We’re diving into the fascinating world of “bolt screw” – a vital yet often overlooked aspect of mechanical fasteners. As experts in fastening solutions, Prince Fastener is committed to providing in-depth knowledge and practical insights to help you make informed decisions for your projects. Whether you’re an engineer, a DIY enthusiast, or simply curious about how things work, this blog post will unravel the intricacies of bolts and screws, their differences, and their applications. Stay tuned as we explore the unique characteristics, strengths, and uses of these essential components that hold our world together. Let’s begin this journey of discovery and understanding!

At Prince Fastener, we understand the critical role of reliable fasteners in your projects. While the terms “bolt” and “screw” often get used interchangeably, there are significant differences in their design, function, and application. Let’s delve into these distinctions to ensure you choose the perfect fastener for your needs.

Bolt vs. Screw: Key Differences Explained by Prince Fastener

| Recurso | Parafuso | Parafuso |

| Rosqueamento | Typically features partial threading along the shank. | Almost always features full threading from head to tip. |

| Instalação | Requires a nut for secure fastening; you tighten the nut. | You directly drive it into pre-tapped holes or it self-taps into materials. |

| Aplicativo | Excels in structural applications bearing significant loads. | Suits precision fastening and lighter load applications. |

Prince Fastener Defines Bolts and Screws

Parafusos: Prince Fastener defines a bolt as an externally threaded fastener designed for insertion through holes in assembled parts. Users typically tighten a nut to achieve clamping force. The head usually prevents rotation during installation.

Parafusos: Prince Fastener describes a screw as an externally threaded fastener that can be inserted into holes. It engages with pre-formed internal threads or forms its threads. You typically tighten a screw by applying torque to its head.

Threading and Design: Prince Fastener Highlights the Variations

Bolts from Prince Fastener: We often manufacture bolts with partial threads, leaving a smooth shank section.

Screws from Prince Fastener: Our screws almost always feature threads that run the entire length of the shank, right up to the head.

Usage and Installation: Prince Fastener’s Expert Insights

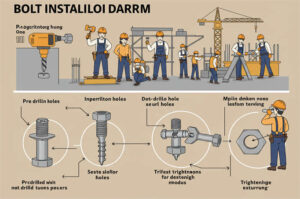

Installing Prince Fastener Bolts: You insert bolts through materials, ensuring enough thread protrudes for the nut. Wrenches or socket wrenches are the standard tools for tightening.

Installing Prince Fastener Screws: You directly drive screws into materials. Self-tapping screws eliminate the need for pre-drilled holes. Screwdrivers or drivers (like hex drivers) are the typical tools.

Application Scenarios: Where Prince Fastener’s Bolts and Screws Excel

Prince Fastener Bolts: These are ideal for structural applications needing high shear strength and stress resistance, such as construction or machinery assembly. Hex head bolts are a common choice when wrench access is available.

Prince Fastener Screws: These fasteners are better suited for precision fastening and lighter loads, such as in furniture or electronic devices. Self-tapping screws for wood simplify and speed up assembly by eliminating pre-drilling.

Prince Fastener’s In-Depth Analysis of Bolt Screws

Prince Fastener emphasizes that while bolts and screws might look similar, their design and application differ significantly. Our analysis, based on industry standards, provides a comprehensive understanding.

Definitions and Functions According to Prince Fastener

Prince Fastener on Bolts: Following ANSI-ASME B18.2.1 standards, we define a bolt as an externally threaded fastener designed to pass through holes in assembled components. Tightening a nut typically secures the assembly. The head’s design often prevents rotation during this process.

Prince Fastener on Screws: Also adhering to ANSI-ASME B18.2.1, Prince Fastener considers a screw an externally threaded fastener that you insert into a hole. It engages with pre-existing internal threads or creates its own. Turning the head typically provides the fastening action. Screws generally don’t require a nut and suit self-tapping or pre-tapped hole applications.

Background and Definitions from Prince Fastener

Prince Fastener notes that both bolts and screws are fixadores mecânicos that join two or more parts. However, their design and application vary considerably. Research indicates that bolts are externally threaded fasteners designed to pass through holes and secure with a nut.

Conversely, Prince Fastener defines screws as fasteners that you insert into a hole, engaging with pre-formed internal threads or creating their own. You typically secure them by applying torque to the head.

