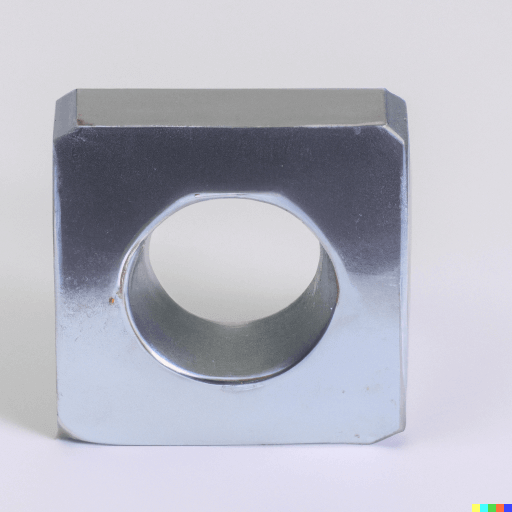

You see many different types of nuts when you shop for hardware, but square nuts stand out for their shape and function. Take a look at the most popular options below:

| Type of Square Nut |

|---|

| Standard Square Nuts |

| Flange Square Nuts |

| Heavy Square Nuts |

Square nuts have four sides, which gives them extra stability and helps resist loosening. Compared to hex nuts, they need special tools and can be harder to install in tight spots. Prince Fastener offers square nuts that fit many projects, so you can find what works best for your needs.

Key Takeaways

- Square nuts are very stable because they have four sides. They do not come loose easily. This makes them good for building and heavy jobs.

- Standard square nuts are useful for many things. People use them in furniture and electrical work. They hold tight and spread out pressure well.

- Heavy square nuts work well when you need to hold a lot of weight. They are used in bridges and steel buildings. They last long and can handle tough places.

- Thin square nuts fit in small spaces. They are easy to put in tight equipment. They help projects look neat when finished.

- Weld square nuts make putting things together easier. They let you make strong, lasting connections. People use them in cars and big machines.

Standard Square Nuts

Features of Standard Square Nuts

Standard square nuts have a simple and strong design. They have four flat sides. This gives them more surface area than some other nuts. The shape helps spread pressure out. This means softer materials do not get damaged. Tools can grip these nuts better. This makes it easier to tighten or loosen them. The square shape keeps the nut from slipping. It also stops the nut from turning too much. This is helpful in channel systems or with t-slot nuts.

Here are some things that make standard square nuts special:

| Design Feature | Description |

|---|---|

| Shape | Four-sided, larger contact area than hex or flange nuts |

| Surface Area | Distributes pressure, protects softer materials |

| Stability in Assembly | Reduces loosening from vibration or movement |

| Grip during Tightening | Flat sides help tools grip better |

| Anti-Rotation | Prevents slipping, works well in channel and t-slot nut systems |

You can find standard square nuts with different threading. This lets you match them with the right bolts. Square head machine bolts work best with these nuts. They are good for places where you need strong fasteners. If you work on overhead lines or heavy-duty jobs, this combo is very strong.

Applications in Construction

Standard square nuts are used in many construction jobs. They work well with square bolts to hold things together. You will see them in pole line hardware. These nuts are also used in heavy machines and furniture making. People use them in electrical and plumbing work too. Some people use them in crafts or old cars because they look classic and last a long time.

| Application Area | Description |

|---|---|

| Construction | Used in frameworks, ironwork, and building restoration |

| Manufacturing | Found in machinery and agricultural equipment |

| Furniture Making | Secures joints in cabinetry |

| Electrical and Plumbing | Used in older panels and junction boxes |

| Artisan Crafts | Adds style and function to art and vintage projects |

Tip: If you want strong fasteners for your project, Prince Fastener has many square nuts, t-slot nuts, and flange nuts for you.

You can trust standard square nuts for strength and stability. They are good for building, fixing, or making new things. They are a great choice when you need nuts that work with t-slot nuts and flange nuts in many jobs.

Heavy Square Nuts

Strength and Durability

Heavy square nuts are good for tough jobs. They are thicker and bigger than standard nuts. This makes them stronger and last longer. Their shape and size help them handle heavy loads. They can take rough conditions without breaking. You can trust them when you need a strong hold.

Check out the mechanical properties that make these nuts reliable:

| Property | Description |

|---|---|

| Tensile Strength | Needed for high-load places |

| Hardness | Helps them resist wear and last longer |

| Proof Load | Keeps them strong under pressure |

| Heat Treatment | Makes them better for tough jobs |

Heavy square nuts have these minimum values:

- Minimum yield strength: 105 ksi (724 MPa)

- Minimum tensile strength: 130 ksi (896 MPa)

- Minimum elongation: 20%

- Minimum reduction in area: 45%

These nuts resist torque stress better than finished hex nuts. Their thick body gives more safety and stability. You can use them where regular nuts might not work.

