If you want strong results, you need to match the right screw to your project. For wood, wood screws grip better and reduce splitting. For metal, metal screws hold tight and resist rust. Many people make mistakes with wood screw vs metal screw choices. They use wood screws in metal, or metal screws in wood, and end up with damage or weak joints. You also need to think about rust and how much weight your project will hold. Let’s help you avoid these common slip-ups.

Основные выводы

- Choose wood screws for wood projects. They grip better and reduce the risk of splitting.

- Use metal screws for metal applications. They resist rust and provide strong holds in hard materials.

- Always match the screw type to your material. Using the wrong screw can lead to weak joints or damage.

- Consider environmental factors. For outdoor projects, opt for rust-resistant screws like stainless steel or galvanized.

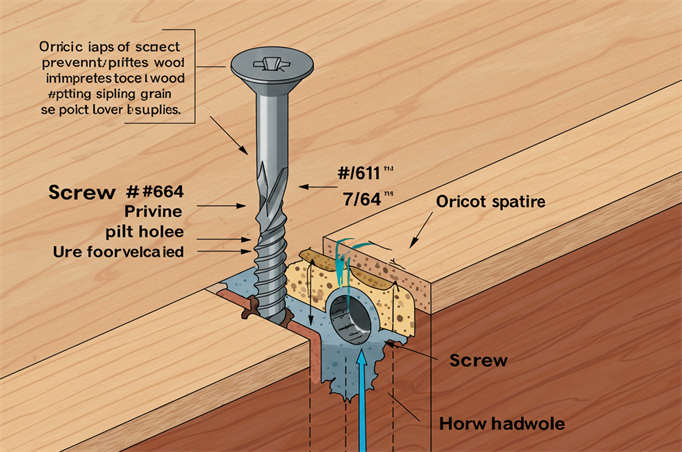

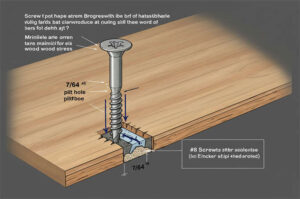

- Pre-drill when necessary. This helps prevent splitting in hardwood and ensures a secure fit.