Key Differences: A Prince Fastener Comparative Table

| Recurso | Bolt by Prince Fastener | Screw by Prince Fastener |

| Thread Engagement | Primarily relies on a nut. | Directly engages with the material or pre-tapped threads. |

| Design de cabeça | Often designed to prevent rotation during tightening. | Designed for torque application via various drive types. |

| haste | Often partially threaded with a smooth shank. | Typically fully threaded. |

| Installation Tool | Primarily wrenches or sockets acting on the nut. | Primarily screwdrivers or drivers acting on the head. |

| Self-Tapping | Generally does not self-tap. | Many types are self-tapping or self-drilling. |

| Primary Load | Suited for shear and tension loads in structural joints. | Suited for clamping force and positional holding. |

Prince Fastener on Technical Standards and Considerations

Prince Fastener acknowledges the guidelines from the U.S. Customs and Border Protection for distinguishing between bolts and screws.

Prince Fastener’s Understanding of Bolt Classification: If a fastener has a head designed to prevent rotation and you secure it solely by turning a nut, we classify it as a bolt.

Prince Fastener’s Understanding of Screw Classification: If a fastener foi projetado for securing into pre-formed or self-tapped holes by applying torque to the head, we consider it a screw. Additionally, the CBP requires screws to meet at least five out of nine specific criteria (such as head angle and thread length) for classification.

Prince Fastener recognizes that the distinction between bolts and screws can sometimes blur in practical applications, mainly when bolts são usados as fully threaded fasteners. Esse can occasionally lead to debate.

Real-World Applications: Prince Fastener’s Perspective

Prince Fastener Bolts in Action: We recommend our bolts for scenarios demanding high strength and shear resistance, such as bridges, machinery structures, or automotive assembly. Hex head bolts are common when wrench operation is necessary.

Prince Fastener Screws in Action: Our screws are ideal for applications requiring precise fastening, like furniture assembly, electronic devices, or wood connections. Self-tapping screws, like those for particleboard, offer convenience by eliminating the need for pilot holes.

Safety and Cost Considerations from Prince Fastener

Prince Fastener on Security: We offer bolts with break-away designs (like Tricone® security bolts, requiring specialized removal tools) for security-critical applications.

Prince Fastener on Screw Security: Our screws can feature unique drive heads (like Torx or patented designs) to enhance security.

Prince Fastener on Cost: Bolts generally have a higher overall cost due to the necessity of a matching nut, while screws, which do not require additional components, can be more economical.

Prince Fastener Details, Usage, and Installation Methods

Prince Fastener on Bolt Installation: You typically need pre-drilled holes for bolts. The clamping force comes from the nut. Bolts generally do not self-tap. During installation, the bolt’s length must allow sufficient protrusion for the nut.

Prince Fastener on Screw Installation: Many of our screws are self-tapping, forming their threads in the material. Esse eliminates the need for pre-drilled holes or nuts. You directly drive screws into the material, and their length is usually less than the material’s thickness.

Application Scenarios and Strength: Prince Fastener’s Recommendations

Prince Fastener on Bolt Applications and Strength: Due to the smooth shank section, our bolts offer increased shear strength, making them suitable for structural applications bearing significant loads, such as bridges and machinery assembly. They are also more common in applications requiring frequent disassembly.

Prince Fastener on Screw Applications and Strength: Our screws’ full threading provides a tighter grip, making them ideal for precision fastening. They are commonly used in furniture, electronics, or lighter-load applications like wood or plastic.

Safety and Specialized Applications: Prince Fastener’s Solutions

Prince Fastener’s Security Bolts: We offer shear bolts where the head breaks off after installation, preventing unauthorized removal. These require specialized tools for installation.

Prince Fastener’s Security Screws: Our security screws feature unique drive patterns (like Tricone® security bolts) and require proprietary tools for removal.

Prince Fastener Addresses Controversies and Complexities

Prince Fastener acknowledges that the distinction between bolts and screws isn’t always clear-cut. Definitions can vary across time, regions, and manufacturers. Some fasteners might even exhibit characteristics of both (like a fully threaded bolt mimicking a screw). Therefore, we advise selecting based on the specific application and load requirements.

Research, as Prince Fastener understands it, indicates that the difference between bolts and screws lies not just in design but also in application scenarios and strength requirements. When choosing, consider the load, material, and installation tools. For instance, structural projects benefit from bolts, while lightweight material fastening suits screws. As Prince Fastener emphasizes, understanding these differences contributes to project safety and durability.

Key Characteristics of Bolts by Prince Fastener

As a leading provider, Prince Fastener highlights the essential characteristics that make our bolts reliable and effective in numerous applications.

