If you want the best long-term durability, stainless steel bolts often stand out. Your choice of material has a big impact on how well bolts last. Corrosion resistance, strength, cost, and maintenance all play a role. Stainless steel works well in tough environments, but ss bolts are not always the only option. Think about where you will use the bolts and what your project needs before you decide.

Основные выводы

- Stainless steel bolts do not rust easily, so they work well outside and near water. This makes them good for places where rust is a problem.

- Think about how strong your project needs to be. Stainless steel bolts are strong, but carbon steel and titanium can hold heavier things better.

- You do not need to do much to take care of stainless steel bolts. Clean them sometimes and use anti-seize to help them last longer and work better.

- Stainless steel bolts cost more at first, but they last a long time. This can help you save money because you will not need to buy new bolts often.

- Always pick the right bolt material for your project. This helps keep your project safe and working well.

Bolt Durability Factors

Когда picking bolts, you want them to last a long time. Four things decide how strong a bolt is: corrosion resistance, strength, maintenance, and cost. These things help you see how stainless steel bolts compare to others.

Устойчивость к коррозии

Corrosion resistance shows how well a bolt can stop rust. If bolts are outside or near water, they need strong protection. Water and chemicals can make bolts rust and get weak. Stainless steel bolts are great at stopping rust, even in tough places. Some bolts, like Grade 316 stainless steel, work well in saltwater. Other bolts have coatings, like hot-dip galvanizing, which puts zinc on steel. This helps stop rust, but it is not as good as stainless steel in saltwater. If you mix metals, galvanic corrosion can happen and make bolts wear out faster.

Tip: Always pick bolts that match where you use them. Pollution and temperature changes can make bolts age and break faster.

Прочность

Strength means how much force a bolt can take before it breaks. You want bolts that meet the right strength rules. Stainless steel bolts are strong, but some bolts, like Grade 8 steel or titanium, are even stronger. The kind of load—static, moving, or shaking—also matters when you choose.

| Материал | Предел прочности |

|---|---|

| Titanium (Grade 5) | 900 MPa |

| Steel (Grade 8) | 1500 MPa |

| Нержавеющая сталь 316 | 505 MPa |

Обслуживание

Maintenance is how often you need to check or clean bolts. Stainless steel bolts do not need much care. You can clean them easily, and they do not need extra work. Some bolts, like ASTM A193 Grade B8, need special marks and heating. Others, like ASTM F593 Group 1, must pass rust tests.

| Тип болта | Maintenance Requirements | Additional Processes |

|---|---|---|

| Type 304 Stainless Steel | Optional cleaning (descaling, pickling) | None required |

| ASTM A193 Grade B8 | Must be annealed and stamped | Specific thread count and marking |

| ASTM F593 Group 1 | Must pass corrosion test, stamped | Optional thread specifications |

Расходы

Cost is important for every project. Stainless steel bolts cost more than galvanized bolts. Galvanized bolts are cheaper, but stainless steel bolts last longer and fight rust better. In tough places, paying more for stainless steel bolts can save money later.

- Stainless steel bolts: Cost more, best for hard jobs

- Galvanized bolts: Cost less, good for simple jobs

You should always look at these things before picking bolts. This helps you get the right bolts for your job and where you use them.

Stainless Steel Bolts Overview

Stainless Steel Fasteners Properties

People pick stainless steel bolts when there is water or chemicals. Крепеж из нержавеющей стали have special features that make them a good choice for strong and rust-proof jobs.

- Stainless steel has chromium. Chromium makes a thin layer on the bolt. This layer stops rust and keeps the bolt safe for a long time.

- Stainless steel bolts stay shiny and do not rust, even after many years.

- You do not need to add extra coatings or treatments. Stainless steel bolts are strong and last a long time.

- These fasteners work well with chemicals, oils, solvents, and acids.

Corrosion Resistance of Stainless Steel

Stainless steel bolts are very good at stopping rust. The chromium in them makes a layer that protects the bolt from rust. In places near the ocean, stainless steel bolts last longer than galvanized steel bolts. Galvanized steel has a zinc layer that can wear off. When that happens, the steel under it can rust. Stainless steel bolts keep their strength and look good in saltwater. This makes them great for outside and ocean jobs. You get bolts that last a long time and work well.

