[table id=5 /]

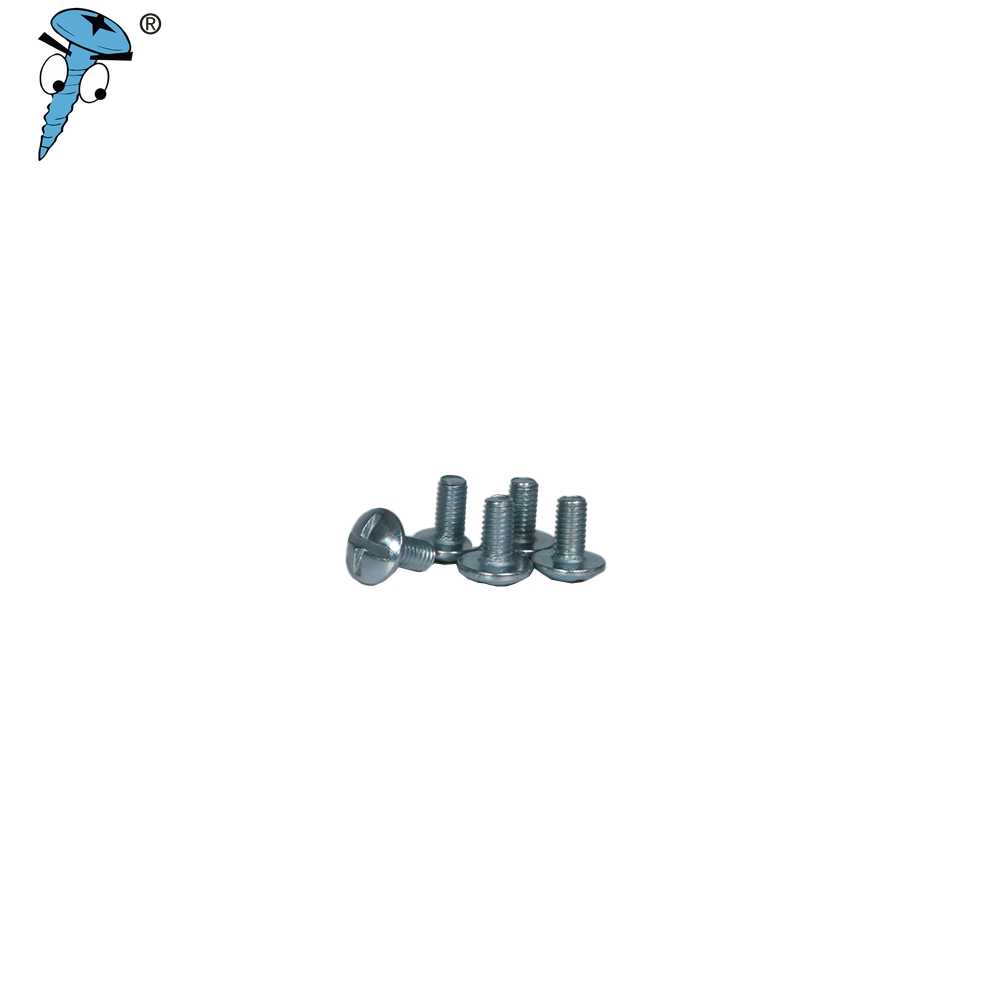

Product: Truss Head Machine Screw

Material: Steel,stainless, etc

Standards: GB,ANSI,ASME,DIN,JIS,UNI,NF, or according to Customer’s requirements, etc

Size: Diameter from M3mm-M20mm, length from 6.5mm-150mm.

Head: Hex, Round, pan, flat, truss, oval , etc.

Slot: Philips, slotted, pozi, square, torx , etc.

Finish: Zinc, Chrome, Electrophoresis, Dacromet, Ruspert, etc.

Salt mist of time: 24hrs-1000hrs

Color: White,yellow, black, silver,colorful,etc.

Usage: Furniture, appliance, automobile, electronic industry, hardware &electrical Machinery, building, infrastructure, aviation, etc.

What Is a Truss Head Machine Screw?

Prince fastener Machine screws are uniformly threaded screws of ¼ inch nominal diameter or much less that are designed to be threaded into uniformly threaded nuts or threaded holes in the components they are meant to fasten. Machine screws are reachable in a extensive array of configurations, materials, driver head kinds and sizes. As their title implies, computer screws are used to fasten more than a few aspects collectively in machines, tools, appliances, digital units and automobiles of each and every description. They are reachable in surely each fabric consisting of steel, stainless steel, brass and even nylon.

Uniform Threads of Truss Head Machine Screw

Uniform threads preserve the specific equal diameter all through the whole size of the threaded part of the Prince fastener. This is as adverse to tapered threads with a pointed stop such as on woodenscrews, which are meant to reduce their personal thread into the softer timber or plastic fabric they are being threaded into.

Truss Head Machine Screw. Bolts

Although computing device screws are typically viewed to be smaller than bolts, Prince fastener laptop screws additionally have a tendency to be targeted as such if the major tightening of the fixed joint is carried out via turning the head of the screw. With a bolt, the

essential tightening technique would possibly be performed by using turning the nut retaining the bolt thru a hole.

Truss Head Machine Screw Applications

Machine screws are versatile in the range of kinds of joints they can fasten. They can be used for fastening two or greater factors with thru holes and a nut at the back of all the components. They can be surpassed via two or greater factors and then sooner or later threaded into the rearmost component, which is stable and uniformly threaded and acts as the nut in the joint. Two opposing computing device screws can additionally be used with threaded couplings to separate two plates or boards via the distance equal to the size of the coupling. Prince fastener Machine screws are additionally used for many kinds of electrical connections and terminal strips. They are additionally used to fasten many gasketed gadgets that are sandwiched collectively such as water-proof motor casings. They can additionally be threaded into Prince manufacturer fasteners, which are threaded metal inserts solid proper into plastic parts.

Head Types of Machine screw

Prince fastener Machine screws are on hand in a vast assortment of driver head types, along with fashionable slotted, Phillips head, hex socket head for use with Allen wrenches, Torx six-pointed star, square-drive socket head and protection heads, which are without problems pushed in however very challenging to remove.

Threading Methods of Truss Head Machine Screw

Prince fastener Machine screws may additionally have their threads shaped by means of die cutting, the place some fabric is genuinely reduce out of the grooves forming the thread, or by means of rolling or roll forming the place the thread is rolled into the screw by way of unique rolling dies below very excessive strain the place no cloth is removed.