When you choose a screw barrel supplier, you want great quality. You need careful engineering and strong materials. You also want custom designs. Picking the right supplier helps your factory work faster. It makes your products better. It keeps your costs down. Look closely at each supplier before you pick one. Here is how your choice affects your factory:

- Good suppliers help you make better products and save money.

- Bad choices can cause costly mistakes and waste money.

- If you balance cost and quality, you can avoid problems later.

要点

- Figure out what your factory needs first. This helps you not make expensive mistakes. It also helps you find the best supplier.

- Pick suppliers who use strong materials. Make sure they have good engineering skills. This helps your screw barrels work well and last longer.

- See if suppliers offer custom screw designs. Custom screws can help your factory work better. They can also make your products higher quality.

- Read reviews about the supplier. Check if they have certifications. This helps you know if you can trust them.

- Ask if the supplier gives help after you buy. Good suppliers help you fix and care for your machines. This keeps your machines working well.

Define What Your Factory Needs

Before you look for a screw barrel supplier, know what your factory needs. This helps you avoid mistakes that cost money. It also makes finding the right supplier easier.

Material and Resin Compatibility

You must match screw and barrel materials to the resins you use. Some materials work better with certain plastics or additives. If you choose the wrong one, your machine can wear out early or break. Here is a table that shows common screw materials and how they are used:

| 材料タイプ | 説明 |

|---|---|

| AISI 4140 | This is the most common screw material. It is used in most extrusion and injection screws. |

| AISI 4340 | This material is stronger because it has nickel and molybdenum. |

| NITRALLOY 135-M | This is like 4140 but not as strong. |

| 300 STAINLESS | This is used when you need to stop rust, like 304 and 316 grades. |

| 17-4 PH STAINLESS | This is strong and does not rust easily. It is good for hard jobs. |

| D2 AND H13 TOOL STEELS | These are best when you use rough fillers or tough plastics. |

Tip: If you use glass-filled or rough resins, pick tool steels or stainless steel. This helps your machine last longer.

Production Volume and Output

Think about how much you want to make. How much you produce changes what screw and barrel you need. Here are some things to remember:

- If you want to make more, you need bigger screws and longer barrels.

- The right length-to-diameter ratio melts plastic faster and better.

- If you run fast or use special plastics, you might need a custom screw.

A good supplier will ask about how much you make each day. They will help you pick the right size and shape.

Machine and Application Fit

Your screw and barrel must fit your machines and what you make. Different brands and models need different things. Here is a table to show what matters:

| ファクター | 説明 |

|---|---|

| Machine Model and Brand | Each machine has its own needs for barrel length, mounting, and screw design. |

| Processing Material | Some plastics, like glass-filled, need special barrel materials. |

| Design Parameters | Screw diameter and L/D ratio change how your machine melts and moves plastic. |

| Heating and Cooling | If it does not fit, you can get overheating or bad temperature control. |

If you skip this step, you might get bad products or your machine could stop working. Make sure you know what you need before you talk to any supplier.

Choosing a Screw Barrel Supplier

Choosing the right screw barrel supplier helps your factory work better. It can stop problems before they start. You want a supplier who knows how to make screw barrels that fit your needs. Let’s see what is most important.

Engineering and Design Capabilities

You need a supplier with good engineering skills. They should make custom designs for your machines and materials. Good suppliers use new technology and skilled workers. This helps every screw barrel work well.

Here’s a table that shows what good engineering and design skills look like:

| Capability | 説明 |

|---|---|

| Custom Design Services | Making screw designs that fit special factory needs. |

| Optimization of Screw Profiles | Changing screw designs to work better and last longer. |

| Material Research for Wear Resistance | Finding materials that do not wear out fast. |

| Tailored Specifications | Changing designs to fit different factory jobs. |

Some suppliers, like Zhejiang Jinteng Machinery Manufacturing Co., Ltd., focus on custom screw designs. They use new technology and skilled workers to make screw barrels last longer. Zhitian checks quality and tests their products a lot. This means their screw barrels are very good. Alibaba Manufacturer uses CNC machines to make screw barrels. This means you get parts that fit your needs.

Tip: Ask your screw barrel supplier how they design their products. See if they can show you custom work they did for other factories.

Material Quality and Wear Resistance

The material you pick changes how long your screw barrel lasts. You want a supplier who uses strong materials that do not wear out fast. Some new coatings, like tungsten carbide spray and nickel-boron, help barrels last longer. Ceramic linings also help stop wear.

