Are you interested in the newest trends for fastener bolts nuts in 2025? Keeping up with changes in the fastener industry helps you make good choices for your projects. New technology and materials are now very important for fasteners. The table below shows some main changes:

| Trend | 説明 |

|---|---|

| IoT Integration | Collects data in real time for better work and quality. |

| Advanced Materials | Uses nanostructured alloys for strong and special uses. |

| 3D Printing | Makes custom designs faster. |

| Environmental Sustainability | Uses eco-friendly ways and recycled materials. |

| Specialized Fasteners | Has tight tolerances for aerospace and medical fields. |

You can see these changes happening right now. The fastener industry is growing by 4.4% every year. New strong and eco-friendly materials make fasteners work better. Efforts to help the environment are lowering harm. Think about how these trends can help you do better in your work.

要点

- Keep learning about new fastener trends like IoT and advanced materials. These can help your projects work better and faster.

- Think about using eco-friendly fasteners made from recycled stuff. This helps the planet and lowers harm to nature.

- Use 3D printing to make custom fasteners. This makes them faster and lets you create special shapes for your needs.

- Work closely with suppliers to pick the best fasteners for your projects. This makes your work safer and helps it perform well.

- Check often for compliance and certifications. This makes sure your fasteners follow rules and are safe to use.

Key Drivers in the Fastener Industry

Technology and Smart Manufacturing

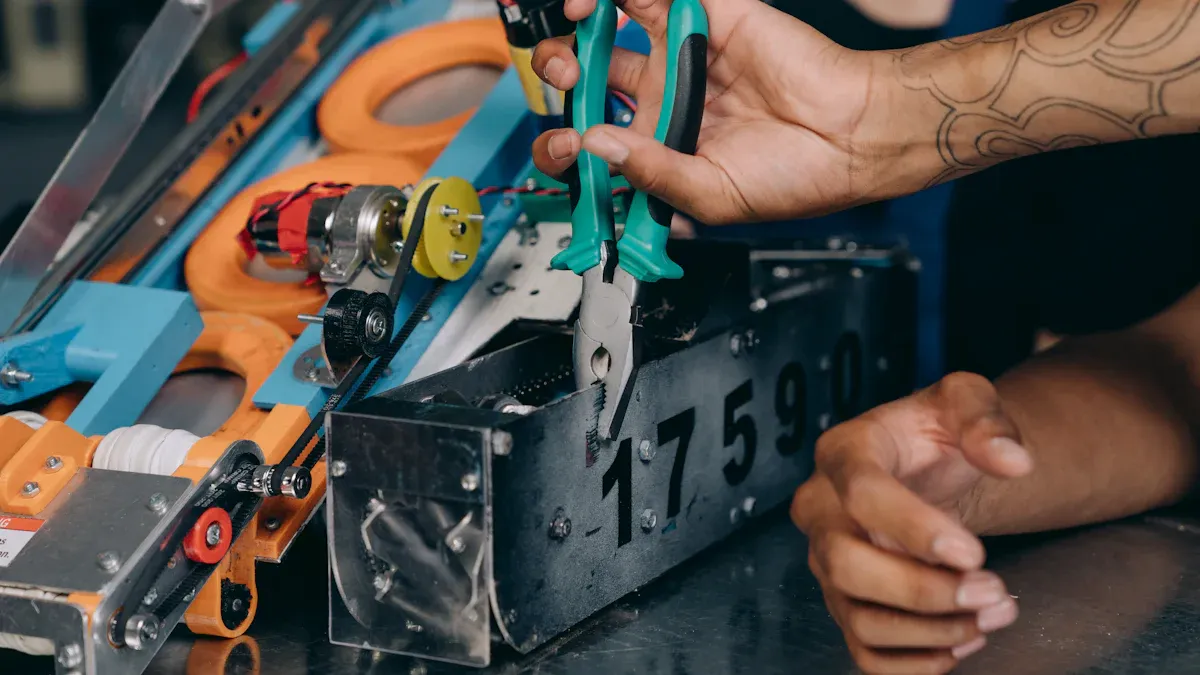

Technology is changing how people use fasteners. Smart manufacturing helps make custom fasteners faster and cheaper. Digital design tools, like 3D printing, let you make special shapes and sizes. You can try out new ideas more quickly with these tools.

| Technology | Impact on Customization |

|---|---|

| IoT and Smart Tech | Real-time monitoring of tension and conditions for better precision. |

Smart fasteners have sensors inside them now. These sensors check things like temperature, stress, and vibration. The data helps keep equipment safe and working well. Smart manufacturing also means less waste and lower energy use.