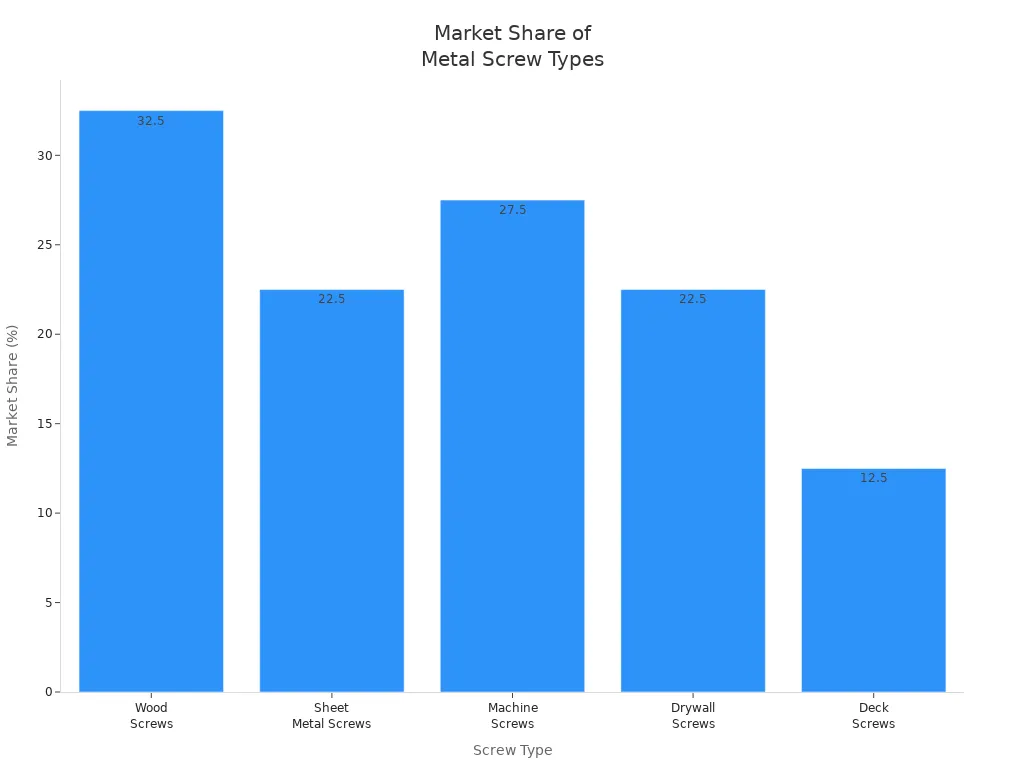

Wood Screws vs Metal Screws

Ключевые различия

When you look at wood screw vs metal screw options, you’ll notice some key differences that really matter for your project. Let’s break them down so you can spot the right screw at a glance.

| Особенность | Шурупы по дереву | Металлические винты |

|---|---|---|

| Тип нити | Coarse threads, wider spaced | Sharp, deep threads covering entire length |

| Shank Design | May have a smooth, threadless shank | No smooth shank, fully threaded |

- Шурупы по дереву have rough threads and a smooth shank. This design helps you grip wood tightly without splitting it.

- Metal screws feature sharp, deep threads that run the full length. These threads cut through metal and hold strong.

Tip: Always match the screw type to your material. Using the wrong one can lead to weak joints or even damage.

You also need to think about coatings and finishes. Wood screws often come untreated or with finishes for wood. Metal screws usually have galvanized or stainless coatings to fight rust.

Типичные случаи использования

You’ll find wood screws everywhere in furniture and construction. They work best for:

- Furniture assembly and framing

- Cabinetry and shelving

- Decking, fencing, and landscaping (especially with corrosion-resistant coatings)

- Residential and commercial construction projects

Wood screws grip wood tightly and help prevent splitting when you drill.

Metal screws show up in manufacturing and repair jobs. You’ll see them used for:

- Fastening metal parts in HVAC and automotive work

- Electronics and machine assembly

- Attaching drywall to studs

- Building outdoor decks and fences

The key differences between these screws make each one perfect for its own job. If you use wood screws in metal, you won’t get a strong hold. If you use metal screws in wood, you might split the wood or strip the threads. Always check your material before you choose.

Wood Screws Pros and Cons

Advantages of Wood Screws

When you work with wood, you want fasteners that make your job easier and your project stronger. Here are some pros you’ll notice with wood screws:

- Sharp, pointed tips and coarse threads let you drive screws into softwood and hardwood with less effort.

- The smooth shank near the head helps pull boards together tightly, giving you a solid grip and reducing the risk of splitting.

- You often don’t need to pre-drill in softer woods, which saves you time and energy.

- The threaded design keeps joints secure, so your furniture or framing stays stable for years.

- Wood screws come in different shapes and sizes, so you can pick the best one for trim, moldings, or heavy-duty builds.

Tip: If you want even more holding power, choose screws with optimized geometry. These can boost withdrawal strength, especially in dense timber.

Disadvantages of Wood Screws

Of course, there are cons to using wood screws. You should know about these before you start your next project:

- Wood screws can corrode if you use them outdoors or in damp places. Humidity, salty air, and pollution all speed up rust.

- Galvanized screws rely on a zinc coating, which wears off over time. Stainless steel screws resist rust better, but they cost more.

- Some woods have chemicals or acidic pH that make screws oxidize faster.