Strength of Stainless Steel Bolts

You need strong bolts for hard jobs. Stainless steel bolts are tough and can hold heavy loads. They keep their strength and last a long time. The table below shows how strong some stainless steel bolts are:

| Class | Minimum Tensile Strength (MPa) |

|---|---|

| ISO 3506 Class 70 | 700 |

| Unmarked (Class 50) | 500 |

| 304/316 Grade (Annealed) | 483 |

Stainless steel bolts are good for building things. You can trust them for jobs that need strong and heat-proof bolts.

Maintenance Needs

Stainless steel bolts do not need much care, but you should stop them from sticking. Here are some steps you can follow:

- Put anti-seize on the threads before you use them.

- Use a torque wrench to make them tight enough.

- Line up bolts and parts so they do not cross-thread.

- Pick stainless steel grades that do not stick easily.

- Use coatings to make them slide better.

- Do not mix metals to stop galvanic corrosion.

These steps help your bolts last longer and work better.

Cost of Stainless Steel Bolts

Stainless steel bolts cost more than regular or galvanized bolts. You pay more because they last longer and do not rust. The price is worth it if you use them where there is water, chemicals, or near the ocean. You save money over time because you do not have to change the bolts often.

Tip: If you need bolts that are strong and last in tough places, болты из нержавеющей стали are the best choice for strength, rust protection, and long life.

Carbon Steel Bolts

Устойчивость к коррозии

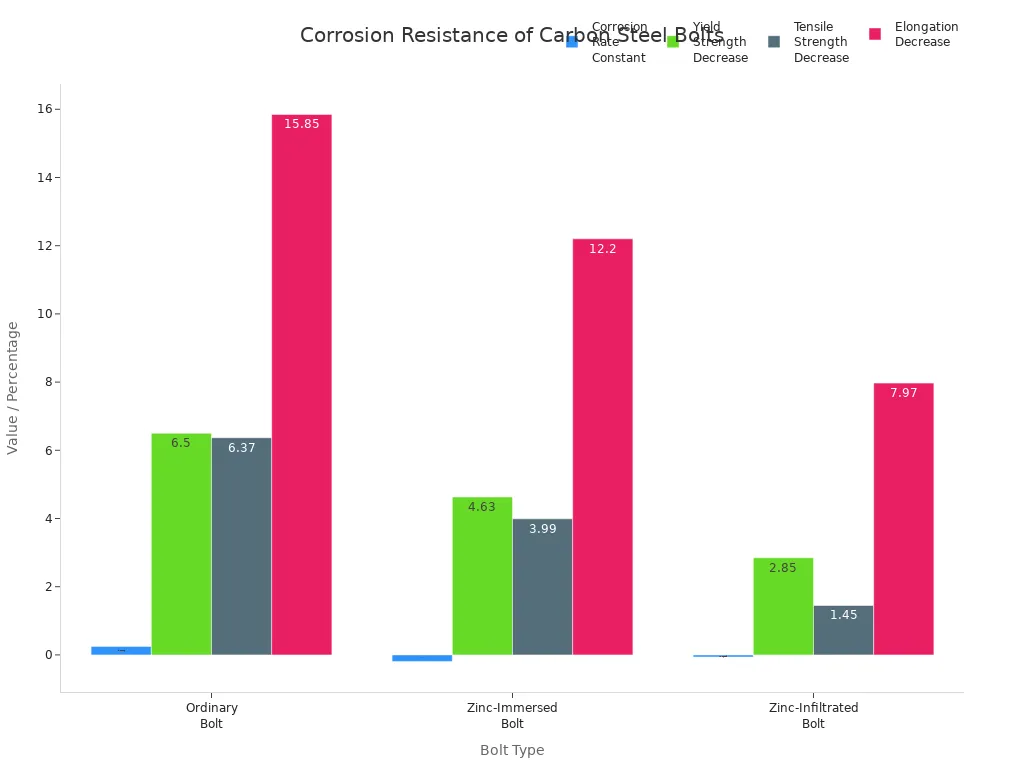

You may choose болты из углеродистой стали for many projects, but you need to know how they handle rust. Carbon steel bolts do not have chromium or other anti-corrosion elements. This makes them sensitive to moisture and chemicals. If you use them outside or in wet places, they can rust quickly. The table below shows how different carbon steel bolts react in humid or acidic environments:

| Тип болта | Corrosion Rate Constant | Yield Strength Decrease | Tensile Strength Decrease | Elongation Decrease |

|---|---|---|---|---|

| Ordinary Bolt | 0.25026 | 6.50% | 6.37% | 15.85% |

| Zinc-Immersed Bolt | -0.19605 | 4.63% | 3.99% | 12.20% |

| Zinc-Infiltrated Bolt | -0.06209 | 2.85% | 1.45% | 7.97% |

If you want better corrosion resistance, you can use galvanized bolts or galvanized steel bolts. These have a zinc layer that protects the steel from rust.

