カスタムセルフドリリングスクリュー

産業用ファスナーねじのカスタマイズニーズにお応えするサービスに尽力しております。.

Have you been searching for a leading fastener manufacturer that ensures your standard demand will be met?

Prince Fastener has developed innovation in excellent productivity, analysis, and distribution of products. Here’s why we stand out;

- 24/7 Customer line service, we never miss out on your inquiry

- Multiple utilization of our manufactured products

- Professional in providing quality of resources hence we supply to custom needs in screws

- Outstanding experience in over 30 years in producing fastener

こんにちは。 プリンスファスナー,glad to have a chance to introduce our Custom Self-Drilling Screws for wholesalers and importers.

クイックビュー

- → Advantages of wholesale Prince fastener custom self-drilling screws

- → カスタムセルフドリリングスクリューの人気商品

- → HOW TO EVALUATE WHOLESALE PRICES FOR CUSTOM SELF-DRILLING SCREWS?

- → Estimation in Production & Delivery for Custom Self-drilling Screws

- → カスタムセルフドリリングねじはどのように段階的に製造されるのか?

- → The Standard Making of Prince Fastener Custom Self-drilling Screws

- → Types of Custom Self-drilling Screws

- → Usual Mistakes iN Custom Self-drilling Screws Applications

- カスタムセルフドリリングねじに関する完全FAQガイド

Advantages of wholesale Prince fastener custom self-drilling screws

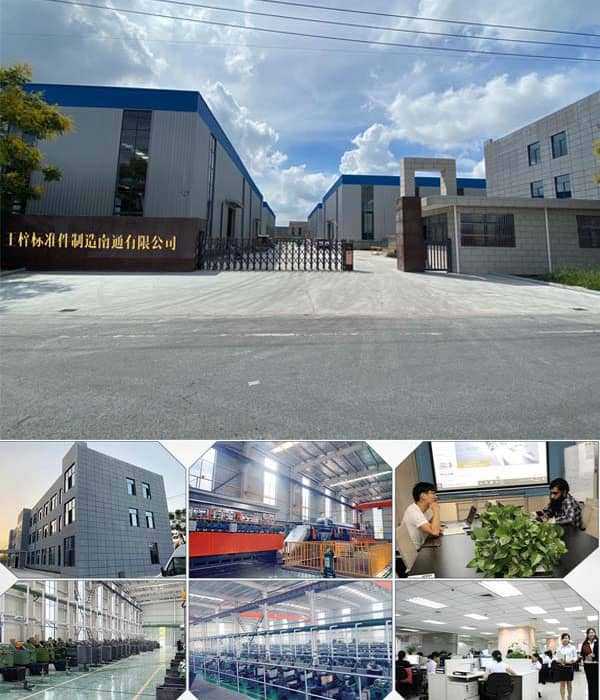

Prince Fastener is one of a kind worldwide distributor of excellent fastener products. Our specialization in the fabrication of all kinds of screws has reached internationally in Hong Kong, Korea, Japan, Australia, the UK, Europe, and the Middle East. Be it emphasized enough that we are known to meet requests in custom, OEM, and ODM orders. We go over the top in providing the best results without compromising the features of our products. With a developed innovation in analysis and development, we have succeeded to qualify in national and international standards moreover receiving certifications in ISO, DIN, ANSI/ASME, JIS, and GB types.

Customized fastener services are widely in demand in business nowadays but Prince Fastener put precision in the need to specialize in the market of custom self-drilling screws. With the production process of custom self-drilling screws in surface treatment namely, blue zinc plating, yellow zinc plating, nickel plating, black zinc plating, gray phosphorus galvanizing, black phosphorus galvanizing, brass plating, steam plating, hot dip galvanizing, silver plating, gold plating, etc. Prince fasteners have the competence, effectiveness, and success in the field of manufacturing and distributing special screws, especially custom self-drilling screws.

We are highly motivated in increasing the productivity of making custom self-drilling screws supplier as we are growing daily in supplying different brands and manufacturers in domestic and abroad. Prince fastener custom self-drilling screws can be utilized in use for toys, handbags, furniture, building materials, sanitary ware, electronics, lighting, automobile, new energy, watches, instruments, speakers, motorcycles, cellphones, cameras, appliances, machinery, and aviation navigation fields, etc. How can i find a reliable fastener manufacturer?-Prince Fastener-Fastener manufacturer

カスタムセルフドリリングスクリューの人気商品

セルフドリリングコンクリートビス

Self-drilling Metal Screw

Self-drilling Screw for Plastic

Hexagon Head Self Drilling Screw

Self-drilling Screw Wood

厚鋼板用セルフドリリングねじ

セルフドリリングスクリュー

Self-drilling Screw for Steel

カスタムセルフドリリングスクリュー

HOW TO EVALUATE WHOLESALE PRICES FOR CUSTOM SELF-DRILLING SCREWS?