General Characteristics of Prince Fastener Bolts

- Structure: Prince Fastener’s bolts typically consist of a head and a shank with external threads. The threaded portion engages with a nut or internal threads.

- Removable Connections: Prince Fastener designs our bolt connections for easy disassembly, facilitating maintenance and replacement.

- Standardization: Most Prince Fastener bolts adhere to national or international standards, ensuring interchangeability and widespread usability.

- Material Variety: Prince Fastener offers bolts in various materials, including carbon steel, alloy steel, stainless steel, and non-metallic options like plastics for specialized needs.

- Strength Grades: Prince Fastener offers bolts in different grades, which indicate their mechanical properties, particularly tensile and yield strength. High-strength bolts often feature alloy steel and undergo heat treatment.

- Nut Engagement: Prince Fastener’s bolts typically require a nut for fastening, achieving clamp load through tightening. In some cases, you can directly thread them into internally threaded components.

- Anti-Loosening Features: Prince Fastener offers bolts with features like specialized thread designs, anti-loosening washers, or self-locking nuts to prevent loosening due to vibration.

Different Types of Prince Fastener Bolts and Their Characteristics

Prince Fastener manufactures a wide array of bolts, each with unique features tailored to specific applications:

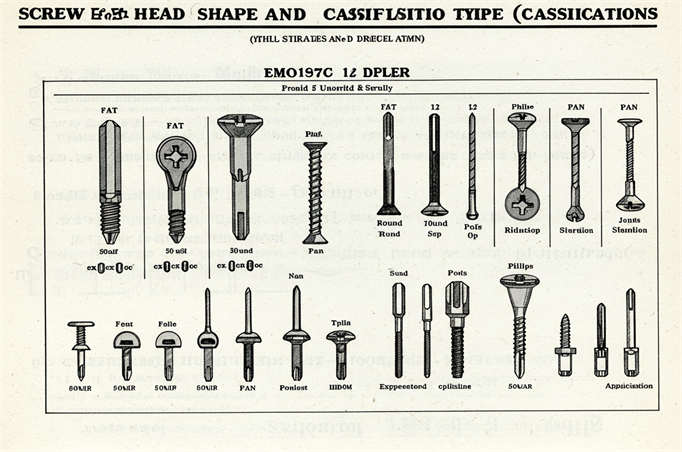

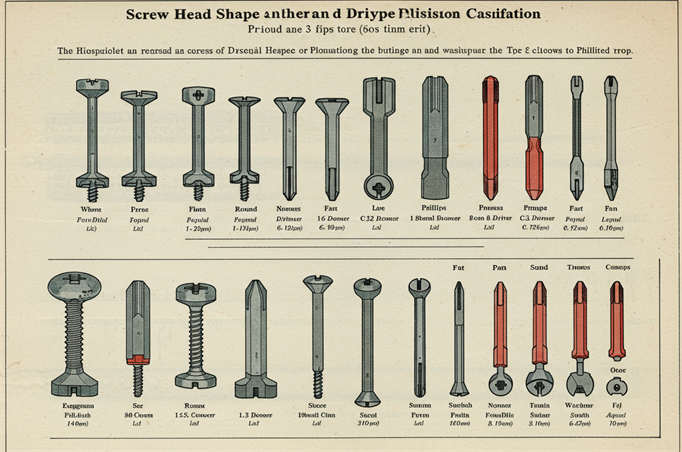

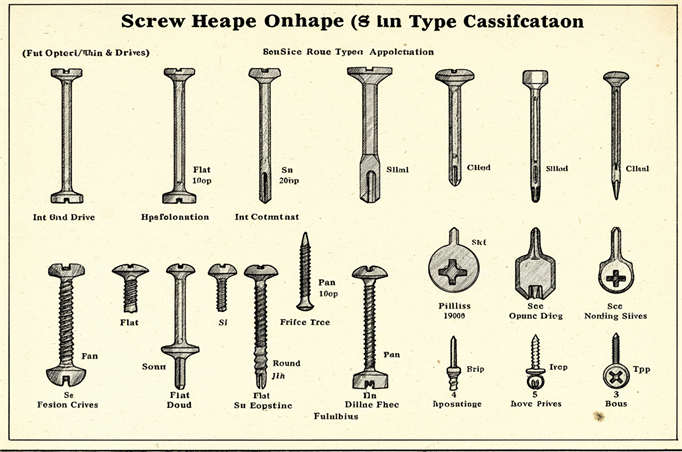

Prince Fastener Bolts by Head Shape:

- Hex Head Bolts: The most common type from Prince Fastener, offering a hexagonal head for easy wrench tightening and high torque application.

