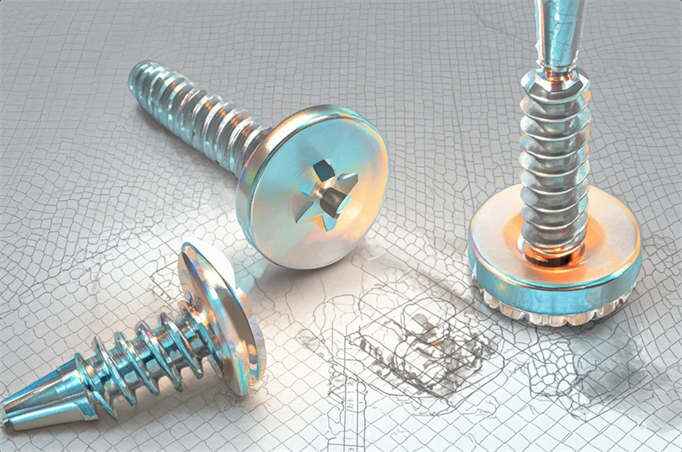

In modern industrial manufacturing and construction, the importance of screws as connectors goes without saying. Wafer Head Screws are outstanding due to their unique design and excellent performance. They cleverly combine the features of a thin round head and a washer face, providing a larger contact area and stronger connection reliability without damaging the surface of the connector.

These screws are generally made from high-strength steel or stainless steel and have good mechanical properties and corrosion resistance, maintaining stable connection effects in various harsh environments. Wafer Head Screws are widely used in mechanical engineering, electronics industry, and construction, and have become the first choice for many engineers and designers, providing a strong guarantee for the safety and reliability of equipment.

What are Wafer Head Screws?

Wafer Head Screws are a common type of standard fastener with the following characteristics:

Structural Features

- Head Shape: The head is thin and round with a small flat surface on top. This design provides a larger contact area without damaging the surface of the connector.

- Washer Face Design: The washer face (also known as the washer surface) helps the screw distribute pressure more effectively, reducing damage to joints and enhancing connection stability.

Materials and Characteristics

- Material: Generally made from high-strength steel or stainless steel to ensure good mechanical performance and corrosion resistance.

- Features: High preload force and stability, capable of maintaining good connection performance in various environments.

Main Applications

- Mechanical Engineering: Used for connecting and securing machinery and equipment, such as engines and transmission systems.

- Electronics Industry: Used in the assembly and fixing of electronic products, such as circuit boards and casings.

- Construction Industry: Used for connecting and securing building structures, such as steel structures, doors, and windows.

Advantages

- Stable Connection: The washer face design distributes pressure, reducing the likelihood of loosening.

- Protects Connectors: The thin round head and washer face design minimize damage to the surface of the connector.

- Versatility: Suitable for connecting various materials and structures, with wide applicability.

Due to their excellent performance, Wafer Head Screws have become the choice for many important standard fasteners in the industry.

What Mechanical Components are Suitable for Assembly with Wafer Head Screws?

Wafer Head Screws are mainly suitable for mechanical component assembly. Here are some common application scenarios:

Assembling Mechanical Components

- Equipment Housings and Covers: Used to fix equipment housings and covers, such as engine housings and motor covers, providing a stable connection.

- Mechanical Structure Connectors: Used to connect various components like brackets and frames in mechanical systems, ensuring the strength and reliability of the structure.

- Electronic Product Assembly: In electronic product assembly, used to fix circuit boards, casings, and other parts, maintaining close safety of the equipment.

- Automotive Component Fixing: Used to fix vehicle body components, seats, interiors, and other parts, ensuring the solidity and safety of the vehicle.

Features and Advantages

- Stable Connection: The washer face design distributes pressure, reducing the chance of loosening, suitable for performance-stable connections.

- Protects Connectors: The thin round head and washer face design minimize damage to the surface of the connector.

- Versatility: Suitable for connecting various materials and structures, with wide applicability.

Due to their excellent performance, Wafer Head Screws have become an important choice for assembling many mechanical components.

What are the Advantages of Wafer Head Screws?

Wafer Head Screws have the following advantages:

Overall Design Advantages

- Thin Round Head Design: The head is relatively thin and round, with a small flat surface on top. This design provides a larger contact area without damaging the surface of the connected parts, reducing damage to the connected parts.

- Washer Face Design: The washer face (also known as the washer surface) helps the screw distribute pressure more effectively, reducing damage to joints and enhancing connection stability.

Feature Advantages

- Stable Connection: Because the washer face design can distribute pressure, the screw is less likely to loosen after installation, suitable for performance-stable connection areas.

- Protects Connectors: The thin round head and washer face design reduce damage to the surface of the connector, extending the connector’s service life.

- Versatility: Suitable for connecting metals, plastics, and other materials and structures, with wide applicability.

Application Advantages

- Easy Installation: Generally installed using standard tools, such as hex wrenches, making the installation process simple and practical.

- Easy Maintenance: Because the connection is stable, maintenance doesn’t require frequent replacement or retightening, reducing maintenance costs.

Comprehensive Advantages

- Enhances Product Reliability: Wafer Head Screws used in machinery, electronics, and other equipment can improve overall stability and reduce failures.

- Improves Product Appearance: The thin round head design helps ensure the screw’s appearance is neat after installation, enhancing the product’s overall aesthetics.

These advantages have made Wafer Head Screws an important choice for standard fasteners in many industries, widely used in machinery, electronic equipment, automotive industries, and other fields.

What Materials are Suitable for Wafer Head Screws?