The estimated wholesale price for Custom Self-drilling screws should include the below,

Manufacturing Costs/ Raw Materials

Our main objective is the production of our fastener screws and custom self-drilling screws in world-class factories and machinery made from high-quality raw materials that are then introduced to advanced testing types of equipment.

Free Sample Products for Testing

We generally provide our clients with free fastener screws to show our confidence in the quality of our products with the only cost of freight charges.

Packaging & Distribution

We accommodate further packaging requirements by our clients and customers for a reasonable fee. The transportation of Prince Fastener custom self-drilling screws will be facilitated accordingly.

Customized Fastener to Your Design

Be it emphasized enough that prince fastener is known for producing OEM and ODM orders, as well as meeting customer requirements, especially for custom self-drilling screws.

Freights & Custom Clearance Costs

The overall costs of miscellaneous, clearance, and other customs fees upon the importation of goods.

カスタム・クリアランス費用

この費用には、仕向地の通関費用、関税、その他雑費が含まれます。

ファスナーの工場に協力したいですか、またはカスタムファスナーを取得したいですか?

プリンスファスナーは、あなたのための競争力のあるコストで高品質のネジを作成するためにここにあり、あなたのビジネスのための技術的なサポートと排他的なサービスを提供します。

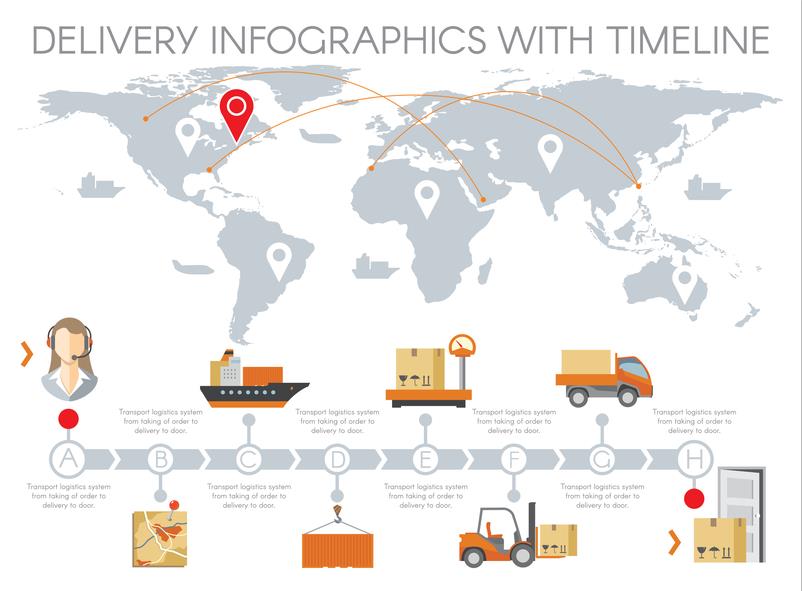

Estimation in Production & Delivery for Custom Self-drilling Screws

Prince Fastener can only increase manufacturing and development in order to meet the demand in the industry for custom self-drilling screws. Final results will always be guaranteed in excellent quality and value as the process we take in every step will always be to prioritize exceptional service as a mission. To estimate the time process of every production of custom self-drilling screws we take deep research and indulge in the attributes of the best brand we can supply. Hence, the precision of results is well-taken care to the potential of the capacity to develop future success. The evaluation of delivery and transportation of our custom self-drilling screws can only be estimated to the course of logistics in your area as well as domestic cases but it is for certain that these characteristics play a vital role in every transaction. In exaggeration, our high volume in production to meet your demand in the request for custom self-drilling screws is as competitive as we are in product quality and manufacturing experience in an extension of our incomparable service profile.

Custom Self-drilling screws Design and Manufacturing

Prince Fastener designs and manufactures the custom self-drilling screws in our own fastener factory

製品梱包時間

Put the custom self-drilling screws into pp bag or small white boxes,then put them into a package,they will take a short time to do it.

国際配送にかかる時間と通関にかかる時間

Need time to ship the custom self-drilling screws worldwide by sea or by air, and then make custom clearances also need time.

