Marine-Grade Fasteners: Materials of Marine Fasteners

In the realm of marine fastening, even innovative fastener devices are faced with the common challenges brought by saltwater elements that make the survival of materials difficult at times. The unhinged corrosive elements caused by saltwater have led to the significant development of marine-grade fasteners to sustain and resist its damage. Marine-grade fasteners are designed to withstand saltwater corrosion and exhibit reliability and durability to ensure the security of connected parts. Unlike standard fasteners, marine-grade fasteners are engineered to resist the continuous force of corrosion brought by saltwater and other existing troubles. With its fortunate existence, the marine industry has been triumphant in the field of fastening ever since they were fabricated and is now continually evolving for a better future.

In the realm of marine fastening, even innovative fastener devices are faced with the common challenges brought by saltwater elements that make the survival of materials difficult at times. The unhinged corrosive elements caused by saltwater have led to the significant development of marine-grade fasteners to sustain and resist its damage. Marine-grade fasteners are designed to withstand saltwater corrosion and exhibit reliability and durability to ensure the security of connected parts. Unlike standard fasteners, marine-grade fasteners are engineered to resist the continuous force of corrosion brought by saltwater and other existing troubles. With its fortunate existence, the marine industry has been triumphant in the field of fastening ever since they were fabricated and is now continually evolving for a better future.

The Significance of Marine Fasteners

The singular purpose of marine-grade fasteners outweighs their standard counterparts for several reasons such as their specialized diversity and features. With thriving properties in conditions of aggressive saltwater challenges, extreme weather fluctuations, and constant exposure to moisture and temperatures, these exceptional qualities of marine fasteners are the reasons for their incomparable design.

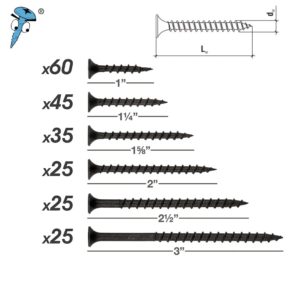

An exemplary sub-category of marine fasteners is the marine wood screws. They are specially tailored to connect or hold parts of wood materials in boat decks, wooden piers, and other wooden structures of the marine industry. They comprise unique engineered parts that resist corrosive elements and minimize other problems like wood splitting. This feature is made possible because of the marine wood screws tapered heads and threads, which specifically match the needs of marine-related wood applications.

The harsh combination of saltwater corrosion, dynamic forces, saline and minerals, and extreme pressure make up the demanding standards on marine fasteners to be able to survive in their crucial position. They must endure and maintain mechanical integrity while executing the expected functionality and efficient prevention of structural failure from load distribution. Moreover, the extreme need for mechanical strength on marine fasteners poses a foundational component that fastens for durability and long-lasting security, which is why they are indispensable devices in the critical environment of the industry.

Choosing Fastener Material for Marine Applications

Knowing the wide variation of materials in fasteners can improve the chances of establishing a successful marine fastening. Few materials on marine fasteners are known for their ability to provide enhanced corrosion resistance even with the presence of highly corrosive elements and environmental conditions. The following materials are preferable selection of marine fasteners:

Knowing the wide variation of materials in fasteners can improve the chances of establishing a successful marine fastening. Few materials on marine fasteners are known for their ability to provide enhanced corrosion resistance even with the presence of highly corrosive elements and environmental conditions. The following materials are preferable selection of marine fasteners:

Stainless Steel Alloys

A primary choice among the multitude of fastener materials that are usually utilized in marine applications is stainless steel alloy, their chromium content generates an effective protection that prevents oxidation. Made from alloy contents, iron, and other metal elements, stainless steel marine fasteners are resistant to rust and corrosion that is caused by chemicals and other prevailing troubles like saltwater. To properly employ the right selection of stainless steel, it is crucial to know their different types and features as it will be a fundamental aspect to consider in the kind of application.

Read More: Facts About Stainless Steel Fasteners That You Should Know

Titanium Alloys

The mixture of titanium and other chemical elements proposes an excellent tensile strength and corrosion resistance that can be an alternative to stainless steel fasteners. They showcase toughness yet easy machining capability that becomes a priced metal that can combat saltwater corrosion and provide remarkable reliability at the same time. Titanium alloys share numerous amounts of different metals like aluminum, vanadium, molybdenum, zirconium, and more with a variety of titanium grades that offer varying results.

Brass and Bronze

The two common materials brass and bronze offer good resistance to corrosion which is advantageous in marine applications. They possess a distinct quality in terms of aesthetics that makes an attractive choice due to their gold-like appearance. Brass and bronze fasteners owe their popularity to the shielding effect they provide, forming a protective oxide layer against corrosive elements like salt water. However, their natural corrosion resistance becomes a vulnerable feat from stainless steel fasteners which offer higher tensile strength. This critical factor makes them only applicable to certain areas of marine applications that do not usually require heavy load resistance.

High-Precision Marine Fasteners from Prince Fastener

Prince Fastener Manufacturing Co., Ltd. has a rich experience of over 30 years in manufacturing high-quality marine-grade fasteners for reliable fastening and connections. With an excellent reputation for delivering satisfaction to thousands of industries worldwide, the company is a proud expert that offers precision in competitive pricing of wholesale and bulk purchases. Our marine fasteners are proven to comply with International standards of ISO, DIN, ANSI, and more. Get to know more about the capabilities and services of Prince Fastener by contacting us with your industry requirements and demands.