Here are some common materials for barrels and screws:

Barrel materials:

- Xaloy X-102 — Good for most jobs with normal resins

- Xaloy X-220 — Works with some chemicals

- Xaloy X-306 — Best for strong chemicals

- Xaloy X-800 — Good for tough jobs and filled resins

Screw materials:

- AISI 4140 — Used for most jobs

- AISI 4340 — Stronger, good for deep and small screws

- 17-4 PH Stainless — Stops rust, good for small screws

- D2 and H13 Tool Steel — Good for rough jobs and some rust

- CPM Tool Steel — Works with rough materials like fiberglass

- Hastelloy C-276 — Great for strong chemicals

- Inconel — Works with high heat and chemicals

Nitrided steel is a good choice for cost, strength, and wear. Tool steels like D2, H13, and CPM are best for tough jobs with lots of heat and wear.

Note: If you use rough or filled resins, ask your supplier about special coatings and tool steels. These can help your machines last longer and save money.

Customization Options

Every factory is different. You need a supplier who can change screw diameter, pitch, flight thickness, and depth. These changes help materials move better and make your work faster. Some suppliers offer special screw shapes, like Maddock mixers, to help melt and mix plastics better.

Here’s a table that shows how changing screw barrels can help your factory:

| Customization Option | Impact on Performance |

|---|---|

| Changing screw diameter, pitch, flight thickness, and depth | Helps materials move better |

| Using special screw shapes (like Maddock mixers) | Helps melt and mix plastics |

| Picking different materials and coatings (like tungsten carbide) | Makes screw barrels last longer |

| Adding starve feeding systems | Controls screw length, lowers motor work, helps even mixing |

Longer barrels give more time for melting and mixing. This helps with tough materials. Bigger diameters make more products but use more power. Smaller diameters help control pressure but move less material. Flight depth and pitch also change how materials move.

- Longer barrels help melt and mix, good for tough jobs.

- Bigger diameters make more products but need more power.

- Deeper flights slow down materials, shallow flights move them faster.

Callout: Custom screw barrel designs can really help your factory. Talk to your supplier about your materials and what you want to make. The right design can make your products better and save energy.

Picking a screw barrel supplier with good engineering, strong materials, and custom options helps you get the best results. You will get better products, longer machine life, and smoother work.

Supplier Evaluation Criteria

Manufacturing Standards and Certifications

When you pick a screw barrel supplier, you should look for proof of good quality. The best suppliers follow strict rules and have certificates. These certificates help you trust what they make. Here are some things to check:

- ISO 9001:2008 means the supplier follows world quality rules.

- Good suppliers use strong checks from start to finish.

- They use special tools to measure and make sure parts fit.

If you ask about these things, you can feel sure about the supplier’s work. You know they care about making safe and good products.

Product Protection and Durability

You want your screw barrels to last a long time. Good suppliers add things that protect their products and keep them working well. Here is what you should look for:

- People often write reviews about how long the products last and how easy they are to use.

- Good reviews talk about helpful support after you buy.

- Feedback from other factories can show if the supplier tells the truth.

- A strong warranty means the supplier trusts their product to last.

- Fast help with problems lets you fix things quickly.

- Getting spare parts and repairs easily keeps your machines working.

Tip: Read reviews and ask about warranties before you buy. This helps you stop problems and save money on repairs.

After-Sales Support

After you buy, you need help to keep things working well. Top suppliers give many kinds of help. Here is a table to show what you can get:

| Type of Support | 説明 |

|---|---|

| Customer Service | Helps you choose the right screw and barrel for your machines. |

| Engineering Services | Gives help at your factory for checks and repairs. |

| Quality Control | Gives you reports about heat, materials, and sizes. |

| Repairs | Fixes broken parts and helps with design changes. |

If your supplier gives these services, you can fix problems fast and keep your factory running. Good help means less worry for you and better results for your business.

Assessing Supplier Reputation

References and Customer Reviews

You should know if a screw barrel supplier is honest before buying. Checking references and customer reviews helps you learn what others think. Here’s an easy way to check:

| ステップ | 説明 |

|---|---|

| 1 | Ask the supplier for a list of people to contact. |

| 2 | Call or message these people to ask about the supplier. |

| 3 | Tell them you will keep their answers private. |

| 4 | Try to talk to other customers for more information. |

| 5 | Speak by phone or face-to-face for better answers. |

| 6 | Write down your questions and ask again if needed. |

When you read reviews, look for comments about how good the products are. Check if people say the delivery was fast and if the support was helpful. Good reviews often talk about friendly service and products that last a long time. If you see lots of good reviews, you can feel sure about your choice.

Tip: Always ask for references and read reviews before you buy. Honest feedback from other factories can help you avoid problems.