- If you use wood screws in metal, you won’t get a strong hold. That’s a big disadvantage in the wood screw vs metal screw debate.

| Type of Screw | Устойчивость к коррозии | Durability in Humid Environments |

|---|---|---|

| Galvanized Screws | Zinc coating, can corrode over time | Poor, especially with moisture |

| Винты из нержавеющей стали | Rust-resistant due to chromium | Excellent, ideal for outdoors |

Best Uses for Wood Screws

You’ll see the pros of wood screws shine in these projects:

- Building furniture, cabinets, and shelves

- Installing trim, moldings, and door jambs

- Decking, fencing, and landscaping (especially with rust-resistant screws)

- High-torque jobs with hardwood or manmade materials

If you want flush finishes, bugle head screws work well for trim. Trim head screws help you avoid splitting delicate wood. Production screws handle tough woods and heavy-duty tasks.

So, when you weigh the pros and cons, wood screws are your go-to for most carpentry and woodworking. Just remember to pick the right type for your environment and project needs.

Metal Screws Pros and Cons

Advantages of Metal Screws

If you work with metal, you need strong fasteners. Metal screws are great for tough jobs. They have fine threads and are threaded all over. This helps them grip steel, aluminum, and other hard stuff. Some are self-tapping or self-drilling. These save time because you don’t need to drill first. You just screw them in, and they make their own path. This makes building things faster and neater.

Here’s a quick look at what makes metal screws strong:

| Особенность | Описание |

|---|---|

| Дизайн резьбы | Fine, tight threads touch more of the hard material. |

| Point Style | Hard tips make holes and form threads for better grip. |

| Material Hardness | Made from strong steel or alloys, so they don’t bend or break. |

| Стили головы | Flat, pan, and hex heads spread out force and let you turn them harder. |

Metal screws also fight rust really well. Stainless steel screws work in wet or salty places. Zinc-plated screws slow down rust, so things last longer. Hot-dipped galvanized screws are best for outside because they stop rust even more.

| Тип материала | Corrosion Resistance Description |

|---|---|

| Нержавеющая сталь | Has iron, chromium, and nickel. 316-grade is best for tough places. |

| Zinc-Plated Screws | Zinc coating slows rust a lot, but they can still rust. |

| Hot-Dipped Galvanized | Best at stopping rust outside, but not as good as stainless steel. |

Tip: For the best rust protection, pick stainless steel for harsh places or hot-dipped galvanized for outdoors.

Disadvantages of Metal Screws

Metal screws have some downsides, especially if you use them in wood. They work best in metal and hard stuff, but not in wood. Here are the main problems:

- Sheet metal screws are the same width all over, so they can split wood.

- Wood changes shape with water, but metal screws don’t move with it. This can make joints fail or wear out.

- The fine threads don’t hold well in wood, so joints can get loose or screws can pop out.

- Metal screws don’t handle wood’s movement, so cracks or damage can happen over time.

If you use metal screws in wood, you’ll see more problems than good things. You might get weak joints, split wood, or screws that won’t stay tight.

Best Uses for Metal Screws

Metal screws are best for jobs that need strength and last a long time. You’ll see their good points in these jobs:

- Holding light fixtures to metal ceilings or walls

- Attaching metal cable holders

- Putting in HVAC parts

- Building metal buildings from kits

- Mounting motors and pumps in factories

- Fixing metal roofs or siding

- Fastening metal frames in walls

- Installing metal stairs and railings

- Mounting electronics in metal boxes

- Building outdoor metal furniture

You’ll see even more good things when you use metal screws for fixing metal gates, adding brackets, or fixing trailers. Their rust resistance means your work lasts through weather and time. If you want to avoid problems, use metal screws for metal and hard materials. That way, you get the most good things and the least bad things in your work.

Wood Screw vs Metal Screw: Side-by-Side Comparison

When you stand in the hardware aisle, the wood screw vs metal screw debate can feel confusing. Let’s break it down side by side so you can see which one fits your project best.