Tip: Prince Fastener sells heavy square nuts that meet strict rules for strength and durability. You can count on them for your hardest projects.

Structural Applications

Heavy square nuts are used in big construction jobs. They are found in steel structures, bridges, and buildings. These nuts help keep things safe and steady. If you build something that needs to last, you want nuts that can handle heavy loads.

Here are some common uses for heavy square nuts:

- Construction jobs where strong holds matter

- Steel frameworks and big projects

- Bridges and tall buildings

- Projects with lots of stress and heavy weight

Heavy square nuts help keep structures safe. You know your nuts will not loosen or break under pressure. If you work on bridges or tall buildings, you need nuts that are strong and reliable.

Heavy square nuts are a smart pick for safety and strength. You can get them at Prince Fastener, along with other nuts for any job.

Thin Square Nuts

Thin Profile Benefits

You might wonder why thin square nuts are so popular in modern projects. Their slim design gives you several advantages. If you need a compact solution, these nuts fit right in. You can use them when space matters most. Here are some reasons you might choose thin square nuts:

- Space Efficiency: The low-profile shape lets you build smaller, lighter products. You can fit these nuts into tight spots without trouble.

- Aesthetic Appeal: Thin square nuts sit flush with surfaces. Your finished project looks neat and professional. This matters in electronics and furniture where appearance counts.

- Load Distribution: These nuts spread stress across the surface. You get a strong, reliable connection. Your materials stay safe from damage.

If you want your project to look good and work well, thin square nuts are a smart choice. Prince Fastener offers these nuts for jobs where every millimeter matters.

Uses in Tight Spaces

Thin square nuts shine when you work in limited spaces. You can install them where standard nuts won’t fit. Their shape helps you line them up quickly. You don’t need much room to turn your tool. That makes your job easier.

The geometry of square nuts allows for easier alignment and engagement with tools in tight spaces, making them more effective than hexagonal nuts, which require more rotational clearance.

You can use thin square nuts in:

- Compact equipment and electronics

- Small furniture joints

- Sheet metal assemblies

- Miniature models and crafts

These nuts work well in places where you need a secure hold but don’t have much room. You can trust them for tight corners and narrow channels. If you need nuts for a small project, Prince Fastener has options that fit your needs.

Thin square nuts help you build smarter and faster. You get strength, style, and space-saving benefits all in one package.

Weld Square Nuts

Welding Advantages

Weld square nuts give you a strong and lasting way to fasten parts together. You can weld these nuts right onto metal surfaces. This makes your work faster and easier. You do not need to reach both sides of your project. You just place the nut where you want it and weld it in place. This saves you time and effort, especially when you work on big projects.

Here are some reasons why weld square nuts make your job better:

- You get permanent, secure threaded connections.

- You spend less time on assembly and save on labor costs.

- You do not need access to both sides of the assembly.

- You always get consistent, repeatable thread locations.

- You boost the structural integrity of your finished work.

When you use weld square nuts, you know your fasteners will not move or loosen. The weld holds the nut tight. This gives you peace of mind, especially when safety matters. Prince Fastener offers weld square nuts that help you finish your projects with confidence.

Tip: Weld square nuts work well with sheet metal and thin materials. You can use them in places where other nuts would be hard to install.

Automotive and Fabrication Uses

You will see weld square nuts in many industries. They are popular in car factories, appliance shops, and heavy machinery plants. These nuts help you build strong frames and panels. You can use them in spots where you need a flat surface or where tools cannot reach.

Here is a quick look at where weld square nuts shine:

| Scenario | Advantages |

|---|---|

| Automotive Manufacturing | Provides stable and strong fastening points due to precise alignment. |

| Appliance Assembly | Flat surfaces are ideal for robotic welding lines and automated production. |

| Heavy Machinery Frames | Helps evenly distribute the load on thin sheet metals. |

You can use weld square nuts in many applications. They help you make cars, build machines, and put together appliances. These nuts give you a clean look and a strong hold. You do not have to worry about loose parts or weak spots.

If you want to make your work easier and your projects stronger, try weld square nuts from Prince Fastener. You will see how much faster and safer your assembly can be.

Cage Square Nuts

Installation and Structure

If you work with racks or panels, cage square nuts make your job easier. You can install these nuts without welding or tapping threads. The spring-loaded cage lets you snap the nut into place, so you don’t need special tools for every step. You just pick the right nut for your rack, check the thread size, and make sure it fits the hole. Specialized tools help you compress the cage for quick insertion.

Here’s how you install cage square nuts:

- Choose the correct nut for your rack. Check thread size, hole compatibility, and material.

- Use a tool to compress the spring cage for easy insertion.

- Align the nut with the rack rail hole and gently snap it into place.

