You want to know how to measure a screw? Start by checking the length, diameter, and thread pitch. Grab a ruler, caliper, or thread gauge for the most accurate results. Sometimes you wonder if you should include the head in your measurement, or if you need to use metric or imperial units. These questions pop up a lot when you’re measuring a screw for home projects. You’ll see wood screws, セルフタッピングねじ, and machine screws in everything from furniture to appliances. DIY kits with fasteners fly off the shelves every year, so measuring a screw correctly helps you get the job done right.

要点

- Measure the screw from the tip to the head. Use a ruler or caliper to be exact. If it is a flat head screw, measure the head too.

- To find the screw diameter, measure across the outer threads. Measure at the widest part. Calipers help you get the best result.

- Count the threads per inch for imperial screws. For metric screws, measure the space between threads. This tells you the thread pitch.

- Always check your measurements again to avoid errors. Put the screw on a flat surface to keep it straight.

- Know the difference between imperial and metric screws. Make sure you use the right system for your project. This helps you avoid fitting problems.

How to Measure Screw Length

Measuring from Tip to Head

Measuring the length of a screw might sound tricky, but you can do it with just a ruler or a caliper. You want to get the most accurate measurement, so follow these steps:

- Place the screw on a flat surface. Make sure the screw is straight and not tilted.

- Align the zero mark of your ruler or caliper with the tip of the screw.

- If you use a caliper, insert the screw lengthwise until it touches the base of the head. Rotate the knob until it clicks to lock the measurement.

- Read the value on your ruler or caliper. This number shows the screw length.

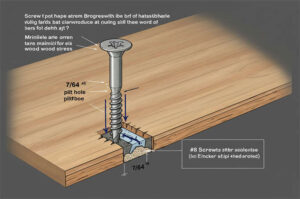

- For countersunk screws, measure from the top of the head to the tip. For other screws, measure from right under the head to the tip.

Tip: Always double-check your measurement. If you use a caliper, you get a more precise reading than with a ruler.

Including the Head or Not

You might wonder if you should include the head when measuring screws. The answer depends on the type of screw you have. Here’s a quick guide:

| ねじ込み式 | Measurement Method |

|---|---|

| Flat Head | Measure from the top of the head to the tip. |

| Pan Head | Measure from right under the head to the tip. |

If you have a flat head screw, include the head in your measurement. For pan head screws, start measuring right under the head. This difference matters because it affects how the screw fits in your project.

Tools for Measuring Length

Choosing the right tool helps you get the best results. Here’s a look at some common tools and how accurate they are:

| Tool Type | 説明 | Precision Level |

|---|---|---|

| Screw Thread Micrometer | Uses special tips to match thread angles for accurate measurements. | High accuracy for thread measurements. |

| Thread Pitch Gauge | Quickly checks the pitch of external threads using serrated leaves. | Moderate accuracy, good for quick checks. |

| 3-wire Thread Measurement | Uses three wires and a micrometer for pitch diameter. | Very high accuracy, great for precision work. |

Most people use a ruler or caliper for measuring the length of a screw. Calipers give you a more exact number, especially if you want to measure small screws. If you work with lots of screws or need to be super precise, you might want to try a screw thread micrometer or a 3-wire thread measurement tool.

注記: Humidity can change the size of screws. High humidity might cause screws to rust or swell, which can mess up your measurements. Always measure screws in a dry place for the best results.

Now you know how to measure screw length, when to include the head, and which tools to use. With these tips, you can measure screws like a pro.

Measure Screw Diameter

Outer Thread to Outer Thread

When you measure screw diameter, you want to find the width of the threaded part. This is the widest point across the threads. You do not measure the head or the shaft without threads. You only measure from the outer edge of one thread to the outer edge on the opposite side. This gives you the true diameter.

Here’s a simple way to do it:

- Hold the screw so you can see the threads clearly.

- Place your measuring tool across the threads at the widest point.

- Make sure you measure straight across, not at an angle.

- Read the number on your tool. This is the screw’s diameter.

You use this method for most screws, whether you are working with wood, metal, or plastic. The diameter is usually the first number you see in a screw size label.