ロジスティクス

You’ll finish the whole process and get what you want. You just wait for the local logistics to haul the Custom Self-drilling screws from the port to your destination.

Prince fastener will introduce you all the process of the Custom Self-drilling screws production.

プリンスファスナー製造工程

プリンスファスナーねじ製造の基本コンセプト

1、プリンスファスナー製造ねじに分けることができます:冷間圧造、ホット機械加工(旋盤、フライス盤など)。

2、冷間圧造はプラスチック金属を使用することで、冷間機械的な圧力や描画を使用して、金属の固体変形に達する。

3、ホットアップセッティングは、加熱と圧力処理後の材料の形状を満たすようにすることです。

設計要件。

4、プリンスファスナーの機械加工は、頭の6つのコーナーの特殊または特殊なボルトの小バッチは、フライス加工後にオンになります。

5、スクリューボルトのスレッド:機械的および手動ねじ切り、ダイスに似ています。

6、ミリングテール:一般的にプリンスファスナーカッティングマシンの終わりまでに完了します。

7、冷間圧造と熱間動揺の違い:冷間圧造ボルトの表面はより美しく、ダース赤いボルト表面の酸化皮は良く見えません;

現象の原因と成形過程の原因の分析

1、偏心:2つの赤と不適切なインストールと調整マシン。

2、ミノ:インストール不良と不適切なプリンスファスナー調整機で。

3、頭部が丸くない:ダイまたはパンチの成形の選択が十分でない。

4、亀裂のモードを再生する:亀裂やダイスのR角、モデルが2つの衝突によって打たれるように。

5、ヘッドダブル:パンチが悪い。

6、フラッシュ:不良、パンチング成形は、主にパンチとダイの間の穴のクリアランスが大きすぎるか、または短すぎる赤い棒である。

7、クラック角度:パンチ針バーストまたは2パンチとパンチは重くない。

8、ヘッドクラッキング:材料、または金型(金型のパンヘッド六角ワッシャーヘッドなど)、および潤滑油を使用してエラー。

一般的な圧延の不利な現象と原因の分析

1、加工亀裂:歯板とプリンスファスナーの古いマシンを調整します。

2、鈍い尾:機械が適切に調整されていない、歯板が古すぎる。

3、曲がったテール:シートボードのシートのコントロールスクリューがきつすぎる。

4、尾:歯の摩耗プレートと不適切な調整機。

The Standard Making of Prince Fastener Custom Self-drilling Screws

プリンスファスナー-ねじの製造工程 | ねじの作り方

生産設備

The sequence of manufacturing in the specialization of design on Prince Fastener products includes; using high-quality raw materials such as stainless steel, carbon steel, alloy steel, etc. Establishment of advanced testing equipment e.g. 3-dimensional projector, spectral filter, Rockwell hardness tester, thread forming machine, tensile machine, and beyond two hundred other machinery equipment from Taiwan. With the most experienced technicians and a knowledgeable team of production who never cease to innovate development in the quality of service and completion of the standard need of custom self-drilling screws.

革新を共創するチーム

As we require the highest attainments in manufacturing and service we are most satisfied with the workforce that our organization is comprised. With the leading professional achievement in domestic and international standards, the team behind the production, testing, inspection, specialists, craftsman, consultants, technicians, engineers, sales or marketing, after-sales customer support, and the overall management is well recognized by Prince fastener. This team of people is the core advantage of our specialization in custom self-drilling screws and fastener products. They define the front-line creation of continuous improvement and accumulated development on a production scale.

工場、機械、そして熟練度

製造業という広大な分野において、プリンスファスナーはあらゆる側面で発展の進歩を絶えず向上させています。疑いなく、当社の専門技術は卓越した価値と水準を示す点で比類のないものです。.

当組織は国際的に認証を受けており、台湾発の最高級設備を活用する中国における多様なネジの迅速な製造メーカーの一つとして認知されています。この卓越した職人技による手法は、プリンスファスナーがカスタムセルフドリリングネジの生産を完璧に遂行することを保証するものです。.

The high degree of competence we exhibit in the production of custom self-drilling screws is to strongly enterprise that our resources will never cease to please the trading in the market. With our competitive prices, prince fastener can achieve repeat orders from big brands and clients, supplying them with the highest quality of custom self-drilling screws. In the large-scale selection that these fastener screws can take we have produced numerous types in sizes, forms, applications, usage, and kinds that have matched up to the main requirements that customers look for especially in making custom self-drilling screws.

