You might feel confused in the hardware aisle. Screws can be labeled in inches, millimeters, or numbers. Picking the right size is important for safety. It also helps you finish your project the right way. US screws use numbers or fractions. Metric screws use millimeters. Mixing these systems can cause problems. You might get cross-threading if you mix them. Look at the tabela abaixo to compare metric and imperial screws:

| Recurso | Metric (ISO/DIN) | Imperial (ANSI/SAE) |

|---|---|---|

| Unidades de medição | Millimeters (M10 = 10 mm) | Inches/Fractions (3/8″) |

| Passo de linha | Millimeters (1.25 mm) | Threads per inch (20 TPI) |

| Labeling | M plus diameter/pitch | Fractional diameter & TPI |

A screw diameter chart can help you match sizes. It also helps you avoid mistakes.

Principais conclusões

- Conheça o difference between US and metric screw sizes. US screws use numbers or fractions. Metric screws use millimeters.

- Always look at the screw size label before you buy. This helps you not make mistakes. It makes sure your project fits well.

- Use a screw diameter chart to change US sizes to metric. This saves time and stops errors.

- Pick the right screw type for the material you use. Different materials need special screws for a strong hold.

- Keep important measuring tools like digital calipers and screw gauges. These tools help you measure right and avoid mistakes.

Screw Sizing Systems Overview

US Gauge and Numbered Sizes

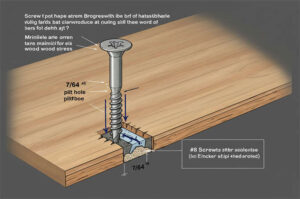

Screws in the US have numbers like #4 or #8. These numbers show how thick the screw is. The US gauge system started a long time ago. It comes from old English ways of measuring. These ways were shaped by Roman and Anglo-Saxon ideas. You mostly see this system in the US. Makers use gauge numbers or fractions of inches. For example, you might use a #8 screw for wood. You might use a ¼ inch screw for furniture. People outside the US do not use this system much.

Tip: When you buy screws in the US, check the gauge number or fraction on the box. This helps you pick the right screw for your job.

Metric Screw Sizes

Most places use the metric system for screws. Metric screws have an “M” and a number. The number shows the diameter in millimeters, like M8 or M10. The metric system is used almost everywhere. It is easy to find matching screws in many countries. Metric screws also show the thread pitch. Thread pitch is the space between threads in millimeters. Groups like ISO make rules for metric screw threads. These rules help makers build screws that fit together. Screws from different countries can work together.

- The metric system is used in most places.

- ISO rules make metric screws easy to match.

- You find metric screws in stores outside the US.

Fractional Inch Sizes

Fractional inch sizes use numbers like 3/8 inch or ½ inch. You see these sizes in the US and sometimes in old British hardware. Fractional sizing comes from the same history as the US gauge system. You measure the screw width in parts of an inch. This way is not used as much now. You still see it in some home stores. Fractional screws are good for jobs that need a tight fit, like plumbing or carpentry.

| Sistema de medição | Descrição | Exemplos |

|---|---|---|

| Imperial | Used in the US, marked by gauge numbers or inch fractions. | #4, #8, ¼ inch, 3/8 inch |

| Métrica | Used in most places, uses millimeters for size and pitch. | M8 x 1.25 x 40 |

Note: ISO rules help you find screws that fit, no matter where you shop.