Прочность

Carbon steel bolts give you высокая прочность. You can increase the strength by adding more carbon. This makes them good for heavy loads and tough jobs. You will find that carbon steel bolts are easy to cut, weld, and shape. Many builders use them for bridges, buildings, and machines. The table below lists the main advantages and disadvantages:

| Advantages of Carbon Steel | Disadvantages of Carbon Steel |

|---|---|

| High Strength: Carbon steel can achieve higher strength by increasing the carbon content. | Corrosion: Carbon steel is prone to rust in wet or corrosive environments. |

| Low Cost: Carbon steel is cheaper to produce than stainless steel. | Poor corrosion resistance: No anti-corrosion elements such as chromium are added, so it is sensitive to oxidation and corrosion. |

| Easy to Process: Carbon steel is easy to cut, weld and form. | Н/Д |

Обслуживание

You need to check carbon steel bolts often, especially if you use them outside. Cleaning, tightening, and coating help them last longer. Here is a simple maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Clean | At least once a year |

| Re-tighten | Every 6 to 12 months |

| Check alignment | During each inspection |

| Apply protective coatings | Every 2 to 3 years |

| Apply corrosion inhibitors | Annually |

Tip: If you skip these steps, your bolts may rust or break faster.

Расходы

Carbon steel bolts cost less than ss bolts and galvanized bolts. You save money when you buy them in bulk. The table below compares prices:

| Тип болта | Price per Unit |

|---|---|

| Углеродистая сталь | $0.30-$0.70 |

| Нержавеющая сталь | $0.80-$1.50 |

| Оцинкованная сталь | 30-50% more than carbon steel |

- Carbon steel bolts are generally less expensive than stainless steel and galvanized steel bolts.

- Stainless steel bolts can be 2-3 times more expensive than carbon steel bolts.

- Galvanized bolts are cheaper than stainless steel but still pricier than carbon steel.

You can use carbon steel bolts for many jobs if you want to save money. If you need better rust protection, you may want to pay more for galvanized bolts or ss bolts.

Galvanized Steel Bolts

Устойчивость к коррозии

You can trust galvanized steel bolts to fight rust in many outdoor settings. These bolts have a zinc coating that shields the steel from moisture and air. This layer stops oxidation, so the bolts last longer even in harsh weather. The zinc coating gives you strong protection, especially for fences, bridges, and outdoor equipment.

| Выгода | Описание |

|---|---|

| Устойчивость к коррозии | Zinc coating protects steel from oxidation, even in tough outdoor environments. |

| Extended Service Life | Zinc layer helps bolts last decades, reducing the need for frequent replacements. |

| Cost-Effectiveness | More affordable than stainless steel bolts, good for large projects on a budget. |