Industry Demands and Customization

Different industries need different fasteners. Aerospace companies want fasteners that handle heat and pressure. Medical device makers need fasteners made from safe materials. The marine industry needs fasteners that do not rust in saltwater. Car makers use strong steel fasteners for safety.

- Aerospace: Needs fasteners for extreme conditions.

- Medical Devices: Uses biocompatible materials.

- Marine: Requires corrosion-resistant fasteners.

- Automotive: Prefers high-strength steel.

You work with suppliers to design fasteners that fit your needs. Custom fasteners help make products safer and better.

Sustainability and Eco-Friendly Materials

Sustainability is important in the fastener industry now. You can pick fasteners made from recycled steel or aluminum. Some companies use coatings that are safe for the environment. New ways to make fasteners use less energy and make less waste.

- High-solids and water-based systems lower air pollution.

- Low-temperature curing saves energy.

- Heavy-metal-free coatings protect the environment.

- Phosphate-free processes reduce water pollution.

You help the planet by choosing eco-friendly fasteners. These trends show you can have strong, safe products and still care for the earth.

Trends Shaping Fastener Bolts and Nuts

Smart Fasteners and IoT

Smart fasteners are changing how you use bolts and screws. These fasteners have sensors inside them. The sensors collect data and send it wirelessly. They share information about load, torque, vibration, and temperature. You get this data right away. It helps you find problems early and keep things safe.

| 特徴 | 説明 |

|---|---|

| Integration of Sensors | Smart fasteners have sensors that watch different things. |

| Wireless Technology | They use wireless signals to send data. |

| Data Transmission Capabilities | You can see load, torque, vibration, and temperature as they happen. |

Smart fasteners help with predictive maintenance. They warn you before something breaks. You can stop breakdowns and fix things faster. You also get better quality control when making things. These trends let you track your products from start to finish.

- Real-time data helps with predictive maintenance.

- Quality control gets better in factories.

- You can trace products in many industries.

Manufacturers use smart fasteners in lots of ways. Some companies put sensors in bolts to check for stress or heat. If a screw gets loose or stressed, the system sends an alert. Fastenal uses these tools to watch machines and work faster. Smart fasteners keep your projects safe and running well.

Tip: Smart fasteners can change how you design and fix things. You can make things work better and keep them strong with connected fasteners.

Advanced Coatings and Durability

You want fasteners that last longer and work better. Advanced coatings help protect bolts and screws. New coatings like zinc plating stop rust and wear. These coatings help fasteners last in tough places.

- Plating helps stop rust and wear.

- Coatings make fasteners look better and conduct electricity.

- Rust protection keeps fasteners strong.

- Durability means less damage over time.

- Special coatings work in tough places.

- Cheaper coatings save money on repairs.

You can pick from many coating types. Zinc coatings work well in wet places and cost less. Nickel coatings last longer and look nice. Hot-dip galvanized coatings protect best outside. Some coatings, like NanoGalv and Magni, fight rust even in hard conditions.

| Coating Type | 耐食性 | 耐久性 | Best Use Cases |

|---|---|---|---|

| NanoGalv® | Very strong | High | Hard places, long use |

| Magni Coatings | Best protection | Very high | Marine, aerospace, military |

| Zinc-Nickel | Medium | Medium | Cars, easy jobs |

| Traditional Coatings | Low | Low | Regular factory work |

These coatings save you money over time. They lower repair costs and keep fasteners strong. These trends help you pick the best fastener for your job.

3D Printing in Fastener Production

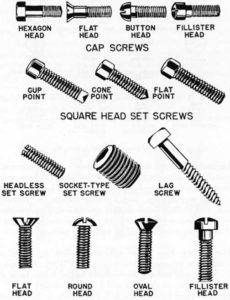

3d printing is a new and exciting trend. You can use it to make custom bolts, screws, and nuts. This lets you create special shapes without new tools.

- Metal powder bed fusion and binder jetting make custom fasteners.

- You can use stainless steel, titanium, and strong plastics.

- 3d printing works best for small batches or test pieces.

- You get fast samples and shorter wait times.

- On-demand making saves space and money.

