The self-drilling screw is called “SELF DRILLING screw” or “self-drilling screw”; north Chinese call it “swallowtail screw.” Its implementation standard is GB/T 15856.1-2002, standard German DIN7504N-1995, Japanese standard JIS B 1124-2003.

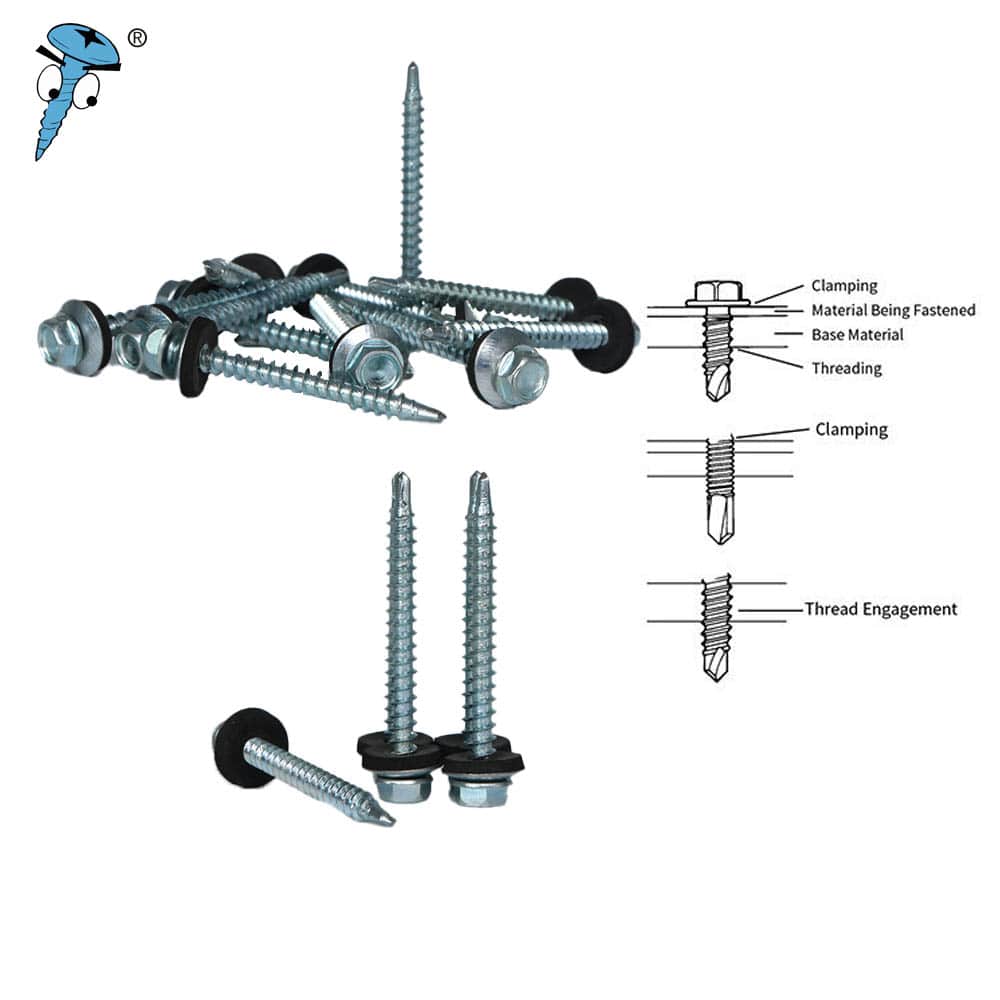

This kind of screw has a drill tail point, the tip is like a twist drill bit, so it is named. During assembly, the screw can drill out the center hole by itself, and then with the help of the adjacent thread part, it squeegee out the matching thread in the hole on the carrier, so it is called a self-drilling and self-tapping screw.

- Self-drilling and self-tapping screw with cross-groove disc head. The Cross Recessed pan head drilling trial with tapping Screw Thread is standard: GB/T 15856. 1-2002 has the following specifications :(, also known as round head drill tail).

- Cross groove countersunk head self-drilling and self-tapping screw. The executive standard is: GB/T 15856.2-2002 :(also known as horizontal head drilling, salad head drilling).