Using Calipers or Ruler

You have a few choices for tools when measuring screws. Calipers give you the most accurate reading. You can measure down to a thousandth of an inch. Rulers work for quick checks, but they are less precise. If you want to be exact, use calipers. If you just need a rough idea, a ruler will do.

Here’s a quick look at how these tools compare:

| Measurement Tool | Accuracy |

|---|---|

| Calipers | Up to 0.001 inch |

| Rulers | Less accurate |

| Micrometers | More accurate |

If you use calipers, open the jaws and place them on the outer threads. Close the jaws gently until they touch both sides. Read the measurement on the scale. If you use a ruler, lay it flat across the threads and read the number at the widest point. Always double-check your measurement to avoid mistakes.

You might see different screw diameters for different jobs. Here are some common sizes you’ll find in furniture assembly and home projects:

| ネジサイズ | 一般的な用途 | 注記 |

|---|---|---|

| #6 x 1“ | Light-duty wood joinery, trim, hinges | Ideal for indoor applications where less force is required |

| #8 x 1-1/4″ | Cabinets, furniture assembly | A go-to for interior wood connections |

| #10 x 1-1/2″ | Drywall into studs, heavy frames | Offers strong hold without splitting studs |

| #12 x 2″ | Metal brackets, structural hardware | Often used where added grip strength is needed |

| #14 x 2-1/2″ | License plates, decking clips | Common in outdoor use; pair with corrosion-resistant coatings |

| M6 x 16mm | Automotive parts, light machinery | Metric size, used in imported or precision builds |

| M4 x 10mm | Electronics, appliance panels | Very small, precise threading |

If you are measuring screws for furniture, you will probably use sizes like #8 or #10. For electronics, you might see M4 or smaller. Always check the size before you start your project.

Tip: If you want to avoid mistakes, measure twice. Use calipers for best results, especially if you need the screw to fit perfectly.

Measuring screws gets easier with practice. Once you know how to measure the diameter, you can pick the right screw every time.

Measure Screw Size and Thread Pitch

Counting Threads per Inch (Imperial)

If you want to measure screw size for imperial screws, you need to count the threads per inch (TPI). This tells you how many thread peaks run along one inch of the screw. Here’s how you do it:

- Place a ruler along the threads of the screw.

- Count the number of thread peaks across half an inch.

- Double that number to get the threads per inch.

- You can use a TPI gauge for a quick check.

Counting threads helps you match the right screw for your project. If you’re measuring screws for furniture or repairs, knowing the TPI makes sure you get the correct fit.

Measuring Thread Pitch (Metric)