- Square Head Bolts: Prince Fastener provides these with a square head suitable for wrench use.

- Countersunk Bolts: Prince Fastener’s countersunk bolts feature a conical head that sits flush with the surface after installation, which is ideal for aesthetic or low-profile requirements.

- Round Head/Pan Head Bolts: Prince Fastener offers these with a rounded or flat-topped circular head, providing a larger bearing surface.

- T-Head Bolts: Prince Fastener manufactures these with a T-shaped head for T-slots of profiles.

- Eye Bolts: Prince Fastener’s eye bolts feature a looped head for lifting applications.

- Flange Bolts: Prince Fastener’s flange bolts have a built-in flange under the head, increasing the bearing area and preventing loosening.

- Carriage Bolts: Prince Fastener’s carriage bolts typically have a smooth, domed head with a square neck that embeds into the material to prevent rotation.

Prince Fastener Bolts by Thread Type:

- Coarse Thread Bolts: Prince Fastener’s coarse thread bolts have a larger pitch, offering higher strength for general connections, though with less self-locking capability.

- Fine Thread Bolts: Prince Fastener’s fine thread bolts have a smaller pitch, providing better self-locking and vibration resistance. They are suitable for precision adjustments or high vibration loads.

- Imperial Thread Bolts: Prince Fastener offers bolts with thread dimensions based on the imperial system.

Prince Fastener Bolts by Performance and Application:

- High-Strength Bolts: Prince Fastener’s high-strength bolts use specific materials and heat treatments for high load-bearing capacity in critical connections.

- High-Precision Bolts: Prince Fastener manufactures these with tight tolerances for applications requiring precise alignment.

- Self-Locking Bolts: Prince Fastener provides special designs or coatings to prevent loosening due to vibration.

- Expansion Bolts: Prince Fastener’s expansion bolts use a wedge to create a friction grip, which is ideal for anchoring in concrete and similar materials.

- Anchor Bolts / Foundation Bolts: Prince Fastener supplies these to secure large equipment or structures for foundations.

- Low-Head/Ultra-Low-Head Cap Screws: Prince Fastener offers these with reduced head heights for space-constrained applications or where a low profile is desired.

- Set Screws: Prince Fastener’s set screws often lack a prominent head and use their tip to secure parts in relation to each other. They are available with various tip styles.

- Self-tapping screws (sometimes categorized as bolts): Prince Fastener provides these, which can create their threads in pre-drilled holes.

- Serrated Bolts: Prince Fastener’s serrated bolts have teeth under the head or on other parts to increase friction and prevent rotation in unique connection requirements.

- Connecting Rod Bolts: Prince Fastener manufactures these with high strength, tightening force, and reliability for critical engine components.

Prince Fastener emphasizes that bolts’ key characteristics depend on achieving the correct tightening level. We offer various types, materials, and strength grades to meet your needs. Choosing the right bolt from Prince Fastener is crucial for ensuring connection stability, reliability, and durability. We encourage our customers to understand these features so they can make informed decisions in their designs and applications.

Key Characteristics of Screws by Prince Fastener

As a leading supplier, Prince Fastener provides screws with distinct characteristics that make them indispensable in various industries, from everyday furniture to precision machinery.

General Characteristics of Prince Fastener Screws

- Structure: Prince Fastener’s screws typically consist of a head and a threaded shank. The head facilitates tightening or turning, while the threads engage with the material or pre-tapped holes.

- Principle of Operation: Relying on the helix principle, Prince Fastener’s screws convert rotational motion into linear motion, simultaneously securing one or more objects. Through thread engagement, they create clamping force or positional holding.

- Independent Use: Unlike bolts, which often require nuts, Prince Fastener’s screws are generally used independently, directly threading into the material or self-tapping during installation.

- Removibilidade: Most threaded connections with Prince Fastener’s screws are reversible, allowing for repeated assembly and disassembly.

- Diverse Head Shapes and Drives: Prince Fastener offers screws with various head shapes (e.g., flat, round, pan, countersunk, hex) and drive types (e.g., slotted, Phillips, hex socket, Torx) to suit different application needs.

- Material Variety: Prince Fastener manufactures screws from a range of materials, including metals (steel, stainless steel, copper, aluminum, titanium) and plastics (e.g., nylon), to meet diverse strength, corrosion resistance, and conductivity requirements.