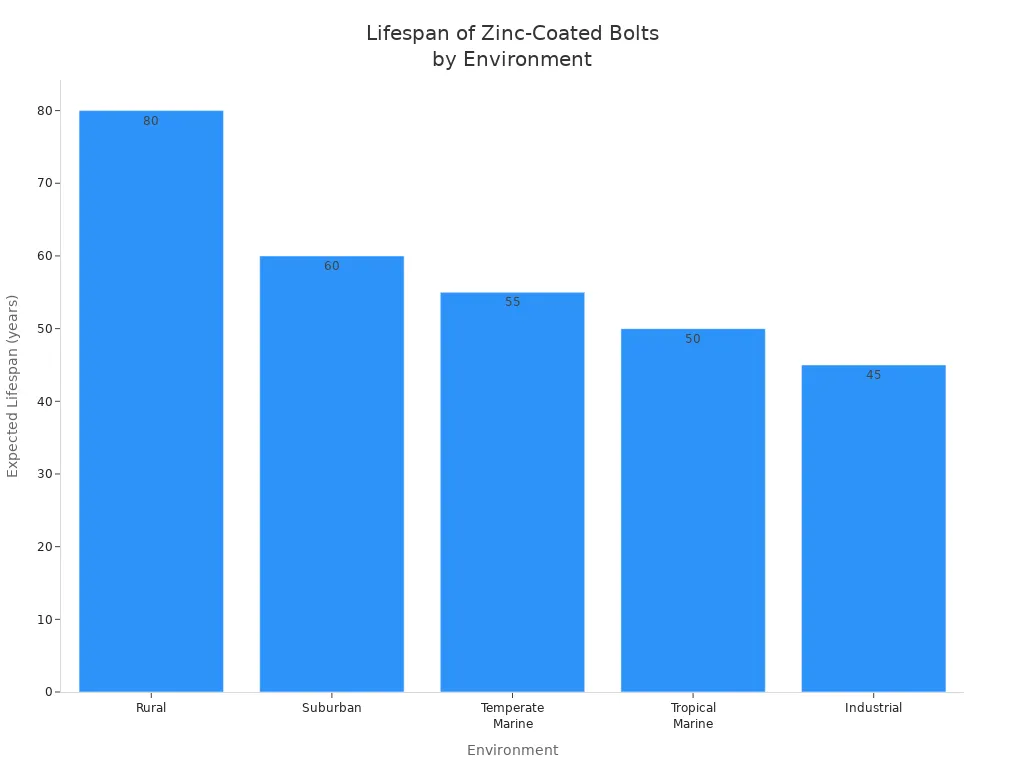

You can see how long the zinc coating lasts in different places:

| Environment | Expected Lifespan |

|---|---|

| Rural | 80+ years |

| Suburban | 60+ years |

| Temperate Marine | 55+ years |

| Tropical Marine | 50+ years |

| промышленный | 45+ years |

Note: Even in the most corrosive areas, hot-dip galvanized steel can last over 70 years before needing major maintenance.

Прочность

Galvanized bolts give you solid strength for most building jobs. The steel core holds loads well, but the zinc coating does not make the bolt stronger. You get a tensile strength between 38,000 and 62,000 PSI. This is lower than ss bolts, which reach up to 150,000 PSI, but it works for many outdoor and construction uses.

- Galvanized steel bolts: 38,000–62,000 PSI tensile strength

- Stainless steel bolts: 100,000–150,000 PSI tensile strength

You should pick galvanized bolts for projects that need good strength and rust protection but not the highest load ratings.

Обслуживание

You need to check galvanized steel bolts from time to time, especially near the ocean. In coastal areas, bolts may start to rust after 5–7 years if salty winds hit them directly. If you use them in sheltered spots, the zinc coating can last 15–25 years. You can make them last longer by painting over the zinc or rinsing them with clean water.

- Rinse bolts with water in salty areas.

- Use extra paint or powder coating for more protection.

- Check bolts often if they are close to the sea or exposed to wind.

Tip: Always look at where you install the bolts. Wind, salt, and rain can change how often you need to maintain them.

Расходы

Galvanized steel bolts cost less than ss bolts. You save money at the start, which helps if you have a big project. The process to coat steel with zinc is simple and cheap. However, the zinc layer can wear off over time, especially in harsh places. You might need to replace or maintain these bolts sooner than stainless steel bolts. While you pay less at first, you may spend more on upkeep or replacements later.

If you want a budget-friendly option for outdoor use, galvanized bolts give you a good mix of price and performance.

Латунные болты

Устойчивость к коррозии

Brass bolts give you strong protection against rust. You do not see rust on brass because it does not contain iron. In wet places, brass bolts keep their shape and color. You may notice a greenish patina forming over time. This patina acts as a shield and stops more corrosion. Brass bolts work well in plumbing, marine, and chemical settings. If you use brass in salty water, you should know about dezincification. This process can weaken the bolt, especially if chlorides are present. Naval brass resists corrosion better, but it can still face problems in harsh saltwater. You usually do not need extra coatings for brass bolts because they resist corrosion on their own.

Tip: Brass bolts are a smart choice for plumbing and marine jobs where ss bolts might be too expensive or not needed.

Прочность

Brass bolts offer good strength for many uses. You can rely on them for repeated loads and changing temperatures. Brass is softer than steel but harder than aluminum. The table below shows how brass compares to other materials:

| Материал | Brinell Hardness | Strength Comparison |

|---|---|---|

| Латунь | ~60 | Softer than steel, harder than aluminum |

| Mild Steel | 130 | Much stronger than brass |

| Углеродистая сталь | 163-600 | Very strong, much stronger than brass |

| Алюминий | Varies | Lighter, some alloys match mild steel |

You should not use brass bolts for heavy-duty jobs where ss bolts or carbon steel bolts are needed. Brass works best for light to medium loads.

