You can read a machine screw dimensions chart with ease, even if you are new to hardware. This chart shows you the size, thread, and length of each screw. When you need to pick the right screw for your project, this simple guide will help. You can match machine screws to your needs by checking the correct numbers. Prince Fastener wants you to feel confident every time you use a screw.

Principais conclusões

- A machine screw dimensions chart helps you choose the right screw by showing size, thread, and length.

- Sempre check if you need metric or imperial screws to avoid mixing them up, which can lead to fitting issues.

- Measure screw length from the bottom of the head to the tip to ensure it matches your material thickness.

- Different head types and drive types affect how you use screws; choose the right one for your tools and project needs.

- Practice reading screw charts regularly to build confidence in selecting the right screws for your projects.

What Is a Machine Screw Dimensions Chart?

Chart Purpose and Overview

A machine screw dimensions chart helps you pick the right screw. It shows details like size, diameter, and thread count. Sometimes, it lists both imperial and metric measurements. The chart lets you compare screw sizes fast. You do not need to guess or measure each screw by hand.

A screw size chart is a guide for matching screw specifications to your needs. You will see columns for size, diameter, and thread count. Some charts show how to convert between imperial and metric systems. Metric fasteners have more size choices in smaller steps. This is good for projects needing exact measurements. Imperial fasteners use inch-based sizes. These are common in the United States.

The history of the machine screw dimensions chart shows why standardization matters. In the early 1800s, Henry Maudslay made interchangeable machine screws possible. Joseph Whitworth and William Sellers later set standards in the UK and US. The Unified Thread Standard and ISO metric standards came next. These made it easier to find the right screw anywhere in the world. The screw-cutting lathe and machine tools helped make these charts important.

When to Use a Screw Size Chart

Use a screw size chart when you need to pick a screw for a new project or replace an old one. The chart helps you check size, thread, and length. This helps you avoid mistakes. Many charts list lots of screw sizes. You get many options. If you work with machine screws, the chart helps you match the right screw to the material and job.

Prince Fastener suggests keeping a screw size chart close by. This guide helps you understand screw specifications. It helps you make confident choices every time you need a screw.