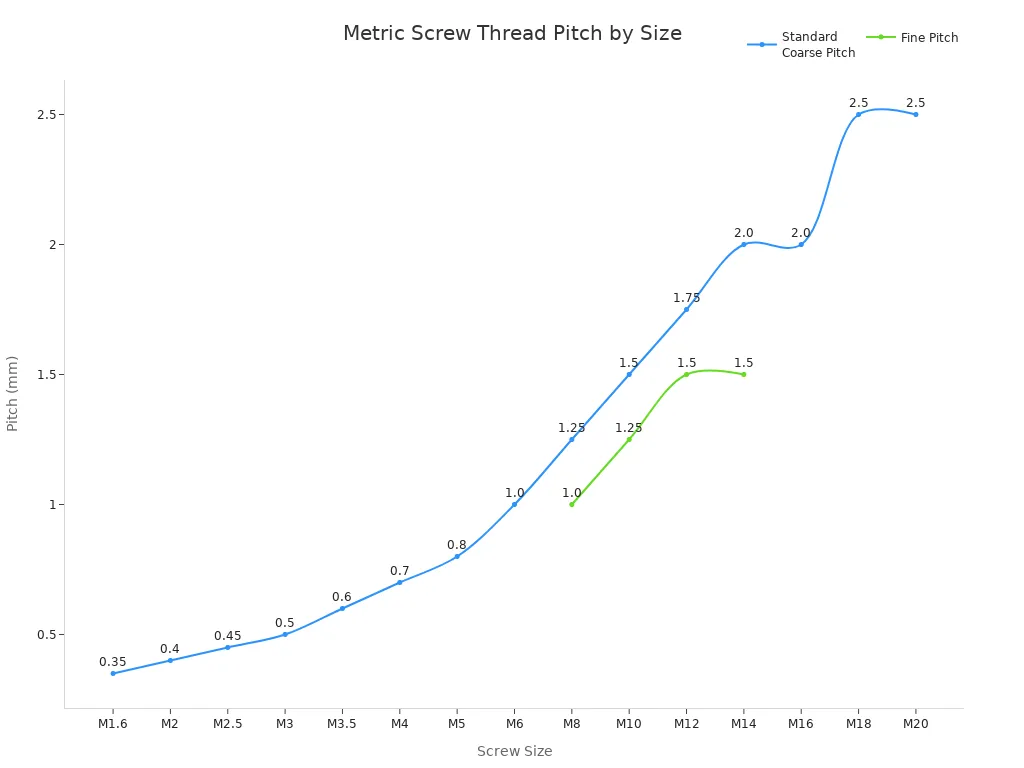

Metric screws use thread pitch instead of TPI. When you’re measuring the thread pitch, you check the distance between two thread peaks, usually in millimeters. The pitch tells you how far the screw moves with each turn. You’ll see different pitch values for each size.

Here’s a table showing standard and fine pitch for common metric screw sizes:

| ネジサイズ | Standard / Coarse Pitch (mm) | Fine Pitch (mm) |

|---|---|---|

| M1.6 | 0.35 | – |

| M2 | 0.40 | – |

| M2.5 | 0.45 | – |

| M3 | 0.50 | – |

| M3.5 | 0.60 | – |

| M4 | 0.70 | – |

| M5 | 0.80 | – |

| M6 | 1.00 | – |

| M8 | 1.25 | 1.00 |

| M10 | 1.50 | 1.25 |

| M12 | 1.75 | 1.50 |

| M14 | 2.00 | 1.50 |

| M16 | 2.00 | – |

| M18 | 2.50 | – |

| M20 | 2.50 | – |

If you’re measuring the thread pitch on automotive screws, you’ll notice some common sizes like M10x1.25 or M12x1.75. These numbers help you pick the right screw for cars or machinery.

Using Thread Gauges

Thread gauges make measuring the thread pitch and screw size much easier. You just match the gauge to the threads until you find the perfect fit. This tool helps you avoid mistakes and makes sure your screws work with nuts or tapped holes.

- Thread pitch gauges are important in automotive, construction, and aerospace work.

- They help you get precise measurements, which keeps fasteners reliable.

When you measure screw size, you’ll see both coarse and fine threads. Coarse threads work well in rough conditions and resist damage from dirt. Fine threads are stronger and better for precise jobs. Here’s a quick comparison:

| 特徴 | 粗ネジ | ファイン・スレッド |

|---|---|---|

| 強さ | Weaker than fine threads | Stronger due to larger stress area |

| Susceptibility to Loosening | More prone to loosening from vibration | Less susceptible due to shallow pitch |

| Suitability for Materials | Suitable for rough conditions and construction | Better for precise measurements and hard materials |

| タップの容易さ | More difficult to tap into hard materials | Easier to tap into hard materials |

| Torque Requirement | Requires more torque for equivalent preload | Requires less torque for equivalent preload |

Fine threads have higher tensile strength and allow for finer adjustments. Coarse threads handle rough jobs and resist damage. When you’re measuring screws, always check if you need coarse or fine threads for your project.

Tip: Use a thread gauge when measuring the thread pitch. It saves time and helps you get the right size every time.