You can make fasteners with shapes that normal methods cannot do. But 3d printing has limits. It may not work for very strong needs or big batches. You must check if the materials fit your industry rules.

Note: 3d printing gives you speed and choices. You can try new ideas fast and change designs without waiting.

New Materials and Alloys

Many new materials are used for fasteners now. These materials help with problems like weight, strength, and rust. Composites, titanium, strong plastics, and light alloys are popular for tough jobs.

| Material Type | 説明 | Application Areas |

|---|---|---|

| Composites | More use of light composites | Cars, planes |

| チタン | Strong titanium alloys | High-stress jobs |

| High-strength Polymers | Tough plastics for better work | Cars, factories |

| Lightweight Alloys | Alloys that are light and strong | Planes, cars |

These materials help you in many ways. Titanium alloys fight rust and last longer in hard places. Carbon fiber and composites make things lighter for cars and planes. Strong plastics give you tough screws for hard jobs. Bio-based composites are good for the environment.

- Titanium alloys help planes use less fuel.

- Composites make cars lighter and cleaner.

- Rust-proof bolts last longer in wind and solar power.

- Recyclable materials help the planet.

- Eco-friendly ways lower pollution from making fasteners.

- You pay more at first, but save money because fasteners last longer.

These trends show how new materials and alloys help you work better and protect the earth. You can pick the best fastener for your project, whether you need strong screws or light bolts.

Fastener Bolt Market Growth and Regional Trends

Market Expansion and Projections

The fastener bolt market is getting bigger every year. Many new projects and industries are starting up. The global market will grow from about USD 87.56 billion in 2024 to almost USD 137.29 billion by 2034. This means the market will grow at a steady rate of 4.60% each year from 2025 to 2034. There are a few main reasons for this growth:

- The construction industry is growing fast as cities get bigger and more buildings are built, especially in new economies.

- The automotive industry needs more fasteners because electric vehicles are getting more popular.

- New technology in factories helps make better fasteners, so more companies want them.

- The aerospace industry also needs strong and reliable fasteners.

These trends are shaping the future of the fastener industry. As more people need homes, cars, and planes, the need for good fasteners keeps going up.

Asia-Pacific and Global Developments

Asia-Pacific is the top region for making and using fasteners. This area has the biggest share of the market, with a growth rate between 3.5% and 5% and a market share of 44–47%. The table below shows why Asia-Pacific is important:

| Region | Growth Rate (CAGR) | Market Share (%) | Key Drivers |

|---|---|---|---|

| Asia-Pacific | 3.5–5% | 44–47% | Infrastructure and EV investments in China, India, and Southeast Asia |

The automotive industry is growing fast in China, Japan, India, and South Korea, especially with more electric vehicles. Big building projects in India, Indonesia, and Vietnam also make more demand for fasteners. Electronics factories in China, South Korea, and Japan are making more products, so they need more high-precision fasteners. Companies in Asia-Pacific are also using new materials and better ways to make fasteners, which helps the market grow even more.

Note: Watching these trends in different regions helps you plan for what you will need and stay ahead in the fastener bolt market.

Industry Applications of Custom Fasteners

Construction and Infrastructure

Custom fasteners are very important in building and infrastructure. They help in places with tough weather, like wind farms or oil rigs. Standard bolts sometimes are not strong enough or do not stop rust. Custom anchor systems are made for special building needs. They help connect beams, columns, and trusses safely. These fasteners help buildings meet safety rules and stay strong.

- Custom fasteners work well in hard places.

- They give the right fit and strength for special jobs.

- You use them to hold important parts together.

- Engineers make sure they follow safety rules.

Automotive and Transportation

You need fasteners in cars and trucks for many reasons. They hold engine parts and body panels in place. These fasteners must not come loose from shaking or bumps. Strong fasteners keep brakes and airbags safe. Sometimes, you need special fasteners for new car designs. Removable fasteners help fix and check cars easily.

- Fasteners join the chassis and engine.

- You pick types that stop shaking.

- Removable screws make repairs easy.

- Custom fasteners help keep cars safe.

Aerospace and High-Performance Sectors

Aerospace and high-performance jobs have strict needs. Fasteners for space and planes must handle heat and radiation. Regular bolts do not work for new aircraft. Engineers and suppliers make strong screws and bolts for these jobs. These fasteners must meet special load and weather needs.

- Fasteners work in space and flight.