Key Differences in Screw Sizing

Units and Notation

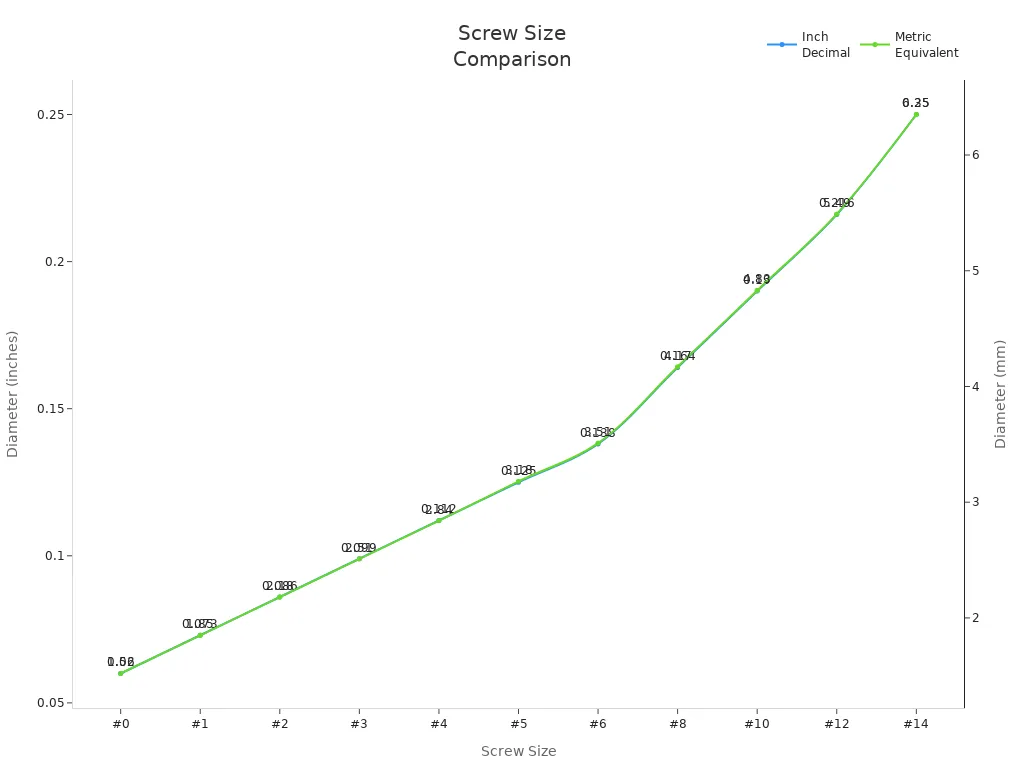

You will notice that screw sizes use different units and notations. US screws often use numbers or fractions, like #8 or 1/4″. Metric screws use millimeters, such as M6 or M8. Each system has its own way to show the size. For example, a #8 screw measures about 0.164 inches in diameter, which is close to 4.17 mm. Fractional sizes, like 1/4″, are common in the US and match up with metric sizes in some cases. The table below helps you compare these systems:

| Tamanho do parafuso | Polegada Decimal | Fração mais próxima | Equivalente métrico |

|---|---|---|---|

| #6 | 0,138 pol. | 9/64″ | 3,51 mm |

| #8 | 0,164 pol. | 5/32″ | 4,17 mm |

| #10 | 0,190 pol. | 3/16″ | 4,83 mm |

| 1/4″ | 0,250 pol. | 1/4″ | 6,35 mm |

You can also see how these sizes compare in the chart below:

Tip: Always check the label for the unit and notation before you buy screws. This helps you avoid confusion.

Threads per Inch vs. Pitch

You will find that US screws use “threads per inch” (TPI) to show how many threads fit in one inch. A higher TPI means the threads are closer together. Metric screws use “pitch,” which is the distance between threads in millimeters. If you mix up TPI and pitch, the screw may not fit or hold well. This can cause the screw to strip or break.

- Roscas por polegada (TPI): Counts the number of threads in one inch. Higher TPI means finer threads.

- Thread Pitch: Measures the space between threads in millimeters. Used for metric screws.

- Why it matters: Using the wrong thread type can lead to poor fit or damage.

Common Home Uses

You will see different screw sizes used for different home projects. For light woodwork, you might use a #6 x 1″ screw. For furniture, a #8 x 1-1/4″ screw works well. Drywall jobs often use #10 x 1-1/2″ screws. For heavy-duty tasks, like attaching metal brackets, you may need a #12 x 2″ screw.

| Tamanho do parafuso | Usos comuns | Notas |

|---|---|---|

| #6 x 1″ | Marcenaria leve, guarnições, dobradiças | Good for indoor projects |

| #8 x 1-1/4″ | Armários, montagem de móveis | Great for wood connections |

| #10 x 1-1/2″ | Drywall em vigas, estruturas pesadas | Strong hold for walls |

| #12 x 2″ | Suportes metálicos, ferragens estruturais | Extra grip strength |

Note: Choosing the right screw size for your project helps you get a strong, safe result.