- Tratamento de superfície: To enhance corrosion resistance, wear resistance, or aesthetics, Prince Fastener often applies surface treatments like galvanizing, chrome plating, phosphating, or black oxide to our screws.

Significant Classifications and Characteristics of Prince Fastener Screws

Prince Fastener offers a wide variety of screws, categorized by their application and structural features:

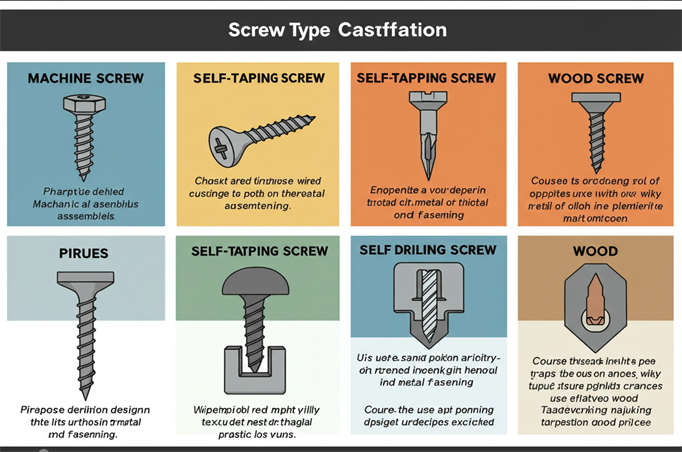

Prince Fastener Machine Screws:

- Características: Typically feature standardized threads (like metric or Unified), a cylindrical shank, and a blunt tip. Prince Fastener designs these for threading into pre-tapped holes and sometimes uses them with nuts (similar to bolts).

- Formulários: Widely used in electronics, machinery components, and automotive industries where precise and repeatedly disassembled connections are necessary.

Prince Fastener Self-Tapping Screws:

- Características: Prince Fastener designs these with unique thread forms that can cut or form mating threads when driven into softer materials (like wood, plastic, or thin sheet metal). They often have a pointed tip.

- Formulários: It is extensively used in woodworking, plastic assembly, and sheet metal connections, improving installation efficiency by eliminating pre-tapping.

Prince Fastener Self-Drilling Screws / TEK Screws:

- Características: Prince Fastener manufactures these with a drill-bit-like cutting edge at the tip, allowing them to drill their pilot hole, tap threads, and fasten in a single operation.

- Formulários: Primarily used for connecting steel structures, roofing, and metal sheeting, enhancing construction efficiency.

Prince Fastener Wood Screws:

- Características: Specifically designed for wood connections, Prince Fastener’s wood screws feature a large thread pitch, deep threads, often a tapered shank or partial unthreaded section, and various head styles (e.g., flat, round, oval countersunk).

- Formulários: Used for securing metal or non-metal components to wood or joining wooden parts.

Prince Fastener Set Screws / Grub Screws:

- Características: Prince Fastener’s set screws typically lack a prominent head (or feature an internal drive like a hex socket) and fully thread. You tighten them to exert force with their tip against another part’s surface, securing the relative position of two components or transmitting torque. They come with various tip styles (e.g., flat, cone, cup, dog) to meet different contact and holding requirements.

- Formulários: Used for securing gears, pulleys, or levers onto shafts or adjusting component clearances.

Prince Fastener Security Screws / Tamper-Proof Screws:

- Características: Prince Fastener offers these with specialized head drive types that require unique tools for tightening or removal, preventing unauthorized tampering. Common types include pin Torx, triangular, tri-wing, and snake-eye (twin hole).

- Formulários: It is used in public utilities, electronic equipment, and license plates where preventing theft or vandalism is crucial.

Prince Fastener Low Head / Thin Head Screws:

- Características: Prince Fastener’s low or thin head screws have a reduced head height compared to standard screws, suitable for space

As we conclude this comprehensive exploration of bolts and screws, we hope you’ve gained valuable insights into the distinctions and applications of these critical fastening components. At Prince Fastener, we understand the importance of selecting the right fastener for your specific needs, and we’re dedicated to providing you with high-quality products and expert guidance. Whether you’re tackling a complex engineering project or a simple DIY task, remember that the right bolt or screw can make all the difference in ensuring the reliability and longevity of your work. We invite you to explore our extensive range of fasteners and discover how prendedor de príncipe can be your trusted partner in achieving excellence in fastening solutions. Thank you for joining us on this informative journey, and we look forward to assisting you in your future endeavors!