Key Parts of the Screw Size Guide

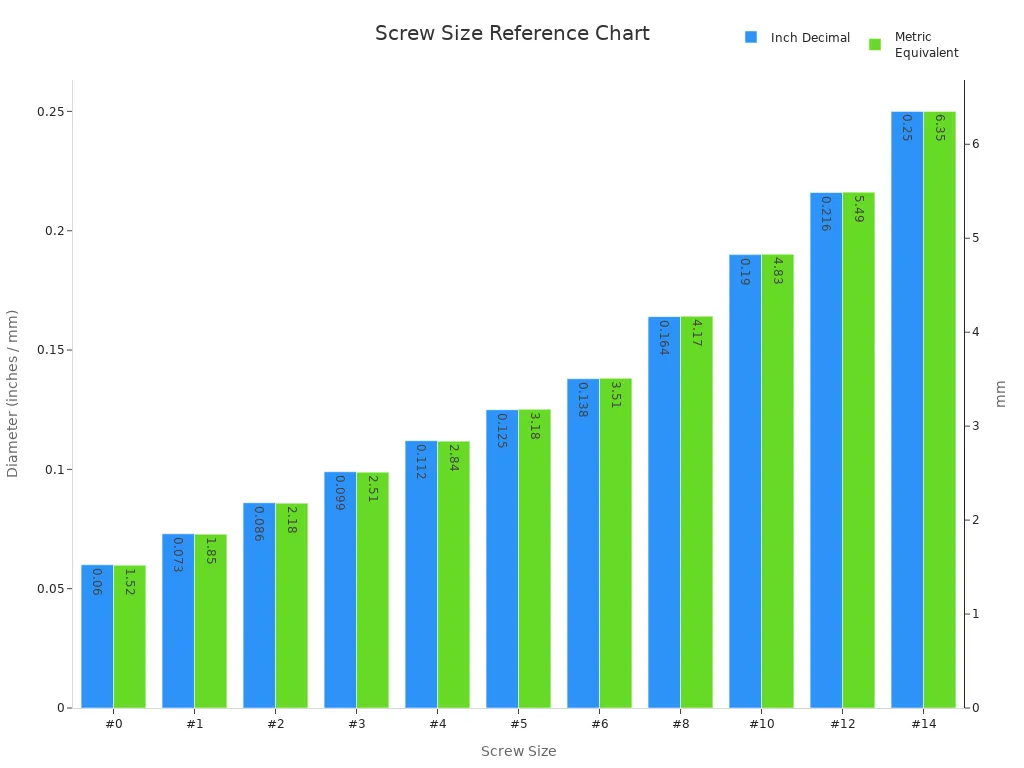

Gauge Numbers and Diameter

When you look at a machine screw dimensions chart, you will see gauge numbers and diameters listed. Gauge numbers show the thickness of the screw. The higher the gauge, the larger the diameter. For example, a #4 screw is thinner than a #10 screw. You can use the gauge as a quick reference for size. Most screw size guides list standard gauge numbers, such as #2, #4, #6, #8, #10, and #12. Each gauge matches a specific diameter, so you can pick the right screw for your project.

Thread Count and Pitch

Thread count and pitch tell you how many threads are on the screw. In imperial systems, you see threads per inch (TPI), like 10-32, which means 10 gauge and 32 threads per inch. Metric screws use pitch, which is the distance between threads in millimeters, such as M6 × 1.0. The table below shows the main differences:

| Recurso | Metric Thread | Imperial Thread |

|---|---|---|

| Unit | Milímetros (mm) | Inches (inch) |

| Representation | Thread diameter and pitch, e.g., M10 × 1.5 | Bolt diameter and threads per inch (TPI) |

| Padrões | ISO Metric Standards | UNC (Unified Coarse Thread) and UNF (Unified Fine Thread) |

| Recursos de design | Uniform pitches, usually 1, 1.25, 1.5, etc. | Coarse and fine thread designs with different thread counts |

Tip: Always check if you need metric or imperial screws. Mixing them can cause problems. Rounding errors and visual confusion are common. Metric and imperial screws may look similar, but their thread pitch and fit are different.

Length Measurement

Screw length is another key part of the screw size guide. You measure the length from the bottom of the head to the tip. The chart lists screw lengths in both inches and millimeters. Here is a quick look at typical screw lengths and their tolerances:

| Nominal Screw Length | Tolerance on Length |

|---|---|

| Up to 1/2 in., Incl. | -0.02 |

| Over 1/2 to 1 in., Incl. | -0.03 |

| Over 1 to 2 in., Incl. | -0.06 |

| Over 2 in. | -0.09 |

You should always match the screw length to your material thickness.

Head and Drive Types

The head and drive type affect how you use the screw. The chart lists many head types, such as pan, flat, round, and hex. Each head type works best for certain jobs. The drive type shows what tool you need, like a Phillips or slotted screwdriver. Here are some common head types:

| Tipo de cabeça | Descrição | Usos comuns |

|---|---|---|

| Frigideira | Slightly rounded top, flat underside | Uso geral |

| Plano | Countersunk, flat head | Flush finishes |

| Hex | Six-sided head | Industrial use |

| Botão | Low profile, rounded top | Furniture, appliances |

| treliça | Wide base, low profile | Decorative finishes |

You can find more head types in a full screw size guide.

Material e acabamento

O material and finish affect the screw’s strength and resistance to rust. The chart lists common materials like stainless steel, zinc-plated steel, and nylon. Each material has its own benefits. Stainless steel resists corrosion. Nylon is lightweight and resists chemicals. The table below shows some options:

| Material | Durabilidade | Resistência à corrosão | Leve |

|---|---|---|---|

| Aço inoxidável | Sim | Sim | No |

| Zinc-plated steel | Sim | Sim | No |

| Nylon | Sim | Sim | Sim |

Prince Fastener recommends checking the material and finish in the screw specifications before you choose a screw. This helps you get the best results for your project.

How to Read a Screw Size Chart

Understanding how to read screw sizes can help you choose the right fastener for any project. You can follow a simple process to use a machine screw dimensions chart and avoid mistakes. This guide will show you each step, explain the chart layout, and walk you through a real example.

Finding the Right Screw Size Reference

You can quickly find the correct screw size reference by looking at the chart’s main columns. Most charts organize screw sizes by gauge, decimal inch, nearest fraction, and metric equivalent. This makes it easy to compare different standards and pick the right screw for your needs.

| Tamanho do parafuso | Polegada Decimal | Fração mais próxima | Equivalente métrico |

|---|---|---|---|

| #0 | 0.060 in. | 1/16″ | 1.52 mm |

| #1 | 0.073 in. | 5/64″ | 1.85 mm |

| #2 | 0.086 in. | 3/32″ | 2.18 mm |

| #3 | 0.099 in. | 7/64″ | 2.51 mm |

| #4 | 0.112 in. | 7/64″ | 2.84 mm |

| #5 | 0.125 in. | 1/8″ | 3.18 mm |

| #6 | 0,138 pol. | 9/64″ | 3,51 mm |

| #8 | 0,164 pol. | 5/32″ | 4,17 mm |

| #10 | 0,190 pol. | 3/16″ | 4,83 mm |

| #12 | 0,216 pol. | 7/32″ | 5,49 mm |

| #14 | 0,250 pol. | 1/4″ | 6,35 mm |

You can use this table as a quick reference when you need to match a screw to a hole or a part. Prince Fastener recommends keeping a printed chart in your toolbox for fast access.