Обслуживание

You need to check brass bolts often, especially in plumbing. Follow these steps to keep them working well:

- Inspect bolts for tarnish, corrosion, or damage.

- Clean with a soft cloth and mild soap.

- Remove tough tarnish using a paste of vinegar, salt, and flour.

- Apply a protective coating after cleaning.

- Store bolts in a dry, ventilated place.

- Use silicone-based lubricants to make installation easier.

- Avoid mixing brass bolts with other metals to stop galvanic corrosion.

- Regular checks help you spot leaks or wear early.

Расходы

Brass bolts cost more than carbon steel bolts but less than ss bolts. You pay for their corrosion resistance and good looks. Brass bolts look shiny and gold, so people use them for decoration and in high-end devices. You save money on maintenance because brass does not rust easily. If you want bolts for plumbing, electronics, or decorative jobs, brass gives you a good balance of price and performance.

Note: Brass bolts may not match the strength or corrosion resistance of ss bolts, but they offer unique benefits for special jobs.

Алюминиевые болты

Устойчивость к коррозии

Aluminum bolts help stop rust. You can use them outside and not worry much. Galvanic corrosion is not a big problem unless you put them in seawater or mix with other metals.

- There is little risk of rust in dry places.

- You can use coatings like Lanocote for extra safety. These coatings help aluminum bolts work with ss bolts in marine jobs.

- Aluminum bolts make a thin oxide layer. This layer keeps air and water from hurting the bolt.

Note: Aluminum bolts do not protect as well as ss bolts in salty water, but they work fine outside in most places.

Прочность

Aluminum bolts are light and still strong for their size. You can use them in cars, bikes, and planes where weight matters. They are not as strong as ss bolts or titanium bolts, but they work for many jobs. The table below shows how strong they are:

| Материал | Tensile Strength (MPa) |

|---|---|

| Алюминий | 570 |

| Нержавеющая сталь | 700 – 800 |

| Titanium (Grade 5) | 900 – 1100 |

Aluminum bolts are not as strong as ss bolts or titanium bolts. You should not use them for heavy loads or places with lots of stress.

Обслуживание

You do not need to do much to care for aluminum bolts. They do not rust and do not need paint or oil. You should check them for cracks or damage, especially if they shake or bend a lot.

- Clean bolts with soap and water.

- Look for signs of damage or wear.

- Do not mix with other metals to stop galvanic corrosion.

Tip: Use coatings if you put aluminum bolts near ss bolts or in salty air.

Расходы

Aluminum bolts cost less than titanium bolts but more than carbon steel bolts. You pay more because they are light and do not rust. You can save money on fuel or energy since aluminum bolts make things lighter. The table below shows the main good and bad points for cars and planes:

| Преимущества | Недостатки |

|---|---|

| Light and Strong | Not as Strong as Other Bolts |

| Great at Stopping Rust | Not Very Hard |

| Easy to Work With | Can Change with Heat |

| Good for Electricity and Heat | Can Break from Repeated Bending |

| Can Be Recycled |

If you want bolts that are light, easy to use, and do not rust, aluminum bolts are a good pick for many jobs. If you need the strongest bolts and best rust protection, ss bolts are still the top choice.

Титановые болты

Устойчивость к коррозии

Titanium bolts give you outstanding protection against rust. You can use them in places with saltwater, chemicals, or high humidity. Titanium forms a thin oxide layer that stops corrosion. This layer repairs itself if scratched. You do not need to worry about rust, even in harsh marine environments. Titanium bolts often last longer than ss bolts in extreme conditions. If you work on boats, chemical plants, or outdoor gear, titanium bolts help you avoid problems with rust.

Tip: Choose titanium bolts for jobs where ss bolts might not last long enough in very corrosive places.

Прочность

Titanium bolts offer high strength and low weight. You get bolts that are as strong as steel but much lighter. Titanium bolts handle heavy loads and resist stretching. You can use them in racing cars, airplanes, and bikes. The table below shows how titanium bolts compare to ss bolts and other materials:

| Материал | Tensile Strength (MPa) | Weight (g/cm³) |

|---|---|---|

| Титан | 900 – 1100 | 4.5 |

| SS Bolts | 700 – 800 | 7.9 |

| Алюминий | 570 | 2.7 |

You see that titanium bolts give you more strength per weight than ss bolts. This helps you build lighter and stronger projects.

