Modern Solutions in Concrete Fastening: Concrete Screws and How to Use Them

Fixing connections in hard and solid materials has been a struggle until innovative engineering solutions came to light with the modern challenges of fastening. Concrete is today’s ubiquitous material in the construction and building industry which relies heavily on durable mechanical devices to impart a solid foundation. Some of these components are developed specifically to match the environmental and other requirements of the construction industry, like the development of concrete screws.

Using concrete screws is one of the fastest methods to fasten or attach objects to concrete materials due to their serrated cutting thread. This special type of thread can cut through concrete and be further enhanced to provide a long-lasting connection by adding chemical adhesives like epoxy. They are an essential hardware device in the industry because of their better-holding power in heavy-duty assembly but also because they are removable components that leave little to no damage on materials.

What are Concrete Screws?

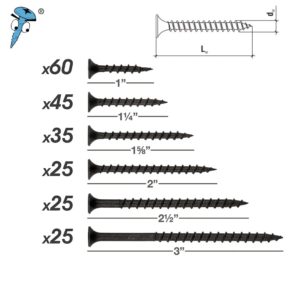

Concrete screws are designed specifically for concrete applications to secure objects in a reliable setting and sometimes a functional assembly. Their special modification suits the critical demands of concrete fastening which mainly involves heavy-duty connections. The screws have various types of heads, sizes, and materials. The bigger the project the more diameter size is required in concrete screws: and common head drives include hex and Philip’s head for easier and quick installation process.

Tips for Installing Concrete Screws

The general ways of installing any kind of fastener are almost similar to one another yet for some special applications, their crucial specifications can require more processes that need precision. Fortunately, for concrete fastening, though it is considered a critical industry, the installation process of concrete screws is somewhat easy and convenient for most workers. The process for installing concrete screws can be easily run down into four steps: drill, clean, insert, and drive.

- Use a special drill bit to drill a pilot hole onto the surface of the workpiece. Make sure to pre-drill a hole with the same width as the shank of your concrete screw.

- When the desired hole is achieved, clean the surface to remove all possible obstructions. This will make it easier for the concrete screw to penetrate cleanly into the concrete materials.

- Insert the concrete screw in the hole and ensure it is properly proportioned before tightening the connections.

When using concrete screws in a project, be aware of their drawbacks to avoid the risks of unsuccessful concrete fastening. Some examples can be:

- Crumbly concrete or mortar are inadequate materials to work on with concrete screws as they can be easily chipped on or broken down during the drilling of concrete screws.

- Make sure to have pre-drilling on the surface before inserting the screw as their tip are vulnerable parts of the body.

Overall, concrete screws are vital components in the construction and building industry thus they should be used fittingly in all considerations to avoid mishandling in concrete fastening. They are excellent devices that provide reliable structural integrity in concrete or wood materials. Moreover, when selected right and used properly during connections, concrete screws have remarkable durability. In the event of a failure in using concrete screws, proper analysis and opinion from professionals should be pursued right away, therefore it is best advised to only purchase high-quality concrete screws with complying standards of well-known organizations.

Want to know more about concrete screws and concrete fastening? Visit the leading manufacturer and supplier of the most reliable fastening components around the world – Prince Fastener Manufacturing Co., Ltd. With a diverse range of fasteners and extensive experience in delivering precision for products and services, the company ensures to meet the specifications of your industry projects.