動的に、膨大な数の国内 ファスナーメーカー 市場シェアの集中度が低く、シェアが上昇し続けているため、カスタムセルフドリリングスクリューの主要企業は、ファスナー製品の生産を独占するために高品質な競争力を獲得しようと努めている。.

カスタムセルフドリリングスクリュー事業の確立方法の理解

家具製造の需要と同様に、機械用ファスナー産業の急成長は、最終製品の結果を得るための重要な用途が不可欠であることから、引き続き向上を続けている。.

締結部品製品の選定にあたっては、サプライチェーンソリューションの検討から始めるべきです。ここでプリンスファスナーが貢献します。カスタムセルフドリリングスクリューには提案すべき利点があります。 主に家具製造、電子機器、建設、自動車、家電、さらには医療分野など、いくつかの異なる産業に適用される. カスタムセルフドリリングねじの使用用途は、ガラス、木材、金属、金属板、コンクリート、真鍮などの標準的な素材をカバーします。.

前述の通り、カスタムセルフドリリングスクリューの重要性は、構築する事業に貢献し得る要素を評価する上でも主要な鍵となる。綿密な調査は、後の計画策定と実行の指針となる。 カスタムセルフドリリングスクリューの市場価値を理解するためには、以下の順序で革新を図る必要があります:市場調査、事業計画、資金調達、立地選定、事業構造、事業登録、ならびに登録要件と税務要件の確保。当社は収集しました このウェブサイトからの信頼できる情報を活用し、起業時に重要な詳細を明らかにします。.

完了後は、市場のニッチ分野と動向を継続的に調査する意欲が求められます。 プリンスファスナーは、カスタムセルフドリリングスクリューの供給に関わる課題に積極的に対応します。カタログからファスナーの種類を選定される場合、技術支援を求められる場合、あるいはカスタムセルフドリリングスクリューの購入ニーズに関するご相談の場合でも、当社は需要を満たすプロセスを明確に説明し、確実なサービスと最高品質の対応を保証します。 組織と顧客への誠実な取り組みを通じ、初日から最高の忠誠心をもってサービスを提供することをお約束します。カスタムセルフドリリングスクリュー及びステンレススクリュー製造において他社を凌駕する企業として、中国国内メーカー中100%の製品合格率を達成し、業界トップの地位を獲得した経緯を共有できることを誇りに思います。. 中国におけるステンレス鋼及びカスタムセルフドリリングねじの主要メーカー。.

Types of Custom Self-drilling Screws

The classification of the types of custom self-drilling screws will allow you to have an overview of their usage and application.

Hence, they can be further classified into more factors contributing to the elements (sizes, forms, and color) and custom differences.

Classic Self-drilling Screw

This screw can be typically mistaken as a セルフタッピングネジ but the major difference they matter is that custom self-drilling screws don’t need a pre-drilled pilot hole to tap on an exterior material because it has a drill point with a cutting bit.

六角頭セルフドリリングねじ

Another name for this is wrench screws, they have a particular advantage and greater transition that allows the application of the screw to grip from all sides.

Metal Self-drilling screw

As the name itself, this custom self-drilling screw applies to kinds of metal such as steel, brass, aluminum, etc. They are useful in fastening metal and allowing the decrease of pressure and work on drilling on metal types of surfaces.

Truss head self-drilling screw

This is a threaded screw that is round in head and wide, also known as a mushroom head screw. They are commonly used in applications with electronic and metal parts that are only in humid surroundings.

Countersunk head self-drilling screw

This screw can be easily differentiated from the others as it has a flat type of head instead of a round. They are usually used in furniture making and wood surfaces.

Usual Mistakes iN Custom Self-drilling Screws Applications

Your custom self-drilling screws maybe aren’t at fault for wobbling and putting damage to the material you are working on. Sometimes these instances can also be caused by several mistakes you involuntarily know. Here’s a guide to knowing what you should do and not do on using the custom self-drilling screws.

Choosing the right kind of screw

When deciding on what custom self-drilling screw you are going to use you need to consider the type of components they are made from as it can affect the performance of drilling the screw into the materials they are fastened. Prince fasteners’ primary standard materials are carbon steel, high carbon steel, spring steel, stainless steel, alloy steel, zinc-aluminum alloy, free-cutting iron, aluminum, and copper with DIN/ISO grades: A2, A4, 4.8, 8, 8.8, 10, 10.9, 12.9, A194: 8/ 8M / 8MA /6/2H, A193: B8 / B8A/B8M/B7/B6, 410/304/316, etc. Custom self-drilling screw sizes range from M3 to M24 (3/16” to 1”) cold formed and other sizes larger than M24 (1”) hot forged and machined. This characteristic is a factor that contributes to achieving perfect results which you can work on choosing and deciding along with our experienced representatives to fully accumulate the demand of customization you best need.