Обслуживание

You do not need to do much to care for titanium bolts. They do not rust or corrode, so you do not need coatings or special cleaners. You should check them for wear or damage if you use them in places with vibration or stress. You can clean titanium bolts with soap and water. You do not need to worry about mixing titanium bolts with other metals, because they do not cause galvanic corrosion easily.

- Inspect bolts for cracks or wear.

- Clean with mild soap and water.

- Use in places where you need low maintenance.

Note: Titanium bolts need less care than ss bolts, especially in tough environments.

Расходы

Titanium bolts cost more than ss bolts, carbon steel bolts, or aluminum bolts. You pay a premium for their strength, light weight, and rust protection. The price can be three to five times higher than ss bolts. You should use titanium bolts for special jobs where you need the best performance. For most everyday projects, ss bolts give you a better balance of price and durability.

| Тип болта | Average Cost per Unit |

|---|---|

| Титан | $2.00 – $5.00 |

| SS Bolts | $0.80 – $1.50 |

| Углеродистая сталь | $0.30 – $0.70 |

If you want bolts that last in the harshest places and keep things light, titanium bolts are worth the investment.

SS Bolts vs. Other Materials

Corrosion Resistance Comparison

You want bolts that last in wet, salty, or chemical-filled places. Stainless steel bolts give you the best protection against rust. The chromium in stainless steel forms a shield that keeps water and air away. You can use stainless steel bolts near the ocean, in food factories, or in medical tools. Galvanized bolts also fight rust, but the zinc coating can wear off over time. Galvanized steel works well for outdoor fences and bridges, but it does not last as long in saltwater. Carbon steel bolts need coatings to stop rust, and these coatings can chip or fade. Brass bolts resist rust and form a green patina that protects them, but they can weaken in salty water. Aluminum bolts make a thin oxide layer that helps stop rust, but they do not work well in seawater. Titanium bolts give you top protection. You can use them in the harshest places, and they will not rust.

Here is a table to help you compare corrosion resistance:

| Материал | Устойчивость к коррозии | Лучшие примеры использования |

|---|---|---|

| Нержавеющая сталь | Превосходно | Marine, food, medical |

| Оцинкованная сталь | Good (zinc wears off) | Outdoor, construction |

| Углеродистая сталь | Moderate (needs coating) | Machinery, indoor |

| Латунь | Good (patina forms) | Plumbing, decorative |

| Алюминий | Good (not in seawater) | Aviation, electronics |

| Титан | Превосходно | Aerospace, marine, chemical |

Tip: If you need bolts for wet or salty places, stainless steel bolts or titanium bolts give you the longest life.

Strength Comparison

You need bolts that hold heavy loads and do not break. Stainless steel bolts give you high strength for most jobs. You can use them in buildings, bridges, and machines. Galvanized bolts have a steel core, so they are strong, but the zinc coating does not add strength. Galvanized steel bolts work well for fences and outdoor gear. Carbon steel bolts give you even higher strength, especially if you pick Grade 8 bolts. You see these bolts in big machines and heavy construction. Brass bolts are softer and work best for light loads. Aluminum bolts are light and strong for their weight, but you should not use them for heavy jobs. Titanium bolts give you the highest strength and lowest weight. You find them in airplanes, race cars, and bikes.

Here is a table to help you compare strength:

| Материал | Strength Level | Типичные случаи использования |

|---|---|---|

| Углеродистая сталь | Высокий | Construction, machinery |

| Нержавеющая сталь | Высокий | Marine, medical, food |

| Оцинкованная сталь | Moderate to High | Outdoor, fencing |

| Латунь | Low to Moderate | Electrical, decorative |

| Алюминий | Умеренный | Aviation, electronics |

| Титан | Very High | Aerospace, military |

Note: For most building jobs, stainless steel bolts and carbon steel bolts give you the strength you need. Titanium bolts are best for special jobs where weight matters.

Cost Comparison

You want bolts that fit your budget and last a long time. Stainless steel bolts cost more than galvanized bolts and carbon steel bolts. You pay more at first, but you save money because you do not need to replace them often. Galvanized bolts cost less and work well for big outdoor projects. Galvanized steel bolts are a good choice if you want to save money and still get rust protection. Carbon steel bolts are the cheapest, but you may spend more on coatings and upkeep. Brass bolts cost more than carbon steel bolts but less than stainless steel bolts. You pay for their look and rust resistance. Aluminum bolts cost more than carbon steel bolts but less than titanium bolts. You save money on weight and fuel in cars and planes. Titanium bolts cost the most. You use them only when you need the best strength and rust protection.