- Custom shapes fit new materials.

- Experts help solve new problems.

Electronics and Consumer Goods

Custom fasteners help in electronics and everyday products. They stop electrical noise and keep things cool. Fasteners must fit in small spaces and handle shaking. Custom screws are made for each job, so products work well.

- Precision fasteners stop electrical problems.

- They keep devices stable and cool.

- Screws handle shaking in gadgets.

You see these trends in the fastener industry now. Custom fasteners help each field do better. As the market grows, you can use 3d printing and new materials to stay ahead.

Selecting and Sourcing Custom Fastener Bolts Nuts

Assessing Application Needs

First, you should know what your project needs. Every job needs different fasteners, bolts, or a screw. Picking the right one keeps your work safe and strong. The table below shows what to check:

| Criteria | 説明 |

|---|---|

| 素材適合性 | Make sure the fastener matches the materials you join. |

| Environmental Considerations | Think about heat, moisture, or chemicals that may affect performance. |

| Fastener Strength | Know the load and stress the fastener must handle. |

| 耐久性 | Pick fasteners that last under stress and tough conditions. |

| Size Considerations | Choose the correct length and shape for your job. |

| Installation Best Practices | Use the right methods for secure fittings. |

| Regular Maintenance | Plan for checks to keep fasteners working well. |

Tip: Always pick a fastener that fits your project. This helps you stop problems before they start.

Supplier Collaboration and Quality

It helps to work with your supplier closely. You can tell them what your project needs. The supplier can help you pick the best bolts or screw. Good suppliers give you lots of choices. They help you solve problems that are hard. Here are some things to remember:

- Suppliers who listen can make custom fasteners for special jobs.

- A big product range means you have more choices.

- In places like marine or offshore, suppliers work with engineers for the best solution.

- Suppliers who care about quality make sure your fasteners are good.

Note: Working well with your supplier gives you better results and fewer mistakes.

Compliance and Certification

You need to check if your fasteners follow the rules. Many jobs need fasteners with special certifications. These rules cover how the fastener is made and what it is made from. They also check how it works. Look for these things:

- Some jobs need fasteners with safety and performance certifications.

- Certifications check strength, material, and how the fastener is made.

- Quality checks help you trust your fastener bolt market choices.

- Safety rules make sure your screw or bolt works in tough places.

- Many jobs use ASTM, ISO, or SAE standards for fasteners.

Remember: Certified fasteners help you follow the law and keep your projects safe.

You should learn about new trends to keep up with fasteners in 2025. These changes help you make better products, work faster, and protect the environment. Begin by making new fastener designs, using smart ways to build, and trying new technology like AI and 3D printing.

- Make new fastener designs for what industries need now

- Use smart building methods to save time and materials

- Try new tools to make fasteners fit your needs

Keep talking with your suppliers and learn about new things happening in the industry.

よくあるご質問

What are the main benefits of using custom fastener bolts nuts in industrial fasteners?

Custom fastener bolts nuts give you a better fit. They make things stronger and safer. These industrial fasteners match what your project needs. Custom fastener bolt procurement helps you fix special problems. You get better product quality and fewer failures. Picking the right nuts and bolts helps you do a better job.

How do sustainable fastener solutions impact fastener bolt procurement and sourcing strategies?

Sustainable fastener solutions help lower waste and save energy. You help the planet by picking eco-friendly fasteners. Sourcing strategies that use these solutions support your company’s green goals. Fastener bolt procurement with sustainable choices also follows new rules in the global fastener markets.

Why should you consider 3d printing technology in fastener manufacturing and fastener production?

3d printing technology helps you make fastener bolts nuts fast. You can try new designs and make fasteners quicker. This new way lets you create custom industrial fasteners. Sourcing strategies with 3d printing give you more choices for nuts and screw types.

What are the best sourcing strategies for fastener bolt procurement in the global fasteners market?

You should look at different suppliers and check their quality. Find fastener solutions that are good for the planet. Good sourcing strategies help you get strong industrial fasteners. Fastener bolt procurement works best with trusted sources. You save money and get better nuts and screw options.

How do technological advancements and sustainable practices shape the future of industrial fasteners?

Technological advancements bring new materials and smart designs. Sustainable practices help you pick eco-friendly fastener bolts nuts. You see more new ideas in fastener bolt procurement and sourcing. These changes make the fastener market better and greener for everyone.