Correct length size

Custom self-drilling screws are the peak of the invention as they take over the precision of use and enable less work than usual. The errors of using and picking the wrong size of screws can hinder the proper administering of custom self-drilling screws. Length size will mostly matter on how thick or thin your material needs to be fastened. Each adequate product will give out the best results when chosen correctly in assembly. You can consult with Prince fastener experts if you are not sure of the right size of custom self-drilling screws to purchase.

Wrong drill point and positioning

There’s not always a code for working with your custom self-drilling screws, sometimes it could be how you point it on the surface and the pressure that executes the drilling. When fastening the custom self-drilling screw you won’t need to put out immense strength as its advantage includes the elimination of pressure drilling already, point the tip of the screw to the desired area, and start drilling lightly with the use of your tool. Here’s a short clip showing how to position and drill with precision.

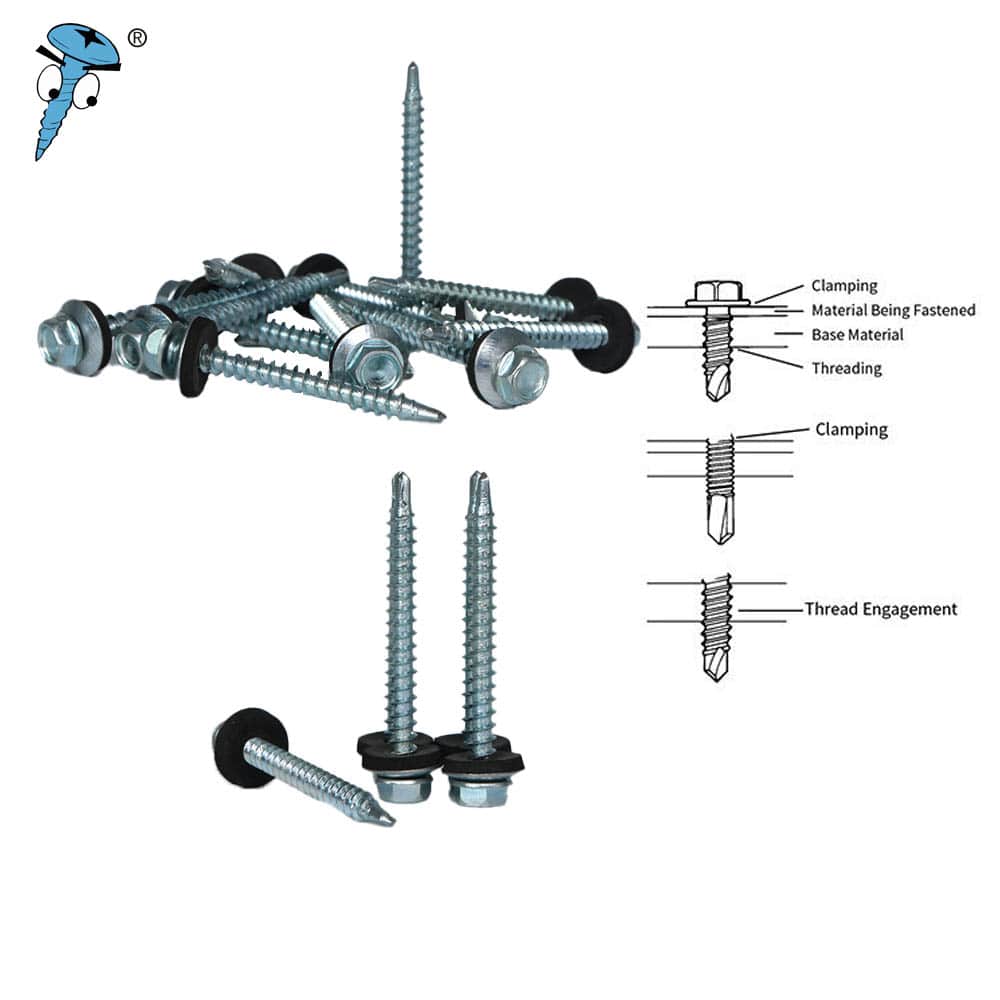

The relative properties to consider

Don’t to hate that disappointment you get after drilling on a metal sheet and ending with a wobbly screw? There’s an actual explanation for why this occurrence can appear. It’s because you’ve chosen the wrong custom self-drilling screw adhering to the fastening of the metal sheet on materials in the wrong way. You might consider using other types of custom self-drilling screws that will suit the purpose of fastening the objects. For instance, when you are using the custom self-drilling screw on pipelines or roofing installation you can opt to choose the kind of screw that has a ring model with a sealing gasket for protection from the water entering and coming out of the surface. Here’s an example of the fastener screw product you can use for this case under the category of custom self-drilling screws.