Imperial vs Metric Systems

主な相違点

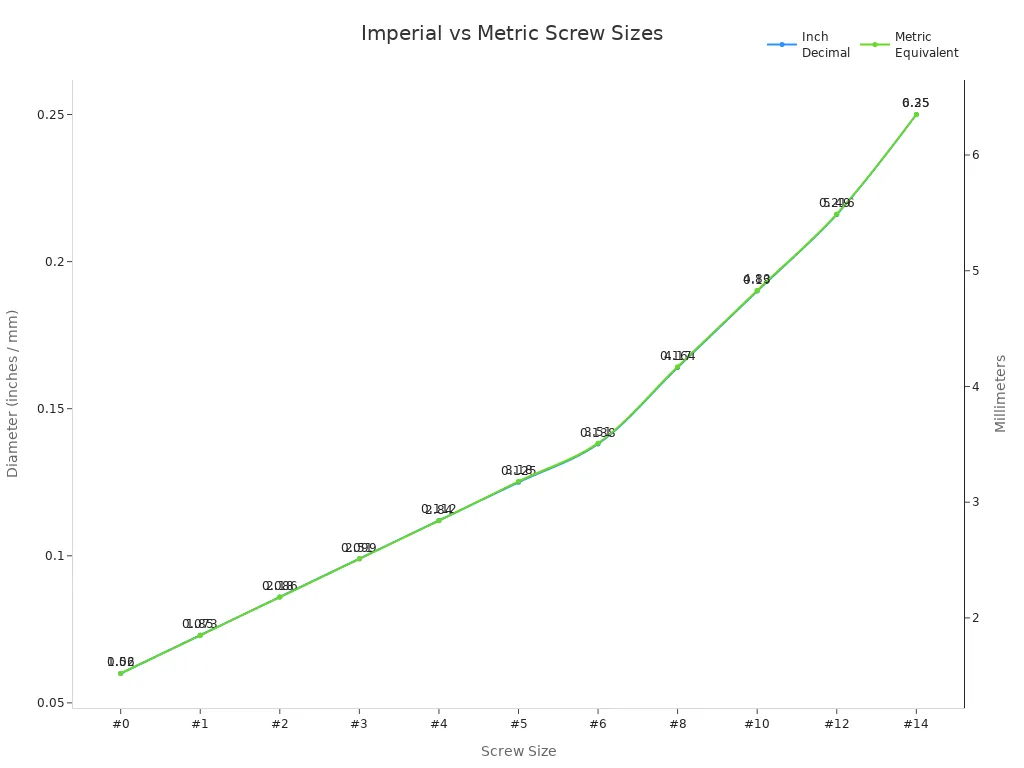

You might notice that screws come in two main measurement systems: imperial and metric. The system you use often depends on where you live or where your project comes from. In the United States, you usually see imperial screws. Most other countries use metric screws. If you work on imported furniture or cars, you will probably run into metric sizes.

Imperial screws use inches and fractions. You measure their thread density in Threads Per Inch (TPI). For example, a screw might be labeled as “#8-32,” which means size 8 with 32 threads per inch. Metric screws use millimeters for both length and diameter. Instead of TPI, metric screws use thread pitch, which is the distance between threads in millimeters. For example, an M6 x 1.0 screw is 6 mm wide with a 1.0 mm thread pitch.

Tip: Always check which system your project uses before you buy screws. Mixing them up can cause headaches!

Here’s a quick look at how imperial and metric screws compare:

| ネジサイズ | Inch Decimal | Nearest Fraction | Metric Equivalent |

|---|---|---|---|

| #6 | 0.138 in. | 9/64″ | 3.51 mm |

| #8 | 0.164 in. | 5/32″ | 4.17 mm |

| #10 | 0.190 in. | 3/16″ | 4.83 mm |

| #12 | 0.216 in. | 7/32″ | 5.49 mm |

| #14 | 0.250 in. | 1/4″ | 6.35 mm |

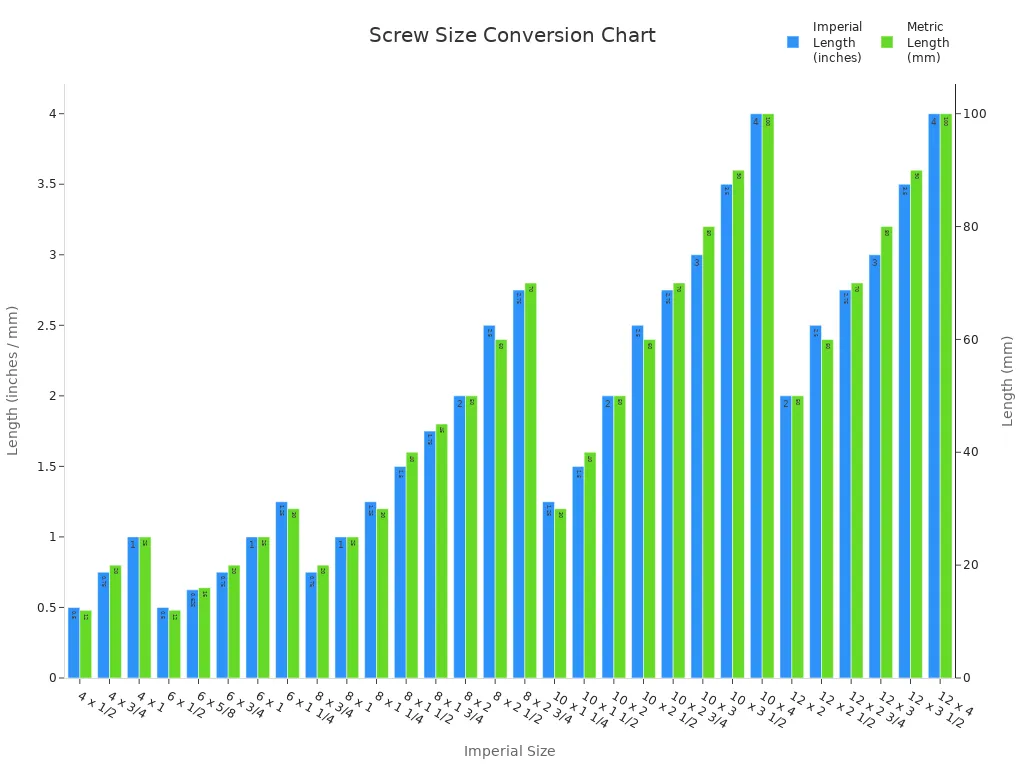

Simple Conversion Chart

If you need to match imperial screws to metric ones, use this chart for a quick reference. It helps you find the closest size when you only have one system on hand.

| IMPERIAL SIZE (NO x INCH) | METRIC SIZE (MM APPROX.) |

|---|---|

| 6 x 1 | 3.5 x 25 |

| 8 x 1 | 4.0 x 25 |

| 8 x 1 1/2 | 4.0 x 40 |

| 10 x 2 | 5.0 x 50 |

| 12 x 2 | 6.0 x 50 |

Note: These conversions are close, but not exact. Always double-check the fit before you start your project.

Now you know how to spot the difference between imperial and metric screws. With these charts, you can pick the right screw every time.

Common Mistakes and Tips

Avoiding Errors

You might think measuring screws is simple, but small mistakes can lead to big problems. Here are some common errors people make:

- Measuring the wrong part of the screw. Sometimes you measure the head instead of the threaded part.

- Using the wrong tool. A ruler might seem easy, but it can give you a rough result. Calipers or thread gauges work better.

- Not checking the head type. Flat head and pan head screws need different measuring methods.

- Skipping the thread pitch. If you forget to check the pitch, your screw might not fit.

- Reading the ruler at an angle. This can make your measurement off by a few millimeters.

Tip: Always measure on a flat surface. This helps you keep the screw straight and get a true reading.

Double-Checking Measurements

You want your project to go smoothly, so double-checking your measurements is key. Here are some practical tips to help you get it right every time:

- Use a vernier caliper to measure the outer diameter of the thread. This gives you the nominal size.

- For screws with a protruding head, measure from the base of the head to the tip. For countersunk screws, include the head in your measurement.

- Grab a thread gauge and match it to the thread ridges. This helps you find the correct pitch.

- Look at the head shape. This tells you which tool you need for installation.

Here’s a quick table to help you remember what to check:

| ステップ | What to Do | Why It Matters |

|---|---|---|

| Measure Diameter | Use caliper on outer threads | Ensures correct fit |

| Measure Length | Check if head should be included | Matches screw to project |

| Identify Pitch | Use thread gauge | Prevents mismatched fit |

| Verify Head Type | Observe head shape | Picks right screwdriver |

🛠️ Double-check your measurements before you buy or install screws. This saves you time and avoids frustration.

Measuring screws gets easier with practice. If you slow down and follow these steps, you’ll avoid most mistakes and get the right screw every time.