- Don’t overtighten screws. This keeps the nut from getting damaged.

- Inspect nuts regularly to make sure they stay secure.

Tip: Proper installation keeps your rack strong and stable. You avoid equipment failures and keep your gear safe.

When you follow these steps, you get a secure connection. The nut stays in place and spreads the load across the panel. You protect your rack and your equipment. Prince Fastener offers cage square nuts that help you build reliable systems.

Sheet Metal Applications

Cage square nuts work well in sheet metal projects. You can use them in server racks, industrial cabinets, and even cars. These nuts let you mount parts to panels with square holes. You don’t need to weld or tap threads, so you save time and keep your panels looking clean.

Check out some common applications:

| Application Area | Description |

|---|---|

| Server Racks | Cage square nuts are used to mount components to panels with square holes, providing strong support. |

| Industrial Cabinets | They allow for easy installation and repositioning of components without damaging the panel. |

| Automotive Applications | Their design enables quick assembly and disassembly, enhancing maintainability in vehicles. |

You can install and remove these nuts whenever you need. This makes your project serviceable and easy to update. You get strong, stable threaded support for your panels. If you want to build something that lasts, cage square nuts are a smart choice.

- Easy installation without welding or tapping threads

- Serviceable and allows for disassembly and repositioning

- Provides strong and stable threaded support

Prince Fastener supplies cage square nuts for all kinds of sheet metal jobs. You can trust these nuts to keep your panels secure and your equipment safe.

Specialty Square Nuts

Corrosion-Resistant Types

You want your nuts to last a long time. This is important when you work in tough places. Corrosion-resistant square nuts help keep your projects safe and strong. These nuts are made from special materials that stop rust and damage. Stainless steel, Inconel, and Monel are common choices. Each material has its own benefits.

Check out how these materials work:

| Material | Properties | Uses |

|---|---|---|

| Stainless Steel | Great at stopping rust, strong, and lasts long | Used in boats, food factories, and medicine |

| Inconel | Handles high heat, stops rust and oxidation | Used in planes, gas turbines, and reactors |

| Monel | Very good at stopping rust, works well in water and chemicals | Used in boats, chemical plants, and hot jobs |

Monel is special because it can handle seawater and strong chemicals. It is hard and resists wear. Some types of Monel stay strong even in freezing cold. If you need nuts for ships or chemical plants, 12CrMo1V stainless steel nuts are tough and reliable. Prince Fastener sells corrosion-resistant nuts for hard jobs.

Tip: Pick corrosion-resistant nuts if you need them to last in harsh places. You will save time and money because you do not have to replace them often.

Custom and Non-Standard Options

Sometimes you need nuts that fit odd spaces or special threads. Custom square nuts help with these problems. You can use them in furniture, especially where you cannot see the fastener. Using these nuts with square bolts gives more stability because they have a bigger surface area.

Stanlok makes custom nuts for tricky jobs. You might need nuts made from low carbon steel, stainless steel, or alloys like Inconel and Monel. These materials help you meet tough rules for strength and performance. Special pattern nuts are good when space is tight or threads are unusual.

- Custom nuts fit furniture and hidden spots.

- Stanlok has nuts for special thread needs.

- You can pick from many materials like stainless steel, Inconel, and Monel.

Prince Fastener can help you find the right specialty nuts for your project. You get good support and advice. Specialty nuts make your work easier and safer, even for hard jobs.

Square Nuts vs T-Nuts

Key Differences

You might want to know how square nuts and t-nuts are different. Both types help you make strong connections, but they are not the same. The table below shows the main ways they are different:

| Feature | T-Nuts | Square Nuts |

|---|---|---|

| Design | Flat plate with prongs for gripping material | Threaded nut with internal threads for securing a bolt |

| Installation | Needs pre-drilled holes or slots | Needs a hole for the bolt to pass through |

| Load Capacity | Lower load-bearing capacity | Higher load-bearing capacity and torque resistance |

| Installation Complexity | More complex due to pre-drilling requirement | Simpler installation process |

| Applications | Works best in materials that cannot hold threads well | Used in many applications including woodworking |

| Access | Can be installed from one side | May need access from both sides |

| Appearance | Flush surface appearance | Can stick out from the surface |

T-nuts sit flat with the surface. You can put them in from just one side. This is helpful if you cannot reach the back. Square nuts are stronger and can handle more twisting force. They are easy to put in and hold things tightly.

Choosing the Right Fastener

When you pick between square nuts and t-nuts, think about what your project needs. T-nuts are good for woodworking, making furniture, climbing gear, car parts, and DIY jobs. They give you a strong connection that lets electricity flow. They come in different thread sizes and fit many t-slots.

Square nuts can be used in more places. You can use them in building things, machines, and other jobs that need a lot of strength. They do not loosen easily and can hold heavy things.