Other factors to be considered in applications are listed through this link.

With prince fasteners’ flexibility in delivering the best quality of service, we have anticipated the common problems our clients will have to encounter which is why our production is always in continuous improvement and development of sustaining the demands of the industry. Whether you are in the sourcing, taking account of technicalities, and research process, Prince Fastener can fulfill our duties to accommodate the best we can in all aspects.

Here’s a video representation of common mistakes using custom self-drilling screws.

Common mistakes when using self drilling screws (European Handypeople)

The Complete FAQ Guide about Custom Self-drilling screws

クイック・インデックス

1,What are self-drilling screws?

2,What’s the difference between self-drilling screws and Self-tapping screws?

3,Can I use self-drilling screws on any surface?

4,Can you make customized self-drilling screws?

5,What other fastener screws can you manufacture?

6,Do you offer exportation of your products?

7,Can you provide free samples of fastener screws?What screws are best for particle board?

8,Where can I send you my inquiry?

11. How do you drill and remove custom self-drilling screws?

1. What are self-drilling screws?

It is a type of fastener that is used to hold materials together as well as fastening and can considerably be more used in applications with the advantage of eliminating the additional work in industrial processes.

2. What's the difference between self-drilling screws and Self-tapping screws?

There is a wide variety to be considered in listing the difference between self-tapping and self-drilling screws. However, the factors we take to focus on are the characteristics that they differ in usage, application, and purpose.

3. Can I use self-drilling screws on any surface?

This fastener can vary in forms and sizes yet it can be used on different surfaces such as wood, metal, plastics types, metal sheet, concrete and more.

4. Can you make customized self-drilling screws?

Prince Fastener according to your needs and we are a proud manufacturer of custom screws that have been widely recognized in different countries for being a one-stop supplier of fastener materials.

5. What other fastener screws can you manufacture?

As complex as our company are we have gathered some of our main selling products to be socket head cap screws, double head cap screws, screws, T U screws, square head screws, joint screws, expansion screws, dental, tooth bars, external hexagon nuts, nuts, heavy nuts, thick blocks, flat gaskets, concave gaskets, retaining rings, spring washers, screws and other high-strength stainless steel fasteners for the chemical industry and various non-standard parts.

6. Do you offer exportation of your products?

With over 30 years of experience in manufacturing our company has grown to supply the demand in the industry anywhere around the world. Prince fastener does not only stop at innovating the quality of standards in our products but moreover to expand our reach as a supplier.

7. Can you provide free samples of fastener screws?

Prince Fastener is a proud fastener supplier and distributor that can always generate solutions for clients and customers hence we generally provide free fastener samples to show the value we put on quality in service.

8. Where can I send you my inquiry?

To properly administer your inquiries please send us a message in this link. We have an excellent record of keeping our clients and customers acquainted with the best service dealing with fastener products.

9. How long will it take to process the production of a custom self-drilling screw?

Prince fastener prioritizes you from the start of your inquiry and we will consistently follow the update of both divisions in order to meet a similar goal. The process of manufacturing to distribution of custom self-drilling screws will be taken accordingly to our standard procedure to ensure the best high-quality solution for the clients and customers. We take the flexibility in aspects of producing and exporting the fastener products, for that reason the certainty of time telling will be inaccurate but fundamental to our extent.

10. Will prince fastener be able to sustain on supply for the long term?

Having the inarguable accomplishment of manufacturing quality fastener products as well as custom self-drilling screws, prince fastener is dedicated to serving the industry of fastening screws beyond expectations. We are a reliable wholesale supplier and custom producer that aspire to achieve endless association.

11. How do you drill and remove custom self-drilling screws?

To start with the application you need a drill as a tool of force, position the custom self-drilling screw at a straight point of your target area and put a mild amount of pressure until it has passed through your material and fastened them together. When removing custom self-drilling screws you can simply use the drill and in the reverse direction to loosen it.

12. What payment methods does your company accept?

We accept payments by TT, L/C, and western union.