Совместимость материалов

You want your screws to match your material. If you use the wrong type, you might end up with weak joints or even damage.

| Материал | Шурупы по дереву | Металлические винты | Примечания |

|---|---|---|---|

| Plywood (3/4″) | Good grip, strong | Poor grip | Use wider shank for best results |

| MDF (1″ thick) | Needs pilot hole | Not recommended | Avoid splitting by pre-drilling |

| Fiberboard | Wears threads fast | Not ideal | Resin can strip threads |

| Steel/Aluminum | Not suitable | Превосходно | Use self-tapping or self-drilling screws |

| Wood + Thin Metal | Possible, but tricky | Хорошо | Watch for expansion and corrosion issues |

- Wood screws work well in plywood and solid wood. You get a strong hold, especially if you use the right length and shank width.

- In MDF or fiberboard, you need to pre-drill to avoid splitting. These materials can also wear down screw threads faster.

- Metal screws shine in steel and aluminum. They cut threads as they go, especially if you pick self-tapping types.

- If you try to attach thin metal to wood, you can use wood screws, but you might run into problems. The different expansion rates of wood and metal can loosen the connection over time. In damp places, you also risk corrosion where the two materials meet.

Tip: Always check your material before you pick a screw. The right match means fewer headaches later.

Holding Power

You want your project to stay together, so holding power matters a lot. This is where the right screw makes a big difference.

- Wood screws have coarse threads and a smooth shank. This design pulls wood pieces tight and keeps them from splitting. You get strong holding power in softwood and hardwood.

- Metal screws have fine threads that grip metal tightly. In wood, though, they don’t hold as well. The threads can strip out, and the joint may loosen over time.

- In plywood, wood screws can hold up to 310 pounds if you use the right size. In MDF, the holding power drops, so you need to pre-drill and use deep threads.

- Metal screws in steel or aluminum give you a solid, long-lasting hold. They resist vibration and won’t back out easily.

| Тип винта | Best Holding Power In | Max Load (lbs) Example |

|---|---|---|

| Шурупы по дереву | Wood, plywood | 310 (plywood, 3/4″) |

| Металлические винты | Steel, aluminum | Varies by thickness |

If you want the best holding power, always match the screw to your material. Using the wrong one can lead to weak joints or even failure.

Installation Ease

You want your project to go smoothly. The right screw can save you time and effort.

- Wood screws often go into softwood without pre-drilling. In hardwood, you should drill a pilot hole close to the screw’s core size. This helps prevent splitting and makes driving easier.

- Metal screws can be self-tapping or self-drilling. If you use them in thin metal (under 1/8″), you can skip pre-drilling. For thicker or harder metals, you need to drill a hole first. This keeps the screw from breaking or stripping.

- In fiberboard or MDF, always pre-drill for wood screws. This stops the material from splitting or crumbling.

- If you use metal screws in wood, you might find them hard to drive. The fine threads don’t bite into wood well, so you’ll struggle to get a tight fit.

Note: Self-drilling screws can save you a lot of time in metal projects. For wood, a quick pilot hole in tough spots makes life easier.

Cost and Durability

You want your project to last, but you also want to stay on budget. Here’s how wood screws and metal screws compare:

| Особенность | Шурупы по дереву | Металлические винты |

|---|---|---|

| Цена | Usually cheaper | Can cost more, especially stainless |

| Устойчивость к ржавчине | Varies (galvanized, stainless) | High (zinc, galvanized, stainless) |

| Продолжительность жизни | Good indoors, varies outdoors | Excellent in harsh conditions |

| Replacement Cost | Низкий | Higher for specialty screws |

- Wood screws cost less, especially if you buy plain steel or zinc-coated types. For outdoor use, stainless steel costs more but lasts longer.

- Metal screws, especially stainless or hot-dipped galvanized, cost more up front. They pay off with better rust resistance and longer life, especially in wet or outdoor settings.

- If you use the wrong screw, you might have to replace it sooner. That means more time and money spent fixing your project.

Tip: For outdoor or damp places, spend a little more on rust-resistant screws. You’ll save money and hassle in the long run.