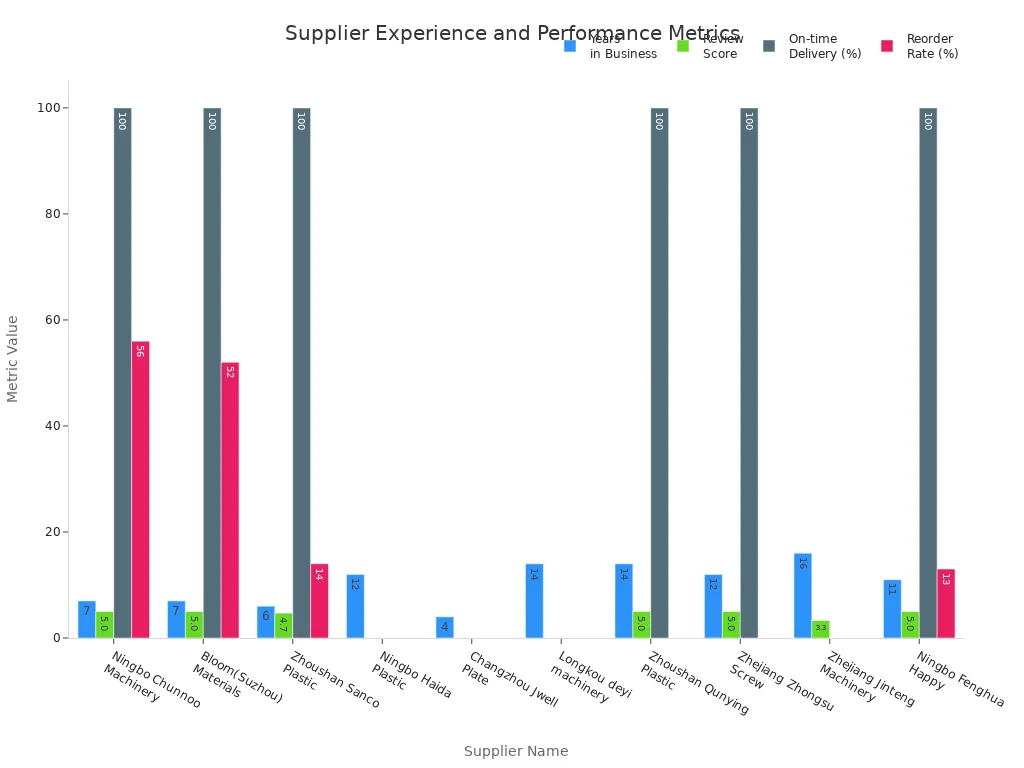

Track Record and Experience

A supplier’s past work tells you a lot about them. You want someone with lots of experience and a good record. Check how many years they have worked, how fast they answer, and how often people buy again. Here’s a table with some important facts:

| サプライヤー | Years in Business | Response Time | Review Score | On-time Delivery | Reorder Rate | Estimated Online Revenue |

|---|---|---|---|---|---|---|

| Ningbo Chunnoo Machinery Company Limited | 7 | ≤2h | 5.0 | 100% | 56% | $1.3M+ |

| Bloom(Suzhou) Materials Co., Ltd. | 7 | ≤1h | 5.0 | 100% | 52% | $180K+ |

| Zhoushan Sanco Plastic Machinery Co., Ltd. | 6 | ≤4h | 4.7 | 100% | 14% | $40K+ |

| Ningbo Haida Plastic Machinery Co., Ltd. | 12 | ≤6h | 該当なし | 該当なし | 該当なし | 該当なし |

| Changzhou Jwell Plate And Sheet Equipment Co., Ltd. | 4 | ≤4h | 該当なし | 該当なし | 該当なし | 該当なし |

| Longkou deyi machinery group co.,ltd | 14 | ≤3h | 該当なし | 該当なし | 該当なし | 該当なし |

| Zhoushan Qunying Plastic Machinery Manufactory | 14 | ≤4h | 5.0 | 100% | 該当なし | $2.7K+ |

| Zhejiang Zhongsu Screw Co., Ltd. | 12 | ≤6h | 5.0 | 100% | 該当なし | $680+ |

| Zhejiang Jinteng Machinery Manufacture Co., Ltd. | 16 | ≤13h | 3.3 | 0% | 該当なし | $3.9K+ |

| Ningbo Fenghua Happy Stationery Co., Ltd. | 11 | ≤4h | 5.0 | 100% | 13% | $540K+ |

Suppliers with new machines and good technology usually make better screw barrels. If a supplier has high review scores and delivers on time, you can expect good service. Many factories pick suppliers with good records because they want products they can trust.

- Pick suppliers with new equipment and careful work.

- Check if they deliver on time and if people buy again.

- Suppliers with good records often get better reviews.

A long history and good work mean the supplier cares about quality. When you see happy customers, you know you are making a smart choice.