Interpreting Chart Columns and Rows

Each machine screw dimensions chart has columns and rows that show important screw specifications. You will see columns for size, type, and measurements. The rows list different screw sizes and types, both in US and metric standards. Some charts also include the nominal decimal outside diameter (OD), pitch choices, and standard sizes.

| Column/Row Type | Descrição |

|---|---|

| Sizes and Types | Includes various sizes and types of screws, both US and metric standards. |

| Organization | The chart is organized in an easy-to-read format for better accessibility. |

| Additional Information | Contains nominal decimal OD of screws, pitch choices, and standard sizes. |

When you read the chart, start by finding the gauge or metric size. Next, check the diameter and thread count. Look for the screw length that matches your project. Always check the head and drive type, as well as the material and finish, to make sure the screw fits your needs.

Tip: Always clean the screw before measuring. Dirt or burrs can cause errors. Hold calipers straight and take several readings for accuracy.

| Common Mistakes in Diameter Measurement |

|---|

| Measuring over dirt, debris, or burrs. |

| Applying excessive pressure with calipers, which can distort readings. |

| Holding calipers at an incorrect angle to the fastener’s axis. |

| Not taking multiple readings. |

Example: Reading a 10-32 Screw

Let’s walk through a real example using a 10-32 screw. This will show you how to match diameter, thread count, and length to your needs.

Understand the measurement systems

Check if the chart uses imperial or metric. A 10-32 screw uses the imperial system.Find the screw size

Look for #10 in the chart. The decimal diameter is 0.19 inches, and the nearest fraction is 3/16″. The metric equivalent is 4.83 mm.Check the thread count

The “32” in 10-32 means 32 threads per inch. This is a fine thread, which works well for machine screws in metal parts.

| Tamanho da rosca | OD |

|---|---|

| #10 – 32 | 0.19″ |

Measure the screw length

Use a ruler or calipers to measure from the bottom of the head to the tip. Make sure the screw length matches your material thickness.Review the screw specifications

Check the head type, drive type, and material. For example, a 10-32 pan head screw with a Phillips drive in stainless steel works well for many machines.

Note: Always match the screw to your project. Consider the material, the thickness, and the environment. Stainless steel resists rust, while zinc-plated screws cost less.

Step-by-Step Guide to Using the Chart

Follow these steps to read any machine screw dimensions chart:

- Learn the difference between imperial and metric systems.

- Use calipers to measure the screw’s diameter.

- Measure the screw length from the correct points.

- Determine the thread pitch or thread count.

- Compare your measurements to the chart for a match.

- Double-check the head, drive, material, and finish.

When you select a screw, think about the project’s needs. For example, if you work with metal, choose a screw with the right thread count and material. If you need a flush finish, pick a flat head. Always use the chart as your guide.

- Fabric type: Match the screw thread to the material for a secure fit.

- Compatibility: Make sure the screw size fits your tools and parts.

- Length: Choose a screw length that holds parts together without sticking out.

- Head and drive: Pick the right head and drive for your screwdriver or drill.

Prince Fastener encourages you to practice reading charts and measuring screws. With time, you will feel confident choosing the right screw for any job.

Using the Chart for Screw Selection

Matching Screws to Materials

A machine screw dimensions chart helps you pick screws for different materials. The right screw makes your project work better. The chart shows which screws fit wood, metal, or plastic. Always check what material you have before picking a screw.

| Project Requirement? | Recommended Fastener |

|---|---|

| Moisture or chemical exposure | Plastic screw |

| Electrical insulation | Plastic screw |

| Weight reduction | Plastic screw |

| High mechanical stress | Metal screw |

| Structural load-bearing | Metal screw |

| Elevated temperature | Metal screw |

Plastic screws stop rust and keep electricity from passing through. They are light and do not make sparks. Use them if your project needs to resist water or needs insulation. Metal screws are strong and can handle heavy loads. They work well when you need strength or heat resistance.