In the wood screw vs metal screw debate, you need to look at your material, the holding power you need, how easy the screws are to install, and your budget. When you match the right screw to your job, you get a project that lasts and looks great.

Выбор правильного винта

Факторы, которые необходимо учитывать

When you start choosing the right screw, you want to look at a few important things. Picking the best screw means your project stays strong and safe. Here’s what you should think about:

- Совместимость материалов: Make sure your screw matches the material. Шурупы по дереву work best in wood. Metal screws are made for metal.

- Дизайн резьбы: Coarse threads grip wood. Fine threads cut through metal.

- Length and Diameter: The screw should be long enough to hold your materials together, but not so long that it pokes out the other side. The diameter needs to fit the material’s density and strength.

- Coating and Finish: If your project faces moisture or chemicals, pick screws with coatings like zinc or stainless steel.

- Типы дисков: Some screws use Phillips heads, others use flat or hex heads. Choose the type that makes installation easy for you.

You also need to think about the environment. If your project sits outside or in a humid spot, use stainless steel or coated screws. For places with chemicals or high heat, pick screws that can handle those conditions.

| Тип винта | Грузоподъемность |

|---|---|

| Heavy-Duty | Высокий |

| Стандарт | Medium |

| Light-Duty | Низкий |

Tip: Always check the thickness of your materials. The screw should be at least twice as long as the material is thick for a strong hold.

Распространенные ошибки

You want your project to last, so watch out for these mistakes when choosing the right screw:

- Choosing the Wrong Type of Screw: Using a wood screw in metal can cause rust or breakage. Metal screws in wood may split the wood or not hold well.

- Using the Incorrect Screw Size: If your screw is too short, it won’t hold. If it’s too long, it can poke out and cause safety problems.

Many people forget to match the screw to the environment. If you use the wrong coating, your screws might rust or corrode quickly.

Quick Decision Guide

Need help choosing the right screw fast? Try this checklist:

- For wood projects, pick wood screws with sharp points and deep threads.

- For metal jobs, use machine screws or self-drilling screws for tight fits.

- If you work with sheet metal or roofing, self-drilling screws save time.

- Always check material compatibility, load needs, and environmental exposure.

- If your project faces moisture or chemicals, choose screws with strong coatings.

- Decide if you want a permanent or temporary connection.

- Make sure installation is easy for you and the screw meets strength needs.

Remember, choosing the right screw keeps your project safe, strong, and looking good.

You now know the main differences between wood screws and metal screws. Wood screws grip wood grains with coarse threads. Metal screws work best in metal and resist rust. Lag screws handle heavy-duty jobs. Self-tapping screws give you flexibility for both wood and metal.

- Use wood screws for wood-to-wood projects.

- Pick metal screws for metal parts or outdoor use.

- Try self-tapping screws if you need versatility.

Remember, humidity and temperature can change how screws perform, especially in wood. Always match your screw to your material and environment for the best results.

Часто задаваемые вопросы

What’s the main difference between a wood screw and a metal screw?

You’ll spot the difference by looking at the threads. A wood screw has coarse threads and a smooth shank. A metal screw has fine threads that run the whole length. Each type fits its own applications and best practices.

Can I use metal screws in wood projects?

You shouldn’t use metal screws in wood. Metal screws don’t grip wood well. You might split the wood or get a weak hold. For wood, always pick a wood screw. This matches the right applications and best practices.

How do I choose the right screw for outdoor use?

You want screws with rust-resistant coatings. Stainless steel or galvanized screws work best outside. Always check your project’s environment before you pick a screw. This helps you follow applications and best practices for durability.

Do I need to pre-drill holes for screws?

You don’t always need to pre-drill for wood screws in softwood. In hardwood or metal, you should drill a pilot hole first. This makes driving the screw easier and keeps your project strong. It’s one of the top applications and best practices.

What happens if I use the wrong screw?

If you use the wrong screw, your project can fail. You might see loose joints, stripped threads, or even damage. Always match the screw to your material and follow applications and best practices for the best results.