Here is a table to help you compare cost:

| Материал | Cost Level | When to Choose |

|---|---|---|

| Углеродистая сталь | Низкий | Basic jobs, indoor |

| Оцинкованная сталь | Low to Moderate | Outdoor, budget projects |

| Нержавеющая сталь | Moderate to High | Tough jobs, long-term use |

| Латунь | Умеренный | Decorative, plumbing |

| Алюминий | Умеренный | Aviation, light weight |

| Титан | Very High | Aerospace, racing, marine |

- Stainless steel bolts give you the best mix of strength and rust protection, but you pay more.

- Galvanized bolts help you save money and work well outside, but they do not last as long in tough places.

- Carbon steel bolts are cheap, but you need to check and coat them often.

If you want bolts that last and need little care, stainless steel bolts are worth the extra cost for most jobs.

Choosing the Right Bolt

Project Needs

You should start by thinking about what your project requires. Each job needs bolts with different properties. If you build a bridge, you need bolts with high strength. If you work on plumbing, you want bolts that resist water and chemicals. Always match the bolt material to the job. For example, stainless steel bolts work well for projects that need both strength and corrosion resistance. Specialty alloys like titanium or Inconel fit extreme jobs, such as aerospace or chemical plants.

Here is a table to help you compare bolt materials for different needs:

| Тип материала | Основные свойства | Cost Implications |

|---|---|---|

| Углеродистая сталь | Good strength, needs protection outdoors | Low cost, best for indoor use |

| Нержавеющая сталь | Many grades, strong, resists rust | Moderate to high cost |

| Specialty Alloys | Top performance in harsh conditions | High cost, special jobs |

| Coatings/Plating | Adds corrosion resistance to carbon steel | Extra cost for coatings |

Environment

You must consider where you will use the bolts. Outdoor jobs need bolts that fight rust and weather. Marine environments require bolts that resist saltwater. Temperature matters too. Some bolts get brittle in cold weather. You should also match the bolt to the materials you join. Using bolts that do not match can cause corrosion or weaken the joint.

- Corrosion resistance is vital for outdoor and marine jobs.

- Temperature resistance helps in places with extreme heat or cold.

- Compatibility with joined materials prevents damage and extends bolt life.

Tip: Always check the environment before choosing your bolt. The right choice keeps your project safe and strong.

Budget

You need to balance quality and cost. Some bolts cost more but last longer. Carbon steel bolts save money for simple indoor jobs. Stainless steel bolts cost more but reduce maintenance and replacement costs over time. Specialty alloys and coatings add to the price but may be needed for special jobs. Make a list of what matters most for your project, then choose the bolt that fits your budget and needs.

- Low-cost bolts work for basic jobs.

- Higher-cost bolts offer better protection and strength.

- Spending more now can save money later by reducing repairs.

Note: Picking the right bolt material helps you avoid problems and keeps your project on track.

You want bolts that last for years. Stainless steel bolts give you top durability in wet, salty, or chemical-filled places. Choose them for outdoor, marine, or food projects. If you work indoors or have a tight budget, carbon steel or galvanized bolts may fit your needs. Always match the bolt material to your project and environment. For special jobs, ask an expert for advice.

Remember: Picking the right bolt keeps your project safe and strong.

Часто задаваемые вопросы

What makes ss bolts better for outdoor use?

You get strong rust protection with ss bolts. The chromium layer stops water and air from causing damage. You can use ss bolts for outdoor projects like fences, decks, and bridges.

Can you use ss bolts with other metals?

You should avoid mixing ss bolts with metals like aluminum or carbon steel. This can cause galvanic corrosion. If you must mix, use protective coatings or washers.

Are ss bolts stronger than galvanized bolts?

You get higher strength with ss bolts. Galvanized bolts have a zinc coating for rust, but the steel core is not as strong as ss bolts. Choose ss bolts for heavy loads.

How often do you need to maintain ss bolts?

You do not need much maintenance for ss bolts. You can clean them once a year. Use anti-seize on threads to stop sticking. Check for damage during inspections.

Do ss bolts cost more than other bolts?

You pay more for ss bolts than for carbon steel or galvanized bolts. The extra cost gives you longer life and less rust. You save money over time with fewer replacements.