Screw Diameter Chart & Conversion

Choosing the right screw size can feel tricky. You see numbers, fractions, and millimeters on boxes. You want your project to fit together perfectly. A screw diameter chart helps you compare US, metric, and fractional sizes. You can use it to match screws for wood, metal, or plastic. You avoid mistakes and save time.

US to Metric Equivalents

You often need to convert US screw sizes to metric. You see US screws labeled with numbers like #8 or #10. Metric screws use millimeters, such as M4 or M5. You can use a screw diameter chart to find the closest match. For example, a #8 screw measures about 0.164 inches, which is close to 4.2 mm. You can see more examples in the table below:

| US Screw Size | Polegada Decimal | Equivalente métrico (mm) | Common Use |

|---|---|---|---|

| #6 | 0.138 | 3.51 | Light woodwork |

| #8 | 0.164 | 4.17 | Furniture, cabinets |

| #10 | 0.190 | 4.83 | Drywall, frames |

| 1/4″ | 0.250 | 6.35 | Heavy-duty |

You can see how these sizes compare in the chart below:

Tip: Always check a screw diameter chart before you buy screws. You avoid mixing up sizes and get a better fit.

You should know that conversion charts account for tolerances in screw manufacturing. When you convert a dimension like 20 mm ±2 mm to inches, you get 0.79” ±0.08”. The upper limit becomes 0.87” and the lower limit 0.71”. This means the converted range can be wider than the original. You need to adjust the limits to match the real screw size. Rounding can also cause errors. If you round 1.0 mm to 0.04 inches, you may miss the exact size needed for tight fits.

Fractional to Metric and US

You see fractional inch sizes like 3/8″ or 1/2″ in many US stores. You may want to match these to metric or US gauge sizes. A screw diameter chart helps you do this quickly. You can use the table below to compare fractional, metric, and US sizes:

| Fractional Inch | Polegada Decimal | Equivalente métrico (mm) | Nearest US Gauge |