You can measure a screw with confidence if you follow a few simple steps. Start by placing the screw on a flat surface and use a ruler or caliper to measure its length and diameter. Grab a thread pitch gauge or count the threads to find the pitch. Here’s a quick checklist to help you measure a screw every time:

- Measure length from the correct point.

- Measure diameter at the widest thread.

- Check thread pitch with a gauge or ruler.

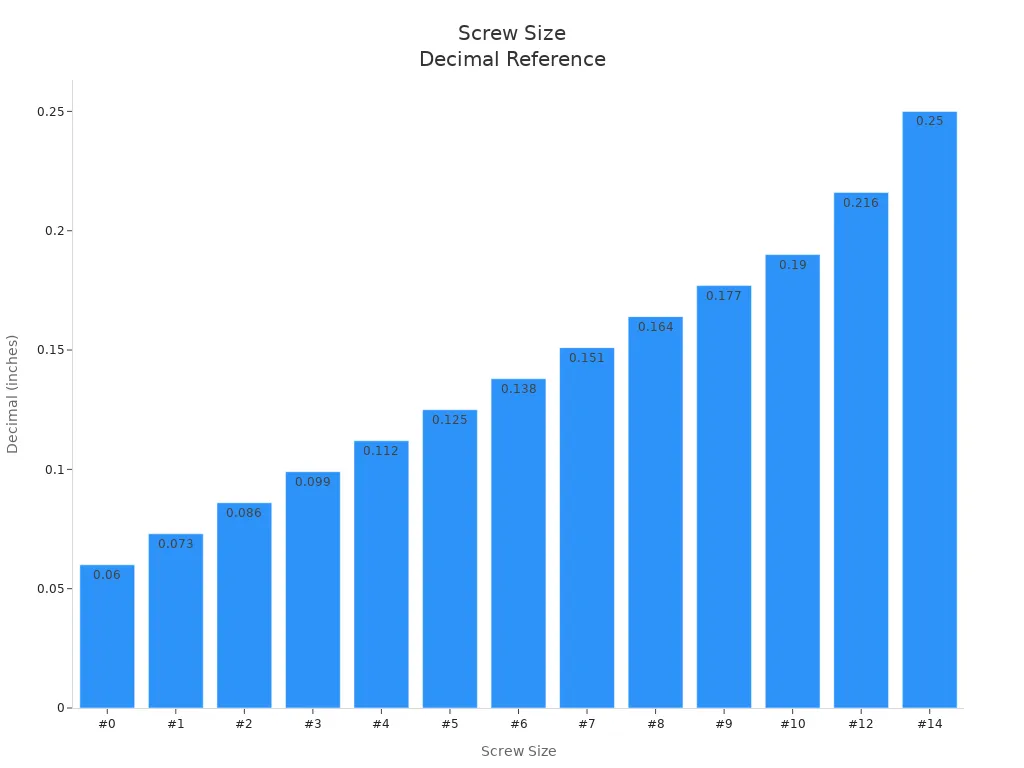

Keep a quick reference guide handy. Many guides offer tables with screw sizes and decimal measurements, like this:

| ネジサイズ | Decimal |

|---|---|

| #6 | .138 |

| #8 | .164 |

| #10 | .190 |

Store screws in a dry place and organize them by size. You’ll find that with a little practice, you can measure a screw accurately for any project.

よくあるご質問

How do you know if you should measure the screw with the head included?

You check the screw type first. If you see a flat or countersunk head, measure from the top of the head to the tip. For other heads, start right under the head.

What tool gives the most accurate screw measurement?

You get the best results with a digital caliper. It measures length and diameter down to tiny fractions. If you want a quick check, use a ruler.

Can you measure screw pitch without a thread gauge?

Yes, you can count the threads along one inch for imperial screws. For metric screws, measure the distance between two thread peaks with a ruler. A thread gauge makes it faster.

Why do screws come in both imperial and metric sizes?

Manufacturers use different systems in different countries. You see imperial sizes mostly in the U.S. Metric sizes show up in Europe and Asia. Always check your project’s requirements.

What if you don’t have a caliper or thread gauge?

Tip: Use a ruler for length and diameter. For pitch, count threads or measure the gap between them. You can borrow tools from a hardware store if you need more accuracy.