Comparing and Negotiating

Requesting Quotes and Proposals

When you compare suppliers, ask for clear quotes. You should get a detailed price from each company. This helps you know what you will get. Most suppliers want your contact details and what your factory needs. You need to give your company name, phone, and email. You also share what screw or barrel you want. Tell them the size, type, and if you need a new part or a rebuild.

Here’s a table showing what you should include in your request:

| Field | 説明 |

|---|---|

| Company & Contact Information | Name, company, phone, email, address |

| Feed Screw Information | OEM brand, shank length, new or rebuild |

| Barrel Information | New or rebuild, length, diameter, liner alloy type |

Tip: Check your specs before you send them. This helps the supplier give you the right price and delivery time.

Value Beyond Price

Price is important, but it is not everything. You should look at what else the supplier gives you. Some companies give free help with your machines. This can save you money when you set up new equipment. Others give longer warranties or quick help after you buy. These extras can help a lot.

Think about these things when you compare suppliers: total cost, not just the first price, free help or support, warranty length, how fast the supplier answers, and quality of materials. Better materials or longer life can cost more at first. If a cheap barrel breaks, you might spend more fixing it.

Delivery and Warranty Terms

Always ask about delivery and warranty before you choose. Most suppliers give at least a one-year warranty for screw barrels. Fast delivery helps your factory keep working. If a supplier delivers quickly and has a good warranty, you can trust them more.

Here are some things to check: delivery time and shipping, warranty period (at least one year), and what the warranty covers (parts, labor, repairs).

Callout: Good delivery and warranty mean the supplier trusts their products. This helps you avoid problems and keeps your machines working longer.

When you compare and negotiate, do your homework. Set clear goals and know what matters most for your factory. If you build a good relationship with your screw barrel supplier, you can get better prices and help over time.

Long-Term Support

Communication and Responsiveness

Talking with your screw barrel supplier is important. You want answers to your questions fast. Good suppliers keep you updated often. If something goes wrong, you need help right away. Working closely with your supplier helps you avoid problems. This can stop delays or bad quality. Suppliers who want to work with you for a long time listen to what you need. They help you fix problems together.

Here are ways good communication helps your factory:

- You can solve problems before they get big.

- Your supplier helps you get ready for changes.

- Regular talks and feedback keep things working well.

- You know your supplier will help when you need it.

Tip: Pick a supplier who talks with you often and answers fast. This helps your factory work without trouble.

Maintenance and Scalability

You want your machines to last a long time. The best suppliers help you keep your equipment working well. They also help you grow when you need to make more products. They can make custom barrels and screws for your machines. Technical support helps you fix problems and keep things running. Good materials and careful building make your machines last longer.

Here’s what you get from a supplier who helps with maintenance and growth:

- Custom screw barrels made for your factory.

- Technical help to keep machines working.

- Strong parts that last and work well.

- Wholesale prices straight from the maker.

- Quick replacements and ways to make more products.

- New ways to make things that help you compete.

Factories use rules and computer systems to check their machines. You can see how your machines work with special numbers like OEE and MTBF. These tools show if your supplier’s help keeps your machines running without stopping.

Callout: When your supplier helps with repairs and growth, you worry less about breakdowns and spend more time making good products.

Picking the best screw barrel supplier means you look at your resin, machine, and what you want to make. You also check if they have good skills, strong quality, and helpful support. Make a simple list of what you need and give each supplier a score. Work with people who help you grow and fix problems.

A good way to check suppliers helps you find one who fits your needs and helps you in the future.

| Trend Description | Impact on Supplier Selection |

|---|---|

| New materials and smart technology | Suppliers with better choices stand out |

| Sustainability rules | Pick suppliers who have eco-friendly options |

Begin looking for a supplier now and remember to think about long-term help.

よくあるご質問

What should you ask a screw barrel supplier before buying?

Ask about what materials they use. Find out if they make custom designs. Ask how long delivery will take. Ask about their warranty. Ask to see work they did before. Ask if they help after you buy. This helps you know what to expect.

How do you know if a supplier uses high-quality materials?

Look for certificates like ISO 9001. Ask for reports that show material tests. Read what other customers say. Suppliers who share these things care about good quality.

Can you get custom screw barrel designs for your factory?

Yes, most good suppliers can make custom designs. You can tell them about your machines and what you need to make. They will help you pick the best design for your factory.

How long does a screw barrel usually last?

A screw barrel lasts one to five years. How long it lasts depends on the material and resin you use. It also depends on how much you use it. Stronger materials and coatings last longer.

What if your screw barrel breaks during production?

Call your supplier right away. Good suppliers fix or replace broken parts fast. Some give help to fix problems quickly. This helps you get back to work soon.