|---|---|---|---|

| 1/8″ | 0.125 | 3.18 | #5 |

| 3/16″ | 0.188 | 4.76 | #10 |

| 1/4″ | 0.250 | 6.35 | #14 |

| 3/8″ | 0.375 | 9.53 | — |

| 1/2″ | 0.500 | 12.70 | — |

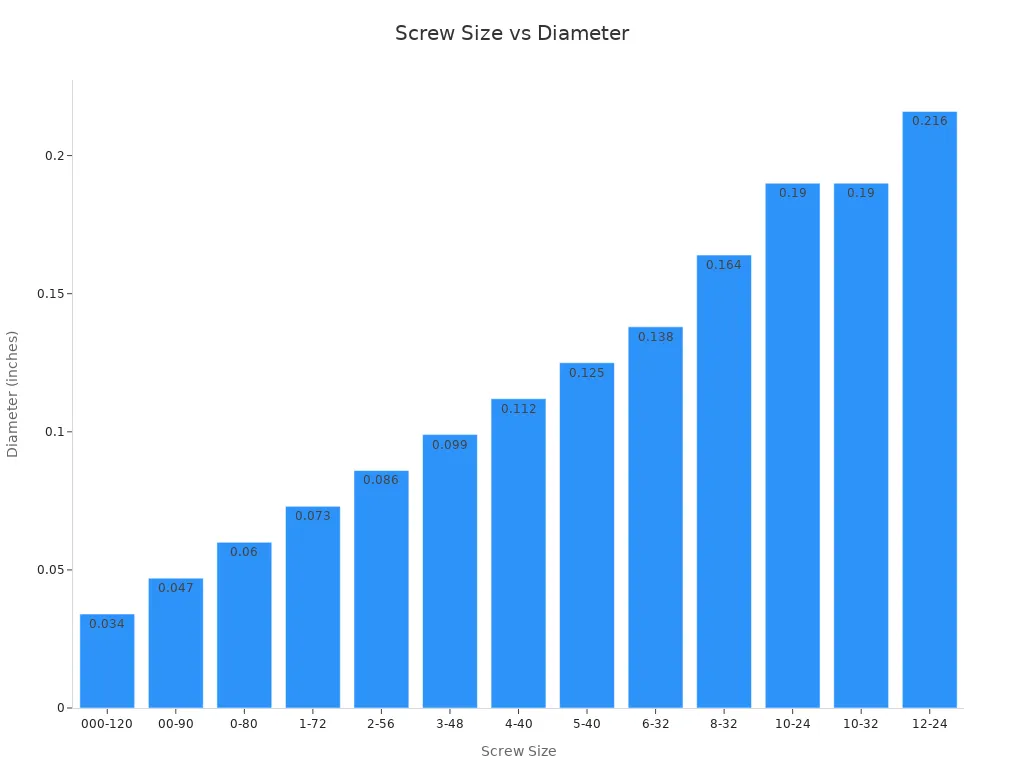

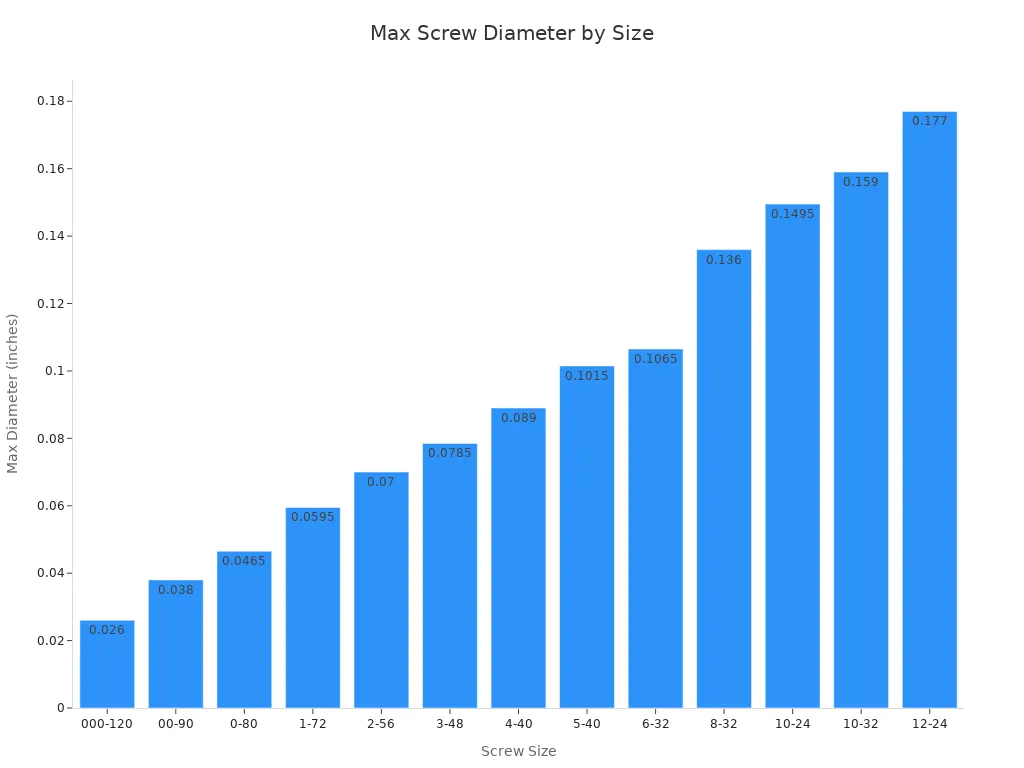

You can also find reliable conversion data in tables from trusted sources. These tables show tap drill sizes and maximum screw diameters for each screw size:

| Tamanho do parafuso | Tap Drill | Maximum Screw Diameter |

|---|---|---|

| 000-120 | #71 | .026 |

| 00-90 | #62 | .038 |

| 0-80 | #56 | .0465 |

| 1-72 | #53 | .0595 |

| 2-56 | #50 | .070 |

| 3-48 | #47 | .0785 |

| 4-40 | #43 | .089 |

| 5-40 | #38 | .1015 |

| 6-32 | #36 | .1065 |

| 8-32 | #29 | .136 |

| 10-24 | #25 | .1495 |

| 10-32 | #21 | .159 |

| 12-24 | #16 | .177 |

You can see the maximum screw diameters in the chart below:

Note: You should use a screw diameter chart for every project. You avoid errors and make sure your screws fit.

Why Conversion Charts Matter

You want your screws to fit and hold strong. You use a screw diameter chart to answer common questions about screw sizes. You plan your project with confidence. You avoid buying the wrong screws. You save money and time.