Here are some things to think about:

- Thread size

- Material

- Board thickness

- If you need a strong or anti-rotation nut

If you want a flat look and need to install from one side, pick t-nuts. If you need more strength and want your nut to stay tight, pick square nuts. Prince Fastener sells both, so you can find what you need.

Tip: Always match your nuts to the material and how much weight they will hold. This keeps your project safe and strong.

You can count on Prince Fastener to help you pick the best nuts. If you need t-nuts for furniture or square nuts for tough jobs, you get good quality and help.

Selecting Square Nuts

Material and Size Factors

When you pick square nuts for your project, you need to think about material and size. These choices affect how well your nuts work and how long they last. You want nuts that fit your job and stand up to the environment.

Take a look at this table to see what matters most:

| Material Type | Description |

|---|---|

| Stainless Steel | Offers corrosion resistance, great for outdoor use. |

| Plain Steel | Best for indoor jobs, less resistant to rust. |

| Size Range | Sizes from M2 to M16, chosen for your needs. |

| Standards Compliance | Makes sure nuts fit and perform well (like DIN 557, DIN 562). |

| Surface Treatment | Zinc plating and other coatings help fight corrosion. |

You want to match the nut material to your environment. Stainless steel works well outside or in wet places. Plain steel fits indoor jobs. Size matters, too. Pick nuts that fit your bolts and match the load. Standards help you get nuts that work with other fasteners.

Here’s another table showing how your choices impact performance:

| Factor | Impact |

|---|---|

| Load Distribution | Spreads force, keeps stress low in tough spots. |

| Corrosion Resistance | Material choice keeps nuts safe from moisture and rust. |

| Structural Integrity | Right size and material make your assembly strong. |

Tip: Prince Fastener offers square nuts in many materials and sizes. You can find nuts that fit your project and meet industry standards.

Matching to Application

You need to match your nuts to your job. Look at the criteria below to help you choose:

- Thread type and size: Make sure your nuts fit the bolt threads.

- Material compatibility: Pick nuts that are as strong as your bolts.

- Strength grade: Choose nuts that can handle the load.

- Surface finish: Get nuts with coatings for rust protection.

- Temperature resistance: Use special nuts for hot or cold jobs.

- Load and application: Pick nuts for general use or structural jobs.

- Installation and accessibility: Choose nuts you can tighten with your tools.

- Standards: Make sure your nuts meet ISO, ASTM, or SAE rules.

Here’s a quick table to guide you:

| Criteria | Description |

|---|---|

| Thread Type & Size | Match pitch, diameter, and tolerance to your bolts. |

| Material Compatibility | Nut material should be equal or stronger than the bolt. |

| Strength Grade | Pick nuts that meet or beat the bolt grade. |

| Coating & Surface Finish | Choose based on environment for rust resistance. |

| Temperature Resistance | Use high-temp alloys for hot jobs, low-temp steels for cold. |

| Load & Application | Select nuts for general, structural, or anti-loosening needs. |

| Installation & Accessibility | Pick nuts based on tool access and torque needs. |

| Standards & Specifications | Make sure nuts follow ISO, ASTM, or SAE standards. |

If you want help picking the right nuts, Prince Fastener can guide you. They offer square nuts for every job, from furniture to big machines. You get quality and advice, so your fasteners work well and last long.

Note: Always check your project’s needs before buying nuts. The right choice keeps your assembly safe and strong.

You now know about the main types of square nuts and where to use them. Here is a simple table to help you remember:

| Type | Common Uses |

|---|---|

| Square Nuts | Woodwork, machinery, panels |

| Cage Nuts | Cabinets, racks, sheet metal |

| Weld Nuts | Automotive, fabrication |

When picking a nut, keep these tips in mind:

- Pick the right material so your nut is strong and does not rust.

- Check the size before you put it together.

- Think about where you will use it and how much space you have.

If you do not know which nut to choose, Prince Fastener can help you find the best one for your project. Always follow the rules for nuts and ask experts if you need help.

FAQ

What makes square nuts different from hex nuts?

Square nuts have four sides. You get more surface area for gripping. They resist loosening better than hex nuts. You might find them easier to tighten with simple tools.

Can I use square nuts for wood projects?

Yes, you can use square nuts in woodworking. They work well with bolts and give you a strong hold. You often see them in furniture and crafts.

How do I choose the right material for my square nut?

Look at your project’s environment. Stainless steel resists rust. Plain steel works indoors. Prince Fastener offers many materials, so you can pick what fits your needs.

Are square nuts easy to install in tight spaces?

You might find square nuts tricky in tight spots. Their shape needs more room to turn. Thin square nuts help when space is limited.

Where can I buy quality square nuts?

You can buy square nuts from Prince Fastener. They offer many types and sizes. You get expert advice and reliable products for your project.