Benefits of Plastic Screws:

- Stops rust

- Keeps electricity from passing through

- Light weight

- Does not make sparks or attract magnets

Limitations of Plastic Screws:

- Not good for heavy jobs

- Can bend or melt in high heat

Benefits of Metal Screws:

- Very strong for heavy jobs

- Can handle high heat

- Many finishes and coatings

The screw you pick changes how well it holds sideways force. For example, a #10 screw made from medium-carbon steel is stronger than a #8 screw. Bigger screws are better for tough jobs. Prince Fastener gives you a quick guide to help match screws to your project.

Tips for Common Applications

The chart helps you find screw types for different jobs. This makes it easier to pick screws for furniture, electronics, or building things. The chart lists screw sizes and types for each job.

| Tipo de parafuso | Descrição | Aplicativos comuns |

|---|---|---|

| Ponta do pão | Rounded top and flat bottom, fits many uses. | Metalworking, electronics, woodworking. |

| Cabeça redonda | Dome-shaped top, looks nice when seen. | Electronics, furniture assembly. |

| Oval Head | Mixes flat and round for a smooth finish. | Used for a nice look. |

- Wood screws are best for furniture. They grip wood and hold parts tight.

- Machine screws are used in electronics. They fasten metal parts and fit well.

| Tipo de parafuso | Descrição | Usos comuns |

|---|---|---|

| Botão | Low profile, rounded head with flat top | Furniture, appliances, equipment assemblies. |

| Frigideira | Short sides, rounded top | Used for jobs needing a flat bottom. |

A quick guide helps you match screw types to your job. Prince Fastener says to check the chart for screw length and head type. This helps you avoid mistakes and makes picking screws easier.

Tip: Always check screw length and diameter before starting. The chart lets you compare sizes and types fast.

Avoiding Sizing Mistakes

You should avoid mistakes when picking screws. The chart helps you check sizes and stops errors. Here are mistakes to watch for:

- Picking the wrong size makes joints loose.

- Tightening too much can break or damage parts.

- Stripped screws make taking things apart hard.

- Bad spacing makes the structure weak.

- A screw that is too short will not hold parts together.

- A screw that is too long can look bad or be unsafe.

- The screw’s diameter changes how it holds weight; too thin does not grip, too thick can split the material.

Experts use the chart to match gauge, diameter, and length to the material. Head size tells you which tool fits the screw. Diameter changes strength and fit. Length shows how deep the screw goes. Thread pitch helps with grip and matching parts.

Note: You can use digital charts for fast picking. Digital charts use colors and cover many topics. Printed charts are slower and do not change. Prince Fastener gives you both digital and printed charts for easy use.

| Vantagem | Digital Charts | Printed Charts |

|---|---|---|

| Compromisso | Colorful and lively | Not colorful |

| Understanding | Quick visual cues | Slower to read |

| Versatilidade | Covers many topics | Limited scope |

| Accessibility | Easy to share and view | Harder to access |

| Learning Styles | Fits many styles | Fewer options |

You can use the chart as a quick guide. This helps you avoid mistakes and makes picking screws simple. Prince Fastener says to check the chart every time you start a new project.

You can learn to use a machine screw dimensions chart by taking easy steps. Prince Fastener says to keep a printed chart close for fast help. Using the chart often helps you pick screws with more confidence and get the right size.

- The chart gives you simple rules for choosing screw sizes.

- Picking the right screw makes your project stronger and look better.

- Printed charts and easy words help you learn faster.

The more you practice, the easier it gets. You get better and feel more sure with every project. Start now and do well with your hardware work!

Perguntas frequentes

What does “10-32” mean on a screw chart?

“10-32” shows the screw size and thread count. The “10” is the gauge or diameter. The “32” means 32 threads per inch. prendedor de príncipe recommends checking both numbers to match your project needs.

How do I know if I need a metric or imperial screw?

Look at your project’s instructions or measure the old screw. Metric screws use millimeters. Imperial screws use inches. Prince Fastener suggests using the same system as your parts for the best fit.

Can I use any screw material for outdoor projects?

No. You should pick stainless steel or coated screws for outdoor use. These resist rust and last longer. Prince Fastener offers many weather-resistant options for outdoor jobs.

Why does screw head type matter?

The head type affects how the screw sits and what tool you need. For example, flat heads sit flush, while pan heads stick out. Prince Fastener helps you choose the right head for your tools and project.

What if I pick the wrong screw length?

A screw that is too short may not hold parts together. A screw that is too long can poke through or cause damage. Prince Fastener recommends checking the chart and measuring before you start.