- You get handy conversion charts for quick reference.

- You match screws to existing hardware.

- You simplify your project planning.

Callout: You should always use a screw diameter chart when you work with different sizing systems. You avoid mismatched screws and get a safer, stronger result.

Identifying & Converting Sizes

Reading Labels and Packaging

You see many numbers and units on screw packaging. You need to check the label for the screw size, which often appears as a gauge number, metric measurement, or inch fractions. US screws use numbers like #8 or inch fractions such as 1/4″. Metric screws show an “M” followed by the diameter in millimeters. You find the length listed next to the diameter. Always look for the thread type, which may be listed as threads per inch or pitch in millimeters. If you read the label carefully, you avoid buying the wrong screw size for your project.

Tip: Compare the label on the box to your project needs. This helps you match the right screw size and avoid confusion.

Using Conversion Tools

Você pode usar digital calipers to measure screw size with accuracy. These tools display the diameter and length on a screen, making it easy to read. Manual conversion charts also help you translate between US, metric, and inch fractions. You find reliable tables that show common screw sizes in all three systems:

| Tamanho do parafuso | Diâmetro (mm) | Length (mm) |

|---|---|---|

| #4 | 3.2 | 10 |

| #6 | 3.5 | 12 |

| #8 | 4.2 | 16 |

You can also use a table to compare US sizes, metric sizes, and inch fractions:

| US Size | Metric Size | Tamanho fracionário |

|---|---|---|

| 1/4″ | 6,35 mm | 0.25″ |

| 5/16″ | 7.94 mm | 0.3125″ |

| 3/8″ | 9.53 mm | 0.375″ |

Note: Digital calipers give you quick and accurate results. You can use them to check screw size before you buy or install.

Matching to Existing Hardware

You need to match new screws to existing hardware for repairs or upgrades. Start by measuring the diameter, length, and thread pitch of the old screw. Use a thread gauge if you have one. If not, compare the screw directly to a reference chart or a known fastener. You must understand the difference between metric and imperial systems to prevent mix-ups. Always check if the old screw uses inch fractions or metric sizing. You avoid mismatched threads and ensure a strong fit.

- Measure the screw size using calipers or a ruler.

- Uso reference charts to match inch fractions to metric sizes.

- Compare screws to known fasteners if you do not have a thread gauge.

Callout: Matching the correct screw size keeps your project safe and secure. You prevent damage and save time.

Choosing the Right Screw

Fatores a serem considerados

You need to think about several factors before you pick a screw for your project. The material you work with matters most. Wood screws have wide threads that grip wood tightly. Drywall screws work best for attaching drywall to wooden studs. Masonry screws are made for concrete and brick. If you work with metal, steel screws or bolts give you strength and load-bearing ability. Stainless steel fasteners resist rust and corrosion, which helps in damp areas. For plastic, self-tapping screws prevent cracking or deformation.

You should also look at the length and diameter of the screw. These features decide how strong the connection will be. The thread type can run along the whole screw or just part of it. Choose a screw material that matches the environment. If you need reliable imperial fasteners, Prince Fastener offers a wide range of quality screws for home improvement.

- Wood: Use Parafusos de madeira for a strong grip.

- Metal: Pick steel screws or bolts for strength.

- Plastic: Select self-tapping screws to avoid damage.

- Masonry: Use masonry screws for concrete or brick.

- Drywall: Choose parafusos drywall for wall panels.

Typical Home Projects

You see imperial fasteners used in many home projects. Furniture assembly often needs #8 or #10 screws. Drywall installation uses #10 x 1-1/2″ screws. For cabinets, #8 x 1-1/4″ screws work well. Heavy-duty tasks, like mounting shelves, may require 1/4″ imperial screws. You find metric screws in newer furniture and imported products. Always check the project instructions for the recommended screw size.

| Project | Common Screw Size | Material |

|---|---|---|

| Furniture Assembly | #8, #10, M4, M5 | Wood, Metal |

| Drywall | #10 x 1-1/2″, M5 | Drywall, Studs |

| Cabinets | #8 x 1-1/4″, M4 | Madeira |

| Shelving | 1/4″, M6 | Wood, Metal |

Tips to Avoid Mistakes

You can avoid common mistakes by following a few simple steps. Inspect screws for rust or corrosion before use. Check for damaged threads to make sure the screw holds well. Never use bent or broken screws, as they weaken the structure. Use adjustable torque settings to prevent over-tightening. Always match the screw type to the job. If you cannot find the exact size, choose the closest imperial or metric screw that fits snugly without forcing it.