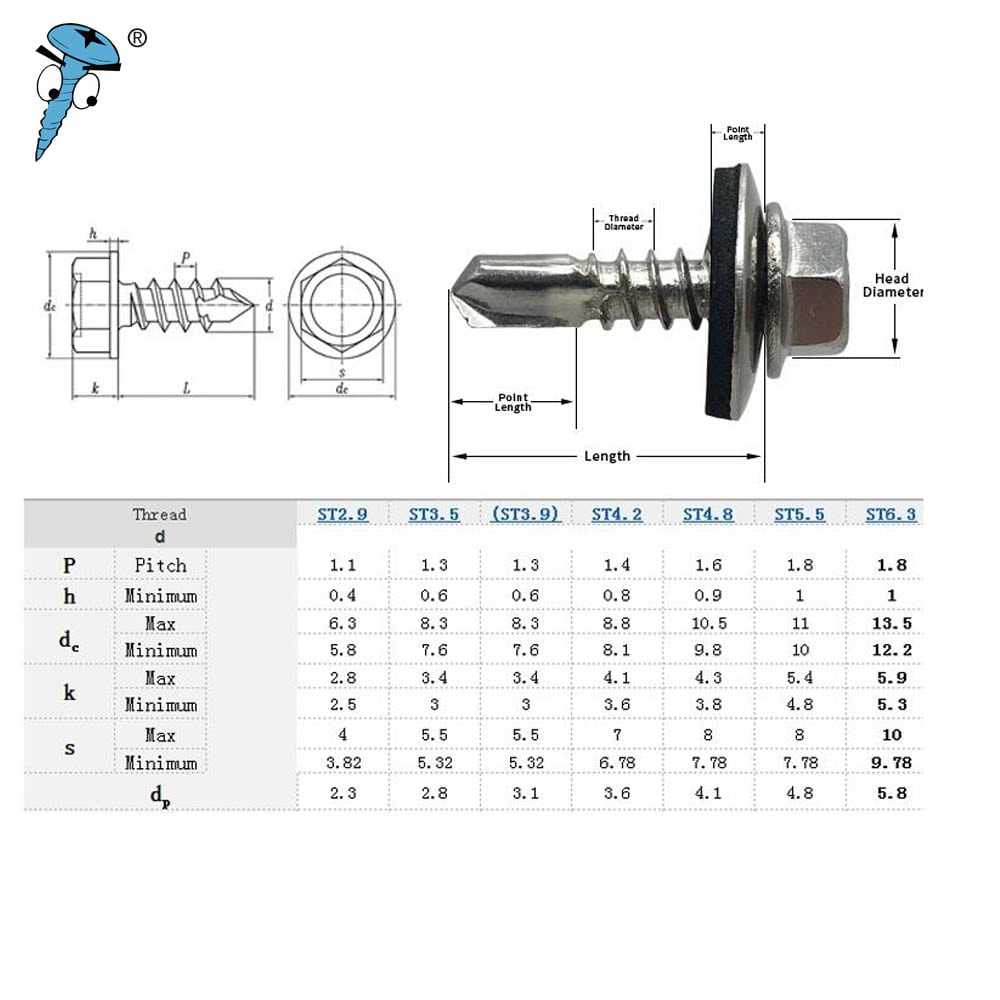

- The implementation standard is GB/T 15856.4-2002. (Also known as Hexagon flange drilling, it is the most commonly used and the largest specification of drilling screw thread.)

- Hexagon flat head drilling screw.Hexagon socket flat head self drilling

Categories of Self Drilling Concrete Screws based on the material

1.Carbon steel drilling and tail screw, 1022A, standard heat treatment steel can be used as drilling and tail screw production material, after heat treatment surface hardness HV560-750, core hardness HV240-450. The standard surface treatment is easy to rust, high hardness, low cost.

2.Stainless steel drill screw, 410, heat treatable, rust resistance better than carbon steel, worse than 304.

3.Stainless steel drill screStainless steel drill screw, 304, can not do heat treatment, rust resistance, low hardness, high cost, and only drill aluminum board, wood, and rubber board.w, 410, heat treatable, rust resistance better than carbon steel, worse than 304.

4.Composite drilling screw, the bit is produced with carbon steel, thread, and head with 304 stainless steel combined production process.

Purpose: Generally used for fastening and connecting plastic steel, aluminum profiles, wood products, thin-wall steel tubes, steel plates, and non-ferrous metal plates.