Wafer Head Screws are mainly suitable for various materials, and the specific choice depends on the application scenario and requirements:

Metal Materials

- Carbon Steel: Suitable for general tightening requirements, low cost, moderate strength.

- Stainless Steel: Good corrosion resistance, suitable for humid or corrosive environments.

- Alloy Steel: Used in situations requiring higher wear resistance and corrosion resistance.

Non-Metal Materials

- Wood: Can be used for wood connections and fixing, especially when higher preload is required.

- Plastic: Suitable for soft plastic materials, providing a stable connection.

Composite Materials

- Composite Materials: In some special applications, screws made of composite materials can leverage the advantages of different materials to provide better characteristics.

When selecting the appropriate material, attention should be paid to the screw’s strength, corrosion resistance, cost, and application scenario to ensure stability and durability in specific uses.

What is the Difference Between Wafer Head Screws and Ordinary Screws?

Wafer Head Screws have significant differences from ordinary screws in design, performance, and application:

Design and Structure

Wafer Head Screws:

- Washer Face Design: Features a large washer face, usually located at the bottom of the screw head. This design increases the contact area with connected parts, distributes pressure, and reduces damage to the connected parts.

- Head Shape: Commonly includes hex heads, round heads, etc. The head is generally wider to accommodate the larger washer surface.

Ordinary Screws:

- Simple Structure: Usually doesn’t have a washer face design, with a narrow head. Common types include flat head, round head, hex head, etc.

- Head Shape: Varied head shapes but generally smaller, suitable for general purposes.

Function and Performance

Wafer Head Screws:

- Anti-Loosening: Due to the larger washer face, they provide better anti-loosening properties.

- Protects Connectors: Reduces damage to the connector’s surface, suitable for areas requiring higher preload.

Ordinary Screws:

- Strong Versatility: Mainly used for connecting various materials and structures, widely used in daily maintenance and simple mechanical connections.

- Low Cost: Due to simple structure, production costs are relatively low.

Main Applications

Wafer Head Screws:

- Heavy Machinery: Suitable for performance-stable, anti-loosening connections in heavy machinery.

- Construction Structures: Used for connecting building structures, such as fixing steel structures.

Ordinary Screws:

- Daily Maintenance: Commonly used in furniture repair, small machine assembly, etc.

- Light Machinery: Suitable for connecting and fixing light machinery.

Wafer Head Screws are more suitable for areas requiring performance stability and anti-loosening, while ordinary screws are more common in daily life and simple mechanical connections, offering practical cost advantages.

How Much is the Cost Difference Between Wafer Head Screws and Ordinary Screws?

The cost difference between Wafer Head Screws and ordinary screws is mainly reflected in the following aspects:

Material Cost

- Wafer Head Screws: Because their design includes a larger washer face, they generally require more material to produce, so material costs are relatively higher.

- Ordinary Screws: Simple structure, less material consumption, low material cost.

Production Cost

- Wafer Head Screws: The washer face requires additional processing steps, increasing processing time and complexity, leading to higher production costs.

- Ordinary Screws: The production process is very simple, usually only requiring heading and thread rolling, resulting in low production costs.

Surface Treatment

- Wafer Head Screws: Due to their structural characteristics, they may require more complex surface treatment processes to ensure performance and durability, which also increases costs.

- Ordinary Screws: Simple surface treatment, low cost.

Overall Cost

- Wafer Head Screws: Due to higher material, processing, and surface treatment costs, the overall cost is generally higher than ordinary screws.

- Ordinary Screws: Due to simple design and low material and production requirements, the overall cost is relatively low.

Because of factors like screw specifications, materials, production batches, etc., the specific cost differences will vary, but generally speaking, the cost of washer face screws will be a certain percentage higher than that of ordinary screws.

What is the Difference in Durability Between Wafer Head Screws and Ordinary Screws?

Wafer Head Screws and ordinary screws have the following differences in durability:

Wafer Head Screws

- Stronger Anti-Loosening Performance: Because of the washer face design, they can better distribute pressure, reducing the chance of loosening under vibration or impact.

- Protects Connectors: The larger washer face reduces damage to the connector’s surface, extending the connector’s service life.

- Suitable for Heavy-Duty Applications: When stable performance and high strength are required, such as in heavy machinery and construction structures, Wafer Head Screws provide a more reliable connection.

Ordinary Screws

- Suitable for General Use: In most daily applications, such as furniture installation and light machinery, ordinary screws are sufficient to meet durability requirements.

- Cost-Effective: Due to simple structure and low manufacturing costs, they are suitable for areas where extreme durability is not required.

- Easy Installation and Maintenance: The assembly and disassembly process is relatively simple, with low maintenance costs.

Comprehensive Comparison

- Durability: Wafer Head Screws perform exceptionally well in areas requiring stable performance and anti-loosening, while ordinary screws offer high cost-effectiveness in general use.

- Applicable Scenarios: Wafer Head Screws are more suitable for heavy machinery and construction structures that require high durability. Ordinary screws are suitable for furniture, light machinery, and other general uses.

Based on actual application scenarios and requirements, choose the appropriate type of screw to ensure connection stability and durability.

Wafer Head Screws play a crucial role in industry and construction due to their unique design and outstanding performance. The integrated design of the thin round head and washer face not only enhances connection reliability but also effectively protects the surface of connectors, extending their service life. Although the cost is relatively high, their high reliability and long lifespan offer a higher cost-performance ratio in many important applications.

As science and technology advance rapidly, the application scope and performance of Wafer Head Screws will continue to develop and improve, providing safer, more reliable, and efficient connection solutions for people’s production activities, once again playing an indispensable role in various fields.