Tip: When you shop for screws, look for trusted brands like Prince Fastener to ensure quality and reliability.

Troubleshooting Screw Sizing

Mismatched Screws and Holes

You may run into problems when you use screws that do not match the holes. This can happen if you pick the wrong size or type. You might see loose joints or unstable shelves. Sometimes, over-tightening a screw causes the wood or metal to crack. Stripped screws make it hard to take things apart and weaken the connection. If you use a wood screw in metal, the grip will not hold, and the screw may break. Drywall screws used outside can rust and fail. Picking the wrong screw type can cause your whole project to fall apart.

- Loose joints and unstable structures

- Material damage from over-tightening

- Parafusos descascados that weaken connections

- Poor grip and breakage with the wrong screw type

- Rust and failure when using indoor screws outdoors

- Screws that are too short may not hold materials together

- Screws that are too long can stick out and create safety hazards

Tip: Always check the screw size and type before you start your project. This helps you avoid common mistakes.

When Exact Sizes Aren’t Available

You may not always find the exact screw size you need. You can choose the closest size that fits snugly without forcing it. If the screw is a little too loose, try using a washer to improve the grip. For holes that are too big, you can use a wall anchor or fill the hole with wood filler before inserting the screw. If you need a longer screw, make sure it does not stick out or create a hazard. You should avoid using a screw that is too short, as it may not hold the materials together.

| Problem | Quick Solution |

|---|---|

| Hole too large | Use anchor or filler |

| Screw too short | Select longer screw |

| Screw too long | Trim or choose shorter |

| Loose fit | Add washer or anchor |

Note: You can solve most sizing issues with simple adjustments and the right accessories.

Essential Measuring Tools

You need the right tools to measure screws and holes. A digital caliper gives you accurate readings for diameter and length. You can use a screw gauge to check thread pitch and size. A simple ruler helps with quick checks. Thread checkers let you match screws to existing hardware. You should keep these tools in your toolbox for every project.

- Digital caliper for precise measurements

- Screw gauge for thread size

- Ruler for quick checks

- Thread checker for matching screws

Callout: Measuring tools help you avoid mistakes and make your projects safer and stronger. 🛠️

You can spot differences between US, metric, and fractional screw diameters. Metric screws measure in millimeters. US screws use gauge numbers and fractions. Decimals are often printed on the packaging. These decimals help you match screw sizes. The table below shows how each system uses decimals and fractions:

| Tipo | Example Specification | Nominal Diameter | Passo de linha | Comprimento |

|---|---|---|---|---|

| Métrica | M10 – 1.0 x 20 | 10 mm | 1,0 mm | 20 mm |

| Fracionário | #10-32 | 0.190 in | 32 threads/in | N/A |

| US | 1/4-20 | 0.250 in | 20 threads/in | N/A |

Using decimals and fractions from a screw diameter chart helps keep your project safe. You make fewer mistakes and your home projects last longer. You can share questions or stories about decimals and fractions in the comments. Knowing how decimals and fractions work makes your job easier and helps you do better work.

Perguntas frequentes

What is the difference between US gauge and metric screw sizes?

US gauge screws have numbers like #8. Metric screws use millimeters, such as M6. US gauge sizes come from old ways of measuring. Metric sizes follow worldwide rules. This makes matching screws easier.

How do I convert screw sizes between US, metric, and fractional systems?

You use a screw diameter chart to convert sizes fast. First, measure the screw with a caliper. Then, look at the chart for the closest size. Checking the chart helps you pick the right screw for your project.

Why do screws have different thread types?

US screws show threads per inch. Metric screws use pitch in millimeters. Thread type changes how well the screw holds. Always match the thread type to your material for the best grip.

What tools help me identify screw sizes accurately?

Digital calipers measure screw diameter and length. A screw gauge checks the thread pitch. Reference charts help you match sizes. These tools help you avoid mistakes and make strong connections.