. You get a strong hold without splitting the wood. Prince Fastener recommends choosing the right screw length for your wood project.

Do I need special tools for self-tapping screws?

You do not need special tools. A standard screwdriver or drill works for most self-tapping screws. For harder materials, use a power drill. Prince Fastener suggests using the right bit size for best results.

Are self-tapping screws reusable?

You can reuse self-tapping screws if the threads in the material stay undamaged. If the hole gets stripped, the screw may not hold well. Prince Fastener advises checking the hole before reusing any screw.

How do I choose the right screw for my project?

Check your material and project needs. Use self-tapping screws for quick jobs and strong holds. Pick traditional screws for delicate work or when you want more control. Prince Fastener can help you select the best screw for your task.